Engineering

-

2017 KAIST Research Day Honors Professor Hoon Sohn

The 2017 KAIST Research Day recognized Professor Hoon Sohn of the Department of Civil and Environmental Engineering as Research Grand Prize Awardee in addition to the 10 most distinguished research achievements of the past year.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator is the highest over the past five years. The indicator combines the factors of the number of research contracts, IPR, royalty income, as well as research overhead cost inclusion.

During the ceremony, which was held on May 23, Professor Jun-Ho Oh of the Department of Mechanical Engineering and Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering also won the Best Research Award. The two professors had the best scores when evaluating their research performance for one-year periods.

Meanwhile, the Research Innovation Award went to Professor YongKeun Park of the Department of Physics. The Research Innovation Award scores the factors of foreign patent registration, contracts of technological transfer and income from technology fees, technology consultations, and startups and selected Professor Park as the top winner.

Professors Yong Hee Lee of the Department of Physics and Jonghwa Shin of the Department of Material Science won the Convergence Research Award. The Convergence Research Award recognizes the most outstanding research team who created innovative research results for a year.

After the ceremony, President Chen Shiyi of the Southern University of Science and Technology gave a distinguished lecture on the “Global & Entrepreneurial Universities for the Age of the Fourth Industrial Revolution.” the Research Day ceremony, KAIST also presented the ten most distinguished research achievements made by KAIST professors during the last year as follows (Click):

▲ Commercialization of 3D Holographic Microscopy by Professor YongKeun Park of the Department of Physics

▲ Designer Proteins with Chemical Modifications by Professor Hee-Sung Park of the Department of Chemistry

▲ Lanthanum-Catalyzed Synthesis of Microporous 3D Graphene-Like Carbons in a Zeolite Template by Professor Ryong Ryoo of the Department of Chemistry

▲ Complete Prevention of Blood Loss by Self-Sealing Hemostatic Needles by Professor Haeshin Lee of the Department of Chemistry

▲ An Immunological Mechanism for the Contribution of Commensal Microbiota Against Herpes Simplex Virus Infection in Genital Mucosa by Heung Kyu Lee of the Graduate School of Medical Science and Engineering

▲ Development of a Pulse-Echo Laser Ultrasonic Propagation Imaging System by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

▲ Bi-refractive Stereo Imaging for Single-Shot Depth Acquisition by Professor Min H. Kim of the School of Computing

▲ Development of Environment Friendly Geotechnical Construction Material Using Biopolymer by Professor Gye-Chun Cho of the Department of Civil and Environmental Engineering

▲ Protein Delivery Via Engineered Exosomes by Professor Chulhee Choi of the Department of Bio and Brain Engineering

▲ Hot Electron Detection Under Catalytic Reactions by Professor Jeong Young Park of the Graduate School of EEWS.

After the ceremony, President Chen Shiyi of the Southern University of Science and Technology gave a distinguished lecture on the “Global & Entrepreneurial Universities for the Age of the Fourth Industrial Revolution.”

(Photo:President Shin poses with the 2017 KAIST Research Grand Prize Winner Professor Hoon Sohn on May 23.)

2017.05.23 View 15535

2017 KAIST Research Day Honors Professor Hoon Sohn

The 2017 KAIST Research Day recognized Professor Hoon Sohn of the Department of Civil and Environmental Engineering as Research Grand Prize Awardee in addition to the 10 most distinguished research achievements of the past year.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator is the highest over the past five years. The indicator combines the factors of the number of research contracts, IPR, royalty income, as well as research overhead cost inclusion.

During the ceremony, which was held on May 23, Professor Jun-Ho Oh of the Department of Mechanical Engineering and Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering also won the Best Research Award. The two professors had the best scores when evaluating their research performance for one-year periods.

Meanwhile, the Research Innovation Award went to Professor YongKeun Park of the Department of Physics. The Research Innovation Award scores the factors of foreign patent registration, contracts of technological transfer and income from technology fees, technology consultations, and startups and selected Professor Park as the top winner.

Professors Yong Hee Lee of the Department of Physics and Jonghwa Shin of the Department of Material Science won the Convergence Research Award. The Convergence Research Award recognizes the most outstanding research team who created innovative research results for a year.

After the ceremony, President Chen Shiyi of the Southern University of Science and Technology gave a distinguished lecture on the “Global & Entrepreneurial Universities for the Age of the Fourth Industrial Revolution.” the Research Day ceremony, KAIST also presented the ten most distinguished research achievements made by KAIST professors during the last year as follows (Click):

▲ Commercialization of 3D Holographic Microscopy by Professor YongKeun Park of the Department of Physics

▲ Designer Proteins with Chemical Modifications by Professor Hee-Sung Park of the Department of Chemistry

▲ Lanthanum-Catalyzed Synthesis of Microporous 3D Graphene-Like Carbons in a Zeolite Template by Professor Ryong Ryoo of the Department of Chemistry

▲ Complete Prevention of Blood Loss by Self-Sealing Hemostatic Needles by Professor Haeshin Lee of the Department of Chemistry

▲ An Immunological Mechanism for the Contribution of Commensal Microbiota Against Herpes Simplex Virus Infection in Genital Mucosa by Heung Kyu Lee of the Graduate School of Medical Science and Engineering

▲ Development of a Pulse-Echo Laser Ultrasonic Propagation Imaging System by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

▲ Bi-refractive Stereo Imaging for Single-Shot Depth Acquisition by Professor Min H. Kim of the School of Computing

▲ Development of Environment Friendly Geotechnical Construction Material Using Biopolymer by Professor Gye-Chun Cho of the Department of Civil and Environmental Engineering

▲ Protein Delivery Via Engineered Exosomes by Professor Chulhee Choi of the Department of Bio and Brain Engineering

▲ Hot Electron Detection Under Catalytic Reactions by Professor Jeong Young Park of the Graduate School of EEWS.

After the ceremony, President Chen Shiyi of the Southern University of Science and Technology gave a distinguished lecture on the “Global & Entrepreneurial Universities for the Age of the Fourth Industrial Revolution.”

(Photo:President Shin poses with the 2017 KAIST Research Grand Prize Winner Professor Hoon Sohn on May 23.)

2017.05.23 View 15535 -

Parasitic Robot System for Turtle's Waypoint Navigation

A KAIST research team presented a hybrid animal-robot interaction called “the parasitic robot system,” that imitates the nature relationship between parasites and host.

The research team led by Professor Phil-Seung Lee of the Department of Mechanical Engineering took an animal’s locomotive abilities to apply the theory of using a robot as a parasite. The robot is attached to its host animal in a way similar to an actual parasite, and it interacts with the host through particular devices and algorithms.

Even with remarkable technology advancements, robots that operate in complex and harsh environments still have some serious limitations in moving and recharging. However, millions of years of evolution have led to there being many real animals capable of excellent locomotion and survive in actual natural environment.

Certain kinds of real parasites can manipulate the behavior of the host to increase the probability of its own reproduction. Similarly, in the proposed concept of a “parasitic robot,” a specific behavior is induced by the parasitic robot in its host to benefit the robot.

The team chose a turtle as their first host animal and designed a parasitic robot that can perform “stimulus-response training.” The parasitic robot, which is attached to the turtle, can induce the turtle’s object-tracking behavior through repeated training sessions.

The robot then simply guides it using LEDs and feeds it snacks as a reward for going in the right direction through a programmed algorithm. After training sessions lasting five weeks, the parasitic robot can successfully control the direction of movement of the host turtles in the waypoint navigation task in a water tank.

This hybrid animal–robot interaction system could provide an alternative solution of the limitations of conventional mobile robot systems in various fields. Ph.D. candidate Dae-Gun Kim, the first author of this research said that there are a wide variety of animals including mice, birds, and fish that could perform equally as well at such tasks. He said that in the future, this system will be applied to various exploration and reconnaissance missions that humans and robots find it difficult to do on their own.

Kim said, “This hybrid animal-robot interaction system could provide an alternative solution to the limitations of conventional mobile robot systems in various fields, and could also act as a useful interaction system for the behavioral sciences.”

The research was published in the Journal of Bionic Engineering April issue.

2017.05.19 View 10568

Parasitic Robot System for Turtle's Waypoint Navigation

A KAIST research team presented a hybrid animal-robot interaction called “the parasitic robot system,” that imitates the nature relationship between parasites and host.

The research team led by Professor Phil-Seung Lee of the Department of Mechanical Engineering took an animal’s locomotive abilities to apply the theory of using a robot as a parasite. The robot is attached to its host animal in a way similar to an actual parasite, and it interacts with the host through particular devices and algorithms.

Even with remarkable technology advancements, robots that operate in complex and harsh environments still have some serious limitations in moving and recharging. However, millions of years of evolution have led to there being many real animals capable of excellent locomotion and survive in actual natural environment.

Certain kinds of real parasites can manipulate the behavior of the host to increase the probability of its own reproduction. Similarly, in the proposed concept of a “parasitic robot,” a specific behavior is induced by the parasitic robot in its host to benefit the robot.

The team chose a turtle as their first host animal and designed a parasitic robot that can perform “stimulus-response training.” The parasitic robot, which is attached to the turtle, can induce the turtle’s object-tracking behavior through repeated training sessions.

The robot then simply guides it using LEDs and feeds it snacks as a reward for going in the right direction through a programmed algorithm. After training sessions lasting five weeks, the parasitic robot can successfully control the direction of movement of the host turtles in the waypoint navigation task in a water tank.

This hybrid animal–robot interaction system could provide an alternative solution of the limitations of conventional mobile robot systems in various fields. Ph.D. candidate Dae-Gun Kim, the first author of this research said that there are a wide variety of animals including mice, birds, and fish that could perform equally as well at such tasks. He said that in the future, this system will be applied to various exploration and reconnaissance missions that humans and robots find it difficult to do on their own.

Kim said, “This hybrid animal-robot interaction system could provide an alternative solution to the limitations of conventional mobile robot systems in various fields, and could also act as a useful interaction system for the behavioral sciences.”

The research was published in the Journal of Bionic Engineering April issue.

2017.05.19 View 10568 -

Prof. Sang-Min Bae Receives 2017 iF Design Award

Prof. Sang-Min Bae and his research team from the Industrial Design Department of KAIST submitted a winning entry to the 2017 iF Design Award named ‘Culture BOXCHOOL’.

The iF Design Award is an internationally renowned design contest that is recognized as one of the top three design awards in the world along with the Red Dot Design Award and the IDEA Design Award. It has been held annually by iF International Forum Design since 1953. A total of 5,575 entries from 59 countries entered the last competition.

Culture BOXCHOOL is a modular container space platform designed for culture sharing in isolated areas. It is delivered as a standard shipping container along with its subsidiary modular parts and it transforms into a gallery, office, or classroom. These modular parts build the interior and exterior by attaching them to the corner castings, which are standard parts on all shipping containers. Two Cultural BOXCHOOL containers can be transformed into three different types of layouts.

The containers can generate their own energy using solar panels that provide sustainable energy to equipment inside. Additionally, hot humid air can flow out through the attic vent, doors, and windows.

“With Culture BOXCHOOL, you can easily and quickly create spaces such as offices and classrooms, or you can easily disassemble and move them to another location.

Thus, it can provide everyone with equal educational opportunities and cultural enjoyment regardless of their geographical location. In addition, because it produces its own energy, it is expected to create a cultural space in a relatively harsh environment such as in developing countries. These social and economic values of Culture BOXCHOOL seem to be what led to us winning the contest. I will continue to strive to create the world’s best designs for needy people.” Professor Bae said.

The ID+IM design laboratory, a research team led by Professor Bae, has been studying philanthropy design since 2005, working on solving various problems throughout society through innovative design. They have received more than 50 awards from the most prestigious design competitions in the world.

2017.05.18 View 9738

Prof. Sang-Min Bae Receives 2017 iF Design Award

Prof. Sang-Min Bae and his research team from the Industrial Design Department of KAIST submitted a winning entry to the 2017 iF Design Award named ‘Culture BOXCHOOL’.

The iF Design Award is an internationally renowned design contest that is recognized as one of the top three design awards in the world along with the Red Dot Design Award and the IDEA Design Award. It has been held annually by iF International Forum Design since 1953. A total of 5,575 entries from 59 countries entered the last competition.

Culture BOXCHOOL is a modular container space platform designed for culture sharing in isolated areas. It is delivered as a standard shipping container along with its subsidiary modular parts and it transforms into a gallery, office, or classroom. These modular parts build the interior and exterior by attaching them to the corner castings, which are standard parts on all shipping containers. Two Cultural BOXCHOOL containers can be transformed into three different types of layouts.

The containers can generate their own energy using solar panels that provide sustainable energy to equipment inside. Additionally, hot humid air can flow out through the attic vent, doors, and windows.

“With Culture BOXCHOOL, you can easily and quickly create spaces such as offices and classrooms, or you can easily disassemble and move them to another location.

Thus, it can provide everyone with equal educational opportunities and cultural enjoyment regardless of their geographical location. In addition, because it produces its own energy, it is expected to create a cultural space in a relatively harsh environment such as in developing countries. These social and economic values of Culture BOXCHOOL seem to be what led to us winning the contest. I will continue to strive to create the world’s best designs for needy people.” Professor Bae said.

The ID+IM design laboratory, a research team led by Professor Bae, has been studying philanthropy design since 2005, working on solving various problems throughout society through innovative design. They have received more than 50 awards from the most prestigious design competitions in the world.

2017.05.18 View 9738 -

Distinguished Professor Lee Elected to the NAS

Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering was elected as a foreign associate to the US National Academy of Sciences (NAS) on May 2. The National Academy of Sciences elected 84 new members and 21 foreign associates in recognition of their distinguished and continuing achievements in their original research. Election to the Academy is widely regarded as one of the highest honors that a scientist can receive.

Professor Lee was also elected in 2010 as a member of the US National Academy of Engineering (NAE) for his leadership in microbial biotechnology and metabolic engineering, including the development of fermentation processes for biodegradable polymers and organic acids. Until 2016, there are only 12 people worldwide who are foreign associates of both NAS and NAE.

He is the first Korean elected to both prestigious academies, the NAS and the NAE in the US. Professor Lee is currently the dean of KAIST Institutes, the world leading institute for multi-and interdisciplinary research. He is also serving as co-chair of the Global Council on Biotechnology and member of the Global Future Council on the Fourth Industrial Revolution, the World Economic Forum.

2017.05.16 View 11124

Distinguished Professor Lee Elected to the NAS

Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering was elected as a foreign associate to the US National Academy of Sciences (NAS) on May 2. The National Academy of Sciences elected 84 new members and 21 foreign associates in recognition of their distinguished and continuing achievements in their original research. Election to the Academy is widely regarded as one of the highest honors that a scientist can receive.

Professor Lee was also elected in 2010 as a member of the US National Academy of Engineering (NAE) for his leadership in microbial biotechnology and metabolic engineering, including the development of fermentation processes for biodegradable polymers and organic acids. Until 2016, there are only 12 people worldwide who are foreign associates of both NAS and NAE.

He is the first Korean elected to both prestigious academies, the NAS and the NAE in the US. Professor Lee is currently the dean of KAIST Institutes, the world leading institute for multi-and interdisciplinary research. He is also serving as co-chair of the Global Council on Biotechnology and member of the Global Future Council on the Fourth Industrial Revolution, the World Economic Forum.

2017.05.16 View 11124 -

Dr. Zi Jing Wong Named 2017 Jeong Hun Cho Awardee

(Photo caption: The 2017 Jeong Hun Cho Scholarship recipients pose with President Shin (left photo) and Dr. Zi Jing Wong, the recipient of the 2017 Jeong Hun Cho Award)

Dr. Zi Jing Wong, a postdoctoral scholar at the University of California, Berkeley was named the 2017 recipient of the Jeong Hun Cho Award. The award recognizes outstanding young scientists in the field of aerospace engineering annually. The recipient receives a 20 million KRW prize.

The Award Committee said that Dr. Wong who earned his MS at KAIST Department of Aerospace Engineering is a rising scholar in the fields of optic meta materials, photonics, imaging, among others. He has published five papers on the realization of a zero refractive index and the control of a refractive index, as well as the realization of a 3D invisibility cloak in Science and Nature Photonics in 2014 and 2015. Dr. Wong also swept the best paper awards from many international academic societies including the US Materials Research Society, IEEE, SPIE, and Metamaterials Congress in 2015. He finished his Ph.D. at the University of California, Berkeley.

The Award Committee also named three recipients of the Jeong Hun Cho Scholarship: Ph.D. candidate Hyon-Tak Kim of the Department of Aerospace Engineering at KAIST, Ph.D. candidate Ho-Song Park from the Department of Mechanical Engineering at Korea University, and Hyong-Jin Choi of Kongju National University High School.

The award was endowed by the family of the late Ph.D. candidate Jeong Hun Cho who died in a rocket lab accident in the Department of Aerospace Engineering in 2003. Cho was posthumously conferred an honorary doctorate degree.

In memory of Cho, his father established the ‘Jeong Hun Cho Award and Scholarship.’ The scholarship annually selects three young scholars from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

2017.05.12 View 12901

Dr. Zi Jing Wong Named 2017 Jeong Hun Cho Awardee

(Photo caption: The 2017 Jeong Hun Cho Scholarship recipients pose with President Shin (left photo) and Dr. Zi Jing Wong, the recipient of the 2017 Jeong Hun Cho Award)

Dr. Zi Jing Wong, a postdoctoral scholar at the University of California, Berkeley was named the 2017 recipient of the Jeong Hun Cho Award. The award recognizes outstanding young scientists in the field of aerospace engineering annually. The recipient receives a 20 million KRW prize.

The Award Committee said that Dr. Wong who earned his MS at KAIST Department of Aerospace Engineering is a rising scholar in the fields of optic meta materials, photonics, imaging, among others. He has published five papers on the realization of a zero refractive index and the control of a refractive index, as well as the realization of a 3D invisibility cloak in Science and Nature Photonics in 2014 and 2015. Dr. Wong also swept the best paper awards from many international academic societies including the US Materials Research Society, IEEE, SPIE, and Metamaterials Congress in 2015. He finished his Ph.D. at the University of California, Berkeley.

The Award Committee also named three recipients of the Jeong Hun Cho Scholarship: Ph.D. candidate Hyon-Tak Kim of the Department of Aerospace Engineering at KAIST, Ph.D. candidate Ho-Song Park from the Department of Mechanical Engineering at Korea University, and Hyong-Jin Choi of Kongju National University High School.

The award was endowed by the family of the late Ph.D. candidate Jeong Hun Cho who died in a rocket lab accident in the Department of Aerospace Engineering in 2003. Cho was posthumously conferred an honorary doctorate degree.

In memory of Cho, his father established the ‘Jeong Hun Cho Award and Scholarship.’ The scholarship annually selects three young scholars from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

2017.05.12 View 12901 -

Gout Diagnostic Strip Using a Single Teardrop

A novel diagnostic strip for gout patients using a single teardrop has been announced by KAIST research team. This technology analyzes biological molecules in tears for a non-invasive diagnosis, significantly reducing the time and expense previously required for a diagnosis.

The research team under Professor Ki-Hun Jeong of the Department of Bio and Brain Engineering succeeded in developing an affordable and elaborate gout diagnostic strip by depositing metal nanoparticles on paper. This technology can not only be used in diagnostic medicine and drug testing, but also in various other areas such as field diagnoses that require prompt and accurate detection of a certain substance.

Gout induces pain in joints due to needle-shaped uric acid crystal build up. In general, therapeutic treatments exist to administer pain relief, stimulate uric acid discharge, and uric acid depressant. Such treatments work for temporary relief, but there have significant limitations. Thus, patients are required to regularly check uric acid concentrations, as well as control their diets. Therefore, simpler ways to measure uric acid would greatly benefit gout control and its prevention in a more affordable and convenient manner.

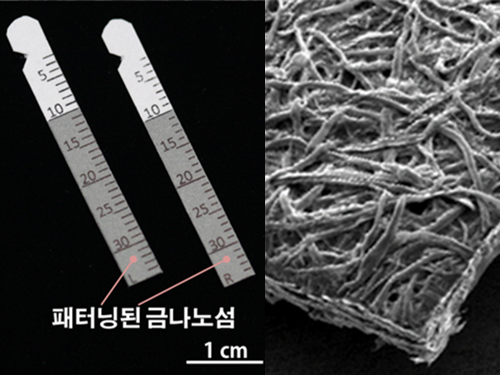

Existing gout diagnostic techniques include measuring uric acid concentrations from blood samples or observing uric acid crystals from joint synovial fluid under a microscope. These existing methods are invasive and time consuming. To overcome their limitations, the research team uniformly deposited gold nanoislands with nanoplasnomics properties on the surface of paper that can easily collect tears.

Nanoplasnomics techniques collect light on the surface of a metal nanostructure, and can be applied to disease and health diagnostic indicators as well as for genetic material detection. Further, metals such as gold absorb stronger light when it is irradiated, and thus can maximize light concentration on board surfaces while maintaining the properties of paper. The developed metal nanostructure production technology allows the flexible manufacturing of nanostructures on a large surface, which in turn allows flexible control of light concentrations.

The research team grafted surface-enhanced Raman spectroscopy on paper diagnostic strips to allow uric acid concentration measurements in teardrops without additional indicators. The measured concentration in teardrops can be compared to blood uric acid concentrations for diagnosing gout.

Professor Jeong explained, “Based on these research results, our strip will make it possible to conduct low-cost, no indicator, supersensitive biological molecule analysis and fast field diagnosis using tears.” He continued, “Tears, as well as various other bodily fluids, can be used to contribute to disease diagnosis and physiological functional research.”

Ph.D. candidate Moonseong Park participated in the research as the first author of the paper that was published in the online edition of ACS Nano on December 14, 2016. Park said, “The strip will allow fast and simple field diagnosis, and can be produced on a large scale using the existing semiconductor process.”

(Figure 1. Optical image of paper gout diagnostic strip covered with gold)

(Figure 2. Scanning delectron microscopic image of paper gout diagnostic strip)

(Figure 3. Scanning electron microscope image of cellulos fiber coated with gold nanoislands)

(Figure 4. Gout diagnosis using tears)

2017.04.27 View 9587

Gout Diagnostic Strip Using a Single Teardrop

A novel diagnostic strip for gout patients using a single teardrop has been announced by KAIST research team. This technology analyzes biological molecules in tears for a non-invasive diagnosis, significantly reducing the time and expense previously required for a diagnosis.

The research team under Professor Ki-Hun Jeong of the Department of Bio and Brain Engineering succeeded in developing an affordable and elaborate gout diagnostic strip by depositing metal nanoparticles on paper. This technology can not only be used in diagnostic medicine and drug testing, but also in various other areas such as field diagnoses that require prompt and accurate detection of a certain substance.

Gout induces pain in joints due to needle-shaped uric acid crystal build up. In general, therapeutic treatments exist to administer pain relief, stimulate uric acid discharge, and uric acid depressant. Such treatments work for temporary relief, but there have significant limitations. Thus, patients are required to regularly check uric acid concentrations, as well as control their diets. Therefore, simpler ways to measure uric acid would greatly benefit gout control and its prevention in a more affordable and convenient manner.

Existing gout diagnostic techniques include measuring uric acid concentrations from blood samples or observing uric acid crystals from joint synovial fluid under a microscope. These existing methods are invasive and time consuming. To overcome their limitations, the research team uniformly deposited gold nanoislands with nanoplasnomics properties on the surface of paper that can easily collect tears.

Nanoplasnomics techniques collect light on the surface of a metal nanostructure, and can be applied to disease and health diagnostic indicators as well as for genetic material detection. Further, metals such as gold absorb stronger light when it is irradiated, and thus can maximize light concentration on board surfaces while maintaining the properties of paper. The developed metal nanostructure production technology allows the flexible manufacturing of nanostructures on a large surface, which in turn allows flexible control of light concentrations.

The research team grafted surface-enhanced Raman spectroscopy on paper diagnostic strips to allow uric acid concentration measurements in teardrops without additional indicators. The measured concentration in teardrops can be compared to blood uric acid concentrations for diagnosing gout.

Professor Jeong explained, “Based on these research results, our strip will make it possible to conduct low-cost, no indicator, supersensitive biological molecule analysis and fast field diagnosis using tears.” He continued, “Tears, as well as various other bodily fluids, can be used to contribute to disease diagnosis and physiological functional research.”

Ph.D. candidate Moonseong Park participated in the research as the first author of the paper that was published in the online edition of ACS Nano on December 14, 2016. Park said, “The strip will allow fast and simple field diagnosis, and can be produced on a large scale using the existing semiconductor process.”

(Figure 1. Optical image of paper gout diagnostic strip covered with gold)

(Figure 2. Scanning delectron microscopic image of paper gout diagnostic strip)

(Figure 3. Scanning electron microscope image of cellulos fiber coated with gold nanoislands)

(Figure 4. Gout diagnosis using tears)

2017.04.27 View 9587 -

Professor Duck-Joo Lee Awarded the 21st Century Grand Prize

Professor Duck-Joo Lee of the Department of Aerospace Engineering was awarded the 21st Century Grand Prize in the field of technology development by the New Industry Management Academy and the 21st Leaders Club on April 13.

Professor Lee was honored in recognition of his contribution to the helicopter industry. He played a part in domestic helicopter development projects including the KUH-1 Surion (Korean Attack Helicopter), a twin-engine, transport utility helicopter as well as LAH (Light Armed Helicopter) and LCH (Light Civil Helicopter) projects.

Since joining KAIST in 1988, Professor Lee supervised more than 26 PhDs and 27 MSs. He was responsible for hosting the 1st Asian-Australian Rotorcraft Forum and Exhibition and currently serves as vice president of the American Helicopter Society and the Korea Drone Industry Promotion Association. He also participated in open online courses on K-MOOC and Coursera.

(Caption: Professor Lee (second from left in the first row) poses after receiving the award.)

2017.04.26 View 8989

Professor Duck-Joo Lee Awarded the 21st Century Grand Prize

Professor Duck-Joo Lee of the Department of Aerospace Engineering was awarded the 21st Century Grand Prize in the field of technology development by the New Industry Management Academy and the 21st Leaders Club on April 13.

Professor Lee was honored in recognition of his contribution to the helicopter industry. He played a part in domestic helicopter development projects including the KUH-1 Surion (Korean Attack Helicopter), a twin-engine, transport utility helicopter as well as LAH (Light Armed Helicopter) and LCH (Light Civil Helicopter) projects.

Since joining KAIST in 1988, Professor Lee supervised more than 26 PhDs and 27 MSs. He was responsible for hosting the 1st Asian-Australian Rotorcraft Forum and Exhibition and currently serves as vice president of the American Helicopter Society and the Korea Drone Industry Promotion Association. He also participated in open online courses on K-MOOC and Coursera.

(Caption: Professor Lee (second from left in the first row) poses after receiving the award.)

2017.04.26 View 8989 -

Professor Jinah Park Received the Prime Minister's Award

Professor Jinah Park of the School of Computing received the Prime Minister’s Citation Ribbon on April 21 at a ceremony celebrating the Day of Science and ICT. The awardee was selected by the Ministry of Science, ICT and Future Planning and Korea Communications Commission.

Professor Park was recognized for her convergence R&D of a VR simulator for dental treatment with haptic feedback, in addition to her research on understanding 3D interaction behavior in VR environments. Her major academic contributions are in the field of medical imaging, where she developed a computational technique to analyze cardiac motion from tagging data.

Professor Park said she was very pleased to see her twenty-plus years of research on ways to converge computing into medical areas finally bear fruit. She also thanked her colleagues and students in her Computer Graphics and CGV Research Lab for working together to make this achievement possible.

2017.04.26 View 11239

Professor Jinah Park Received the Prime Minister's Award

Professor Jinah Park of the School of Computing received the Prime Minister’s Citation Ribbon on April 21 at a ceremony celebrating the Day of Science and ICT. The awardee was selected by the Ministry of Science, ICT and Future Planning and Korea Communications Commission.

Professor Park was recognized for her convergence R&D of a VR simulator for dental treatment with haptic feedback, in addition to her research on understanding 3D interaction behavior in VR environments. Her major academic contributions are in the field of medical imaging, where she developed a computational technique to analyze cardiac motion from tagging data.

Professor Park said she was very pleased to see her twenty-plus years of research on ways to converge computing into medical areas finally bear fruit. She also thanked her colleagues and students in her Computer Graphics and CGV Research Lab for working together to make this achievement possible.

2017.04.26 View 11239 -

KAIST Nanosatellite LINK Launched to the ISS

Courtesy: United Launch Alliance

The KAIST nanosatellite LINK (Little Intelligent Nanosatellite of KAIST) was successfully launched on an Atlas V booster aboard the NASA CRS-7 Mission on April 18 at Space Launch Complex 41, Cape Canaveral Air Force Station in Florida. The KAIST nanosatellite was developed by the research team led by Professor Hyochoong Bang of the Department of Aerospace Engineering.

Aboard the flight to the ISS (International Space Station) were 28 satellites including LINK. They are part of the QB50 Project, an international educational initiative which aims to deploy an array of CubeSat-mounted sensors into Earth’s thermosphere. The project is funded by the European Commission and managed by the von Karman Institute for Fluid Dynamics in Belgium.

The small satellites are hitching a lift into orbit aboard the unmanned resupply spacecraft Cygnus, with a total mass of 83 kilograms. Built to CubeSat specifications, Cygnus will deploy four of the spacecraft following its departure from the space station. LINK will conduct its scientific mission for three months at the station.

The majority of QB50 satellites carry one of three standard instrument packages, consisting of a primary instrument and an array of thermistors, thermocouples, and resistant temperature detectors. LINK is a two-unit CubeSat and weighs two kilograms. It carries an ion-neutral mass spectrometer (INMS), which measures the mass of ions and neutral atoms, as the primary payload of the QB50 project. The secondary payload is two Langmuir probes, which are in-house sensors (m-NLP) developed by Professor Kyong Wook Min’s team of the Department of Physics at KAIST. These are all geared toward collecting long-term continuous in-situ measurements of conditions in Earth’s lower thermosphere.

Professor Bang said, “The QB50 Project is being used for educational purposes. However, the LINK launch will bring a new breakthrough toward collecting information on Earth’s lower thermosphere. Building on these experiences of designing and launching the CubeSat will serve as an opportunity to verify the research results made in our lab firsthand in space.”

(Caption: LINK (Little Intelligent Nanosatellite of KAIST) was launched on an Atlast V booster aboard the NASA CRS-7 Mission on April 18.)

2017.04.25 View 9605

KAIST Nanosatellite LINK Launched to the ISS

Courtesy: United Launch Alliance

The KAIST nanosatellite LINK (Little Intelligent Nanosatellite of KAIST) was successfully launched on an Atlas V booster aboard the NASA CRS-7 Mission on April 18 at Space Launch Complex 41, Cape Canaveral Air Force Station in Florida. The KAIST nanosatellite was developed by the research team led by Professor Hyochoong Bang of the Department of Aerospace Engineering.

Aboard the flight to the ISS (International Space Station) were 28 satellites including LINK. They are part of the QB50 Project, an international educational initiative which aims to deploy an array of CubeSat-mounted sensors into Earth’s thermosphere. The project is funded by the European Commission and managed by the von Karman Institute for Fluid Dynamics in Belgium.

The small satellites are hitching a lift into orbit aboard the unmanned resupply spacecraft Cygnus, with a total mass of 83 kilograms. Built to CubeSat specifications, Cygnus will deploy four of the spacecraft following its departure from the space station. LINK will conduct its scientific mission for three months at the station.

The majority of QB50 satellites carry one of three standard instrument packages, consisting of a primary instrument and an array of thermistors, thermocouples, and resistant temperature detectors. LINK is a two-unit CubeSat and weighs two kilograms. It carries an ion-neutral mass spectrometer (INMS), which measures the mass of ions and neutral atoms, as the primary payload of the QB50 project. The secondary payload is two Langmuir probes, which are in-house sensors (m-NLP) developed by Professor Kyong Wook Min’s team of the Department of Physics at KAIST. These are all geared toward collecting long-term continuous in-situ measurements of conditions in Earth’s lower thermosphere.

Professor Bang said, “The QB50 Project is being used for educational purposes. However, the LINK launch will bring a new breakthrough toward collecting information on Earth’s lower thermosphere. Building on these experiences of designing and launching the CubeSat will serve as an opportunity to verify the research results made in our lab firsthand in space.”

(Caption: LINK (Little Intelligent Nanosatellite of KAIST) was launched on an Atlast V booster aboard the NASA CRS-7 Mission on April 18.)

2017.04.25 View 9605 -

FinTech Conference by KAIST, EDHEC-Risk Institute, Princeton, and Tsinghua

KAIST will partner with EDHEC-Risk Institute, Princeton University, and Tsinghua University to host a series of annual rotation conference on FinTech. The inaugural conference will be held in Princeton on April 26 and is entitled ‘Four-University Rotating FinTech Conference: Wealth Management Systems for Individual Investors.’

The conference will facilitate discussion among all interest parties of academics, practitioners, and regulators from around the world. Professor Woo Chang Kim of the Department of Industrial & Systems Engineering will represent KAIST. Professor Kim is also the head of the Center for Wealth Management Technologies at KAIST.

In addition to Professor Kim, leading experts from the US, Asia, and Europe will present at the conference, including Andrew Yao (Turing Award recipient and founder of IIIS FinTech Center at Tsinghua University), John Bogle (founder of the Vanguard Group, and president of the Bogle Financial Markets Research Center), Lionel Martellini (director of EDHEC-Risk Institute), John Mashey (Bell Labs/Silicon Valley computer scientist/corporate executive), and John Mulvey (professor and founding member of the Bendheim Center for Finance at Princeton University).

This year’s conference will feature following sessions:

· Mass-Customization of Goal-Based Investment Solutions: The New Frontier in Digital Wealth Management Services

· Goal-Based Investment via Multi-Stage Stochastic Goal Programming for Robo-Advisor Services

· Big Data – Yesterday, Today and Tomorrow

· Applying Machine Learning Concepts for Asset Allocation and ALM

· FinTech: Drawing Strengths from Computing Theories

· Savings and Investing to Achieve Retirement Goals: An Update Given Current Market Assumptions · The Rise of Robo-Advisors: A Threat or an Opportunity for the Wealth Management Industry?

The conference will include the participation of official partner Samsung Asset Management.

2017.04.20 View 10438

FinTech Conference by KAIST, EDHEC-Risk Institute, Princeton, and Tsinghua

KAIST will partner with EDHEC-Risk Institute, Princeton University, and Tsinghua University to host a series of annual rotation conference on FinTech. The inaugural conference will be held in Princeton on April 26 and is entitled ‘Four-University Rotating FinTech Conference: Wealth Management Systems for Individual Investors.’

The conference will facilitate discussion among all interest parties of academics, practitioners, and regulators from around the world. Professor Woo Chang Kim of the Department of Industrial & Systems Engineering will represent KAIST. Professor Kim is also the head of the Center for Wealth Management Technologies at KAIST.

In addition to Professor Kim, leading experts from the US, Asia, and Europe will present at the conference, including Andrew Yao (Turing Award recipient and founder of IIIS FinTech Center at Tsinghua University), John Bogle (founder of the Vanguard Group, and president of the Bogle Financial Markets Research Center), Lionel Martellini (director of EDHEC-Risk Institute), John Mashey (Bell Labs/Silicon Valley computer scientist/corporate executive), and John Mulvey (professor and founding member of the Bendheim Center for Finance at Princeton University).

This year’s conference will feature following sessions:

· Mass-Customization of Goal-Based Investment Solutions: The New Frontier in Digital Wealth Management Services

· Goal-Based Investment via Multi-Stage Stochastic Goal Programming for Robo-Advisor Services

· Big Data – Yesterday, Today and Tomorrow

· Applying Machine Learning Concepts for Asset Allocation and ALM

· FinTech: Drawing Strengths from Computing Theories

· Savings and Investing to Achieve Retirement Goals: An Update Given Current Market Assumptions · The Rise of Robo-Advisors: A Threat or an Opportunity for the Wealth Management Industry?

The conference will include the participation of official partner Samsung Asset Management.

2017.04.20 View 10438 -

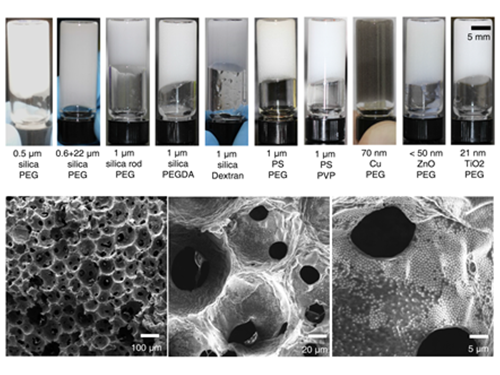

Processable High Internal Phase Pickering Emulsion Using Depletion Attraction

Professor Siyoung Choi’s research team from the KAIST Department of Chemical & Biomolecular Engineering used physical force to successfully produce a stable emulsion.

Emulsions, commonly known as cosmetic products, refer to stably dispersed structures of oil droplets in water (or water droplets in oil). Pickering emulsions refer to emulsions stabilized using solid particles, instead of detergent. Traditionally, it is said that water and oil do not mix. Until recently, detergent was added to mix oil and water for dispersion. Emulsions have traditionally been produced using this technique and are currently used for products such as mayonnaise, sun block, and lotion.

On the other hand, Pickering emulsions have been used after stabilization of chemical treatments on solid particle surfaces to enhance adsorption power. However, there were limitations in its application, since the treatment process is complex and its applicable range remains limited. Instead of chemical treatment on Pickering emulsion surfaces, the research team mixed small macromolecules a few nanometer in size with larger solid particles (tens of nanometers to a few micrometers). This induced depletion force was used to successfully stabilize the emulsion.

Depletion force refers to the force a large number of small particles induces to aggregate the bigger particles, in order to secure free space for themselves. In short, the force induces an attraction between larger particles. Until now, depletion force could only be applied to solids and solid particles. However, the research team used macromolecules and large particles such as solid particles and oil droplets to show the applicability of depletion force between solids and liquids. By introducing macromolecules that act as smaller particles, hydrophilic solid particles enhanced the adsorption of solid particles to the oil droplet surface, while preventing dissociation from the particle surface, resulting in the maintenance of a stable state.

The research team confirmed the possibility of the simple production of various porous macromolecular materials using stable Pickering emulsions. Such porous macromolecules are expected to be applicable in separation film, systems engineering, drug delivery, and sensors, given their large surface area.

Professor KyuHan Kim, the first author said, “Until now, depletion force has only been used between solid colloid particles. This research has scientific significance since it is the first example of using depletion force between solid particles and liquid droplets.”

Professor Choi said, “Beyond its academic significance, this technology could contribute to industries and national competitiveness.” He continued, “Since this technology uses physical force, not chemical, to produce stable emulsion, it can be used regardless of the type of solid particle and macromolecule. Further, it could be used in customized porous material production for special purposes.”

The research was published in Nature Communications online on February 1. In particular, this research is significant since an undergraduate student, Subeen Kim, participated in the project as a second author through the KAIST Undergraduate Research Program (URP). This research was funded by the National Research Foundation of Korea.

(Figure 1: Images of the inner structure of porous macromolecules produced using the new technology)

(Figure 2: Images showing the measurement of rheological properties of Pickering emulsions and system processability)

(Figure 3: Images showing a stable Pickering emulsion system)

2017.04.19 View 9824

Processable High Internal Phase Pickering Emulsion Using Depletion Attraction

Professor Siyoung Choi’s research team from the KAIST Department of Chemical & Biomolecular Engineering used physical force to successfully produce a stable emulsion.

Emulsions, commonly known as cosmetic products, refer to stably dispersed structures of oil droplets in water (or water droplets in oil). Pickering emulsions refer to emulsions stabilized using solid particles, instead of detergent. Traditionally, it is said that water and oil do not mix. Until recently, detergent was added to mix oil and water for dispersion. Emulsions have traditionally been produced using this technique and are currently used for products such as mayonnaise, sun block, and lotion.

On the other hand, Pickering emulsions have been used after stabilization of chemical treatments on solid particle surfaces to enhance adsorption power. However, there were limitations in its application, since the treatment process is complex and its applicable range remains limited. Instead of chemical treatment on Pickering emulsion surfaces, the research team mixed small macromolecules a few nanometer in size with larger solid particles (tens of nanometers to a few micrometers). This induced depletion force was used to successfully stabilize the emulsion.

Depletion force refers to the force a large number of small particles induces to aggregate the bigger particles, in order to secure free space for themselves. In short, the force induces an attraction between larger particles. Until now, depletion force could only be applied to solids and solid particles. However, the research team used macromolecules and large particles such as solid particles and oil droplets to show the applicability of depletion force between solids and liquids. By introducing macromolecules that act as smaller particles, hydrophilic solid particles enhanced the adsorption of solid particles to the oil droplet surface, while preventing dissociation from the particle surface, resulting in the maintenance of a stable state.

The research team confirmed the possibility of the simple production of various porous macromolecular materials using stable Pickering emulsions. Such porous macromolecules are expected to be applicable in separation film, systems engineering, drug delivery, and sensors, given their large surface area.

Professor KyuHan Kim, the first author said, “Until now, depletion force has only been used between solid colloid particles. This research has scientific significance since it is the first example of using depletion force between solid particles and liquid droplets.”

Professor Choi said, “Beyond its academic significance, this technology could contribute to industries and national competitiveness.” He continued, “Since this technology uses physical force, not chemical, to produce stable emulsion, it can be used regardless of the type of solid particle and macromolecule. Further, it could be used in customized porous material production for special purposes.”

The research was published in Nature Communications online on February 1. In particular, this research is significant since an undergraduate student, Subeen Kim, participated in the project as a second author through the KAIST Undergraduate Research Program (URP). This research was funded by the National Research Foundation of Korea.

(Figure 1: Images of the inner structure of porous macromolecules produced using the new technology)

(Figure 2: Images showing the measurement of rheological properties of Pickering emulsions and system processability)

(Figure 3: Images showing a stable Pickering emulsion system)

2017.04.19 View 9824 -

2017 Summer Nuclear Nonproliferation Education Program

The Nuclear Nonproliferation Education and Research Center (NEREC) at KAIST announced its 30 scholarship recipients for the 2017 Summer Nuclear Nonproliferation Education Program on April 18. The six-week program, starting from July 10, will be run in Korea, Japan, and China.

The program provides young global scholars with focused and challenging nuclear nonproliferation studies. Young scholars will be exposed to diverse science and technology policies and practices concurrently conducted in many countries and the future direction for enhancing nuclear nonproliferation. They will participate in a series of seminars, projects, international conferences, and field trips.

Since its launch in 2014, the program has educated 71 young scholars. This year, more than 150 scholars from 37 countries applied for the program, reflecting the growing reputation of the program both at home and abroad. The director of the NEREC, Professor Man-Sung Yim of the Department of Nuclear and Quantum Engineering at KAIST said that young scholars from very prestigious foreign universities have shown strong interest in the program. According to Professor Yim, this year’s recipients are from 26 universities from 16 countries including Harvard University, Oxford University, the National Research Nuclear University of Russia, and the Tokyo Institute of Technology

2017.04.19 View 9955

2017 Summer Nuclear Nonproliferation Education Program

The Nuclear Nonproliferation Education and Research Center (NEREC) at KAIST announced its 30 scholarship recipients for the 2017 Summer Nuclear Nonproliferation Education Program on April 18. The six-week program, starting from July 10, will be run in Korea, Japan, and China.

The program provides young global scholars with focused and challenging nuclear nonproliferation studies. Young scholars will be exposed to diverse science and technology policies and practices concurrently conducted in many countries and the future direction for enhancing nuclear nonproliferation. They will participate in a series of seminars, projects, international conferences, and field trips.

Since its launch in 2014, the program has educated 71 young scholars. This year, more than 150 scholars from 37 countries applied for the program, reflecting the growing reputation of the program both at home and abroad. The director of the NEREC, Professor Man-Sung Yim of the Department of Nuclear and Quantum Engineering at KAIST said that young scholars from very prestigious foreign universities have shown strong interest in the program. According to Professor Yim, this year’s recipients are from 26 universities from 16 countries including Harvard University, Oxford University, the National Research Nuclear University of Russia, and the Tokyo Institute of Technology

2017.04.19 View 9955