research

-

Eggshell-like Cell Encapsulation and Degradation Technology Developed

Some bacteria form endospores on cell walls to protect their DNA in case of nutrient deficiency. When an endospore meets a suitable environment for survival, the cell can revert to the original state from which it can reproduce.

The technique that can artificially control such phenomenon was developed by an international team of researchers. At first, a cell is wrapped and preserved like an egg. When the cell is needed, the technique allows the endospore to decompose while it is alive. Future applications for this technique include cell-based biosensor, cell therapy, and biocatalyst processes.

Professors Insung Choi and Younghoon Lee from the Department of Chemistry at KAIST as well as and Professor Frank Caruso from the University of Melbourne developed this technique which permits a cell to stay alive by coating it with film on a nanometer scale and then to be decomposed while it is alive.

The research finding was published in the November 10th issue of Angewandte Chemie International Edition as the lead article.

Cell encapsulation allows researchers to capture a cell in a tight capsule while it is alive. It is highly recognized in cell-based applications where the control of cell stability and cell-division is the biggest issue.

Traditional cell encapsulation methods utilized organic film or inorganic capsules that are made of organic film moldings. Although these films tightly closed around the cell, because they were not easily decomposable, it was difficult to apply the method.

The research team succeeded in encapsulating each cell in a metal-polyphenol film by mixing tannic acid and iron ion solution with yeast cells.

Usually extracted from oak barks or grape peels, tannic acid is a natural substance. It forms a metal-polyphenol film within ten seconds when it meets iron ions due to its high affinity with cells. Cells encapsulated with this film presented high survival rates. Since the film forms quickly in a simple manner, it was possible to obtain large amount of encapsulated cells.

The research team also found that the metal-polyphenol film was stable in neutral pH, but is easily degradable under a weak acidic condition. Using this property, they were able to control cell division by restoring the cell to its pre-encapsulated state at a desired moment.

Protecting the cell from the external environment like an egg shell, the metal-polyphenol film protected the cell against foreign conditions such as lytic enzymes, extended exposure to UV radiation, and silver nanoparticles. The research indicated that the encapsulated cells had a high survival rate even under extreme environments.

Professor Lee said that “not only the cells remain alive during the encapsulation stage, but also they can be protected under extreme environment.” He added, “This is an advanced cell encapsulation technology that allows controlling cell-division of those cells through responsive shell degradation on-demand.”

Professor Choi commented, “Although the cell encapsulation technology is still in its infancy, as the technology matures the application of cell-manipulation technology will be actualized.” He highlighted that “it will serve as a breakthrough to problems faced by cell-based applications.”

Sponsored by the Ministry of Science, ICT and Future Planning and the National Research Foundation of Korea, the research was led by two Master’s candidates, Ji Hun Park and Kyung Hwan Kim, under the joint guidance of research professors from KAIST and the University of Melbourne.

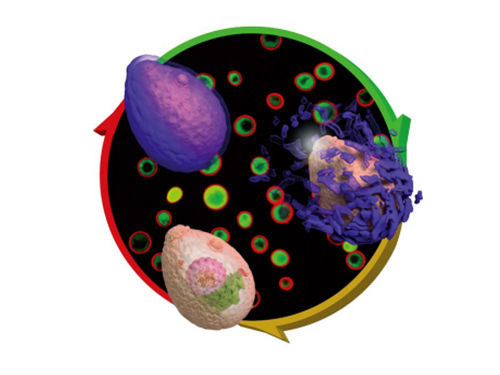

Figure 1: Lead article of Angewandte Chemie

Background: Shows a live native yeast (in green) encapsulated in a metal-polyphenol film (in red) illustrating the vitality of the yeast

Front: A native yeast at each encapsulation stage

Pictured on the bottom left is a cell prior to encapsulation. Following the red arrow, the native yeast is in purple to show metal-polyphenol film formed around the cell. The cell after the green arrow is a visualization of the degradation of the film in weak acidic condition.

Figure 2: A mimetic diagram of cell encapsulation with a metal-polyphenol film

Top: A native yeast before encapsulation

Middle: A native yeast encapsulated with Tannic Acid-Fe (III) Nanoshell – cell-division of the encapsulated cell is controlled by pH and the shell is protected against silver nanoparticle, lytic enzyme, and UV-C

Bottom: Shell degradation on-demand depending on pH

2014.11.18 View 10794

Eggshell-like Cell Encapsulation and Degradation Technology Developed

Some bacteria form endospores on cell walls to protect their DNA in case of nutrient deficiency. When an endospore meets a suitable environment for survival, the cell can revert to the original state from which it can reproduce.

The technique that can artificially control such phenomenon was developed by an international team of researchers. At first, a cell is wrapped and preserved like an egg. When the cell is needed, the technique allows the endospore to decompose while it is alive. Future applications for this technique include cell-based biosensor, cell therapy, and biocatalyst processes.

Professors Insung Choi and Younghoon Lee from the Department of Chemistry at KAIST as well as and Professor Frank Caruso from the University of Melbourne developed this technique which permits a cell to stay alive by coating it with film on a nanometer scale and then to be decomposed while it is alive.

The research finding was published in the November 10th issue of Angewandte Chemie International Edition as the lead article.

Cell encapsulation allows researchers to capture a cell in a tight capsule while it is alive. It is highly recognized in cell-based applications where the control of cell stability and cell-division is the biggest issue.

Traditional cell encapsulation methods utilized organic film or inorganic capsules that are made of organic film moldings. Although these films tightly closed around the cell, because they were not easily decomposable, it was difficult to apply the method.

The research team succeeded in encapsulating each cell in a metal-polyphenol film by mixing tannic acid and iron ion solution with yeast cells.

Usually extracted from oak barks or grape peels, tannic acid is a natural substance. It forms a metal-polyphenol film within ten seconds when it meets iron ions due to its high affinity with cells. Cells encapsulated with this film presented high survival rates. Since the film forms quickly in a simple manner, it was possible to obtain large amount of encapsulated cells.

The research team also found that the metal-polyphenol film was stable in neutral pH, but is easily degradable under a weak acidic condition. Using this property, they were able to control cell division by restoring the cell to its pre-encapsulated state at a desired moment.

Protecting the cell from the external environment like an egg shell, the metal-polyphenol film protected the cell against foreign conditions such as lytic enzymes, extended exposure to UV radiation, and silver nanoparticles. The research indicated that the encapsulated cells had a high survival rate even under extreme environments.

Professor Lee said that “not only the cells remain alive during the encapsulation stage, but also they can be protected under extreme environment.” He added, “This is an advanced cell encapsulation technology that allows controlling cell-division of those cells through responsive shell degradation on-demand.”

Professor Choi commented, “Although the cell encapsulation technology is still in its infancy, as the technology matures the application of cell-manipulation technology will be actualized.” He highlighted that “it will serve as a breakthrough to problems faced by cell-based applications.”

Sponsored by the Ministry of Science, ICT and Future Planning and the National Research Foundation of Korea, the research was led by two Master’s candidates, Ji Hun Park and Kyung Hwan Kim, under the joint guidance of research professors from KAIST and the University of Melbourne.

Figure 1: Lead article of Angewandte Chemie

Background: Shows a live native yeast (in green) encapsulated in a metal-polyphenol film (in red) illustrating the vitality of the yeast

Front: A native yeast at each encapsulation stage

Pictured on the bottom left is a cell prior to encapsulation. Following the red arrow, the native yeast is in purple to show metal-polyphenol film formed around the cell. The cell after the green arrow is a visualization of the degradation of the film in weak acidic condition.

Figure 2: A mimetic diagram of cell encapsulation with a metal-polyphenol film

Top: A native yeast before encapsulation

Middle: A native yeast encapsulated with Tannic Acid-Fe (III) Nanoshell – cell-division of the encapsulated cell is controlled by pH and the shell is protected against silver nanoparticle, lytic enzyme, and UV-C

Bottom: Shell degradation on-demand depending on pH

2014.11.18 View 10794 -

KAIST Develops Core Technology to Synthesize a Helical Nanostructure

Professor Dong-Ki Yoon’s research team of the Graduate School of Nanoscience and Technology (GSNT) at KAIST has developed helical nanostructures using self-assembly processes. The results were published in the Proceedings of the National Academy of Sciences of the United States of America(PNAS) on the October 7th.

This technology enables the synthesis of various helical structures on a relatively large confined area. Its synthesis is often considered the most arduous for three dimensional structures. Formed from liquid crystal, the structure holds a regular helical structure within the confined space of 20 to 300 nanometers. Also, the distance between each pattern increased as the diameter of the nanostructure increased.

Liquid crystals have a unique property of responding sensitively to the surrounding electromagnetic field. The technology, in combination with the electromagnetic property of liquid crystal, is expected to foster the development of highly efficient optoelectronic devices.

Using this technology, it is possible to develop three dimensional patterning technology beyond the current semiconductor manufacturing technology which uses two dimensional photolithography processes. Three-dimensional semiconductor devices are expected to store hundred times more data than current devices. They will also lower costs by simplifying manufacturing processes.

The essence of this research, “self-assembly in confined space,” refers to controlling complex nanostructures, which can be synthesized from materials such as macromolecules, liquid crystal molecules, and biomolecules in relation to surrounding environments including the temperature, concentration, and pH.

The research team produced a confined space with a length of tens of nanometers by using a porous anodized aluminum membrane induced from an electrochemical reaction. They successfully synthesized independently controlled helical nanostructures by forming the helical structures from liquid crystal molecules within that space.

Professor Yoon said, “This research examines the physicochemical principle of controlling helical nanostructures.” He highlighted the significance of the research and commented, “The technology enables the control of complex nanostructures from organic molecules by using confined space and surface reforming.”

He added that, “When grafted with nanotechnology or information technology, this technology will spur new growth to liquid crystal-related industries such as the LCD.”

The research was led by two Ph.D. candidates, Hanim Kim and Sunhee Lee, under the guidance of Professor Yoon. Dr. Tae-Joo Shin of the Pohang Accelerator Laboratory, Professor Sang-Bok Lee of the University of Maryland, and Professor Noel Clark of the University of Colorado also participated.

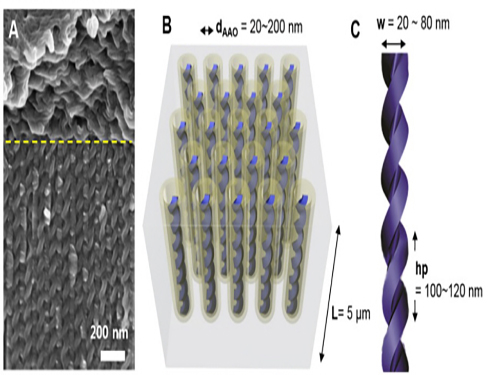

Picture 1. Electron Microscopy Pictures and Conceptual Diagrams of Helical Nanostructures

Picture 2. Electron Microscopy Pictures of Manufactured Helical Nanostructures

2014.10.29 View 9330

KAIST Develops Core Technology to Synthesize a Helical Nanostructure

Professor Dong-Ki Yoon’s research team of the Graduate School of Nanoscience and Technology (GSNT) at KAIST has developed helical nanostructures using self-assembly processes. The results were published in the Proceedings of the National Academy of Sciences of the United States of America(PNAS) on the October 7th.

This technology enables the synthesis of various helical structures on a relatively large confined area. Its synthesis is often considered the most arduous for three dimensional structures. Formed from liquid crystal, the structure holds a regular helical structure within the confined space of 20 to 300 nanometers. Also, the distance between each pattern increased as the diameter of the nanostructure increased.

Liquid crystals have a unique property of responding sensitively to the surrounding electromagnetic field. The technology, in combination with the electromagnetic property of liquid crystal, is expected to foster the development of highly efficient optoelectronic devices.

Using this technology, it is possible to develop three dimensional patterning technology beyond the current semiconductor manufacturing technology which uses two dimensional photolithography processes. Three-dimensional semiconductor devices are expected to store hundred times more data than current devices. They will also lower costs by simplifying manufacturing processes.

The essence of this research, “self-assembly in confined space,” refers to controlling complex nanostructures, which can be synthesized from materials such as macromolecules, liquid crystal molecules, and biomolecules in relation to surrounding environments including the temperature, concentration, and pH.

The research team produced a confined space with a length of tens of nanometers by using a porous anodized aluminum membrane induced from an electrochemical reaction. They successfully synthesized independently controlled helical nanostructures by forming the helical structures from liquid crystal molecules within that space.

Professor Yoon said, “This research examines the physicochemical principle of controlling helical nanostructures.” He highlighted the significance of the research and commented, “The technology enables the control of complex nanostructures from organic molecules by using confined space and surface reforming.”

He added that, “When grafted with nanotechnology or information technology, this technology will spur new growth to liquid crystal-related industries such as the LCD.”

The research was led by two Ph.D. candidates, Hanim Kim and Sunhee Lee, under the guidance of Professor Yoon. Dr. Tae-Joo Shin of the Pohang Accelerator Laboratory, Professor Sang-Bok Lee of the University of Maryland, and Professor Noel Clark of the University of Colorado also participated.

Picture 1. Electron Microscopy Pictures and Conceptual Diagrams of Helical Nanostructures

Picture 2. Electron Microscopy Pictures of Manufactured Helical Nanostructures

2014.10.29 View 9330 -

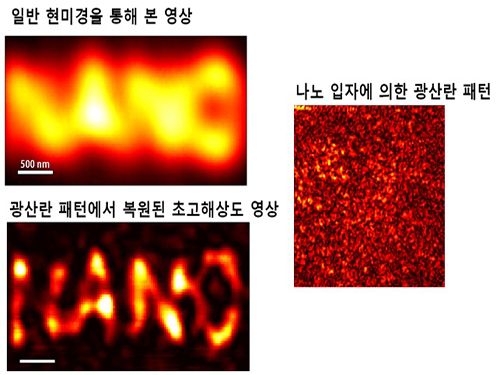

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 10440

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 10440 -

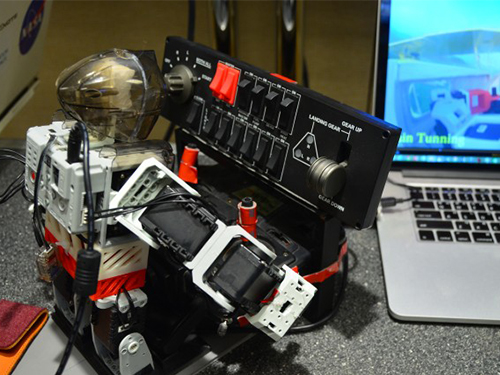

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14150

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14150 -

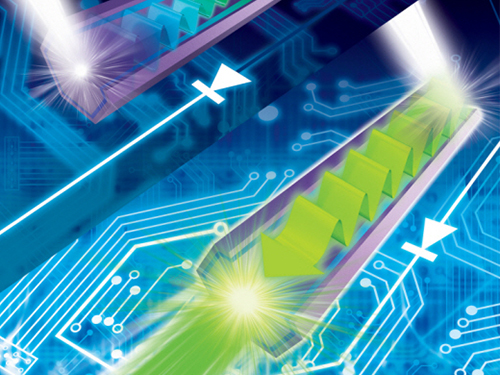

Development of a Photonic Diode with Light Speed, Single-Direction Transfer

A photonic diode using a nitride semiconductor rod can increase the possibility of developing all-optical integrated circuits, an alternative to conventional integrated circuits.

Professor Yong-Hoon Cho's research team from the Department of Physics, KAIST, developed a photonic diode which can selectively transfer light in one way, using semiconductor rods.

The photonic diode has a diameter of hundreds of nanometers (nm) and a length of few micrometers. This size enables its use in large-scale integration (LSI). The diode’s less sensitivity towards polarized light angle makes it more useful.

In an integrated circuit, a diode controls the flow of electrons. If this diode controls light rather than electrons, data can be transferred at high speed, and its loss is minimized to a greater extent. Since these implementations conserve more energy, this is a very promising future technology.

However, conventional electronic diodes, made up of asymmetric meta-materials or photonic crystalline structures, are large, which makes them difficult to be used in LSI. These diodes could only be implemented under limited conditions due to its sensitivity towards polarized light angle.

The research team used nitride semiconductor rods to develop a highly efficient photonic diode with distinct light intensities from opposite ends.

The semiconductor rod yields different amount of energy horizontally. According to the research team, this is because the width of the quantum well and its indium quantity is continuously controlled.

Professor Cho said, "A large energy difference in a horizontal direction causes asymmetrical light propagation, enabling it to be operated as a photonic diode." He added that “If light, instead of electrons, were adopted in integrated circuits, the transfer speed would be expected as great as that of light.”

The research findings were published in the September 10th issue of Nano Letters as the cover paper.

Under the guidance of Professor Cho, two Ph.D. candidates, Suk-Min Ko and Su-Hyun Gong, conducted this research. This research project was sponsored by the National Research Foundation of Korea and KAIST’s EEWS (energy, environment, water, and sustainability) Research Center.

Figure Description: Computer simulated image of photonic diode made of semiconductor rod implemented in an all-optical integrated circuit

2014.09.23 View 11827

Development of a Photonic Diode with Light Speed, Single-Direction Transfer

A photonic diode using a nitride semiconductor rod can increase the possibility of developing all-optical integrated circuits, an alternative to conventional integrated circuits.

Professor Yong-Hoon Cho's research team from the Department of Physics, KAIST, developed a photonic diode which can selectively transfer light in one way, using semiconductor rods.

The photonic diode has a diameter of hundreds of nanometers (nm) and a length of few micrometers. This size enables its use in large-scale integration (LSI). The diode’s less sensitivity towards polarized light angle makes it more useful.

In an integrated circuit, a diode controls the flow of electrons. If this diode controls light rather than electrons, data can be transferred at high speed, and its loss is minimized to a greater extent. Since these implementations conserve more energy, this is a very promising future technology.

However, conventional electronic diodes, made up of asymmetric meta-materials or photonic crystalline structures, are large, which makes them difficult to be used in LSI. These diodes could only be implemented under limited conditions due to its sensitivity towards polarized light angle.

The research team used nitride semiconductor rods to develop a highly efficient photonic diode with distinct light intensities from opposite ends.

The semiconductor rod yields different amount of energy horizontally. According to the research team, this is because the width of the quantum well and its indium quantity is continuously controlled.

Professor Cho said, "A large energy difference in a horizontal direction causes asymmetrical light propagation, enabling it to be operated as a photonic diode." He added that “If light, instead of electrons, were adopted in integrated circuits, the transfer speed would be expected as great as that of light.”

The research findings were published in the September 10th issue of Nano Letters as the cover paper.

Under the guidance of Professor Cho, two Ph.D. candidates, Suk-Min Ko and Su-Hyun Gong, conducted this research. This research project was sponsored by the National Research Foundation of Korea and KAIST’s EEWS (energy, environment, water, and sustainability) Research Center.

Figure Description: Computer simulated image of photonic diode made of semiconductor rod implemented in an all-optical integrated circuit

2014.09.23 View 11827 -

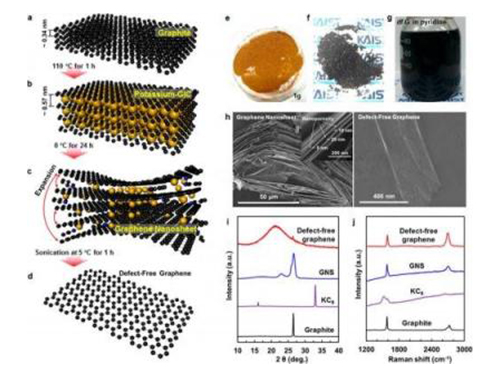

KAIST Researchers Fabricate Defect-free Graphene for Lithium-ion Batteries

Although graphene has been hailed as promising materials for lithium-ion batteries, making it for large-scale production has remained a challenging task for researchers. So far, high-quality graphene has been produced at the expense of large volume. It is possible to fabricate bulk quantities of graphene, but they will likely contain many defects.

Recently, a KAIST research team, headed by Professors Jung-Ki Park and Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering, developed a fabrication method to produce a large amount of defect-free graphene (df-G) while preserving the structural integrity of the graphene.

This research result was published online in the July 11, 2014 issue of Nano Letters, entitled "Defect-free, Size-tunable Graphene for High-performance Lithium Ion Battery."

Phys.org, a science, research and technology news website, published an article on this research. To read article, please visit the link below:

Phys.org, August 22, 2014

“Scientists fabricate defect-free graphene, set record reversible capacity for Co3O4 node in Li-ion batteries”

http://phys.org/news/2014-08-scientists-fabricate-defect-free-graphene-reversible.html

2014.09.07 View 10315

KAIST Researchers Fabricate Defect-free Graphene for Lithium-ion Batteries

Although graphene has been hailed as promising materials for lithium-ion batteries, making it for large-scale production has remained a challenging task for researchers. So far, high-quality graphene has been produced at the expense of large volume. It is possible to fabricate bulk quantities of graphene, but they will likely contain many defects.

Recently, a KAIST research team, headed by Professors Jung-Ki Park and Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering, developed a fabrication method to produce a large amount of defect-free graphene (df-G) while preserving the structural integrity of the graphene.

This research result was published online in the July 11, 2014 issue of Nano Letters, entitled "Defect-free, Size-tunable Graphene for High-performance Lithium Ion Battery."

Phys.org, a science, research and technology news website, published an article on this research. To read article, please visit the link below:

Phys.org, August 22, 2014

“Scientists fabricate defect-free graphene, set record reversible capacity for Co3O4 node in Li-ion batteries”

http://phys.org/news/2014-08-scientists-fabricate-defect-free-graphene-reversible.html

2014.09.07 View 10315 -

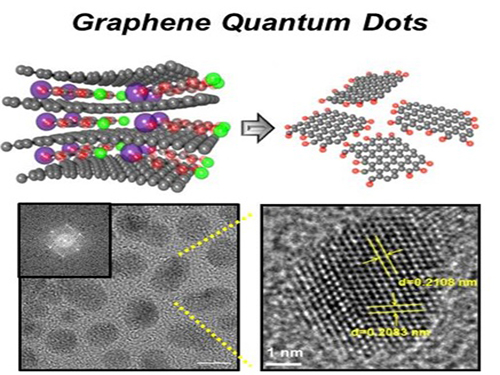

Extracting Light from Graphite: Core Technology of Graphene Quantum Dots Display Developed

Professor Seokwoo Jeon of the Department of Materials Science and Engineering, Professor Yong-Hoon Cho of the Department of Physics, and Professor Seunghyup Yoo of the Department of Electrical Engineering announced that they were able to develop topnotch graphene quantum dots from graphite.

Using the method of synthesizing graphite intercalation compound from graphite with salt and water, the research team developed graphene quantum dots in an ecofriendly way.

The quantum dots have a diameter of 5 nanometers with their sizes equal and yield high quantum efficiency. Unlike conventional quantum dots, they are not comprised of toxic materials such as lead or cadmium. As the quantum dots can be developed from materials which can be easily found in the nature, researchers look forward to putting these into mass production at low cost.

The research team also discovered a luminescence mechanism of graphene quantum dots and confirmed the possibility of commercial use by developing quantum dot light-emitting diodes with brightness of 1,000 cd/m2, which is greater than that of cellphone displays.

Professor Seokwoo Jeon said, “Although quantum dot LEDs have a lower luminous efficiency than existing ones, their luminescent property can be further improved” and emphasized that “using quantum dot displays will allow us to develop not only paper-thin displays but also flexible ones.”

Sponsored by Graphene Research Center in KAIST Institute for NanoCentury, the research finding was published online in the April 20th issue of Advanced Optical Materials.

Picture 1: Graphene quantum dots and their synthesis

Picture 2: Luminescence mechanism of graphene quantum dots

Picture 3: Structure of graphene quantum dots LED and its emission

2014.09.06 View 18415

Extracting Light from Graphite: Core Technology of Graphene Quantum Dots Display Developed

Professor Seokwoo Jeon of the Department of Materials Science and Engineering, Professor Yong-Hoon Cho of the Department of Physics, and Professor Seunghyup Yoo of the Department of Electrical Engineering announced that they were able to develop topnotch graphene quantum dots from graphite.

Using the method of synthesizing graphite intercalation compound from graphite with salt and water, the research team developed graphene quantum dots in an ecofriendly way.

The quantum dots have a diameter of 5 nanometers with their sizes equal and yield high quantum efficiency. Unlike conventional quantum dots, they are not comprised of toxic materials such as lead or cadmium. As the quantum dots can be developed from materials which can be easily found in the nature, researchers look forward to putting these into mass production at low cost.

The research team also discovered a luminescence mechanism of graphene quantum dots and confirmed the possibility of commercial use by developing quantum dot light-emitting diodes with brightness of 1,000 cd/m2, which is greater than that of cellphone displays.

Professor Seokwoo Jeon said, “Although quantum dot LEDs have a lower luminous efficiency than existing ones, their luminescent property can be further improved” and emphasized that “using quantum dot displays will allow us to develop not only paper-thin displays but also flexible ones.”

Sponsored by Graphene Research Center in KAIST Institute for NanoCentury, the research finding was published online in the April 20th issue of Advanced Optical Materials.

Picture 1: Graphene quantum dots and their synthesis

Picture 2: Luminescence mechanism of graphene quantum dots

Picture 3: Structure of graphene quantum dots LED and its emission

2014.09.06 View 18415 -

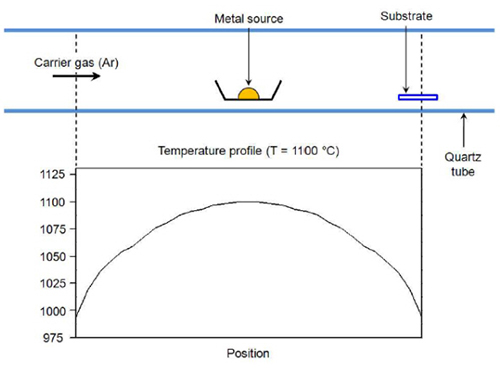

Development of Gold Nanowire Probe Needle with an Increased Sensitivity

Professor Bongsoo Kim

The newly developed nano-probe needle’s thickness estimates only at 0.1 micrometers with an increased 1,000-fold sensitivity and spatial resolution of 1mm.

Professor Bongsoo Kim and his research team from the Department of Chemistry, KASIT, including the first author, Dr. Mijeong Kang, succeeded in measuring nerve signals of a mouse using the world’s thinnest nano-probe needle made of single-crystal gold nanowires.

The newly developed nano-probe needle possesses the thickness of 100 nanometers (nm), which shows 1,000 times more sensitivity than the conventional nerve probe needles, as well as accurately measures nerve signals with an extremely fine resolution of less than 1mm. Unlike the existing probe needles that cause neural tissues to be damaged during insertion, the new nano-probe needle minimizes the damage and thus can detect large nerve signals.

The brain neural probe, which collects and analyzes electrical nerve signals generated in the brain, is the most essential element in brain research. A neural probe should minimize tissue damages, but needs to possess a good electrical sensitivity.

The researchers first applied heat on the gold, which is the necessary material for a probe, until it turned to a vapor phase. Then, the gold evaporation slug was transported to a colder board and left to form single-crystal gold nano structures by condensation. Because the new gold nanowire, produced by using this principle, is a flawless single crystal structure, it shows strong and flexible properties.

Professor Kim and his team applied the nano-probe needle into the brain of a mouse that has been administered a drug to induce epilepsy. They were able to find the exact area in the brain that triggers epilepsy. Furthermore, the researchers also detected neural signal changes in the brain of the mouse when it encountered the intrusion of a stranger mouse.

Professor Bongsoo Kim commented the meaning of his research:

“The new nano-probe needle is able to detect signals from a single nerve cell with high sensitivity while preserving the nerve cells intact. The probe needle will be useful for creating a precise three-dimensional brain map, as well as providing electrical treatment for brain diseases such as dementia and Parkinson's disease.”

This research results were published online in the August 12, 2014 edition of ACS Nano.

2014.09.06 View 6943

Development of Gold Nanowire Probe Needle with an Increased Sensitivity

Professor Bongsoo Kim

The newly developed nano-probe needle’s thickness estimates only at 0.1 micrometers with an increased 1,000-fold sensitivity and spatial resolution of 1mm.

Professor Bongsoo Kim and his research team from the Department of Chemistry, KASIT, including the first author, Dr. Mijeong Kang, succeeded in measuring nerve signals of a mouse using the world’s thinnest nano-probe needle made of single-crystal gold nanowires.

The newly developed nano-probe needle possesses the thickness of 100 nanometers (nm), which shows 1,000 times more sensitivity than the conventional nerve probe needles, as well as accurately measures nerve signals with an extremely fine resolution of less than 1mm. Unlike the existing probe needles that cause neural tissues to be damaged during insertion, the new nano-probe needle minimizes the damage and thus can detect large nerve signals.

The brain neural probe, which collects and analyzes electrical nerve signals generated in the brain, is the most essential element in brain research. A neural probe should minimize tissue damages, but needs to possess a good electrical sensitivity.

The researchers first applied heat on the gold, which is the necessary material for a probe, until it turned to a vapor phase. Then, the gold evaporation slug was transported to a colder board and left to form single-crystal gold nano structures by condensation. Because the new gold nanowire, produced by using this principle, is a flawless single crystal structure, it shows strong and flexible properties.

Professor Kim and his team applied the nano-probe needle into the brain of a mouse that has been administered a drug to induce epilepsy. They were able to find the exact area in the brain that triggers epilepsy. Furthermore, the researchers also detected neural signal changes in the brain of the mouse when it encountered the intrusion of a stranger mouse.

Professor Bongsoo Kim commented the meaning of his research:

“The new nano-probe needle is able to detect signals from a single nerve cell with high sensitivity while preserving the nerve cells intact. The probe needle will be useful for creating a precise three-dimensional brain map, as well as providing electrical treatment for brain diseases such as dementia and Parkinson's disease.”

This research results were published online in the August 12, 2014 edition of ACS Nano.

2014.09.06 View 6943 -

Regulatory T Cells Influence Liver Damage of Hepatitis A Patients

Liver damage becomes more severe with the decrease of regulatory T cells

“This research will aid the development of hepatitis A targeted drug,” said a KAIST researcher.

The KAIST Graduate School of Medical Science and Engineering’s Professor Eui-Cheol Shin and his research team have identified the mechanism, explaining how the regulatory T cells are responsible for the body’s immune system and how they have induced liver damage of hepatitis A patients.

The research results were published online in the July 9th edition of ‘Gut,’ the world’s most prominent journal in the field of gastroenterology.

Hepatitis A is an acute form of hepatitis caused by hepatitis A virus. The virus spreads through oral contact and enters the body via digestive organs.

Regulatory T cells play an important role in maintaining the homeostasis of the body’s immune system by inhibiting the activation of other immune cells. In the case of chronic viral infections, regulatory T cells are known to contribute to the duration of the infection, weakening the immune response to virus infections. However, there has been no information on what roles the regulatory T cells perform in the case of acute viral infections.

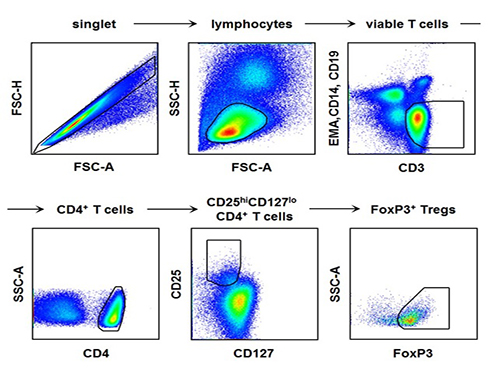

The research team used the fluorescence flow cytometry technique to determine the number and characteristics of a variety of immune cells, including regulatory T cells, in the blood of hepatitis A patients.

Consequently, the researchers confirmed that the decrease in the regulatory T cells immune inhibitory ability was consistent with a significant reduction in the number of regulatory T cells in the blood of hepatitis A patients. Furthermore, it was identified that the more noticeable decrease of regulatory T cells led to the occurrence of a more severe liver injury.

The analysis of hepatitis A patient’s blood proved that the cause of the decrease in the number and function of regulatory T cells was the increased expression of cell surface protein ‘Fas,’ which induces cell death.

Professor Shin said, “This study is the first case which proposes the mechanism for clinical aspects in not only hepatitis A, but also acute virus infection.” He added on the future prospect of the research that: “In the future, we can prevent tissue damage by inhibiting cell death of regulatory T cells for severe acute viral infections that do not have an effective treatment for the virus itself.”

[Picture]

The picture shows the process of fluorescence flow cytometry technique to study regulatory T cell in the blood of hepatitis A patients.

2014.08.11 View 10710

Regulatory T Cells Influence Liver Damage of Hepatitis A Patients

Liver damage becomes more severe with the decrease of regulatory T cells

“This research will aid the development of hepatitis A targeted drug,” said a KAIST researcher.

The KAIST Graduate School of Medical Science and Engineering’s Professor Eui-Cheol Shin and his research team have identified the mechanism, explaining how the regulatory T cells are responsible for the body’s immune system and how they have induced liver damage of hepatitis A patients.

The research results were published online in the July 9th edition of ‘Gut,’ the world’s most prominent journal in the field of gastroenterology.

Hepatitis A is an acute form of hepatitis caused by hepatitis A virus. The virus spreads through oral contact and enters the body via digestive organs.

Regulatory T cells play an important role in maintaining the homeostasis of the body’s immune system by inhibiting the activation of other immune cells. In the case of chronic viral infections, regulatory T cells are known to contribute to the duration of the infection, weakening the immune response to virus infections. However, there has been no information on what roles the regulatory T cells perform in the case of acute viral infections.

The research team used the fluorescence flow cytometry technique to determine the number and characteristics of a variety of immune cells, including regulatory T cells, in the blood of hepatitis A patients.

Consequently, the researchers confirmed that the decrease in the regulatory T cells immune inhibitory ability was consistent with a significant reduction in the number of regulatory T cells in the blood of hepatitis A patients. Furthermore, it was identified that the more noticeable decrease of regulatory T cells led to the occurrence of a more severe liver injury.

The analysis of hepatitis A patient’s blood proved that the cause of the decrease in the number and function of regulatory T cells was the increased expression of cell surface protein ‘Fas,’ which induces cell death.

Professor Shin said, “This study is the first case which proposes the mechanism for clinical aspects in not only hepatitis A, but also acute virus infection.” He added on the future prospect of the research that: “In the future, we can prevent tissue damage by inhibiting cell death of regulatory T cells for severe acute viral infections that do not have an effective treatment for the virus itself.”

[Picture]

The picture shows the process of fluorescence flow cytometry technique to study regulatory T cell in the blood of hepatitis A patients.

2014.08.11 View 10710 -

The Journal of Clinical Investigation: Researchers Uncover the Secret Lymphatic Identity of the Schlemm's Canal

The Journal of Clinical Investigation (JCI), a peer-reviewed, top-tier medical journal published by the American Society for Clinical Investigation, carried a commentary entitled “Schlemm’s Canal: More Than Meets the Eye, Lymphatics in Disguise” in the July 25, 2014 issue.

In the commentary, the authors compared a research paper (“Lymphatic regular PROX1 determines Schlemm’s canal integrity and identity”) by Professor Gou-Young Koh of the Graduate School of Medical Science and Engineering at KAIST with research work from the University of Helsinki (article entitled “The Schlemm’s canal is a VEGF-C/VEGFR-3 responsive lymphatic-like vessel”).

The JCI released a press statement dated July 25, 2014 on its commentary. It mentioned that glaucoma, one of the leading causes of blindness worldwide, elevates eye pressure owing to poor drainage of aqueous humor. A specialized structure called “Schlemm’s canal” funnels aqueous humor from the eye back into circulation, which is critical to prevent pressure buildup in the eye. The article discussed the role of Schlemm’s canal in the context of lymphatic vascular characteristics by reviewing two research group’s papers back-to-back.

For the full text of the press release, please visit the link below:

Press Release from the Journal of Clinical Investigation, July 25, 2014

“Researchers uncover the secret lymphatic identity of the Schlemm’s canal”

http://www.eurekalert.org/pub_releases/2014-07/joci-rut072414.php

2014.07.28 View 8734

The Journal of Clinical Investigation: Researchers Uncover the Secret Lymphatic Identity of the Schlemm's Canal

The Journal of Clinical Investigation (JCI), a peer-reviewed, top-tier medical journal published by the American Society for Clinical Investigation, carried a commentary entitled “Schlemm’s Canal: More Than Meets the Eye, Lymphatics in Disguise” in the July 25, 2014 issue.

In the commentary, the authors compared a research paper (“Lymphatic regular PROX1 determines Schlemm’s canal integrity and identity”) by Professor Gou-Young Koh of the Graduate School of Medical Science and Engineering at KAIST with research work from the University of Helsinki (article entitled “The Schlemm’s canal is a VEGF-C/VEGFR-3 responsive lymphatic-like vessel”).

The JCI released a press statement dated July 25, 2014 on its commentary. It mentioned that glaucoma, one of the leading causes of blindness worldwide, elevates eye pressure owing to poor drainage of aqueous humor. A specialized structure called “Schlemm’s canal” funnels aqueous humor from the eye back into circulation, which is critical to prevent pressure buildup in the eye. The article discussed the role of Schlemm’s canal in the context of lymphatic vascular characteristics by reviewing two research group’s papers back-to-back.

For the full text of the press release, please visit the link below:

Press Release from the Journal of Clinical Investigation, July 25, 2014

“Researchers uncover the secret lymphatic identity of the Schlemm’s canal”

http://www.eurekalert.org/pub_releases/2014-07/joci-rut072414.php

2014.07.28 View 8734 -

Discovery of New Therapeutic Targets for Alzheimer's Disease

A Korean research team headed by Professor Dae-Soo Kim of Biological Sciences at KAIST and Dr. Chang-Jun Lee from the Korea Institute of Science and Technology (KIST) successfully identified that reactive astrocytes, commonly observed in brains affected by Alzheimer’s disease, produce abnormal amounts of inhibitory neurotransmitter gamma-Aminobutyric acid (GABA) in reaction to the enzyme Monoamine oxidase B (Mao-B) and release GABA through the Bestrophin-1 channel to suppress the normal signal transmission of brain nerve cells.

By suppressing the GABA production or release from reactive astrocytes, the research team was able to restore the model mice's memory and learning impairment caused by Alzheimer’s disease. This discovery will allow the development of new drugs to treat Alzheimer’s and other related diseases.

The research result was published in the June 29, 2014 edition of Nature Medicine (Title: GABA from Reactive Astrocytes Impairs Memory in Mouse Models of Alzheimer’s Disease).

For details, please read the article below:

Technology News, July 10, 2014

"Discovery of New Drug Targets for Memory Impairment in Alzheimer’s Disease"

http://technews.tmcnet.com/news/2014/07/10/7917811.htm

2014.07.16 View 9701

Discovery of New Therapeutic Targets for Alzheimer's Disease

A Korean research team headed by Professor Dae-Soo Kim of Biological Sciences at KAIST and Dr. Chang-Jun Lee from the Korea Institute of Science and Technology (KIST) successfully identified that reactive astrocytes, commonly observed in brains affected by Alzheimer’s disease, produce abnormal amounts of inhibitory neurotransmitter gamma-Aminobutyric acid (GABA) in reaction to the enzyme Monoamine oxidase B (Mao-B) and release GABA through the Bestrophin-1 channel to suppress the normal signal transmission of brain nerve cells.

By suppressing the GABA production or release from reactive astrocytes, the research team was able to restore the model mice's memory and learning impairment caused by Alzheimer’s disease. This discovery will allow the development of new drugs to treat Alzheimer’s and other related diseases.

The research result was published in the June 29, 2014 edition of Nature Medicine (Title: GABA from Reactive Astrocytes Impairs Memory in Mouse Models of Alzheimer’s Disease).

For details, please read the article below:

Technology News, July 10, 2014

"Discovery of New Drug Targets for Memory Impairment in Alzheimer’s Disease"

http://technews.tmcnet.com/news/2014/07/10/7917811.htm

2014.07.16 View 9701 -

KAIST develops TransWall, a transparent touchable display wall

At a busy shopping mall, shoppers walk by store windows to find attractive items to purchase. Through the windows, shoppers can see the products displayed, but may have a hard time imagining doing something beyond just looking, such as touching the displayed items or communicating with sales assistants inside the store. With TransWall, however, window shopping could become more fun and real than ever before.

Woohun Lee, a professor of Industrial Design at KAIST, and his research team have recently developed TransWall, a two-sided, touchable, and transparent display wall that greatly enhances users' interpersonal experiences.

With an incorporated surface transducer, TransWall offers audio and vibrotactile feedback to the users. As a result, people can collaborate via a shared see-through display and communicate with one another by talking or even touching one another through the wall. A holographic screen film is inserted between the sheets of plexiglass, and beam projectors installed on each side of the wall project images that are reflected.

TransWall is touch-sensitive on both sides. Two users standing face-to-face on each side of the wall can touch the same spot at the same time without any physical interference. When this happens, TransWall provides the users with specific visual, acoustic, and vibrotactile experiences, allowing them to feel as if they are touching one another.

Professor Lee said, "TransWall concept enables people to see, hear, or even touch others through the wall while enjoying gaming and interpersonal communication. TransWall can be installed inside buildings, such as shopping centers, museums, and theme parks, for people to have an opportunity to collaborate even with strangers in a natural way."

He further added that "TransWall will be useful in places that require physical isolation for high security and safety, germ-free rooms in hospitals, for example." TransWall will allow patients to interact with family and friends without compromising medical safety.

TransWall was exhibited at the 2014 Conference on Computer-Human Interaction (CHI) held from April 26, 2014 to May 1, 2014 in Toronto, Canada.

YouTube Link:

http://www.youtube.com/watch?v=1QdYC_kOQ_w&list=PLXmuftxI6pTXuyjjrGFlcN5YFTKZinDhK

2014.07.15 View 7998

KAIST develops TransWall, a transparent touchable display wall

At a busy shopping mall, shoppers walk by store windows to find attractive items to purchase. Through the windows, shoppers can see the products displayed, but may have a hard time imagining doing something beyond just looking, such as touching the displayed items or communicating with sales assistants inside the store. With TransWall, however, window shopping could become more fun and real than ever before.

Woohun Lee, a professor of Industrial Design at KAIST, and his research team have recently developed TransWall, a two-sided, touchable, and transparent display wall that greatly enhances users' interpersonal experiences.

With an incorporated surface transducer, TransWall offers audio and vibrotactile feedback to the users. As a result, people can collaborate via a shared see-through display and communicate with one another by talking or even touching one another through the wall. A holographic screen film is inserted between the sheets of plexiglass, and beam projectors installed on each side of the wall project images that are reflected.

TransWall is touch-sensitive on both sides. Two users standing face-to-face on each side of the wall can touch the same spot at the same time without any physical interference. When this happens, TransWall provides the users with specific visual, acoustic, and vibrotactile experiences, allowing them to feel as if they are touching one another.

Professor Lee said, "TransWall concept enables people to see, hear, or even touch others through the wall while enjoying gaming and interpersonal communication. TransWall can be installed inside buildings, such as shopping centers, museums, and theme parks, for people to have an opportunity to collaborate even with strangers in a natural way."

He further added that "TransWall will be useful in places that require physical isolation for high security and safety, germ-free rooms in hospitals, for example." TransWall will allow patients to interact with family and friends without compromising medical safety.

TransWall was exhibited at the 2014 Conference on Computer-Human Interaction (CHI) held from April 26, 2014 to May 1, 2014 in Toronto, Canada.

YouTube Link:

http://www.youtube.com/watch?v=1QdYC_kOQ_w&list=PLXmuftxI6pTXuyjjrGFlcN5YFTKZinDhK

2014.07.15 View 7998