ES

-

World's Largest Web Conference To Be Held in Korea

The 2014 International World Wide Web Conference (WWW 2014), the world’s most prestigious academic conference in the field of web, will be held for the first time in Korea. The conference is to be last for five days at Seoul COEX, from 7th to 11th April. International World Wide Web Conference covers a wide range of web-related areas, including technologies, research papers, services and more. Since the first conference in 1994 in Switzerland, it has been held in various parts of North America, Europe, South America and Asia, attracting more than 1000 experts in the field. The 23rd International World Wide Web Conference is managed by the International World Wide Web Conferences Steering Committee (IW3C2) and co-hosted by KAIST and National Agency for Technology and Standards, as well as sponsored by Korea Information Science Society and the World Wide Web Consortium (W3C). Keynote speakers for this year’s conference include inventor of the World Wide Web, Sir Tim Berners-Lee, senior vice president of Microsoft, Dr. Qi Lu, and Carnegie Mellon University’s Prof. Christos Faloutsos, as well as Samsung Electronic’s vice president Jong-Deok Choi. In addition to WWW 2014, BigData Innovators Gathering (BIG 2014) and Web for Access (W4A 2014) is also to be held in joint. KAIST Computer Sciences Department’s Prof. Jinwan Jeong, in charge of directing this year’s conference, said “From one-sided 1st generation web to two-way 2nd generation web, such as blogs, and then recently to the 3rd generation web, which include social networks and semantic webs, the web technologies has grown vastly over the past 25 years. WWW 2014 will be the opportunity for Korea to discuss with the world about the informatization and future of the web.” Pre-registration for WWW 2014 can be applied at the official webpage for WWW 2014 (http://www2014.kr) before 17th February.

2014.02.14 View 11024

World's Largest Web Conference To Be Held in Korea

The 2014 International World Wide Web Conference (WWW 2014), the world’s most prestigious academic conference in the field of web, will be held for the first time in Korea. The conference is to be last for five days at Seoul COEX, from 7th to 11th April. International World Wide Web Conference covers a wide range of web-related areas, including technologies, research papers, services and more. Since the first conference in 1994 in Switzerland, it has been held in various parts of North America, Europe, South America and Asia, attracting more than 1000 experts in the field. The 23rd International World Wide Web Conference is managed by the International World Wide Web Conferences Steering Committee (IW3C2) and co-hosted by KAIST and National Agency for Technology and Standards, as well as sponsored by Korea Information Science Society and the World Wide Web Consortium (W3C). Keynote speakers for this year’s conference include inventor of the World Wide Web, Sir Tim Berners-Lee, senior vice president of Microsoft, Dr. Qi Lu, and Carnegie Mellon University’s Prof. Christos Faloutsos, as well as Samsung Electronic’s vice president Jong-Deok Choi. In addition to WWW 2014, BigData Innovators Gathering (BIG 2014) and Web for Access (W4A 2014) is also to be held in joint. KAIST Computer Sciences Department’s Prof. Jinwan Jeong, in charge of directing this year’s conference, said “From one-sided 1st generation web to two-way 2nd generation web, such as blogs, and then recently to the 3rd generation web, which include social networks and semantic webs, the web technologies has grown vastly over the past 25 years. WWW 2014 will be the opportunity for Korea to discuss with the world about the informatization and future of the web.” Pre-registration for WWW 2014 can be applied at the official webpage for WWW 2014 (http://www2014.kr) before 17th February.

2014.02.14 View 11024 -

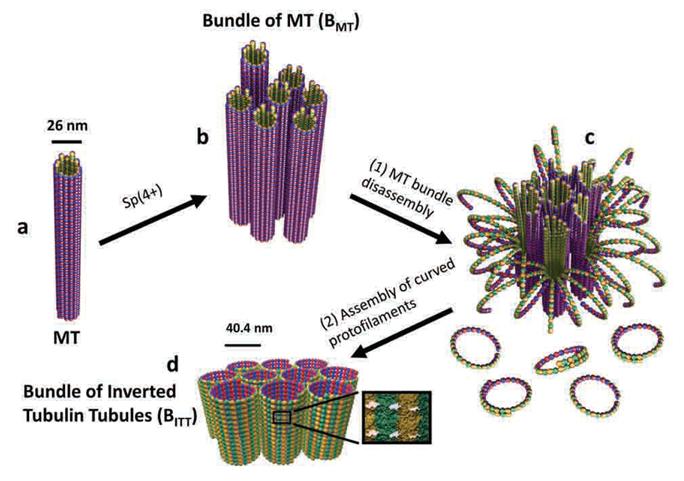

A Molecular Switch Controlling Self-Assembly of Protein Nanotubes Discovered

International collaborative research among South Korea, United States, and Israel research institutionsThe key to the treatment of cancer and brain disease mechanism The molecular switch that controls the self-assembly structure of the protein nanotubes, which plays crucial role in cell division and intracellular transport of materials, has been discovered. KAIST Bio and Brain Engineering Department’s Professor Myeong-Cheol Choi and Professor Chae-Yeon Song conducted the research, in collaboration with the University of California in Santa Barbara, U.S., and Hebrew University in Israel. The findings of the research were published in Nature Materials on the 19th. Microtubules are tube shaped and composed of protein that plays a key role in cell division, cytoskeleton, and intercellular material transport and is only 25nm in diameter (1/100,000 thickness of a human hair). Conventionally, cancer treatment focused on disrupting the formation of microtubules to suppress the division of cancer cells. In addition Alzheimer’s is known to be caused by the diminishing of structural integrity of microtubules responsible for intercellular material transport which leads to failure in signal transfer. The research team utilized synchrotron x-ray scattering and transmission electron microscope to analyze the self assemble structure of protein nanotubes to subnanometer accuracy. As a result, the microtubules were found to assemble into 25nm thickness tubules by stacking protein blocks 4 x 5 x 8nm in dimension. In the process, the research team discovered the molecular switch that controls the shape of these protein blocks. In addition the research team was successful in creating a new protein tube structure. Professor Choi commented that they were successful in introducing a new paradigm that suggests the possibility of controlling the complex biological functions of human’s biological system with the simple use of physical principles. He commented further that it is anticipated that the findings will allow for the application of bio nanotubes in engineering and that this is a small step in finding the mechanism behind cancer treatment and neural diseases.

2014.02.03 View 10922

A Molecular Switch Controlling Self-Assembly of Protein Nanotubes Discovered

International collaborative research among South Korea, United States, and Israel research institutionsThe key to the treatment of cancer and brain disease mechanism The molecular switch that controls the self-assembly structure of the protein nanotubes, which plays crucial role in cell division and intracellular transport of materials, has been discovered. KAIST Bio and Brain Engineering Department’s Professor Myeong-Cheol Choi and Professor Chae-Yeon Song conducted the research, in collaboration with the University of California in Santa Barbara, U.S., and Hebrew University in Israel. The findings of the research were published in Nature Materials on the 19th. Microtubules are tube shaped and composed of protein that plays a key role in cell division, cytoskeleton, and intercellular material transport and is only 25nm in diameter (1/100,000 thickness of a human hair). Conventionally, cancer treatment focused on disrupting the formation of microtubules to suppress the division of cancer cells. In addition Alzheimer’s is known to be caused by the diminishing of structural integrity of microtubules responsible for intercellular material transport which leads to failure in signal transfer. The research team utilized synchrotron x-ray scattering and transmission electron microscope to analyze the self assemble structure of protein nanotubes to subnanometer accuracy. As a result, the microtubules were found to assemble into 25nm thickness tubules by stacking protein blocks 4 x 5 x 8nm in dimension. In the process, the research team discovered the molecular switch that controls the shape of these protein blocks. In addition the research team was successful in creating a new protein tube structure. Professor Choi commented that they were successful in introducing a new paradigm that suggests the possibility of controlling the complex biological functions of human’s biological system with the simple use of physical principles. He commented further that it is anticipated that the findings will allow for the application of bio nanotubes in engineering and that this is a small step in finding the mechanism behind cancer treatment and neural diseases.

2014.02.03 View 10922 -

KAIST-Saudi Nuclear Workforce Training

Nuclear Engineering Intensive Course Program Held in Saudi Arabia from January 5th to 23rd

KUSTAR (The Khalifa University of Science and Technology Studies)-KAIST Institute of Education began its Nuclear Engineering Intensive Course Program on 5th January with researchers from K.A.CARE (King Abdullah City for Atomic and Renewable Energy) of Riyadh, Saudi Arabia.

This program, which was lasted until 23rd January, provided education to students on the basic technologies in the field of nuclear power.

The course involves a wide range of lectures, such as basic nuclear physics, applications using radiation, nuclear reactor design and safety, as well as nuclear power engineering.

In order to utilize the nuclear power and renewable energy, K.A.CARE was established in April 2010. The institution is also involved in the construction of nuclear infrastructure, including the site investigations, the establishment of regulatory bodies and state-owned nuclear companies, along with the newly launched workforce-training program.

The Director of the KUSTAR-KAIST Education Research Institute, Professor Soong-Heung Jang said, “This program is the beginning of long-term cooperation with Saudi Arabia. Our experience can be the basis for the construction of an extensive training program that involves many areas of nuclear engineering field.”

KAIST has been working in close cooperation with various institutions around the world, which also includes the establishment of KUSTAR-KAIST Institute of Education and Research in July 2010. KAIST is also actively cooperating with UAE Khalifa University in Middle East, sharing faculty, holding joint research programs and exchanging students.

2014.02.03 View 11405

KAIST-Saudi Nuclear Workforce Training

Nuclear Engineering Intensive Course Program Held in Saudi Arabia from January 5th to 23rd

KUSTAR (The Khalifa University of Science and Technology Studies)-KAIST Institute of Education began its Nuclear Engineering Intensive Course Program on 5th January with researchers from K.A.CARE (King Abdullah City for Atomic and Renewable Energy) of Riyadh, Saudi Arabia.

This program, which was lasted until 23rd January, provided education to students on the basic technologies in the field of nuclear power.

The course involves a wide range of lectures, such as basic nuclear physics, applications using radiation, nuclear reactor design and safety, as well as nuclear power engineering.

In order to utilize the nuclear power and renewable energy, K.A.CARE was established in April 2010. The institution is also involved in the construction of nuclear infrastructure, including the site investigations, the establishment of regulatory bodies and state-owned nuclear companies, along with the newly launched workforce-training program.

The Director of the KUSTAR-KAIST Education Research Institute, Professor Soong-Heung Jang said, “This program is the beginning of long-term cooperation with Saudi Arabia. Our experience can be the basis for the construction of an extensive training program that involves many areas of nuclear engineering field.”

KAIST has been working in close cooperation with various institutions around the world, which also includes the establishment of KUSTAR-KAIST Institute of Education and Research in July 2010. KAIST is also actively cooperating with UAE Khalifa University in Middle East, sharing faculty, holding joint research programs and exchanging students.

2014.02.03 View 11405 -

Professor Suk-Bok Chang receives 14th Korea Science Award in the field of Chemistry

Professor Suk-Bok Chang from the Department of Chemistry at KAIST received the “2013 Korea Science Award” in chemistry hosted by the National Research Foundation and the Ministry of Science, ICT, and Future Planning, Republic of Korea.

The Korea Science Award is a presidential award of Korea, which was first established in 1987 to recognize research excellence in natural science. Three scientists are selected for the award in every other year.

Professor Chang primarily researches the catalyzing mechanism of carbon-hydrogen bonds in organic molecules. He has succeeded in making great progress in the field of organic chemistry especially in developing a new type of transition metal catalytic behavior that can be applied to low-reactivity compounds.

Hydrocarbons are abundant in nature, but its unreactive nature in ambient conditions makes it unsuitable as reactant for compound synthesis. In addition, the mechanism behind transition metal catalyzed carbon-hydrogen bond synthesis has not been proven sufficiently.

The prediction that fossil fuels will be depleted before the end of the century makes hydrocarbon synthesis an extremely important matter.

The need for an effective hydrocarbon synthesis method inspired Professor Chang to pursue research in the transition metal catalysis method and to develop a catalytic system that would allow efficient synthesis even in ambient conditions.

Professor Chang has been the lead researcher for the Institute for Basic Science’s “molecule catalysis reaction research team” since December 2012 and has been carrying out this research in KAIST.

2014.01.27 View 11318

Professor Suk-Bok Chang receives 14th Korea Science Award in the field of Chemistry

Professor Suk-Bok Chang from the Department of Chemistry at KAIST received the “2013 Korea Science Award” in chemistry hosted by the National Research Foundation and the Ministry of Science, ICT, and Future Planning, Republic of Korea.

The Korea Science Award is a presidential award of Korea, which was first established in 1987 to recognize research excellence in natural science. Three scientists are selected for the award in every other year.

Professor Chang primarily researches the catalyzing mechanism of carbon-hydrogen bonds in organic molecules. He has succeeded in making great progress in the field of organic chemistry especially in developing a new type of transition metal catalytic behavior that can be applied to low-reactivity compounds.

Hydrocarbons are abundant in nature, but its unreactive nature in ambient conditions makes it unsuitable as reactant for compound synthesis. In addition, the mechanism behind transition metal catalyzed carbon-hydrogen bond synthesis has not been proven sufficiently.

The prediction that fossil fuels will be depleted before the end of the century makes hydrocarbon synthesis an extremely important matter.

The need for an effective hydrocarbon synthesis method inspired Professor Chang to pursue research in the transition metal catalysis method and to develop a catalytic system that would allow efficient synthesis even in ambient conditions.

Professor Chang has been the lead researcher for the Institute for Basic Science’s “molecule catalysis reaction research team” since December 2012 and has been carrying out this research in KAIST.

2014.01.27 View 11318 -

Collaborated Performance and Talk Battle Event Held by Graduate School of Culture Technology, KAIST

A unique event consisting of a new media performance and talk battle was held for middle school, high school, and college students during the winter break.

The Graduate School of Culture Technology at KAIST and the Korea Art Conservatory co-organized the 3rd Young Leaders Forum under the title “Collaboration of the Current and the New Culture” on January 18th at the Seoul Namsan Traditional Theater.

The Young Leaders Forum was founded to share knowledge and wisdom among different fields and generations and to foster creative lifestyles through the collaboration of wisdom.

The collaborated performance, “The Garden of Western Heaven”, was performed using new media technology by students from the Graduate School of Culture Technology and actors from the Korea Art Conservatory.

Three panels participated in the “Talk Battle” and held a discussion on “The New Culture from Performance and Collaboration”.

Woong-Rae Cho, CEO of The Mackiss Company, who sponsored the clay road in Gyejok Mountain and the Concert in the Forest, Professor Sung-Kuk Kim from School of Korean Music at Chung-Ang University, and Je-Ho Oh, a graduate student from the Graduate School of Culture Technology at KAIST participated in the discussion and shared their opinions with the audience.

2014.01.27 View 6575

Collaborated Performance and Talk Battle Event Held by Graduate School of Culture Technology, KAIST

A unique event consisting of a new media performance and talk battle was held for middle school, high school, and college students during the winter break.

The Graduate School of Culture Technology at KAIST and the Korea Art Conservatory co-organized the 3rd Young Leaders Forum under the title “Collaboration of the Current and the New Culture” on January 18th at the Seoul Namsan Traditional Theater.

The Young Leaders Forum was founded to share knowledge and wisdom among different fields and generations and to foster creative lifestyles through the collaboration of wisdom.

The collaborated performance, “The Garden of Western Heaven”, was performed using new media technology by students from the Graduate School of Culture Technology and actors from the Korea Art Conservatory.

Three panels participated in the “Talk Battle” and held a discussion on “The New Culture from Performance and Collaboration”.

Woong-Rae Cho, CEO of The Mackiss Company, who sponsored the clay road in Gyejok Mountain and the Concert in the Forest, Professor Sung-Kuk Kim from School of Korean Music at Chung-Ang University, and Je-Ho Oh, a graduate student from the Graduate School of Culture Technology at KAIST participated in the discussion and shared their opinions with the audience.

2014.01.27 View 6575 -

KAIST Participates in the 2014 Davos Forum on January 22-25 in Switzerland

Through the sessions of the Global University Leaders Forum, IdeasLab, and Global Agenda Councils on Biotechnology, KAIST participants will actively engage with global leaders in the discussion of issues on education innovation and technological breakthroughs.

The 2014 Annual Meeting of the World Economic Forum (WEF), known as the Davos Forum, will kick off on January 22-25 in Davos-Klosters, Switzerland, under the theme of "The Reshaping of the World: Consequences for Society, Politics, and Business." Each year, the Forum attracts about 2,500 distinguished leaders from all around the world and provides an open platform to identify the current and emerging challenges facing the global community and to develop ideas and actions necessary to respond to such challenges.

President Sung-Mo Steve Kang and Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering, KAIST, will attend the Forum and engage in a series of dialogues on such issues as Massive Open Online Courses, new paradigms for universities and researchers, the transformation of higher education, the role and value of scientific discoveries, and the impact of biotechnology on the future of society and business.

At the session entitled "New Paradigms for Universities of the Future" hosted by the Global University Leaders Forum (GULF), President Kang will introduce KAIST"s ongoing online education program, Education 3.0. GULF was created in 2006 by WEF, which is a small community of the presidents and senior representatives of the top universities in the world.

Implemented in 2012, Education 3.0 incorporates advanced information and communications technology (ICT) to offer students and teachers a learner-based, team-oriented learning and teaching environment. Under Education 3.0, students study online and meet in groups with a professor for in-depth discussions, collaboration, and problem-solving. KAIST plans to expand the program to embrace the global community in earnest by establishing Education 3.0 Global in order to have interactive real-time classes for students and researchers across regions and cultures.

President Kang will also present a paper entitled "Toward Socially Responsible Technology: KAIST"s Approach to Integrating Social and Behavioral Perspectives into Technology Development" at another session of GULF called "Seeking New Approaches to Critical Global Challenges." In the paper, President Kang points out that notwithstanding the many benefits we enjoy from the increasingly interconnected world, digital media may pose a threat to become a new outlet for social problems, for example, Internet or digital addiction.

Experts say that early exposure to digital devices harms the healthy development of cognitive functions, emotions, and social behavior. President Kang will introduce KAIST"s recent endeavor to develop a non-intrusive technology to help prevent digital addiction, which will ultimately be embedded in the form of a virtual coach or mentor that helps and guides people under risk to make constructive use of digital devices. President Kang stresses the fundamental shift in the science and technology development paradigm from research and development (R&D) to a research and solution development (R&SD), taking serious consideration of societal needs, quality of life, and social impacts when conducting research.

Professor Sang Yup Lee will moderate the IdeasLab session at the Davos Forum entitled "From Lab to Life with the California Institute of Technology (Caltech)." Together with scientists from Caltech, he will discuss scientific breakthroughs that transform institutions, industries, and individuals in the near future, such as the development of damage-tolerant lightweight materials with nanotechnology, the ability to read and write genomes, and wireless lab-in-the-body monitors. In addition, he will meet global business leaders at the session of "Sustainability, Innovation, and Growth" and speak about how emerging technologies, biotechnology in particular, will transform future societies, business, and industries.

As a current special adviser of the World Economic Forum"s (WEF) Chemicals Industry Community, Professor Lee will meet global chairs and chief executive officers of chemical companies and discuss ways to advance the industry to become more bio-based and environmentally friendly. He served as a founding chairman of WEF"s Global Agenda Councils on Biotechnology in 2013.

President Sung-Mo Steve Kang Distinguished Professor Sang Yup Lee

2014.01.17 View 11468

KAIST Participates in the 2014 Davos Forum on January 22-25 in Switzerland

Through the sessions of the Global University Leaders Forum, IdeasLab, and Global Agenda Councils on Biotechnology, KAIST participants will actively engage with global leaders in the discussion of issues on education innovation and technological breakthroughs.

The 2014 Annual Meeting of the World Economic Forum (WEF), known as the Davos Forum, will kick off on January 22-25 in Davos-Klosters, Switzerland, under the theme of "The Reshaping of the World: Consequences for Society, Politics, and Business." Each year, the Forum attracts about 2,500 distinguished leaders from all around the world and provides an open platform to identify the current and emerging challenges facing the global community and to develop ideas and actions necessary to respond to such challenges.

President Sung-Mo Steve Kang and Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering, KAIST, will attend the Forum and engage in a series of dialogues on such issues as Massive Open Online Courses, new paradigms for universities and researchers, the transformation of higher education, the role and value of scientific discoveries, and the impact of biotechnology on the future of society and business.

At the session entitled "New Paradigms for Universities of the Future" hosted by the Global University Leaders Forum (GULF), President Kang will introduce KAIST"s ongoing online education program, Education 3.0. GULF was created in 2006 by WEF, which is a small community of the presidents and senior representatives of the top universities in the world.

Implemented in 2012, Education 3.0 incorporates advanced information and communications technology (ICT) to offer students and teachers a learner-based, team-oriented learning and teaching environment. Under Education 3.0, students study online and meet in groups with a professor for in-depth discussions, collaboration, and problem-solving. KAIST plans to expand the program to embrace the global community in earnest by establishing Education 3.0 Global in order to have interactive real-time classes for students and researchers across regions and cultures.

President Kang will also present a paper entitled "Toward Socially Responsible Technology: KAIST"s Approach to Integrating Social and Behavioral Perspectives into Technology Development" at another session of GULF called "Seeking New Approaches to Critical Global Challenges." In the paper, President Kang points out that notwithstanding the many benefits we enjoy from the increasingly interconnected world, digital media may pose a threat to become a new outlet for social problems, for example, Internet or digital addiction.

Experts say that early exposure to digital devices harms the healthy development of cognitive functions, emotions, and social behavior. President Kang will introduce KAIST"s recent endeavor to develop a non-intrusive technology to help prevent digital addiction, which will ultimately be embedded in the form of a virtual coach or mentor that helps and guides people under risk to make constructive use of digital devices. President Kang stresses the fundamental shift in the science and technology development paradigm from research and development (R&D) to a research and solution development (R&SD), taking serious consideration of societal needs, quality of life, and social impacts when conducting research.

Professor Sang Yup Lee will moderate the IdeasLab session at the Davos Forum entitled "From Lab to Life with the California Institute of Technology (Caltech)." Together with scientists from Caltech, he will discuss scientific breakthroughs that transform institutions, industries, and individuals in the near future, such as the development of damage-tolerant lightweight materials with nanotechnology, the ability to read and write genomes, and wireless lab-in-the-body monitors. In addition, he will meet global business leaders at the session of "Sustainability, Innovation, and Growth" and speak about how emerging technologies, biotechnology in particular, will transform future societies, business, and industries.

As a current special adviser of the World Economic Forum"s (WEF) Chemicals Industry Community, Professor Lee will meet global chairs and chief executive officers of chemical companies and discuss ways to advance the industry to become more bio-based and environmentally friendly. He served as a founding chairman of WEF"s Global Agenda Councils on Biotechnology in 2013.

President Sung-Mo Steve Kang Distinguished Professor Sang Yup Lee

2014.01.17 View 11468 -

Materials Developed for Sodium Rechargeable Battery by EEWS

The research group of Professor William Goddard III, You-Sung Jung, and Jang-Wook Choi from the Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST has developed a new sodium-ion rechargeable battery which operates at a high voltage, can be charged, and stably discharges over 10,000 cycles. The research results were published in the online version of the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on December 30, 2013.

Since the material costs of sodium rechargeable batteries is 30 to 40 times lower than lithium batteries, it has received attention as an energy saving tool for smart grids and as the next generation of lithium rechargeable batteries. Until now, sodium-ion rechargeable batteries have had issues with stability when charging and discharging. The research group developed a vanadium-based electrode to solve these problems.

The group said follow-up research will be continued to develop advanced technology on sodium rechargeable batteries as it is still currently in the beginning stages.

The research team: From left to right is Professors William Goddard, You-Sung Jung, and Jang-Wook Choi

2014.01.13 View 11506

Materials Developed for Sodium Rechargeable Battery by EEWS

The research group of Professor William Goddard III, You-Sung Jung, and Jang-Wook Choi from the Graduate School of Energy, Environment, Water, and Sustainability (EEWS) at KAIST has developed a new sodium-ion rechargeable battery which operates at a high voltage, can be charged, and stably discharges over 10,000 cycles. The research results were published in the online version of the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on December 30, 2013.

Since the material costs of sodium rechargeable batteries is 30 to 40 times lower than lithium batteries, it has received attention as an energy saving tool for smart grids and as the next generation of lithium rechargeable batteries. Until now, sodium-ion rechargeable batteries have had issues with stability when charging and discharging. The research group developed a vanadium-based electrode to solve these problems.

The group said follow-up research will be continued to develop advanced technology on sodium rechargeable batteries as it is still currently in the beginning stages.

The research team: From left to right is Professors William Goddard, You-Sung Jung, and Jang-Wook Choi

2014.01.13 View 11506 -

Professor Sang-Min received an award for scholar of the year from the KAISTian of the Year 2013

KAIST nominates a “Scholar of the Year” each year and presents the award to the recipient at a New Year’s opening ceremony. For the year 2013, Professor Sang-Min Bae of the Industrial Design Department at KAIST was named “KAIST Scholar of 2013” and received the award on January 2, 2014.

Professor Bae has been recognized for his design achievement in 2013: D’Light, a kinetic lighting that employs a transformable lampshade using flexible honeycomb structure, became one of the finalists in the living room and bedroom category of the International Design Excellence Award 2013 and was selected one of the best 100 for the 2013 Good Design Award. Users can easily change the shape and light intensity of the lamp by simply pivoting the lampshade with its small handle.

Professor Bae has also actively pursued his own philanthrophic projects through design: he has given the profits from the sales of his designs including D’Light directly toward a scholarship for needy children.

The Scholar of the Year award is presented to a faculty member or researcher at KAIST who has contributed to the advancement of science and technology such as publication of articles with influential research outcomes, invention of breakthrough technology, implementation of outstanding research projects, and improvement of public life. Professor Bae is the 13 th winner of the KAIST award.

The Korea Times, a leading English language newspaper in Korea, published an article on this award. For the article, please visit http://www.koreatimes.co.kr/www/news/people/2014/01/178_149117.html .

2014.01.09 View 11262

Professor Sang-Min received an award for scholar of the year from the KAISTian of the Year 2013

KAIST nominates a “Scholar of the Year” each year and presents the award to the recipient at a New Year’s opening ceremony. For the year 2013, Professor Sang-Min Bae of the Industrial Design Department at KAIST was named “KAIST Scholar of 2013” and received the award on January 2, 2014.

Professor Bae has been recognized for his design achievement in 2013: D’Light, a kinetic lighting that employs a transformable lampshade using flexible honeycomb structure, became one of the finalists in the living room and bedroom category of the International Design Excellence Award 2013 and was selected one of the best 100 for the 2013 Good Design Award. Users can easily change the shape and light intensity of the lamp by simply pivoting the lampshade with its small handle.

Professor Bae has also actively pursued his own philanthrophic projects through design: he has given the profits from the sales of his designs including D’Light directly toward a scholarship for needy children.

The Scholar of the Year award is presented to a faculty member or researcher at KAIST who has contributed to the advancement of science and technology such as publication of articles with influential research outcomes, invention of breakthrough technology, implementation of outstanding research projects, and improvement of public life. Professor Bae is the 13 th winner of the KAIST award.

The Korea Times, a leading English language newspaper in Korea, published an article on this award. For the article, please visit http://www.koreatimes.co.kr/www/news/people/2014/01/178_149117.html .

2014.01.09 View 11262 -

An Education Donation Club at KAIST Received the Education Minister's Award in 2013

Chalk, one of the student clubs at KAIST, shares knowledge by providing free online classes to teenage students in Korea via Internet.

Chalk, a KAIST student club which donates their educational knowledge, received an award from the Education Minister of the Republic of Korea at the 2nd Donation for Education Award held on December 16th, 2013 at the Plaza Hotel in Seoul.

The Donation for Eduation Award aims to find and reward corporations, organizations, and individuals, which have actively contributed to growing the dreams and talents of students, as well as revitalizing the culture of donation for education. It has been awarded by the Ministry of Education since 2012 to promote the awareness and participation of students for education.

Chalk provides free online video lectures on www.playchalk.com and runs a mentoring-based education program. The club has been recognized for offering online courses, math and science classes in particular, to teenage students who are from socially and economically less privileged backgrounds.

Chalk was founded by five KAIST students in 2011. Their ultimate goal is to create a society where students can fully enjoy the benefits of education, regardless of their economic conditions. About 60 undergraduate students currently participate in the club, with more than 5,000 students attending over 160 lectures without any cost.

2014.01.07 View 10155

An Education Donation Club at KAIST Received the Education Minister's Award in 2013

Chalk, one of the student clubs at KAIST, shares knowledge by providing free online classes to teenage students in Korea via Internet.

Chalk, a KAIST student club which donates their educational knowledge, received an award from the Education Minister of the Republic of Korea at the 2nd Donation for Education Award held on December 16th, 2013 at the Plaza Hotel in Seoul.

The Donation for Eduation Award aims to find and reward corporations, organizations, and individuals, which have actively contributed to growing the dreams and talents of students, as well as revitalizing the culture of donation for education. It has been awarded by the Ministry of Education since 2012 to promote the awareness and participation of students for education.

Chalk provides free online video lectures on www.playchalk.com and runs a mentoring-based education program. The club has been recognized for offering online courses, math and science classes in particular, to teenage students who are from socially and economically less privileged backgrounds.

Chalk was founded by five KAIST students in 2011. Their ultimate goal is to create a society where students can fully enjoy the benefits of education, regardless of their economic conditions. About 60 undergraduate students currently participate in the club, with more than 5,000 students attending over 160 lectures without any cost.

2014.01.07 View 10155 -

Mechanism in regulation of cancer-related key enzyme, ATM, for DNA damage and repair revealed

Professor Kwang-Wook Choi

A research team led by Professor Kwang-Wook Choi and Dr. Seong-Tae Hong from the Department of Biological Sciences at KAIST has successfully investigated the operational mechanism of the protein Ataxia Telangiectasia Mutated (ATM), an essential protein to the function of a crucial key enzyme that repairs the damaged DNA which stores biometric information. The results were published on December 19th Nature Communications online edition.

All organisms, including humans, constantly strive to protect the information within their DNA from damages posed by a number of factors, such as carbonized materials in our daily food intake, radioactive materials such as radon emitting from the cement of buildings or ultraviolet of the sunlight, which could be a trigger for cancer.

In order to keep the DNA information safe, the organisms are always carrying out complex and sophisticated DNA repair work, which involves the crucial DNA damage repair protein ATM. Consequently, a faulty ATM leads to higher risks of cancer.

Until now, academia predicted that the Translationally Controlled Tumor Protein (TCTP) will play an important role in regulating the function of ATM. However, since most of main research regarding TCTP has only been conducted in cultured cells, it was unable to identify exactly what mechanisms TCTP employs to control ATM.

The KAIST research team identified that TCTP can combine with ATM or increase the enzymatic activity of ATM. In addition, Drosophilia, one of the most widely used model organisms for molecular genetics, has been used to identify that TCTP and ATM play a very important role in repairing the DNA damaged by radiation. This information has allowed the researchers to establish TCTP’s essential function in maintaining the DNA information in cell cultures and even in higher organisms, and to provide specific and important clues to the regulation of ATM by TCTP.

Professor Kwang-Wook Choi said, “Our research is a good example that basic research using Drosophilia can make important contributions to understanding the process of diseases, such as cancer, and to developing adequate treatment.”

The research has been funded by the Ministry of Science, ICT and Future Planning, Republic of Korea, and the National Research Foundation of Korea.

Figure 1. When the amount of TCTP protein is reduced, cells of the Drosophila's eye are abnormally deformed by radiation. Scale bars = 200mm

Figure 2. When the amount of TCTP protein is reduced, the chromosomes of Drosophilia are easily broken by radiation. Scale bars = 10 mm.

Figure 3. When gene expressions of TCTP and ATM are reduced, large defects occur in the normal development of the eye. (Left: normal Drosophilia's eye, right: development-deficient eye)

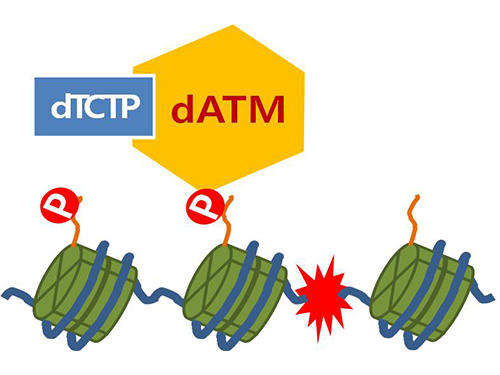

Figure 4. ATM marks the position of the broken DNA, with TCTP helping to facilitate this reaction. DNA (blue line) within the cell nucleus is coiled around the histone protein (green cylinder). When DNA is broken, ATM protein attaches a phosphate group (P). Multiple DNA repair protein recognizes the phosphate as a signal that requires repair and gathers at the site.

2014.01.07 View 13970

Mechanism in regulation of cancer-related key enzyme, ATM, for DNA damage and repair revealed

Professor Kwang-Wook Choi

A research team led by Professor Kwang-Wook Choi and Dr. Seong-Tae Hong from the Department of Biological Sciences at KAIST has successfully investigated the operational mechanism of the protein Ataxia Telangiectasia Mutated (ATM), an essential protein to the function of a crucial key enzyme that repairs the damaged DNA which stores biometric information. The results were published on December 19th Nature Communications online edition.

All organisms, including humans, constantly strive to protect the information within their DNA from damages posed by a number of factors, such as carbonized materials in our daily food intake, radioactive materials such as radon emitting from the cement of buildings or ultraviolet of the sunlight, which could be a trigger for cancer.

In order to keep the DNA information safe, the organisms are always carrying out complex and sophisticated DNA repair work, which involves the crucial DNA damage repair protein ATM. Consequently, a faulty ATM leads to higher risks of cancer.

Until now, academia predicted that the Translationally Controlled Tumor Protein (TCTP) will play an important role in regulating the function of ATM. However, since most of main research regarding TCTP has only been conducted in cultured cells, it was unable to identify exactly what mechanisms TCTP employs to control ATM.

The KAIST research team identified that TCTP can combine with ATM or increase the enzymatic activity of ATM. In addition, Drosophilia, one of the most widely used model organisms for molecular genetics, has been used to identify that TCTP and ATM play a very important role in repairing the DNA damaged by radiation. This information has allowed the researchers to establish TCTP’s essential function in maintaining the DNA information in cell cultures and even in higher organisms, and to provide specific and important clues to the regulation of ATM by TCTP.

Professor Kwang-Wook Choi said, “Our research is a good example that basic research using Drosophilia can make important contributions to understanding the process of diseases, such as cancer, and to developing adequate treatment.”

The research has been funded by the Ministry of Science, ICT and Future Planning, Republic of Korea, and the National Research Foundation of Korea.

Figure 1. When the amount of TCTP protein is reduced, cells of the Drosophila's eye are abnormally deformed by radiation. Scale bars = 200mm

Figure 2. When the amount of TCTP protein is reduced, the chromosomes of Drosophilia are easily broken by radiation. Scale bars = 10 mm.

Figure 3. When gene expressions of TCTP and ATM are reduced, large defects occur in the normal development of the eye. (Left: normal Drosophilia's eye, right: development-deficient eye)

Figure 4. ATM marks the position of the broken DNA, with TCTP helping to facilitate this reaction. DNA (blue line) within the cell nucleus is coiled around the histone protein (green cylinder). When DNA is broken, ATM protein attaches a phosphate group (P). Multiple DNA repair protein recognizes the phosphate as a signal that requires repair and gathers at the site.

2014.01.07 View 13970 -

Professor Yong-Hee Lee of Physics Received the Humboldt Research Award

In recognition of his past accomplishments in research and teaching, Professor Yong-Hee Lee of Physics at KAIST received the Humboldt Research Award in November 2013. The Humboldt Research Award is annually given by the Alexander von Humboldt Foundation to internationally renowned scientists and scholars in the fields of biology, chemistry, computer science, economics, linguistics, management, mathematics, medicine, philosophy, and physics. The winners of the award are offered with 60,000 Euros of research grant as well as an opportunity to undertake prolonged periods of research in collaboration with researchers in Germany.Professor Lee, who may be the first Korean physicist receiving the award, plans to conduct joint research with colleagues at the Technical University of Berlin and University of Würzburg.

2014.01.05 View 9204

Professor Yong-Hee Lee of Physics Received the Humboldt Research Award

In recognition of his past accomplishments in research and teaching, Professor Yong-Hee Lee of Physics at KAIST received the Humboldt Research Award in November 2013. The Humboldt Research Award is annually given by the Alexander von Humboldt Foundation to internationally renowned scientists and scholars in the fields of biology, chemistry, computer science, economics, linguistics, management, mathematics, medicine, philosophy, and physics. The winners of the award are offered with 60,000 Euros of research grant as well as an opportunity to undertake prolonged periods of research in collaboration with researchers in Germany.Professor Lee, who may be the first Korean physicist receiving the award, plans to conduct joint research with colleagues at the Technical University of Berlin and University of Würzburg.

2014.01.05 View 9204 -

Professor Dong-Yol Yang received an award for scholar of the year 2013 from the Korean mechanical engineering community

Professor Dong-Yol Yang from the Department of Mechanical Engineering at KAIST was selected as “the scholar of the year 2013” at an annual event held by the Korean Federation of Mechanical Engineering Societies, the Korea Association of Machinery Industry, and other mechanical engineering research institutes in Korea. The event, the Day of the Machines, is the nation’s biggest gathering for engineers, scholars, and researchers in mechanical engineering, at which winners of the awards for the person of the year in academia, business, and engineering are announced.

Professor Yang was chosen for his lifetime achievement as a scholar in the field of three-dimensional shape precision processing by developing an innovative processing technology that contributes to the advancement of mechanical engineering and industry. He also introduced the three-dimensional fast processing to Korea from 1990 and developed world-class subminiature fast processing, the first of its kind in Korea.In 2013, Professor Yang identified geometric deformation elements in mechanical engineering for the first time in the world, an essential component for nano mobile system and received the best conference paper award at the 3M-Nano International Conference.

2014.01.05 View 9863

Professor Dong-Yol Yang received an award for scholar of the year 2013 from the Korean mechanical engineering community

Professor Dong-Yol Yang from the Department of Mechanical Engineering at KAIST was selected as “the scholar of the year 2013” at an annual event held by the Korean Federation of Mechanical Engineering Societies, the Korea Association of Machinery Industry, and other mechanical engineering research institutes in Korea. The event, the Day of the Machines, is the nation’s biggest gathering for engineers, scholars, and researchers in mechanical engineering, at which winners of the awards for the person of the year in academia, business, and engineering are announced.

Professor Yang was chosen for his lifetime achievement as a scholar in the field of three-dimensional shape precision processing by developing an innovative processing technology that contributes to the advancement of mechanical engineering and industry. He also introduced the three-dimensional fast processing to Korea from 1990 and developed world-class subminiature fast processing, the first of its kind in Korea.In 2013, Professor Yang identified geometric deformation elements in mechanical engineering for the first time in the world, an essential component for nano mobile system and received the best conference paper award at the 3M-Nano International Conference.

2014.01.05 View 9863