-

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13086

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13086 -

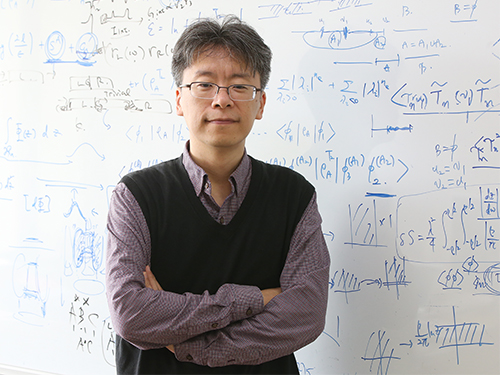

New IEEE Fellow, Professor Jong Chul Ye

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was named a new fellow of the Institute of Electrical and Electronics Engineers (IEEE). IEEE announced this on December 1 in recognition of Professor Ye’s contributions to the development of signal processing and artificial intelligence (AI) technology in the field of biomedical imaging.

As the world’s largest society in the electrical and electronics field, IEEE names the top 0.1% of their members as fellows based on their research achievements.Professor Ye has published more than 100 research papers in world-leading journals in the biomedical imaging field, including those affiliated with IEEE.

He also gave a keynote talk at the yearly conference of the International Society for Magnetic Resonance Imaging (ISMRM) on medical AI technology. In addition, Professor Ye has been appointed to serve as the next chair of the Computational Imaging Technical Committee of the IEEE Signal Processing Society, and the chair of the IEEE Symposium on Biomedical Imaging (ISBI) 2020 to be held in April in Iowa, USA.

Professor Ye said, “The importance of AI technology is developing in the biomedical imaging field. I feel proud that my contributions have been internationally recognized and allowed me to be named an IEEE fellow.”

2019.12.18 View 12388

New IEEE Fellow, Professor Jong Chul Ye

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was named a new fellow of the Institute of Electrical and Electronics Engineers (IEEE). IEEE announced this on December 1 in recognition of Professor Ye’s contributions to the development of signal processing and artificial intelligence (AI) technology in the field of biomedical imaging.

As the world’s largest society in the electrical and electronics field, IEEE names the top 0.1% of their members as fellows based on their research achievements.Professor Ye has published more than 100 research papers in world-leading journals in the biomedical imaging field, including those affiliated with IEEE.

He also gave a keynote talk at the yearly conference of the International Society for Magnetic Resonance Imaging (ISMRM) on medical AI technology. In addition, Professor Ye has been appointed to serve as the next chair of the Computational Imaging Technical Committee of the IEEE Signal Processing Society, and the chair of the IEEE Symposium on Biomedical Imaging (ISBI) 2020 to be held in April in Iowa, USA.

Professor Ye said, “The importance of AI technology is developing in the biomedical imaging field. I feel proud that my contributions have been internationally recognized and allowed me to be named an IEEE fellow.”

2019.12.18 View 12388 -

Professor Il-Doo Kim Named Scientist of the Year by the Journalists

Professor Il-Doo Kim from the Department of Materials Science and Engineering was named the 2019 Scientist of the Year by Korean science journalists. The award was conferred at the 2019 Science Press Night ceremony of the Korea Science Journalists Association (KSJA) on November 29.

Professor Kim focuses on developing nanofiber gas sensors for diagnosing diseases in advance by analyzing exhaled biomarkers with electrospinning technology. His outstanding research was praised and selected as one of the top 10 nanotechnology of 2019 by the Korea Nano Technology Research Society (KoNTRS), the Ministry of Science and ICT (MSIT), and the Ministry of Trade, Industry and Energy (MOTIE).

Professor Kim was honored with the QIAN Baojun Fiber Award, which is awarded every two years by Donghua University in Shanghai, China to recognize outstanding contributions in fiber science and technology. Professor Kim was also elected as an academician of the Asia Pacific Academy of Materials (APAM) on November 21 in Guangzhou, China.

In May, Professor Kim was appointed as an associate editor of ACS Nano, a leading international research journal in the field of nanoscience. In his editorial published in the May issue of ACS Nano, Professor Kim introduced and shared the history of KAIST and its vision for the future with other members of the journal. He hopes this will help with promoting a closer relationship between the members of the journal and KAIST moving forward.

“Above all,” he said in his acceptance speech, “the greatest news for me as an educator is that the first PhD graduate from our lab, Dr. Seonjin Choi, was appointed as the youngest professor in the Division of Materials Science and Engineering at Hanyang University on September 1.”

2019.12.17 View 13643

Professor Il-Doo Kim Named Scientist of the Year by the Journalists

Professor Il-Doo Kim from the Department of Materials Science and Engineering was named the 2019 Scientist of the Year by Korean science journalists. The award was conferred at the 2019 Science Press Night ceremony of the Korea Science Journalists Association (KSJA) on November 29.

Professor Kim focuses on developing nanofiber gas sensors for diagnosing diseases in advance by analyzing exhaled biomarkers with electrospinning technology. His outstanding research was praised and selected as one of the top 10 nanotechnology of 2019 by the Korea Nano Technology Research Society (KoNTRS), the Ministry of Science and ICT (MSIT), and the Ministry of Trade, Industry and Energy (MOTIE).

Professor Kim was honored with the QIAN Baojun Fiber Award, which is awarded every two years by Donghua University in Shanghai, China to recognize outstanding contributions in fiber science and technology. Professor Kim was also elected as an academician of the Asia Pacific Academy of Materials (APAM) on November 21 in Guangzhou, China.

In May, Professor Kim was appointed as an associate editor of ACS Nano, a leading international research journal in the field of nanoscience. In his editorial published in the May issue of ACS Nano, Professor Kim introduced and shared the history of KAIST and its vision for the future with other members of the journal. He hopes this will help with promoting a closer relationship between the members of the journal and KAIST moving forward.

“Above all,” he said in his acceptance speech, “the greatest news for me as an educator is that the first PhD graduate from our lab, Dr. Seonjin Choi, was appointed as the youngest professor in the Division of Materials Science and Engineering at Hanyang University on September 1.”

2019.12.17 View 13643 -

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 10193

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 10193 -

New Members of KAST 2020

< Professor Zong-Tae Bae (Left) and Professor Sang Ouk Kim (Right) >

Professor Zong-Tae Bae from the School of Management Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering became new fellows of the Korean Academy of Science and Technology (KAST) along with 22 other scientists in Korea.

On November 22, KAST announced 24 new members for the year 2020. This includes seven scientists from the field of natural sciences, six from engineering, four from medical sciences, another four from policy research, and three from agriculture and fishery.

The new fellows will begin their term from January next year, and their fellowships wll be conferred during the KAST’s New Year Reception to be held on January 14 in Seoul.

(END)

2019.12.09 View 15200

New Members of KAST 2020

< Professor Zong-Tae Bae (Left) and Professor Sang Ouk Kim (Right) >

Professor Zong-Tae Bae from the School of Management Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering became new fellows of the Korean Academy of Science and Technology (KAST) along with 22 other scientists in Korea.

On November 22, KAST announced 24 new members for the year 2020. This includes seven scientists from the field of natural sciences, six from engineering, four from medical sciences, another four from policy research, and three from agriculture and fishery.

The new fellows will begin their term from January next year, and their fellowships wll be conferred during the KAST’s New Year Reception to be held on January 14 in Seoul.

(END)

2019.12.09 View 15200 -

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9771

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9771 -

KAIST and Google Jointly Develop AI Curricula

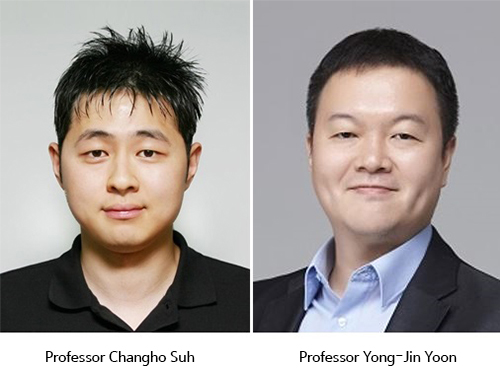

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 17338

KAIST and Google Jointly Develop AI Curricula

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 17338 -

‘Carrier-Resolved Photo-Hall’ to Push Semiconductor Advances

(Professor Shin and Dr. Gunawan (left))

An IBM-KAIST research team described a breakthrough in a 140-year-old mystery in physics. The research reported in Nature last month unlocks the physical characteristics of semiconductors in much greater detail and aids in the development of new and improved semiconductor materials.

Research team under Professor Byungha Shin at the Department of Material Sciences and Engineering and Dr. Oki Gunawan at IBM discovered a new formula and technique that enables the simultaneous extraction of both majority and minority carrier information such as their density and mobility, as well as gain additional insights about carrier lifetimes, diffusion lengths, and the recombination process. This new discovery and technology will help push semiconductor advances in both existing and emerging technologies.

Semiconductors are the basic building blocks of today’s digital electronics age, providing us with a multitude of devices that benefit our modern life. To truly appreciate the physics of semiconductors, it is very important to understand the fundamental properties of the charge carriers inside the materials, whether those particles are positive or negative, their speed under an applied electric field, and how densely they are packed into the material.

Physicist Edwin Hall found a way to determine those properties in 1879, when he discovered that a magnetic field will deflect the movement of electronic charges inside a conductor and that the amount of deflection can be measured as a voltage perpendicular to the flow of the charge. Decades after Hall’s discovery, researchers also recognized that they can measure the Hall effect with light via “photo-Hall experiments”. During such experiments, the light generates multiple carriers or electron–hole pairs in the semiconductors.

Unfortunately, the basic Hall effect only provided insights into the dominant charge carrier (or majority carrier). Researchers were unable to extract the properties of both carriers (the majority and minority carriers) simultaneously. The property information of both carriers is crucial for many applications that involve light such as solar cells and other optoelectronic devices.

In the photo-Hall experiment by the KAIST-IBM team, both carriers contribute to changes in conductivity and the Hall coefficient. The key insight comes from measuring the conductivity and Hall coefficient as a function of light intensity. Hidden in the trajectory of the conductivity, the Hall coefficient curve reveals crucial new information: the difference in the mobility of both carriers. As discussed in the paper, this relationship can be expressed elegantly as: Δµ = d (σ²H)/dσ

The research team solved for both majority and minority carrier mobility and density as a function of light intensity, naming the new technique Carrier-Resolved Photo Hall (CRPH) measurement. With known light illumination intensity, the carrier lifetime can be established in a similar way.

Beyond advances in theoretical understanding, advances in experimental techniques were also critical for enabling this breakthrough. The technique requires a clean Hall signal measurement, which can be challenging for materials where the Hall signal is weak due to low mobility or when extra unwanted signals are present, such as under strong light illumination.

The newly developed photo-Hall technique allows the extraction of an astonishing amount of information from semiconductors. In contrast to only three parameters obtained in the classic Hall measurements, this new technique yields up to seven parameters at every tested level of light intensity. These include the mobility of both the electron and hole; their carrier density under light; the recombination lifetime; and the diffusion lengths for electrons, holes, and ambipolar types. All of these can be repeated N times (i.e. the number of light intensity settings used in the experiment).

Professor Shin said, “This novel technology sheds new light on understanding the physical characteristics of semiconductor materials in great detail.” Dr. Gunawan added, “This will will help accelerate the development of next-generation semiconductor technology such as better solar cells, better optoelectronics devices, and new materials and devices for artificial intelligence technology.”

Profile:

Professor Byungha Shin

Department of Materials Science and Engineering

KAIST

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

2019.11.18 View 16310

‘Carrier-Resolved Photo-Hall’ to Push Semiconductor Advances

(Professor Shin and Dr. Gunawan (left))

An IBM-KAIST research team described a breakthrough in a 140-year-old mystery in physics. The research reported in Nature last month unlocks the physical characteristics of semiconductors in much greater detail and aids in the development of new and improved semiconductor materials.

Research team under Professor Byungha Shin at the Department of Material Sciences and Engineering and Dr. Oki Gunawan at IBM discovered a new formula and technique that enables the simultaneous extraction of both majority and minority carrier information such as their density and mobility, as well as gain additional insights about carrier lifetimes, diffusion lengths, and the recombination process. This new discovery and technology will help push semiconductor advances in both existing and emerging technologies.

Semiconductors are the basic building blocks of today’s digital electronics age, providing us with a multitude of devices that benefit our modern life. To truly appreciate the physics of semiconductors, it is very important to understand the fundamental properties of the charge carriers inside the materials, whether those particles are positive or negative, their speed under an applied electric field, and how densely they are packed into the material.

Physicist Edwin Hall found a way to determine those properties in 1879, when he discovered that a magnetic field will deflect the movement of electronic charges inside a conductor and that the amount of deflection can be measured as a voltage perpendicular to the flow of the charge. Decades after Hall’s discovery, researchers also recognized that they can measure the Hall effect with light via “photo-Hall experiments”. During such experiments, the light generates multiple carriers or electron–hole pairs in the semiconductors.

Unfortunately, the basic Hall effect only provided insights into the dominant charge carrier (or majority carrier). Researchers were unable to extract the properties of both carriers (the majority and minority carriers) simultaneously. The property information of both carriers is crucial for many applications that involve light such as solar cells and other optoelectronic devices.

In the photo-Hall experiment by the KAIST-IBM team, both carriers contribute to changes in conductivity and the Hall coefficient. The key insight comes from measuring the conductivity and Hall coefficient as a function of light intensity. Hidden in the trajectory of the conductivity, the Hall coefficient curve reveals crucial new information: the difference in the mobility of both carriers. As discussed in the paper, this relationship can be expressed elegantly as: Δµ = d (σ²H)/dσ

The research team solved for both majority and minority carrier mobility and density as a function of light intensity, naming the new technique Carrier-Resolved Photo Hall (CRPH) measurement. With known light illumination intensity, the carrier lifetime can be established in a similar way.

Beyond advances in theoretical understanding, advances in experimental techniques were also critical for enabling this breakthrough. The technique requires a clean Hall signal measurement, which can be challenging for materials where the Hall signal is weak due to low mobility or when extra unwanted signals are present, such as under strong light illumination.

The newly developed photo-Hall technique allows the extraction of an astonishing amount of information from semiconductors. In contrast to only three parameters obtained in the classic Hall measurements, this new technique yields up to seven parameters at every tested level of light intensity. These include the mobility of both the electron and hole; their carrier density under light; the recombination lifetime; and the diffusion lengths for electrons, holes, and ambipolar types. All of these can be repeated N times (i.e. the number of light intensity settings used in the experiment).

Professor Shin said, “This novel technology sheds new light on understanding the physical characteristics of semiconductor materials in great detail.” Dr. Gunawan added, “This will will help accelerate the development of next-generation semiconductor technology such as better solar cells, better optoelectronics devices, and new materials and devices for artificial intelligence technology.”

Profile:

Professor Byungha Shin

Department of Materials Science and Engineering

KAIST

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

2019.11.18 View 16310 -

KAIST Alumnus NYU Professor Supports Female AI Researchers

A KAIST alumnus and an associate professor at New York University (NYU), Dr. Kyunghyun Cho donated 3,000 USD to the KAIST Graduate School of AI to support female AI researchers.

Professor Cho spoke as a guest lecturer at the 2019 Samsung AI Forum on November 4 and received 3,000 USD as an honorarium. He donated this honorarium to the KAIST Graduate School of AI with a special request to support the school’s female PhD students attending the 2020 International Conference on Learning Representations (ICLR), where he serves as a program co-chair.

Professor Cho received his BS degree from KAIST’s School of Computing in 2009 and is now serving as an associate professor at NYU’s Computer Science Department and Center for Data Science. His research mainly covers machine learning and natural language processing.

Professor Cho said that he decided to make this donation because “In Korea and even in the US, women in science, technology, engineering, and mathematics (STEM) lack opportunities and environments that allow them to excel.”

Professor Song Chong, the Head of the KAIST Graduate School of AI, responded, “We are so grateful for Professor Kyunghyun Cho’s contribution and we will also use funds from the school in addition to the donation to support our female PhD students who will attend the ICLR.”

(END)

2019.11.15 View 10936

KAIST Alumnus NYU Professor Supports Female AI Researchers

A KAIST alumnus and an associate professor at New York University (NYU), Dr. Kyunghyun Cho donated 3,000 USD to the KAIST Graduate School of AI to support female AI researchers.

Professor Cho spoke as a guest lecturer at the 2019 Samsung AI Forum on November 4 and received 3,000 USD as an honorarium. He donated this honorarium to the KAIST Graduate School of AI with a special request to support the school’s female PhD students attending the 2020 International Conference on Learning Representations (ICLR), where he serves as a program co-chair.

Professor Cho received his BS degree from KAIST’s School of Computing in 2009 and is now serving as an associate professor at NYU’s Computer Science Department and Center for Data Science. His research mainly covers machine learning and natural language processing.

Professor Cho said that he decided to make this donation because “In Korea and even in the US, women in science, technology, engineering, and mathematics (STEM) lack opportunities and environments that allow them to excel.”

Professor Song Chong, the Head of the KAIST Graduate School of AI, responded, “We are so grateful for Professor Kyunghyun Cho’s contribution and we will also use funds from the school in addition to the donation to support our female PhD students who will attend the ICLR.”

(END)

2019.11.15 View 10936 -

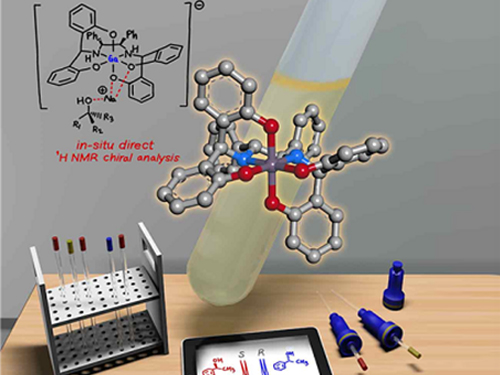

Gallium-Based Solvating Agent Efficiently Analyzes Optically Active Alcohols

A KAIST research team has developed a gallium-based metal complex enabling the rapid chiral analysis of alcohols. A team working under Professor Hyunwoo Kim reported the efficient new alcohol analysis method using nuclear magnetic resonance (NMR) spectroscopy in iScience.

Enantiopure chiral alcohols are ubiquitous in nature and widely utilized as pharmaceuticals. This importance of chirality in synthetic and medicinal chemistry has advanced the search for rapid and facile methods to determine the enantiomeric purities of compounds. To date, chiral analysis has been performed using high-performance liquid chromatography (HPLC) with chiral columns.

Along with the HPLC technique, chiral analysis using NMR spectroscopy has gained tremendous attention as an alternative to traditionally employed chromatographic methods due to its simplicity and rapid detection for real-time measurement. However, this method carries drawbacks such as line-broadening, narrow substrate scope, and poor resolution. Thus, compared with popular methods of chromatographic analysis, NMR spectroscopy is infrequently used for chiral analysis.

In principle, a chiral solvating agent is additionally required for the NMR measurement of chiral alcohols to obtain two distinct signals. However, NMR analysis of chiral alcohols has been challenging due to weak binding interactions with chiral solvating agents. To overcome the intrinsic difficulty of relatively weak molecular interactions that are common for alcohols, many researchers have used multifunctional alcohols to enhance interactions with solvating agents.

Instead, the KAIST team successfully varied the physical properties of metal complexes to induce stronger interactions with alcohols rather than the strategy of using multifunctional analytes, in the hopes of developing a universal chiral solvating agent for alcohols. Compared to the current method of chiral analysis used in the pharmaceutical industry, alcohols that do not possess chromophores can also be directly analyzed with the gallium complexes.

Professor Kim said that this method could be a complementary chiral analysis technique at the industry level in the near future. He added that since the developed gallium complex can determine enantiomeric excess within minutes, it can be further utilized to monitor asymmetric synthesis. This feature will benefit a large number of researchers in the organic chemistry community, as well as the pharmaceutical industry.

(Figure: Schematic view of the in-situ direct 1H NMR chiral analysis.)

-Profile:

Professor Hyunwoo Kim

Department of Chemistry

KAIST

http://mdos.kaist.ac.kr

hwk34@kaist.ac.kr

For more on this article,

please go to https://doi.org/10.1016/j.isci2019.07051

2019.11.14 View 12831

Gallium-Based Solvating Agent Efficiently Analyzes Optically Active Alcohols

A KAIST research team has developed a gallium-based metal complex enabling the rapid chiral analysis of alcohols. A team working under Professor Hyunwoo Kim reported the efficient new alcohol analysis method using nuclear magnetic resonance (NMR) spectroscopy in iScience.

Enantiopure chiral alcohols are ubiquitous in nature and widely utilized as pharmaceuticals. This importance of chirality in synthetic and medicinal chemistry has advanced the search for rapid and facile methods to determine the enantiomeric purities of compounds. To date, chiral analysis has been performed using high-performance liquid chromatography (HPLC) with chiral columns.

Along with the HPLC technique, chiral analysis using NMR spectroscopy has gained tremendous attention as an alternative to traditionally employed chromatographic methods due to its simplicity and rapid detection for real-time measurement. However, this method carries drawbacks such as line-broadening, narrow substrate scope, and poor resolution. Thus, compared with popular methods of chromatographic analysis, NMR spectroscopy is infrequently used for chiral analysis.

In principle, a chiral solvating agent is additionally required for the NMR measurement of chiral alcohols to obtain two distinct signals. However, NMR analysis of chiral alcohols has been challenging due to weak binding interactions with chiral solvating agents. To overcome the intrinsic difficulty of relatively weak molecular interactions that are common for alcohols, many researchers have used multifunctional alcohols to enhance interactions with solvating agents.

Instead, the KAIST team successfully varied the physical properties of metal complexes to induce stronger interactions with alcohols rather than the strategy of using multifunctional analytes, in the hopes of developing a universal chiral solvating agent for alcohols. Compared to the current method of chiral analysis used in the pharmaceutical industry, alcohols that do not possess chromophores can also be directly analyzed with the gallium complexes.

Professor Kim said that this method could be a complementary chiral analysis technique at the industry level in the near future. He added that since the developed gallium complex can determine enantiomeric excess within minutes, it can be further utilized to monitor asymmetric synthesis. This feature will benefit a large number of researchers in the organic chemistry community, as well as the pharmaceutical industry.

(Figure: Schematic view of the in-situ direct 1H NMR chiral analysis.)

-Profile:

Professor Hyunwoo Kim

Department of Chemistry

KAIST

http://mdos.kaist.ac.kr

hwk34@kaist.ac.kr

For more on this article,

please go to https://doi.org/10.1016/j.isci2019.07051

2019.11.14 View 12831 -

AI to Determine When to Intervene with Your Driving

(Professor Uichin Lee (left) and PhD candidate Auk Kim)

Can your AI agent judge when to talk to you while you are driving? According to a KAIST research team, their in-vehicle conservation service technology will judge when it is appropriate to contact you to ensure your safety.

Professor Uichin Lee from the Department of Industrial and Systems Engineering at KAIST and his research team have developed AI technology that automatically detects safe moments for AI agents to provide conversation services to drivers.

Their research focuses on solving the potential problems of distraction created by in-vehicle conversation services. If an AI agent talks to a driver at an inopportune moment, such as while making a turn, a car accident will be more likely to occur.

In-vehicle conversation services need to be convenient as well as safe. However, the cognitive burden of multitasking negatively influences the quality of the service. Users tend to be more distracted during certain traffic conditions. To address this long-standing challenge of the in-vehicle conversation services, the team introduced a composite cognitive model that considers both safe driving and auditory-verbal service performance and used a machine-learning model for all collected data.

The combination of these individual measures is able to determine the appropriate moments for conversation and most appropriate types of conversational services. For instance, in the case of delivering simple-context information, such as a weather forecast, driver safety alone would be the most appropriate consideration. Meanwhile, when delivering information that requires a driver response, such as a “Yes” or “No,” the combination of driver safety and auditory-verbal performance should be considered.

The research team developed a prototype of an in-vehicle conversation service based on a navigation app that can be used in real driving environments. The app was also connected to the vehicle to collect in-vehicle OBD-II/CAN data, such as the steering wheel angle and brake pedal position, and mobility and environmental data such as the distance between successive cars and traffic flow.

Using pseudo-conversation services, the research team collected a real-world driving dataset consisting of 1,388 interactions and sensor data from 29 drivers who interacted with AI conversational agents. Machine learning analysis based on the dataset demonstrated that the opportune moments for driver interruption could be correctly inferred with 87% accuracy.

The safety enhancement technology developed by the team is expected to minimize driver distractions caused by in-vehicle conversation services. This technology can be directly applied to current in-vehicle systems that provide conversation services. It can also be extended and applied to the real-time detection of driver distraction problems caused by the use of a smartphone while driving.

Professor Lee said, “In the near future, cars will proactively deliver various in-vehicle conversation services. This technology will certainly help vehicles interact with their drivers safely as it can fairly accurately determine when to provide conversation services using only basic sensor data generated by cars.”

The researchers presented their findings at the ACM International Joint Conference on Pervasive and Ubiquitous Computing (Ubicomp’19) in London, UK. This research was supported in part by Hyundai NGV and by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT.

(Figure: Visual description of safe enhancement technology for in-vehicle conversation services)

2019.11.13 View 20545

AI to Determine When to Intervene with Your Driving

(Professor Uichin Lee (left) and PhD candidate Auk Kim)

Can your AI agent judge when to talk to you while you are driving? According to a KAIST research team, their in-vehicle conservation service technology will judge when it is appropriate to contact you to ensure your safety.

Professor Uichin Lee from the Department of Industrial and Systems Engineering at KAIST and his research team have developed AI technology that automatically detects safe moments for AI agents to provide conversation services to drivers.

Their research focuses on solving the potential problems of distraction created by in-vehicle conversation services. If an AI agent talks to a driver at an inopportune moment, such as while making a turn, a car accident will be more likely to occur.

In-vehicle conversation services need to be convenient as well as safe. However, the cognitive burden of multitasking negatively influences the quality of the service. Users tend to be more distracted during certain traffic conditions. To address this long-standing challenge of the in-vehicle conversation services, the team introduced a composite cognitive model that considers both safe driving and auditory-verbal service performance and used a machine-learning model for all collected data.

The combination of these individual measures is able to determine the appropriate moments for conversation and most appropriate types of conversational services. For instance, in the case of delivering simple-context information, such as a weather forecast, driver safety alone would be the most appropriate consideration. Meanwhile, when delivering information that requires a driver response, such as a “Yes” or “No,” the combination of driver safety and auditory-verbal performance should be considered.

The research team developed a prototype of an in-vehicle conversation service based on a navigation app that can be used in real driving environments. The app was also connected to the vehicle to collect in-vehicle OBD-II/CAN data, such as the steering wheel angle and brake pedal position, and mobility and environmental data such as the distance between successive cars and traffic flow.

Using pseudo-conversation services, the research team collected a real-world driving dataset consisting of 1,388 interactions and sensor data from 29 drivers who interacted with AI conversational agents. Machine learning analysis based on the dataset demonstrated that the opportune moments for driver interruption could be correctly inferred with 87% accuracy.

The safety enhancement technology developed by the team is expected to minimize driver distractions caused by in-vehicle conversation services. This technology can be directly applied to current in-vehicle systems that provide conversation services. It can also be extended and applied to the real-time detection of driver distraction problems caused by the use of a smartphone while driving.

Professor Lee said, “In the near future, cars will proactively deliver various in-vehicle conversation services. This technology will certainly help vehicles interact with their drivers safely as it can fairly accurately determine when to provide conversation services using only basic sensor data generated by cars.”

The researchers presented their findings at the ACM International Joint Conference on Pervasive and Ubiquitous Computing (Ubicomp’19) in London, UK. This research was supported in part by Hyundai NGV and by the Next-Generation Information Computing Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT.

(Figure: Visual description of safe enhancement technology for in-vehicle conversation services)

2019.11.13 View 20545 -

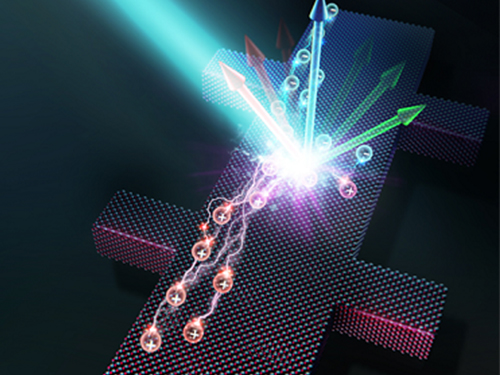

Ultrafast Quantum Motion in a Nanoscale Trap Detected

< Professor Heung-Sun Sim (left) and Co-author Dr. Sungguen Ryu (right) >

KAIST researchers have reported the detection of a picosecond electron motion in a silicon transistor. This study has presented a new protocol for measuring ultrafast electronic dynamics in an effective time-resolved fashion of picosecond resolution. The detection was made in collaboration with Nippon Telegraph and Telephone Corp. (NTT) in Japan and National Physical Laboratory (NPL) in the UK and is the first report to the best of our knowledge.

When an electron is captured in a nanoscale trap in solids, its quantum mechanical wave function can exhibit spatial oscillation at sub-terahertz frequencies. Time-resolved detection of such picosecond dynamics of quantum waves is important, as the detection provides a way of understanding the quantum behavior of electrons in nano-electronics. It also applies to quantum information technologies such as the ultrafast quantum-bit operation of quantum computing and high-sensitivity electromagnetic-field sensing. However, detecting picosecond dynamics has been a challenge since the sub-terahertz scale is far beyond the latest bandwidth measurement tools.

A KAIST team led by Professor Heung-Sun Sim developed a theory of ultrafast electron dynamics in a nanoscale trap, and proposed a scheme for detecting the dynamics, which utilizes a quantum-mechanical resonant state formed beside the trap. The coupling between the electron dynamics and the resonant state is switched on and off at a picosecond so that information on the dynamics is read out on the electric current being generated when the coupling is switched on.

NTT realized, together with NPL, the detection scheme and applied it to electron motions in a nanoscale trap formed in a silicon transistor. A single electron was captured in the trap by controlling electrostatic gates, and a resonant state was formed in the potential barrier of the trap.

The switching on and off of the coupling between the electron and the resonant state was achieved by aligning the resonance energy with the energy of the electron within a picosecond. An electric current from the trap through the resonant state to an electrode was measured at only a few Kelvin degrees, unveiling the spatial quantum-coherent oscillation of the electron with 250 GHz frequency inside the trap.

Professor Sim said, “This work suggests a scheme of detecting picosecond electron motions in submicron scales by utilizing quantum resonance. It will be useful in dynamical control of quantum mechanical electron waves for various purposes in nano-electronics, quantum sensing, and quantum information”.

This work was published online at Nature Nanotechnology on November 4. It was partly supported by the Korea National Research Foundation through the SRC Center for Quantum Coherence in Condensed Matter. For more on the NTT news release this article, please visit https://www.ntt.co.jp/news2019/1911e/191105a.html

-ProfileProfessor Heung-Sun Sim

Department of PhysicsDirector, SRC Center for Quantum Coherence in Condensed Matterhttps://qet.kaist.ac.kr KAIST

-Publication:Gento Yamahata, Sungguen Ryu, Nathan Johnson, H.-S. Sim, Akira Fujiwara, and Masaya Kataoka. 2019. Picosecond coherent electron motion in a silicon single-electron source. Nature Nanotechnology (Online Publication). 6 pages. https://doi.org/10.1038/s41565-019-0563-2

2019.11.05 View 20544

Ultrafast Quantum Motion in a Nanoscale Trap Detected

< Professor Heung-Sun Sim (left) and Co-author Dr. Sungguen Ryu (right) >

KAIST researchers have reported the detection of a picosecond electron motion in a silicon transistor. This study has presented a new protocol for measuring ultrafast electronic dynamics in an effective time-resolved fashion of picosecond resolution. The detection was made in collaboration with Nippon Telegraph and Telephone Corp. (NTT) in Japan and National Physical Laboratory (NPL) in the UK and is the first report to the best of our knowledge.

When an electron is captured in a nanoscale trap in solids, its quantum mechanical wave function can exhibit spatial oscillation at sub-terahertz frequencies. Time-resolved detection of such picosecond dynamics of quantum waves is important, as the detection provides a way of understanding the quantum behavior of electrons in nano-electronics. It also applies to quantum information technologies such as the ultrafast quantum-bit operation of quantum computing and high-sensitivity electromagnetic-field sensing. However, detecting picosecond dynamics has been a challenge since the sub-terahertz scale is far beyond the latest bandwidth measurement tools.

A KAIST team led by Professor Heung-Sun Sim developed a theory of ultrafast electron dynamics in a nanoscale trap, and proposed a scheme for detecting the dynamics, which utilizes a quantum-mechanical resonant state formed beside the trap. The coupling between the electron dynamics and the resonant state is switched on and off at a picosecond so that information on the dynamics is read out on the electric current being generated when the coupling is switched on.

NTT realized, together with NPL, the detection scheme and applied it to electron motions in a nanoscale trap formed in a silicon transistor. A single electron was captured in the trap by controlling electrostatic gates, and a resonant state was formed in the potential barrier of the trap.

The switching on and off of the coupling between the electron and the resonant state was achieved by aligning the resonance energy with the energy of the electron within a picosecond. An electric current from the trap through the resonant state to an electrode was measured at only a few Kelvin degrees, unveiling the spatial quantum-coherent oscillation of the electron with 250 GHz frequency inside the trap.

Professor Sim said, “This work suggests a scheme of detecting picosecond electron motions in submicron scales by utilizing quantum resonance. It will be useful in dynamical control of quantum mechanical electron waves for various purposes in nano-electronics, quantum sensing, and quantum information”.

This work was published online at Nature Nanotechnology on November 4. It was partly supported by the Korea National Research Foundation through the SRC Center for Quantum Coherence in Condensed Matter. For more on the NTT news release this article, please visit https://www.ntt.co.jp/news2019/1911e/191105a.html

-ProfileProfessor Heung-Sun Sim

Department of PhysicsDirector, SRC Center for Quantum Coherence in Condensed Matterhttps://qet.kaist.ac.kr KAIST

-Publication:Gento Yamahata, Sungguen Ryu, Nathan Johnson, H.-S. Sim, Akira Fujiwara, and Masaya Kataoka. 2019. Picosecond coherent electron motion in a silicon single-electron source. Nature Nanotechnology (Online Publication). 6 pages. https://doi.org/10.1038/s41565-019-0563-2

2019.11.05 View 20544