ES

-

KAIST Researchers Develops Hyper-Stretchable Elastic-Composite Energy Harvester

A research team led by Professor Keon Jae Lee (http://fand.kaist.ac.kr) of the Department of Materials Science and Engineering at KAIST has developed a hyper-stretchable elastic-composite energy harvesting device called a nanogenerator.

Flexible electronics have come into the market and are enabling new technologies like flexible displays in mobile phone, wearable electronics, and the Internet of Things (IoTs). However, is the degree of flexibility enough for most applications? For many flexible devices, elasticity is a very important issue. For example, wearable/biomedical devices and electronic skins (e-skins) should stretch to conform to arbitrarily curved surfaces and moving body parts such as joints, diaphragms, and tendons. They must be able to withstand the repeated and prolonged mechanical stresses of stretching. In particular, the development of elastic energy devices is regarded as critical to establish power supplies in stretchable applications. Although several researchers have explored diverse stretchable electronics, due to the absence of the appropriate device structures and correspondingly electrodes, researchers have not developed ultra-stretchable and fully-reversible energy conversion devices properly.

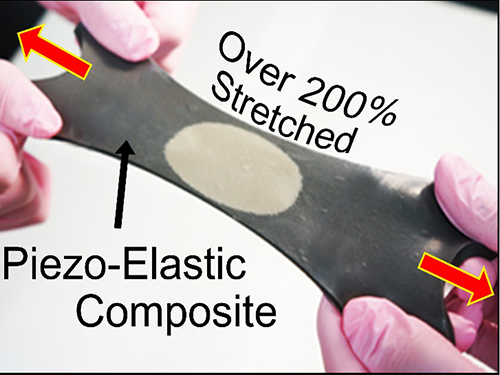

Recently, researchers from KAIST and Seoul National University (SNU) have collaborated and demonstrated a facile methodology to obtain a high-performance and hyper-stretchable elastic-composite generator (SEG) using very long silver nanowire-based stretchable electrodes. Their stretchable piezoelectric generator can harvest mechanical energy to produce high power output (~4 V) with large elasticity (~250%) and excellent durability (over 104 cycles). These noteworthy results were achieved by the non-destructive stress- relaxation ability of the unique electrodes as well as the good piezoelectricity of the device components. The new SEG can be applied to a wide-variety of wearable energy-harvesters to transduce biomechanical-stretching energy from the body (or machines) to electrical energy.

Professor Lee said, “This exciting approach introduces an ultra-stretchable piezoelectric generator. It can open avenues for power supplies in universal wearable and biomedical applications as well as self-powered ultra-stretchable electronics.”

This result was published online in the March issue of Advanced Materials, which is entitled “A Hyper-Stretchable Elastic-Composite Energy Harvester.”

YouTube Link: “A hyper-stretchable energy harvester”

https://www.youtube.com/watch?v=EBByFvPVRiU&feature=youtu.be

Figure: Top row: Schematics of hyper-stretchable elastic-composite generator enabled by very long silver nanowire-based stretchable electrodes.

Bottom row: The SEG energy harvester stretched by human hands over 200% strain.

2015.04.14 View 14091

KAIST Researchers Develops Hyper-Stretchable Elastic-Composite Energy Harvester

A research team led by Professor Keon Jae Lee (http://fand.kaist.ac.kr) of the Department of Materials Science and Engineering at KAIST has developed a hyper-stretchable elastic-composite energy harvesting device called a nanogenerator.

Flexible electronics have come into the market and are enabling new technologies like flexible displays in mobile phone, wearable electronics, and the Internet of Things (IoTs). However, is the degree of flexibility enough for most applications? For many flexible devices, elasticity is a very important issue. For example, wearable/biomedical devices and electronic skins (e-skins) should stretch to conform to arbitrarily curved surfaces and moving body parts such as joints, diaphragms, and tendons. They must be able to withstand the repeated and prolonged mechanical stresses of stretching. In particular, the development of elastic energy devices is regarded as critical to establish power supplies in stretchable applications. Although several researchers have explored diverse stretchable electronics, due to the absence of the appropriate device structures and correspondingly electrodes, researchers have not developed ultra-stretchable and fully-reversible energy conversion devices properly.

Recently, researchers from KAIST and Seoul National University (SNU) have collaborated and demonstrated a facile methodology to obtain a high-performance and hyper-stretchable elastic-composite generator (SEG) using very long silver nanowire-based stretchable electrodes. Their stretchable piezoelectric generator can harvest mechanical energy to produce high power output (~4 V) with large elasticity (~250%) and excellent durability (over 104 cycles). These noteworthy results were achieved by the non-destructive stress- relaxation ability of the unique electrodes as well as the good piezoelectricity of the device components. The new SEG can be applied to a wide-variety of wearable energy-harvesters to transduce biomechanical-stretching energy from the body (or machines) to electrical energy.

Professor Lee said, “This exciting approach introduces an ultra-stretchable piezoelectric generator. It can open avenues for power supplies in universal wearable and biomedical applications as well as self-powered ultra-stretchable electronics.”

This result was published online in the March issue of Advanced Materials, which is entitled “A Hyper-Stretchable Elastic-Composite Energy Harvester.”

YouTube Link: “A hyper-stretchable energy harvester”

https://www.youtube.com/watch?v=EBByFvPVRiU&feature=youtu.be

Figure: Top row: Schematics of hyper-stretchable elastic-composite generator enabled by very long silver nanowire-based stretchable electrodes.

Bottom row: The SEG energy harvester stretched by human hands over 200% strain.

2015.04.14 View 14091 -

Professor Rim Presents at IAEA Workshop in Vienna

Professor Chun-Taek Rim of the Department of Nuclear and Quantum Engineering at KAIST recently attended the International Atomic Energy Agency (IAEA)’s workshop on the Application of Wireless Technologies in Nuclear Power Plant Instrumentation and Control System. It took place on March 30-April 2, 2015, in Vienna, Austria.

Representing Korea, Professor Rim gave a talk entitled “Highly Reliable Wireless Power and Communications under Severe Accident of Nuclear Power Plants (NPPs).” About 20 industry experts from 12 countries such as AREVA (France), Westinghouse (US), Oak Ridge National Laboratory (US), Hitachi (Japan), and ENEA (Italy) joined the meeting.

The IAEA hosted the workshop to explore the application of wireless technology for the operation and management of NPPs. It formed a committee consisting of eminent professionals worldwide in NPP instrumentation and control systems, communications, and nuclear power to examine this issue in-depth and to conduct various research projects for the next three years.

In particular, the committee will concentrate its research on improving the reliability and safety of using wireless technology, not only in the normal operation of nuclear plants but also in extreme conditions such as the Fukushima Daiichi nuclear accident. The complementation, economic feasibility, and standardization of NPPs when applying wireless technology will be also discussed.

Professor Rim currently leads the Nuclear Power Electronics

and Robotics Lab at KAIST (http://tesla.kaist.ac.kr/index_eng.php?lag=eng).

Picture 1: Professors Rim presents his topic at the IAEA Workshop in Vienna.

Picture 2: The IAEA Workshop Participants

2015.04.07 View 13244

Professor Rim Presents at IAEA Workshop in Vienna

Professor Chun-Taek Rim of the Department of Nuclear and Quantum Engineering at KAIST recently attended the International Atomic Energy Agency (IAEA)’s workshop on the Application of Wireless Technologies in Nuclear Power Plant Instrumentation and Control System. It took place on March 30-April 2, 2015, in Vienna, Austria.

Representing Korea, Professor Rim gave a talk entitled “Highly Reliable Wireless Power and Communications under Severe Accident of Nuclear Power Plants (NPPs).” About 20 industry experts from 12 countries such as AREVA (France), Westinghouse (US), Oak Ridge National Laboratory (US), Hitachi (Japan), and ENEA (Italy) joined the meeting.

The IAEA hosted the workshop to explore the application of wireless technology for the operation and management of NPPs. It formed a committee consisting of eminent professionals worldwide in NPP instrumentation and control systems, communications, and nuclear power to examine this issue in-depth and to conduct various research projects for the next three years.

In particular, the committee will concentrate its research on improving the reliability and safety of using wireless technology, not only in the normal operation of nuclear plants but also in extreme conditions such as the Fukushima Daiichi nuclear accident. The complementation, economic feasibility, and standardization of NPPs when applying wireless technology will be also discussed.

Professor Rim currently leads the Nuclear Power Electronics

and Robotics Lab at KAIST (http://tesla.kaist.ac.kr/index_eng.php?lag=eng).

Picture 1: Professors Rim presents his topic at the IAEA Workshop in Vienna.

Picture 2: The IAEA Workshop Participants

2015.04.07 View 13244 -

Polymers with Highly Improved Light-transformation Efficiency

A joint Korean research team, led by Professor Bum-Joon Kim of the Department of Chemical and Biomolecular Engineering at KAIST and Professor Young-Woo Han of the Department of Nanofusion Engineering at Pusan National University, has developed a new type of electrically-conductive polymer for solar batteries with an improved light-transformation efficiency of up to 5%. The team considers it a viable replacement for existing plastic batteries for solar power which is viewed as the energy source of the future.

Polymer solar cells have greater structural stability and heat resistance compared to fullerene organic solar cells. However, they have lower light-transformation efficiency—below 4%—compared to 10% of the latter. The low efficiency is due to the failure of blending among the polymers that compose the active layer of the cell. This phenomenon deters the formation and movement of electrons and thus lowers light-transformation efficiency.

By manipulating the structure and concentration of conductive polymers, the team was able to effectively increase the polymer blending and increase light-transformation efficiency. The team was able to maximize the efficiency up to 6% which is the highest reported ratio.

Professor Kim said, “This research demonstrates that conductive polymer plastics can be used widely for solar cells and batteries for mobile devices.”

The research findings were published in the February 18th issue of the Journal of the American Chemical Society (JACS).

Picture: Flexible Solar Cell Polymer Developed by the Research Team

2015.04.05 View 11381

Polymers with Highly Improved Light-transformation Efficiency

A joint Korean research team, led by Professor Bum-Joon Kim of the Department of Chemical and Biomolecular Engineering at KAIST and Professor Young-Woo Han of the Department of Nanofusion Engineering at Pusan National University, has developed a new type of electrically-conductive polymer for solar batteries with an improved light-transformation efficiency of up to 5%. The team considers it a viable replacement for existing plastic batteries for solar power which is viewed as the energy source of the future.

Polymer solar cells have greater structural stability and heat resistance compared to fullerene organic solar cells. However, they have lower light-transformation efficiency—below 4%—compared to 10% of the latter. The low efficiency is due to the failure of blending among the polymers that compose the active layer of the cell. This phenomenon deters the formation and movement of electrons and thus lowers light-transformation efficiency.

By manipulating the structure and concentration of conductive polymers, the team was able to effectively increase the polymer blending and increase light-transformation efficiency. The team was able to maximize the efficiency up to 6% which is the highest reported ratio.

Professor Kim said, “This research demonstrates that conductive polymer plastics can be used widely for solar cells and batteries for mobile devices.”

The research findings were published in the February 18th issue of the Journal of the American Chemical Society (JACS).

Picture: Flexible Solar Cell Polymer Developed by the Research Team

2015.04.05 View 11381 -

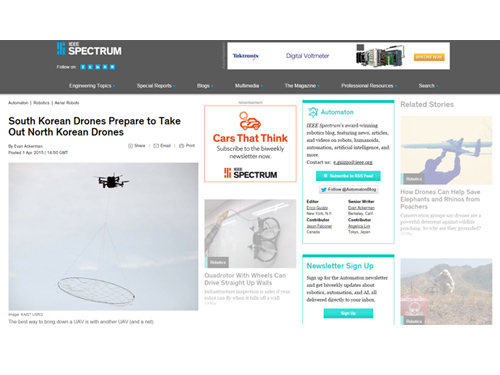

Professor Shim Featured with His Drone System in IEEE Spectrum

The IEEE Spectrum, a technology and science magazine published by the Institute of Electrical and Electronics Engineers (IEEE), featured an article of KAIST’s autonomous unmanned aerial vehicles (UAVs) entitled “South Korea Prepares for Drone vs. Drone Combat,” posted on April 1, 2015.

The article introduces the anti-drone defense system being developed by Professor “David” Hyunchul Shim of the Department of Aerospace Engineering at KAIST. With the goal of developing guard drones that can detect and capture unknown UAVs, the anti-drone defense system consists of reconnaissance drones, agile multi-rotor UAVs equipped with nets which are dropped to snare enemy drones, and transport UAVs to carry smaller drones.

Professor Shim currently leads KAIST’s Unmanned System Research Group (USRG, http://unmanned.kaist.ac.kr/) and Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

For the article, please go to http://spectrum.ieee.org/automaton/robotics/aerial-robots/south-korea-drone-vs-drone.

2015.04.02 View 13663

Professor Shim Featured with His Drone System in IEEE Spectrum

The IEEE Spectrum, a technology and science magazine published by the Institute of Electrical and Electronics Engineers (IEEE), featured an article of KAIST’s autonomous unmanned aerial vehicles (UAVs) entitled “South Korea Prepares for Drone vs. Drone Combat,” posted on April 1, 2015.

The article introduces the anti-drone defense system being developed by Professor “David” Hyunchul Shim of the Department of Aerospace Engineering at KAIST. With the goal of developing guard drones that can detect and capture unknown UAVs, the anti-drone defense system consists of reconnaissance drones, agile multi-rotor UAVs equipped with nets which are dropped to snare enemy drones, and transport UAVs to carry smaller drones.

Professor Shim currently leads KAIST’s Unmanned System Research Group (USRG, http://unmanned.kaist.ac.kr/) and Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

For the article, please go to http://spectrum.ieee.org/automaton/robotics/aerial-robots/south-korea-drone-vs-drone.

2015.04.02 View 13663 -

KAIST & the Classic 500 Co Sign for Mobile Healthcare Research

KAIST and The Classic 500 Co., Ltd., an elder care provider based in Seoul, signed a memorandum of understanding to expand medical services by cooperating on the research of medical services and IT on March 24, 2015.

Twenty people from the two institutions, including President Steve Kang, Dong-Hyun Bak, CEO of The Classic 500 and Mun-Sul Jeong, a former KAIST Chairman of the Board, attended the signing ceremony.

Under the agreement, the two institutions will cooperate on mobile healthcare research and the development of a telemedicine system. They will also research and develop a system to better serve society with medical services.

The Classic 500, established by Konkuk University in Korea, provides nursing care services and assisted living facilities for senior citizens.

2015.03.26 View 8994

KAIST & the Classic 500 Co Sign for Mobile Healthcare Research

KAIST and The Classic 500 Co., Ltd., an elder care provider based in Seoul, signed a memorandum of understanding to expand medical services by cooperating on the research of medical services and IT on March 24, 2015.

Twenty people from the two institutions, including President Steve Kang, Dong-Hyun Bak, CEO of The Classic 500 and Mun-Sul Jeong, a former KAIST Chairman of the Board, attended the signing ceremony.

Under the agreement, the two institutions will cooperate on mobile healthcare research and the development of a telemedicine system. They will also research and develop a system to better serve society with medical services.

The Classic 500, established by Konkuk University in Korea, provides nursing care services and assisted living facilities for senior citizens.

2015.03.26 View 8994 -

KAIST Develops a Credit-Card-Thick Flexible Lithium Ion Battery

Since the battery can be charged wirelessly, useful applications are expected including medical patches and smart cards.

Professor Jang Wook Choi at KAIST’s Graduate School of Energy, Environment, Water, and Sustainability (EEWS) and Dr. Jae Yong Song at the Korea Research Institute of Standards and Science jointly led research to invent a flexible lithium ion battery that is thinner than a credit card and can be charged wirelessly.

Their research findings were published online in Nano Letters on March 6, 2015. Lithium ion batteries are widely used today in various electronics including mobile devices and electronic cars. Researchers said that their work could help accelerate the development of flexible and wearable electronics.

Conventional lithium ion batteries are manufactured based on a layering technology, stacking up anodes, separating films, and cathodes like a sandwich, which makes it difficult to reduce their thickness. In addition, friction arises between layers, making the batteries impossible to bend. The coating films of electrodes easily come off, which contributes to the batteries’ poor performance.

The research team abandoned the existing production technology. Instead, they removed the separating films, layered the cathodes and anodes collinearly on a plane, and created a partition between electrodes to eliminate potential problems, such as short circuits and voltage dips, commonly present in lithium ion batteries.

After more than five thousand consecutive flexing experiments, the research team confirmed the possibility of a more flexible electrode structure while maintaining the battery performance comparable to the level of current lithium ion batteries.

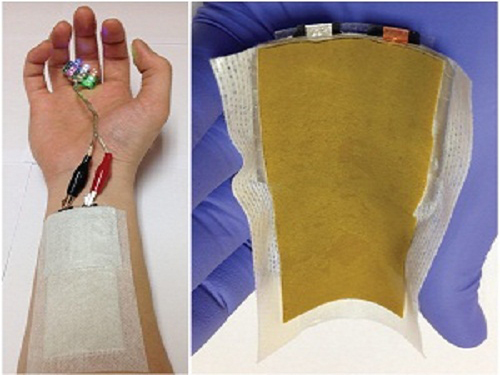

Flexible batteries can be applied to integrated smart cards, cosmetic and medical patches, and skin adhesive sensors that can control a computer with voice commands or gesture as seen in the movie “Iron Man.”

Moreover, the team has successfully developed wireless-charging technology using electromagnetic induction and solar batteries.

They are currently developing a mass production process to combine this planar battery technology and printing, to ultimately create a new paradigm to print semiconductors and batteries using 3D printers.

Professor Choi said, “This new technology will contribute to diversifying patch functions as it is applicable to power various adhesive medical patches.”

Picture 1: Medical patch (left) and flexible secondary battery (right)

Picture 2: Diagram of flexible battery

Picture 3: Smart card embedding flexible battery

2015.03.24 View 12832

KAIST Develops a Credit-Card-Thick Flexible Lithium Ion Battery

Since the battery can be charged wirelessly, useful applications are expected including medical patches and smart cards.

Professor Jang Wook Choi at KAIST’s Graduate School of Energy, Environment, Water, and Sustainability (EEWS) and Dr. Jae Yong Song at the Korea Research Institute of Standards and Science jointly led research to invent a flexible lithium ion battery that is thinner than a credit card and can be charged wirelessly.

Their research findings were published online in Nano Letters on March 6, 2015. Lithium ion batteries are widely used today in various electronics including mobile devices and electronic cars. Researchers said that their work could help accelerate the development of flexible and wearable electronics.

Conventional lithium ion batteries are manufactured based on a layering technology, stacking up anodes, separating films, and cathodes like a sandwich, which makes it difficult to reduce their thickness. In addition, friction arises between layers, making the batteries impossible to bend. The coating films of electrodes easily come off, which contributes to the batteries’ poor performance.

The research team abandoned the existing production technology. Instead, they removed the separating films, layered the cathodes and anodes collinearly on a plane, and created a partition between electrodes to eliminate potential problems, such as short circuits and voltage dips, commonly present in lithium ion batteries.

After more than five thousand consecutive flexing experiments, the research team confirmed the possibility of a more flexible electrode structure while maintaining the battery performance comparable to the level of current lithium ion batteries.

Flexible batteries can be applied to integrated smart cards, cosmetic and medical patches, and skin adhesive sensors that can control a computer with voice commands or gesture as seen in the movie “Iron Man.”

Moreover, the team has successfully developed wireless-charging technology using electromagnetic induction and solar batteries.

They are currently developing a mass production process to combine this planar battery technology and printing, to ultimately create a new paradigm to print semiconductors and batteries using 3D printers.

Professor Choi said, “This new technology will contribute to diversifying patch functions as it is applicable to power various adhesive medical patches.”

Picture 1: Medical patch (left) and flexible secondary battery (right)

Picture 2: Diagram of flexible battery

Picture 3: Smart card embedding flexible battery

2015.03.24 View 12832 -

KVIP Opened in Pangyo

KAIST has opened the KAIST Venture Innovation Program (KVIP) in its Center for Industry Outreach, designed for executive and high-ranking officers of venture companies. Located in Pangyo Techno Valley, KAIST’s Center for Industry Outreach was established in collaboration with the government of Gyeonggi Province to support venture companies in Pangyo for business management training, venture networking, and university-industry cooperation.

The program will be held every Monday for 12 weeks from April 13 to July 6 in KAIST’s Center for Industry Outreach. This executive education program mainly focuses on solving problems that arise when a medium-sized venture company is in the course of growing into a global corporation. The program is divided into four courses which will cover business management, competition in the global market, transformation of a company, and technological innovation.

Professors from various departments at KAIST will give lectures on their fields. Professor Jaeseung Jeong from the Bio and Brain Engineering Department, Professor Hoi-Jun Yoo from the Electrical Engineering Department, Professor Sangmin Bae from the Industrial Design Department, and Professor Kwangjae Sung from the Business and Technology Management Department will each deliver lectures on brain engineering, semiconductor, design, and restructuring.

Industry experts are also invited to give talks, including Dr. Dae-Gyu Byun, the Chief Executive Officer and President of HUMAX Electronics, Dr. Gwang-Cheol Choi, the Chief Executive Officer of SK Engineering & Construction, Mr. Il-young Kim, the former Chief Executive Officer of KT, Dr. Jae-hoon Jeong, the President of the Korea Institute for the Advancement of Technology (KIAT), Dr. Intak Bae, the Chief Executive Officer of Summit Partners, and Mr. Kyung-taek Kwak, a film director.

The department has started recruiting first round applicants for the program, targeting executive and high-ranking officers of middle-sized venture companies. The details of the program can be found on its website, kvip.kaist.ac.kr.

2015.03.23 View 11082

KVIP Opened in Pangyo

KAIST has opened the KAIST Venture Innovation Program (KVIP) in its Center for Industry Outreach, designed for executive and high-ranking officers of venture companies. Located in Pangyo Techno Valley, KAIST’s Center for Industry Outreach was established in collaboration with the government of Gyeonggi Province to support venture companies in Pangyo for business management training, venture networking, and university-industry cooperation.

The program will be held every Monday for 12 weeks from April 13 to July 6 in KAIST’s Center for Industry Outreach. This executive education program mainly focuses on solving problems that arise when a medium-sized venture company is in the course of growing into a global corporation. The program is divided into four courses which will cover business management, competition in the global market, transformation of a company, and technological innovation.

Professors from various departments at KAIST will give lectures on their fields. Professor Jaeseung Jeong from the Bio and Brain Engineering Department, Professor Hoi-Jun Yoo from the Electrical Engineering Department, Professor Sangmin Bae from the Industrial Design Department, and Professor Kwangjae Sung from the Business and Technology Management Department will each deliver lectures on brain engineering, semiconductor, design, and restructuring.

Industry experts are also invited to give talks, including Dr. Dae-Gyu Byun, the Chief Executive Officer and President of HUMAX Electronics, Dr. Gwang-Cheol Choi, the Chief Executive Officer of SK Engineering & Construction, Mr. Il-young Kim, the former Chief Executive Officer of KT, Dr. Jae-hoon Jeong, the President of the Korea Institute for the Advancement of Technology (KIAT), Dr. Intak Bae, the Chief Executive Officer of Summit Partners, and Mr. Kyung-taek Kwak, a film director.

The department has started recruiting first round applicants for the program, targeting executive and high-ranking officers of middle-sized venture companies. The details of the program can be found on its website, kvip.kaist.ac.kr.

2015.03.23 View 11082 -

KAIST and Hancom Sign for Development of Mobile Healthcare

KAIST signed a memorandum of understanding with Hancom, Inc., an office suite developer in Korea, to foster mobile healthcare software programs. President Steve Kang and Chairman Sang-Chul Kim of Hancom held a signing ceremony on March 13, 2015 at the KAIST campus.

Based on the agreement, KAIST and Hancom will exchange research personnel to build Dr. M, a smart healthcare platform developed by the university, collaborate in research and development, and cooperate in the transfer of research developments from the university to the software industry including Hancom.

KAIST and Hancom also signed a memorandum of understanding on the development of software in April 2014. The Hancom-KAIST Research Center opened on campus last October.

2015.03.20 View 9658

KAIST and Hancom Sign for Development of Mobile Healthcare

KAIST signed a memorandum of understanding with Hancom, Inc., an office suite developer in Korea, to foster mobile healthcare software programs. President Steve Kang and Chairman Sang-Chul Kim of Hancom held a signing ceremony on March 13, 2015 at the KAIST campus.

Based on the agreement, KAIST and Hancom will exchange research personnel to build Dr. M, a smart healthcare platform developed by the university, collaborate in research and development, and cooperate in the transfer of research developments from the university to the software industry including Hancom.

KAIST and Hancom also signed a memorandum of understanding on the development of software in April 2014. The Hancom-KAIST Research Center opened on campus last October.

2015.03.20 View 9658 -

Qualcomm Innovation Award Recognizes 20 KAIST Students

The

award provides research fellowships, worth of USD 100,000, to 20 KAIST graduate

students

With an audience of 100 people present,

KAIST held a ceremony for the Qualcomm Innovation Award 2015 at the Information

Technology Convergence building on campus on March 12, 2015.

The Qualcomm Innovation Award, established

in 2010, is a fellowship that supports innovative science and engineering master’s

and doctoral students at KAIST. Qualcomm donated USD 100,000 to KAIST, stipulating that it be used to foster a creative research environment for graduate

students.

To select the recipients, KAIST formed an award committee chaired

by Professor Soo-Young Lee of the Department of Electrical Engineering and accepted research proposals until late January.

The award committee first selected 37

proposals from 75 papers submitted and then chose the final 20 research

proposals on March 12, 2015 after presentation evaluations. The presentations had to show promise of innovation and creativity; prospective influence on wireless communications

and mobile industry; and the prospect of being implemented.

Each recipient received a USD 4,500 research

fellowship along with an opportunity to present their research findings at a

workshop where Qualcomm engineers and other distinguished individuals of the industry

will attend.

Previously, Qualcomm has donated

research fellowships to KAIST graduate students in 2011 and 2013.

2015.03.19 View 10418

Qualcomm Innovation Award Recognizes 20 KAIST Students

The

award provides research fellowships, worth of USD 100,000, to 20 KAIST graduate

students

With an audience of 100 people present,

KAIST held a ceremony for the Qualcomm Innovation Award 2015 at the Information

Technology Convergence building on campus on March 12, 2015.

The Qualcomm Innovation Award, established

in 2010, is a fellowship that supports innovative science and engineering master’s

and doctoral students at KAIST. Qualcomm donated USD 100,000 to KAIST, stipulating that it be used to foster a creative research environment for graduate

students.

To select the recipients, KAIST formed an award committee chaired

by Professor Soo-Young Lee of the Department of Electrical Engineering and accepted research proposals until late January.

The award committee first selected 37

proposals from 75 papers submitted and then chose the final 20 research

proposals on March 12, 2015 after presentation evaluations. The presentations had to show promise of innovation and creativity; prospective influence on wireless communications

and mobile industry; and the prospect of being implemented.

Each recipient received a USD 4,500 research

fellowship along with an opportunity to present their research findings at a

workshop where Qualcomm engineers and other distinguished individuals of the industry

will attend.

Previously, Qualcomm has donated

research fellowships to KAIST graduate students in 2011 and 2013.

2015.03.19 View 10418 -

Interactions Features KAIST's Human-Computer Interaction Lab

Interactions, a bi-monthly magazine published by the Association for Computing Machinery (ACM), the largest educational and scientific computing society in the world, featured an article introducing Human-Computer Interaction (HCI) Lab at KAIST in the March/April 2015 issue (http://interactions.acm.org/archive/toc/march-april-2015).

Established in 2002, the HCI Lab (http://hcil.kaist.ac.kr/) is run by Professor Geehyuk Lee of the Computer Science Department at KAIST. The lab conducts various research projects to improve the design and operation of physical user interfaces and develops new interaction techniques for new types of computers. For the article, see the link below:

ACM Interactions, March and April 2015

Day in the Lab: Human-Computer Interaction Lab @ KAIST

http://interactions.acm.org/archive/view/march-april-2015/human-computer-interaction-lab-kaist

2015.03.02 View 10679

Interactions Features KAIST's Human-Computer Interaction Lab

Interactions, a bi-monthly magazine published by the Association for Computing Machinery (ACM), the largest educational and scientific computing society in the world, featured an article introducing Human-Computer Interaction (HCI) Lab at KAIST in the March/April 2015 issue (http://interactions.acm.org/archive/toc/march-april-2015).

Established in 2002, the HCI Lab (http://hcil.kaist.ac.kr/) is run by Professor Geehyuk Lee of the Computer Science Department at KAIST. The lab conducts various research projects to improve the design and operation of physical user interfaces and develops new interaction techniques for new types of computers. For the article, see the link below:

ACM Interactions, March and April 2015

Day in the Lab: Human-Computer Interaction Lab @ KAIST

http://interactions.acm.org/archive/view/march-april-2015/human-computer-interaction-lab-kaist

2015.03.02 View 10679 -

The Real Time Observation of the Birth of a Molecule

From right to left: Dr. Kyung-Hwan Kim, Professor Hyotcherl Lhee, and Jong-Gu Kim, a Ph.D. candidate

Professor Hyotcherl Lhee of the Department of Chemistry at KAIST and Japanese research teams jointly published their research results showing that they have succeeded in the direct observation of how atoms form a molecule in the online issue of Nature on February 19, 2015.

The researchers used water in which gold atoms ([Au(CN) 2- ]) are dissolved and fired X-ray pulses over the specimen in femtosecond timescales to study chemical reactions taking place among the gold atoms. They were able to examine in real time the instant process of how gold atoms bond together to become a molecule, to a trimer or tetramer state.

This direct viewing of the formation of a gold trimer complex ([Au(CN) 2- ] 3 ) will provide an opportunity to understand complex chemical and biological systems.

For details, please see the following press release that was distributed by the High Energy Accelerator Research Organization, KEK, in Japan:

Direct Observation of Bond Formations

February 18, 2015

A collaboration between researchers from KEK, the Institute for Basic Science (IBS), the Korea Advanced Institute of Science and Technology (KAIST), RIKEN, and the Japan Synchrotron Radiation Research Institute (JASRI) used the SACLA X-ray free electron laser (XFEL) facility for a real time visualization of the birth of a molecular that occurs via photoinduced formation of a chemical bonds. This achievement was published in the online version of the scientific journal “Nature” (published on 19 February 2015).

Direct “observation” of the bond making, through a chemical reaction, has been longstanding dream for chemists. However, the distance between atoms is very small, at about 100 picometer, and the bonding is completed very quickly, taking less than one picosecond (ps). Hence, previously, one could only imagine the bond formation between atoms while looking at the chemical reaction progressing in the test-tube.

In this study, the research group focused on the process of photoinduced bond formation between gold (Au) ions dissolved in water. In the ground state (S 0 state in Fig. 1) Au ions that are weakly bound to each other by an electron affinity and aligned in a bent geometry. Upon a photoexcitation, the S 0 state rapidly converts into an excited (S 1 state in Fig. 1) state where Au-Au covalent bonds are formed among Au ions aligned in a linear geometry. Subsequently, the S 1 state transforms to a triplet state (T 1 state in Fig. 1) in 1.6 ps while accompanying further contraction of Au-Au bonds by 0.1 Å. Later, the T 1 state of the trimer converts to a tetramer (tetramer state in Fig. 1) on nanosecond time scale. Finally, the Au ions returned to their original loosely interacting bent structure.

In this research, the direct observation of a very fast chemical reaction, induced by the photo-excitation, was succeeded (Fig. 2, 3). Therefore, this method is expected to be a fundamental technology for understanding the light energy conversion reaction. The research group is actively working to apply this method to the development of viable renewable energy resources, such as a photocatalysts for artificial photosynthesis using sunlight.

This research was supported by the X-ray Free Electron Laser Priority Strategy Program of the MEXT, PRESTO of the JST, and the the Innovative Areas "Artificial Photosynthesis (AnApple)" grant from the Japan Society for the Promotion of Science (JSPS).

Publication: Nature , 518 (19 February 2015)

Title: Direct observation of bond formation in solution with femtosecond X-ray scattering

Authors: K. H. Kim 1 , J. G. Kim 1 , S. Nozawa 1 , T. Sato 1 , K. Y. Oang, T. W. Kim, H. Ki, J. Jo, S. Park, C. Song, T. Sato, K. Ogawa, T. Togashi, K. Tono, M. Yabashi, T. Ishikawa, J. Kim, R. Ryoo, J. Kim, H. Ihee, S. Adachi. ※ 1: These authors contributed equally to the work.

DOI: 10.1038/nature14163

Figure 1. Structure of a gold cyano trimer complex (Au(CN) 2 - ) 3 .

Figure 2. Observed changes in the molecular structure of the gold complex

Figure 3. Schematic view of the research of photo-chemical reactions by the molecular movie

2015.02.27 View 12894

The Real Time Observation of the Birth of a Molecule

From right to left: Dr. Kyung-Hwan Kim, Professor Hyotcherl Lhee, and Jong-Gu Kim, a Ph.D. candidate

Professor Hyotcherl Lhee of the Department of Chemistry at KAIST and Japanese research teams jointly published their research results showing that they have succeeded in the direct observation of how atoms form a molecule in the online issue of Nature on February 19, 2015.

The researchers used water in which gold atoms ([Au(CN) 2- ]) are dissolved and fired X-ray pulses over the specimen in femtosecond timescales to study chemical reactions taking place among the gold atoms. They were able to examine in real time the instant process of how gold atoms bond together to become a molecule, to a trimer or tetramer state.

This direct viewing of the formation of a gold trimer complex ([Au(CN) 2- ] 3 ) will provide an opportunity to understand complex chemical and biological systems.

For details, please see the following press release that was distributed by the High Energy Accelerator Research Organization, KEK, in Japan:

Direct Observation of Bond Formations

February 18, 2015

A collaboration between researchers from KEK, the Institute for Basic Science (IBS), the Korea Advanced Institute of Science and Technology (KAIST), RIKEN, and the Japan Synchrotron Radiation Research Institute (JASRI) used the SACLA X-ray free electron laser (XFEL) facility for a real time visualization of the birth of a molecular that occurs via photoinduced formation of a chemical bonds. This achievement was published in the online version of the scientific journal “Nature” (published on 19 February 2015).

Direct “observation” of the bond making, through a chemical reaction, has been longstanding dream for chemists. However, the distance between atoms is very small, at about 100 picometer, and the bonding is completed very quickly, taking less than one picosecond (ps). Hence, previously, one could only imagine the bond formation between atoms while looking at the chemical reaction progressing in the test-tube.

In this study, the research group focused on the process of photoinduced bond formation between gold (Au) ions dissolved in water. In the ground state (S 0 state in Fig. 1) Au ions that are weakly bound to each other by an electron affinity and aligned in a bent geometry. Upon a photoexcitation, the S 0 state rapidly converts into an excited (S 1 state in Fig. 1) state where Au-Au covalent bonds are formed among Au ions aligned in a linear geometry. Subsequently, the S 1 state transforms to a triplet state (T 1 state in Fig. 1) in 1.6 ps while accompanying further contraction of Au-Au bonds by 0.1 Å. Later, the T 1 state of the trimer converts to a tetramer (tetramer state in Fig. 1) on nanosecond time scale. Finally, the Au ions returned to their original loosely interacting bent structure.

In this research, the direct observation of a very fast chemical reaction, induced by the photo-excitation, was succeeded (Fig. 2, 3). Therefore, this method is expected to be a fundamental technology for understanding the light energy conversion reaction. The research group is actively working to apply this method to the development of viable renewable energy resources, such as a photocatalysts for artificial photosynthesis using sunlight.

This research was supported by the X-ray Free Electron Laser Priority Strategy Program of the MEXT, PRESTO of the JST, and the the Innovative Areas "Artificial Photosynthesis (AnApple)" grant from the Japan Society for the Promotion of Science (JSPS).

Publication: Nature , 518 (19 February 2015)

Title: Direct observation of bond formation in solution with femtosecond X-ray scattering

Authors: K. H. Kim 1 , J. G. Kim 1 , S. Nozawa 1 , T. Sato 1 , K. Y. Oang, T. W. Kim, H. Ki, J. Jo, S. Park, C. Song, T. Sato, K. Ogawa, T. Togashi, K. Tono, M. Yabashi, T. Ishikawa, J. Kim, R. Ryoo, J. Kim, H. Ihee, S. Adachi. ※ 1: These authors contributed equally to the work.

DOI: 10.1038/nature14163

Figure 1. Structure of a gold cyano trimer complex (Au(CN) 2 - ) 3 .

Figure 2. Observed changes in the molecular structure of the gold complex

Figure 3. Schematic view of the research of photo-chemical reactions by the molecular movie

2015.02.27 View 12894 -

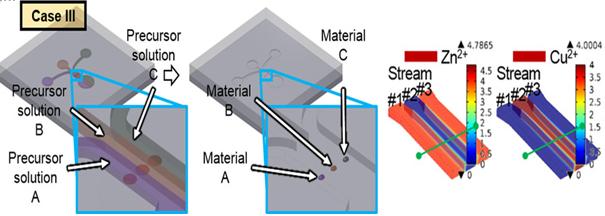

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 11113

KAIST Develops Subminiature, Power-Efficient Air Pollution Sensing Probe

Professor Inkyu Park and his research team from the Department of Mechanical Engineering at KAIST have developed a subminiature, power-efficient air-pollution sensing probe that can be applied to mobile devices. Their research findings were published online in the January 30th issue of Scientific Reports.

As air pollution has increased, people have taken greater interest in health care. The developed technology could allow people to measure independently the air pollution level of their surrounding environments.

Previous instruments used to measure air pollution levels were bulky and consumed a lot of power. They also often produced inaccurate results when measuring air pollution in which different toxic gases were mixed. These problems could not be resolved with existing semiconductor manufacturing process.

Using local temperature field control technology, Professor Park’s team succeeded in integrating multiple heterogeneous nanomaterials and fitting them onto a small, low-power electronic chip. This microheating sensor can heat microscale regions through local hydrothermal synthesis. Because it requires a miniscale amount of nanomaterials to manufacture, the sensor is most suitable for mobile devices.

Professor Park said, “Our research will contribute to the development of convergence technology in such field as air pollution sensing probes, biosensors, electronic devices, and displays.”

The team's research was supported by the Ministry of Education and the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1 – The Concept of Multiple Nanomaterial Device and Numerical Simulation Results of Precursor Solutions

Figure 2 - Multiple Nanomaterial Manufactured in a Microscale Region

2015.02.27 View 11113