-

“A drop of water shall be returned with a rushing river.”

- Chinese KAISTians Donate Supplies to Fight COVID-19 in Daegu -

The Chinese community at KAIST donated 2.49 million won worth of personal protective equipment on March 4 to support on-site medical personnel in the city of Daegu. South Korea has been witnessing a significant surge in novel COVID-19 transmissions, and Daegu and nearby North Gyeongsang Province are the most affected regions.

As the COVID-19 situation grows more serious globally day by day, a Chinese master’s student from the KAIST Department of Civil and Environmental Engineering, Yuewen Jia, suggested a fundraising campaign on the KAIST Chinese Community’s WeChat messenger chat room, and her idea was enthusiastically supported by many peer-members. The KAIST Chinese Community is comprised of 105 undergraduates, graduates, post-doctoral fellows, researchers, and professors.

With Jia’s post-doc colleague Pei Li volunteering to manage the fundraising process, a total of 2.49 million won was collected in 12 days between January 27 and February 7.

The donors, including Qin Xu, a PhD candidate in the School of Electrical Engineering, reportedly asked for their donations to be used to support on-site medical personnel affected by the outbreak. They believed that medical supplies are the most essential in times like these. The group purchased personal protective equipment online and waited for more than 20 days until the items were finally delivered to them. The goods include 1,280 protective caps, 57 protective suits, 15 protective glasses, and two protective face shields.

Given the surging spread of the COVID-19 disease in Korea, where the confirmed cases have increased multi-fold since mid-February, the KAIST Chinese Community decided that their items should be used immediately in Korea, instead of being sent back to their home country as they had planned.

Guoyuan An, a student representative of the community studying for his master’s degree in the School of Computing, said, “Earlier, some members of the KAIST Chinese Community who had visited China were self-quarantined for two weeks in a special facility designated by KAIST as a precautionary measure. Thanks to the outstanding care we received from offices at KAIST including the COVID-19 Task Force Team, the International Office, the Student Offices, and the Clinic, those who were quarantined could return to campus safe and healthy.”

He continued, “KAIST and the Koreans as a whole spared no effort in helping China and Chinese people living in Korea fight the COVID-19 outbreak in its early days, and all of the members of the KAIST Chinese Community felt deeply grateful for all the attention and aid. This has been a definitive reason for us to change the donate recipient from China to Korea.”

“As an old Chinese saying goes, ‘A drop of water shall be returned with a rushing river.’ This proverb means that even if you receive a little help from others, you should return the favor with all you can when others are in need. We decided to make a donation ourselves in hopes that our small contribution could help on-site medical personnel work for the health and wellbeing of Koreans who are affected in that area.” he explained.

The donated items were delivered to the Division of Disaster Preparedness and Emergency Management at the Daegu Metropolitan Government Office, with help from the on-campus medical center KAIST Clinic Pappalardo Center and the KAIST International Scholar and Student Services (ISSS) Team.

Dr. Yun-Jung Lee, the executive director of the KAIST Clinic Pappalardo Center, expressed “a huge thank you to the KAIST Chinese Community for pitching in to help battle this national and global crisis.”

She added, “Their donations have been passed to those in desperate need, and their warm-hearted act of kindness will go a long way.”

(END)

2020.03.05 View 9782

“A drop of water shall be returned with a rushing river.”

- Chinese KAISTians Donate Supplies to Fight COVID-19 in Daegu -

The Chinese community at KAIST donated 2.49 million won worth of personal protective equipment on March 4 to support on-site medical personnel in the city of Daegu. South Korea has been witnessing a significant surge in novel COVID-19 transmissions, and Daegu and nearby North Gyeongsang Province are the most affected regions.

As the COVID-19 situation grows more serious globally day by day, a Chinese master’s student from the KAIST Department of Civil and Environmental Engineering, Yuewen Jia, suggested a fundraising campaign on the KAIST Chinese Community’s WeChat messenger chat room, and her idea was enthusiastically supported by many peer-members. The KAIST Chinese Community is comprised of 105 undergraduates, graduates, post-doctoral fellows, researchers, and professors.

With Jia’s post-doc colleague Pei Li volunteering to manage the fundraising process, a total of 2.49 million won was collected in 12 days between January 27 and February 7.

The donors, including Qin Xu, a PhD candidate in the School of Electrical Engineering, reportedly asked for their donations to be used to support on-site medical personnel affected by the outbreak. They believed that medical supplies are the most essential in times like these. The group purchased personal protective equipment online and waited for more than 20 days until the items were finally delivered to them. The goods include 1,280 protective caps, 57 protective suits, 15 protective glasses, and two protective face shields.

Given the surging spread of the COVID-19 disease in Korea, where the confirmed cases have increased multi-fold since mid-February, the KAIST Chinese Community decided that their items should be used immediately in Korea, instead of being sent back to their home country as they had planned.

Guoyuan An, a student representative of the community studying for his master’s degree in the School of Computing, said, “Earlier, some members of the KAIST Chinese Community who had visited China were self-quarantined for two weeks in a special facility designated by KAIST as a precautionary measure. Thanks to the outstanding care we received from offices at KAIST including the COVID-19 Task Force Team, the International Office, the Student Offices, and the Clinic, those who were quarantined could return to campus safe and healthy.”

He continued, “KAIST and the Koreans as a whole spared no effort in helping China and Chinese people living in Korea fight the COVID-19 outbreak in its early days, and all of the members of the KAIST Chinese Community felt deeply grateful for all the attention and aid. This has been a definitive reason for us to change the donate recipient from China to Korea.”

“As an old Chinese saying goes, ‘A drop of water shall be returned with a rushing river.’ This proverb means that even if you receive a little help from others, you should return the favor with all you can when others are in need. We decided to make a donation ourselves in hopes that our small contribution could help on-site medical personnel work for the health and wellbeing of Koreans who are affected in that area.” he explained.

The donated items were delivered to the Division of Disaster Preparedness and Emergency Management at the Daegu Metropolitan Government Office, with help from the on-campus medical center KAIST Clinic Pappalardo Center and the KAIST International Scholar and Student Services (ISSS) Team.

Dr. Yun-Jung Lee, the executive director of the KAIST Clinic Pappalardo Center, expressed “a huge thank you to the KAIST Chinese Community for pitching in to help battle this national and global crisis.”

She added, “Their donations have been passed to those in desperate need, and their warm-hearted act of kindness will go a long way.”

(END)

2020.03.05 View 9782 -

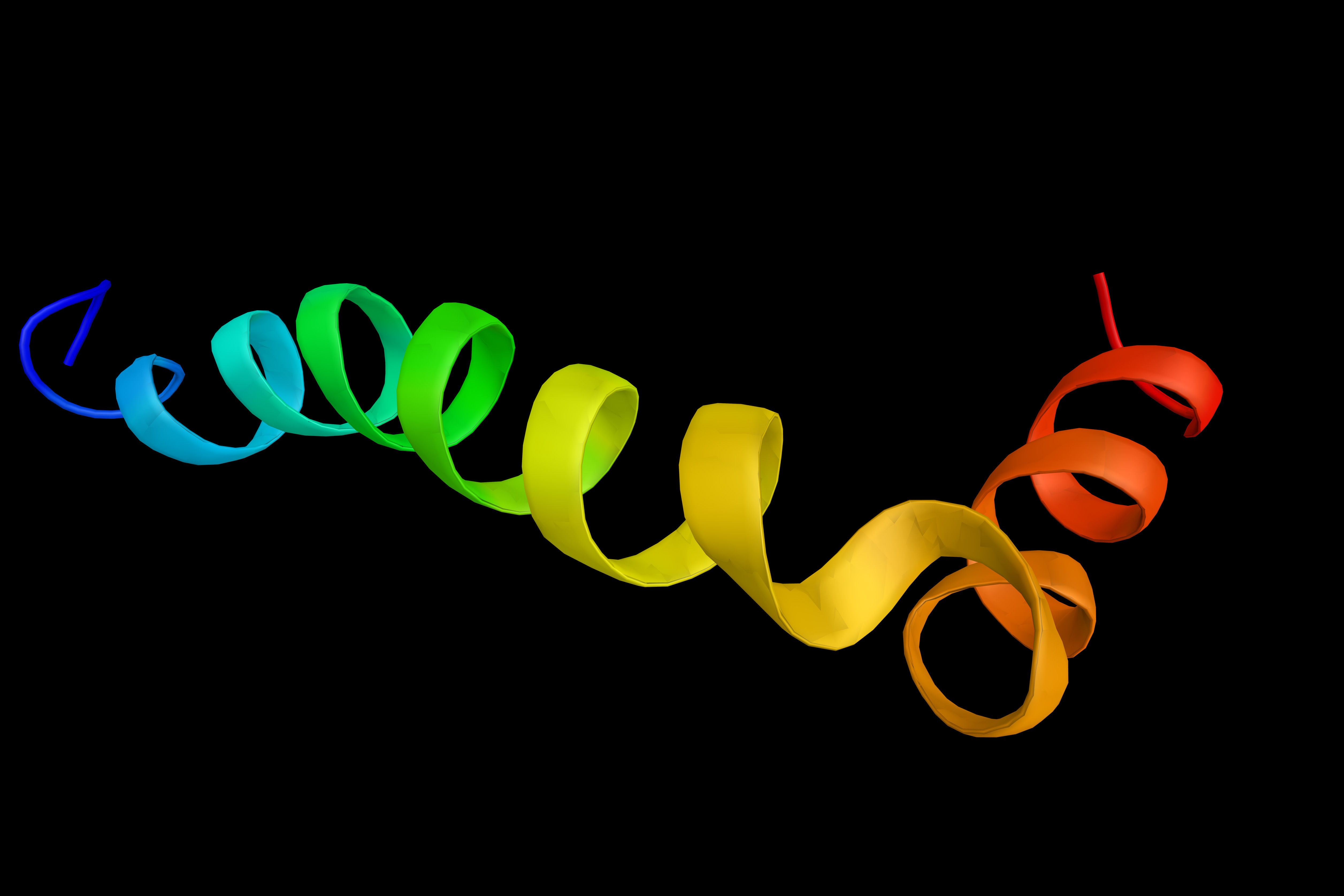

Coordination Chemistry and Alzheimer’s Disease

It has become evident recently that the interactions between copper and amyloid-b neurotoxically impact the brain of patients with Alzheimer’s disease. KAIST researchers have reported a new strategy to alter the neurotoxicity in Alzheimer’s disease by using a rationally designed chemical reagent.

This strategy, developed by Professor Mi Hee Lim from the Department of Chemistry, can modify the coordination sphere of copper bound to amyloid-b, effectively inhibiting copper’s binding to amyloid-b and altering its aggregation and toxicity. Their study was featured in PNAS last month.

The researchers developed a small molecule that is able to directly interact with the coordination sphere of copper–amyloid-b complexes followed by modifications via either covalent conjugation, oxidation, or both under aerobic conditions. The research team simply utilized copper–dioxygen chemistry to design a chemical reagent.

Answering how peptide modifications by a small molecule occur remains very challenging. The system includes transition metals and amyloidogenic proteins and is quite heterogeneous, since they are continuously being changed. It is critical to carefully check the multiple variables such as the presence of dioxygen and the type of transition metal ions and amyloidogenic proteins in order to identify the underlying mechanisms and target specificity of the chemical reagent.

The research team employed various biophysical and biochemical methods to determine the mechanisms for modifications on the coordination sphere of copper–Aꞵ complexes. Among them, peptide modifications were mainly analyzed using electrospray ionization-mass spectrometry.

Mass spectrometry (MS) has been applied to verify such peptide modifications by calculating the shift in exact mass. The research team also performed collision-induced dissociation (CID) of the target ion detected by MS to pinpoint which amino acid residue is specifically modified. The CID fragmentizes the amide bond located between the amino acid residues. This fragmental analysis allows us to identify the specific sites of peptide modifications.

The copper and amyloid-b complexes represent a pathological connection between metal ions and amyloid-b in Alzheimer’s disease. Recent findings indicate that copper and amyloid-b can directly contribute toward neurodegeneration by producing toxic amyloid-b oligomers and reactive oxygen species.

Professor Lim said, “This study illustrates the first experimental evidence that the 14th histidine residue in copper–amyloid-b complexes can be specifically modified through either covalent conjugation, oxidation, or both. Considering the neurotoxic implications of the interactions between copper and amyloid-b, such modifications at the coordination sphere of copper in amyloid-b could effectively alter its properties and toxicity.”

“This multidisciplinary study with an emphasis on approaches, reactivities, and mechanisms looks forward to opening a new way to develop candidates of anti-neurodegenerative diseases,” she added. The National Research Foundation of Korea funded this research.

2020.03.03 View 7869

Coordination Chemistry and Alzheimer’s Disease

It has become evident recently that the interactions between copper and amyloid-b neurotoxically impact the brain of patients with Alzheimer’s disease. KAIST researchers have reported a new strategy to alter the neurotoxicity in Alzheimer’s disease by using a rationally designed chemical reagent.

This strategy, developed by Professor Mi Hee Lim from the Department of Chemistry, can modify the coordination sphere of copper bound to amyloid-b, effectively inhibiting copper’s binding to amyloid-b and altering its aggregation and toxicity. Their study was featured in PNAS last month.

The researchers developed a small molecule that is able to directly interact with the coordination sphere of copper–amyloid-b complexes followed by modifications via either covalent conjugation, oxidation, or both under aerobic conditions. The research team simply utilized copper–dioxygen chemistry to design a chemical reagent.

Answering how peptide modifications by a small molecule occur remains very challenging. The system includes transition metals and amyloidogenic proteins and is quite heterogeneous, since they are continuously being changed. It is critical to carefully check the multiple variables such as the presence of dioxygen and the type of transition metal ions and amyloidogenic proteins in order to identify the underlying mechanisms and target specificity of the chemical reagent.

The research team employed various biophysical and biochemical methods to determine the mechanisms for modifications on the coordination sphere of copper–Aꞵ complexes. Among them, peptide modifications were mainly analyzed using electrospray ionization-mass spectrometry.

Mass spectrometry (MS) has been applied to verify such peptide modifications by calculating the shift in exact mass. The research team also performed collision-induced dissociation (CID) of the target ion detected by MS to pinpoint which amino acid residue is specifically modified. The CID fragmentizes the amide bond located between the amino acid residues. This fragmental analysis allows us to identify the specific sites of peptide modifications.

The copper and amyloid-b complexes represent a pathological connection between metal ions and amyloid-b in Alzheimer’s disease. Recent findings indicate that copper and amyloid-b can directly contribute toward neurodegeneration by producing toxic amyloid-b oligomers and reactive oxygen species.

Professor Lim said, “This study illustrates the first experimental evidence that the 14th histidine residue in copper–amyloid-b complexes can be specifically modified through either covalent conjugation, oxidation, or both. Considering the neurotoxic implications of the interactions between copper and amyloid-b, such modifications at the coordination sphere of copper in amyloid-b could effectively alter its properties and toxicity.”

“This multidisciplinary study with an emphasis on approaches, reactivities, and mechanisms looks forward to opening a new way to develop candidates of anti-neurodegenerative diseases,” she added. The National Research Foundation of Korea funded this research.

2020.03.03 View 7869 -

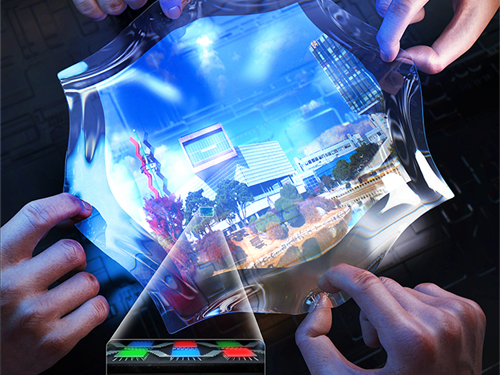

Stress-Relief Substrate Helps OLED Stretch Two-Dimensionally

Highly functional and free-form displays are critical components to complete the technological prowess of wearable electronics, robotics, and human-machine interfaces.

A KAIST team created stretchable OLEDs (Organic Light-Emitting Diodes) that are compliant and maintain their performance under high-strain deformation. Their stress-relief substrates have a unique structure and utilize pillar arrays to reduce the stress on the active areas of devices when strain is applied.

Traditional intrinsically stretchable OLEDs have commercial limitations due to their low efficiency in the electrical conductivity of the electrodes. In addition, previous geometrically stretchable OLEDs laminated to the elastic substrates with thin film devices lead to different pixel emissions of the devices from different peak sizes of the buckles.

To solve these problems, a research team led by Professor Kyung Cheol Choi designed a stretchable substrate system with surface relief island structures that relieve the stress at the locations of bridges in the devices. Their stretchable OLED devices contained an elastic substrate structure comprising bonded elastic pillars and bridges. A patterned upper substrate with bridges makes the rigid substrate stretchable, while the pillars decentralize the stress on the device.

Although various applications using micropillar arrays have been reported, it has not yet been reported how elastic pillar arrays can affect substrates by relieving the stress applied to those substrates upon stretching. Compared to results using similar layouts with conventional free-standing, flat substrates or island structures, their results with elastic pillar arrays show relatively low stress levels at both the bridges and plates when stretching the devices. They achieved stretchable RGB (red, green, blue) OLEDs and had no difficulties with material selection as practical processes were conducted with stress-relief substrates.

Their stretchable OLEDs were mechanically stable and have two-dimensional stretchability, which is superior to only one-direction stretchable electronics, opening the way for practical applications like wearable electronics and health monitoring systems.

Professor Choi said, “Our substrate design will impart flexibility into electronics technology development including semiconductor and circuit technologies. We look forward this new stretchable OLED lowering the barrier for entering the stretchable display market.”

This research was published in Nano Letters titled Two-Dimensionally Stretchable Organic Light-Emitting Diode with Elastic Pillar Arrays for Stress Relief. (https://dx.doi.org/10.1021/acs.nanolett.9b03657). This work was supported by the Engineering Research Center of Excellence Program supported by the National Research Foundation of Korea.

-Profile

Professor Kyung Cheol Choi

kyungcc@kaist.ac.kr

http://adnc.kaist.ac.kr/

School of Electrical Engineering

KAIST

2020.02.27 View 9675

Stress-Relief Substrate Helps OLED Stretch Two-Dimensionally

Highly functional and free-form displays are critical components to complete the technological prowess of wearable electronics, robotics, and human-machine interfaces.

A KAIST team created stretchable OLEDs (Organic Light-Emitting Diodes) that are compliant and maintain their performance under high-strain deformation. Their stress-relief substrates have a unique structure and utilize pillar arrays to reduce the stress on the active areas of devices when strain is applied.

Traditional intrinsically stretchable OLEDs have commercial limitations due to their low efficiency in the electrical conductivity of the electrodes. In addition, previous geometrically stretchable OLEDs laminated to the elastic substrates with thin film devices lead to different pixel emissions of the devices from different peak sizes of the buckles.

To solve these problems, a research team led by Professor Kyung Cheol Choi designed a stretchable substrate system with surface relief island structures that relieve the stress at the locations of bridges in the devices. Their stretchable OLED devices contained an elastic substrate structure comprising bonded elastic pillars and bridges. A patterned upper substrate with bridges makes the rigid substrate stretchable, while the pillars decentralize the stress on the device.

Although various applications using micropillar arrays have been reported, it has not yet been reported how elastic pillar arrays can affect substrates by relieving the stress applied to those substrates upon stretching. Compared to results using similar layouts with conventional free-standing, flat substrates or island structures, their results with elastic pillar arrays show relatively low stress levels at both the bridges and plates when stretching the devices. They achieved stretchable RGB (red, green, blue) OLEDs and had no difficulties with material selection as practical processes were conducted with stress-relief substrates.

Their stretchable OLEDs were mechanically stable and have two-dimensional stretchability, which is superior to only one-direction stretchable electronics, opening the way for practical applications like wearable electronics and health monitoring systems.

Professor Choi said, “Our substrate design will impart flexibility into electronics technology development including semiconductor and circuit technologies. We look forward this new stretchable OLED lowering the barrier for entering the stretchable display market.”

This research was published in Nano Letters titled Two-Dimensionally Stretchable Organic Light-Emitting Diode with Elastic Pillar Arrays for Stress Relief. (https://dx.doi.org/10.1021/acs.nanolett.9b03657). This work was supported by the Engineering Research Center of Excellence Program supported by the National Research Foundation of Korea.

-Profile

Professor Kyung Cheol Choi

kyungcc@kaist.ac.kr

http://adnc.kaist.ac.kr/

School of Electrical Engineering

KAIST

2020.02.27 View 9675 -

Professor Hojong Chang’s Research Team Wins ISIITA 2020 Best Paper Award

The paper written by Professor Hojong Chang’s research team from KAIST Institute for IT Convergence won the best paper award from the International Symposium on Innovation in Information Technology Application (ISIITA) 2020, held this month at Ton Duc Thang University in Vietnam.

ISIITA is a networking symposium where leading researchers from various fields including information and communications, biotechnology, and computer systems come together and share on the convergence of technology.

Professor Chang’s team won the best paper award at this year’s symposium with its paper, “A Study of Single Photon Counting System for Quantitative Analysis of Luminescence”. The awarded paper discusses the realization of a signal processing system for silicon photomultipliers.

The silicon photomultiplier is the core of a urinalysis technique that tests for sodium and potassium in the body using simple chemical reactions. If our bodily sodium and potassium levels exceed a certain amount, it can lead to high blood pressure, cardiovascular problems, and kidney damage.

Through this research, the team has developed a core technique that quantifies the sodium and potassium discharged in the urine. When the reagent is injected into the urine, a very small amount of light is emitted as a result of the chemical reaction. However, if there is a large amount of sodium and potassium, they interrupt the reaction and reduce the emission. The key to this measurement technique is digitizing the strength of this very fine emission of light. Professor Chang’s team developed a system that uses a photomultiplier to measure the chemiluminescence.

Professor Chang said, “I look forward for this signal processing system greatly helping to prevent diseases caused by the excessive consumption of sodium and potassium through quick and easy detection.”

Researcher Byunghun Han who carried out the central research for the system design added, “We are planning to focus on miniaturizing the developed technique, so that anyone can carry our device around like a cellphone.”

The research was supported by the Ministry of Science and ICT.

(END)

2020.02.27 View 10640

Professor Hojong Chang’s Research Team Wins ISIITA 2020 Best Paper Award

The paper written by Professor Hojong Chang’s research team from KAIST Institute for IT Convergence won the best paper award from the International Symposium on Innovation in Information Technology Application (ISIITA) 2020, held this month at Ton Duc Thang University in Vietnam.

ISIITA is a networking symposium where leading researchers from various fields including information and communications, biotechnology, and computer systems come together and share on the convergence of technology.

Professor Chang’s team won the best paper award at this year’s symposium with its paper, “A Study of Single Photon Counting System for Quantitative Analysis of Luminescence”. The awarded paper discusses the realization of a signal processing system for silicon photomultipliers.

The silicon photomultiplier is the core of a urinalysis technique that tests for sodium and potassium in the body using simple chemical reactions. If our bodily sodium and potassium levels exceed a certain amount, it can lead to high blood pressure, cardiovascular problems, and kidney damage.

Through this research, the team has developed a core technique that quantifies the sodium and potassium discharged in the urine. When the reagent is injected into the urine, a very small amount of light is emitted as a result of the chemical reaction. However, if there is a large amount of sodium and potassium, they interrupt the reaction and reduce the emission. The key to this measurement technique is digitizing the strength of this very fine emission of light. Professor Chang’s team developed a system that uses a photomultiplier to measure the chemiluminescence.

Professor Chang said, “I look forward for this signal processing system greatly helping to prevent diseases caused by the excessive consumption of sodium and potassium through quick and easy detection.”

Researcher Byunghun Han who carried out the central research for the system design added, “We are planning to focus on miniaturizing the developed technique, so that anyone can carry our device around like a cellphone.”

The research was supported by the Ministry of Science and ICT.

(END)

2020.02.27 View 10640 -

Professor Jong Chul Ye Appointed as Distinguished Lecturer of IEEE EMBS

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was appointed as a distinguished lecturer by the International Association of Electrical and Electronic Engineers (IEEE) Engineering in Medicine and Biology Society (EMBS). Professor Ye was invited to deliver a lecture on his leading research on artificial intelligence (AI) technology in medical video restoration. He will serve a term of two years beginning in 2020.

IEEE EMBS's distinguished lecturer program is designed to educate researchers around the world on the latest trends and technology in biomedical engineering. Sponsored by IEEE, its members can attend lectures on the distinguished professor's research subject.

Professor Ye said, "We are at a time where the importance of AI in medical imaging is increasing.” He added, “I am proud to be appointed as a distinguished lecturer of the IEEE EMBS in recognition of my contributions to this field.”

(END)

2020.02.27 View 11091

Professor Jong Chul Ye Appointed as Distinguished Lecturer of IEEE EMBS

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was appointed as a distinguished lecturer by the International Association of Electrical and Electronic Engineers (IEEE) Engineering in Medicine and Biology Society (EMBS). Professor Ye was invited to deliver a lecture on his leading research on artificial intelligence (AI) technology in medical video restoration. He will serve a term of two years beginning in 2020.

IEEE EMBS's distinguished lecturer program is designed to educate researchers around the world on the latest trends and technology in biomedical engineering. Sponsored by IEEE, its members can attend lectures on the distinguished professor's research subject.

Professor Ye said, "We are at a time where the importance of AI in medical imaging is increasing.” He added, “I am proud to be appointed as a distinguished lecturer of the IEEE EMBS in recognition of my contributions to this field.”

(END)

2020.02.27 View 11091 -

KAIST Launches AI Alliance with KT, Hyundai, ETRI, Hanyang University

KAIST launched the AI collaboration alliance “AI One Team” partnering with the nation’s top telecommunications company KT, the Electronics and Telecommunications Research Institute (ETRI), Hyundai Heavy Industries Holdings, and Hanyang University on February 21.

President Sung-Chul Shin signed the MOU with KT CEO Hyun-Mo Koo, Hyundai Heavy Industries Holdings Vice President Ki-Sun Chung, President Myung Joon Kim of ETRI, and Hanyang University President Woo-Seung Kim to help the nation’s AI technology stay ahead of the global level. Vice Minister of Science and ICT Seokyoung Jang also attended the signing ceremony held at KAIST.

Four parties representing the government, industry, research institutes, and universities all agreed to collaborate to establish an educational platform fostering AI talents; develop AI technologies applicable to industrial sites; nurture an AI technology eco-system that will embrace SEMs and venture companies; and incubate startups to help improve their technological competitiveness.

KAIST will take the lead in fostering AI talents in collaboration with ETRI and Hanyang University, offering an online/offline educational program featuring AI curricula that will be practically applicable to the industry. The alliance will also create a platform that will match job seekers and companies, especially for SMEs and venture firms that are having trouble finding competitive experts.

Hyundai Heavy Industries Holdings is focusing on developing technologies in the fields of robotics and smart factories. Hyundai’s collaboration with KT is pushing the digital transformation in the new domains of 5G-based robots and smart factories. The two companies plan to expand their technological know-how to SMEs, venture firms, and startups. The secretariat of the AI One Team will facilitate collaborative projects among the partners to help produce tangible results.

President Shin expressed his high hopes on this alliance for AI technology. He declared, “The winner takes all in the field of AI. Our close collaboration will pave the way for Korea, and each of our partners will lead AI technology in the global market. We will spare no effort for this alliance.”

2020.02.21 View 5383

KAIST Launches AI Alliance with KT, Hyundai, ETRI, Hanyang University

KAIST launched the AI collaboration alliance “AI One Team” partnering with the nation’s top telecommunications company KT, the Electronics and Telecommunications Research Institute (ETRI), Hyundai Heavy Industries Holdings, and Hanyang University on February 21.

President Sung-Chul Shin signed the MOU with KT CEO Hyun-Mo Koo, Hyundai Heavy Industries Holdings Vice President Ki-Sun Chung, President Myung Joon Kim of ETRI, and Hanyang University President Woo-Seung Kim to help the nation’s AI technology stay ahead of the global level. Vice Minister of Science and ICT Seokyoung Jang also attended the signing ceremony held at KAIST.

Four parties representing the government, industry, research institutes, and universities all agreed to collaborate to establish an educational platform fostering AI talents; develop AI technologies applicable to industrial sites; nurture an AI technology eco-system that will embrace SEMs and venture companies; and incubate startups to help improve their technological competitiveness.

KAIST will take the lead in fostering AI talents in collaboration with ETRI and Hanyang University, offering an online/offline educational program featuring AI curricula that will be practically applicable to the industry. The alliance will also create a platform that will match job seekers and companies, especially for SMEs and venture firms that are having trouble finding competitive experts.

Hyundai Heavy Industries Holdings is focusing on developing technologies in the fields of robotics and smart factories. Hyundai’s collaboration with KT is pushing the digital transformation in the new domains of 5G-based robots and smart factories. The two companies plan to expand their technological know-how to SMEs, venture firms, and startups. The secretariat of the AI One Team will facilitate collaborative projects among the partners to help produce tangible results.

President Shin expressed his high hopes on this alliance for AI technology. He declared, “The winner takes all in the field of AI. Our close collaboration will pave the way for Korea, and each of our partners will lead AI technology in the global market. We will spare no effort for this alliance.”

2020.02.21 View 5383 -

Professor Minsoo Rhu Recognized as Facebook Research Scholar

Professor Minsoo Rhu from the School of Electrical Engineering was selected as the recipient of the Systems for Machine Learning Research Awards presented by Facebook.

Facebook launched the award last year with the goal of funding impactful solutions in the areas of developer tookits, compilers and code generation, system architecture, memory technologies, and machine learning accelerator support.

A total of 167 scholars from 100 universities representing 26 countries submitted research proposals, and Facebook selected final 10 scholars. Professor Rhu made the list with his research topic ‘A Near-Memory Processing Architecture for Training Recommendation Systems.’ He will receive 5,000 USD in research funds at the award ceremony which will take place during this year’s AI Systems Faculty Summit at the Facebook headquarters in Menlo Park, California.

Professor Rhu’s submission was based on research on ‘Memory-Centric Deep Learning System Architecture’ that he carried out for three years under the auspices of Samsung Science and Technology Foundation from 2017. It was an academic-industrial cooperation research project in which leading domestic companies like Samsung Electronics and SK Hynix collaborated to make a foray into the global memory-centric smart system semiconductor market.

Professor Rhu who joined KAIST in 2018 has led various systems research projects to accelerate the AI computing technology while working at NVIDIA headquarters from 2014.

(END)

2020.02.21 View 10226

Professor Minsoo Rhu Recognized as Facebook Research Scholar

Professor Minsoo Rhu from the School of Electrical Engineering was selected as the recipient of the Systems for Machine Learning Research Awards presented by Facebook.

Facebook launched the award last year with the goal of funding impactful solutions in the areas of developer tookits, compilers and code generation, system architecture, memory technologies, and machine learning accelerator support.

A total of 167 scholars from 100 universities representing 26 countries submitted research proposals, and Facebook selected final 10 scholars. Professor Rhu made the list with his research topic ‘A Near-Memory Processing Architecture for Training Recommendation Systems.’ He will receive 5,000 USD in research funds at the award ceremony which will take place during this year’s AI Systems Faculty Summit at the Facebook headquarters in Menlo Park, California.

Professor Rhu’s submission was based on research on ‘Memory-Centric Deep Learning System Architecture’ that he carried out for three years under the auspices of Samsung Science and Technology Foundation from 2017. It was an academic-industrial cooperation research project in which leading domestic companies like Samsung Electronics and SK Hynix collaborated to make a foray into the global memory-centric smart system semiconductor market.

Professor Rhu who joined KAIST in 2018 has led various systems research projects to accelerate the AI computing technology while working at NVIDIA headquarters from 2014.

(END)

2020.02.21 View 10226 -

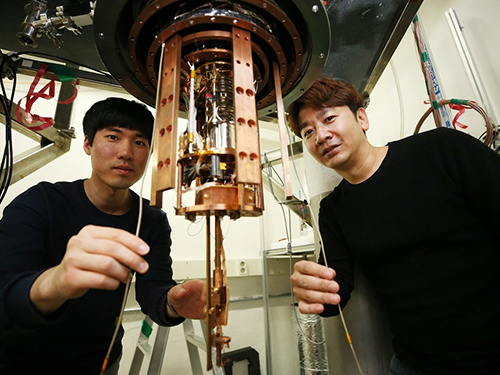

Black Phosphorous Tunnel Field-Effect Transistor as an Alternative Ultra-low Power Switch

Researchers have reported a black phosphorus transistor that can be used as an alternative ultra-low power switch. A research team led by Professor Sungjae Cho in the KAIST Department of Physics developed a thickness-controlled black phosphorous tunnel field-effect transistor (TFET) that shows 10-times lower switching power consumption as well as 10,000-times lower standby power consumption than conventional complementary metal-oxide-semiconductor (CMOS) transistors.

The research team said they developed fast and low-power transistors that can replace conventional CMOS transistors. In particular, they solved problems that have degraded TFET operation speed and performance, paving the way to extend Moore’s Law.

In the study featured in Nature Nanotechnology last month, Professor Cho’s team reported a natural heterojunction TFET with spatially varying layer thickness in black phosphorous without interface problems. They achieved record-low average subthreshold swing values over 4-5 dec of current and record-high, on-state current, which allows the TFETs to operate as fast as conventional CMOS transistors with as much lower power consumption.

"We successfully developed the first transistor that achieved the essential criteria for fast, low-power switching. Our newly developed TFETs can replace CMOS transistors by solving a major issue regarding the performance degradation of TFETs,"Professor Cho said.

The continuous down-scaling of transistors has been the key to the successful development of current information technology. However, with Moore’s Law reaching its limits due to the increased power consumption, the development of new alternative transistor designs has emerged as an urgent need.

Reducing both switching and standby power consumption while further scaling transistors requires overcoming the thermionic limit of subthreshold swing, which is defined as the required voltage per ten-fold current increase in the subthreshold region. In order to reduce both the switching and standby power of CMOS circuits, it is critical to reduce the subthreshold swing of the transistors.

However, there is fundamental subthreshold swing limit of 60 mV/dec in CMOS transistors, which originates from thermal carrier injection. The International Roadmap for Devices and Systems has already predicted that new device geometries with new materials beyond CMOS will be required to address transistor scaling challenges in the near future. In particular, TFETs have been suggested as a major alternative to CMOS transistors, since the subthreshold swing in TFETs can be substantially reduced below the thermionic limit of 60 mV/dec. TFETs operate via quantum tunneling, which does not limit subthreshold swing as in thermal injection of CMOS transistors.

In particular, heterojunction TFETs hold significant promise for delivering both low subthreshold swing and high on-state current. High on-current is essential for the fast operation of transistors since charging a device to on state takes a longer time with lower currents. Unlike theoretical expectations, previously developed heterojunction TFETs show 100-100,000x lower on-state current (100-100,000x slower operation speeds) than CMOS transistors due to interface problems in the heterojunction. This low operation speed impedes the replacement of CMOS transistors with low-power TFETs.

Professor Cho said, “We have demonstrated for the first time, to the best of our knowledge, TFET optimization for both fast and ultra-low-power operations, which is essential to replace CMOS transistors for low-power applications.” He said he is very delighted to extend Moore’s Law, which may eventually affect almost every aspect of life and society. This study (https://doi.org/10.1038/s41565-019-0623-7) was supported by the National Research Foundation of Korea.

Publication:

Kim et al. (2020) Thickness-controlled black phosphorus tunnel field-effect transistor for low-power switches. Nature Nanotechnology. Available online at https://doi.org/10.1038/s41565-019-0623-7

Profile:

Professor Sungjae Cho

sungjae.cho@kaist.ac.kr

Department of Physics

http://qtak.kaist.ac.kr/

KAIST

Profile:

Seungho Kim, PhD Candidate

krksh21@kaist.ac.kr

Department of Physics

http://qtak.kaist.ac.kr/

KAIST

(END)

2020.02.21 View 12494

Black Phosphorous Tunnel Field-Effect Transistor as an Alternative Ultra-low Power Switch

Researchers have reported a black phosphorus transistor that can be used as an alternative ultra-low power switch. A research team led by Professor Sungjae Cho in the KAIST Department of Physics developed a thickness-controlled black phosphorous tunnel field-effect transistor (TFET) that shows 10-times lower switching power consumption as well as 10,000-times lower standby power consumption than conventional complementary metal-oxide-semiconductor (CMOS) transistors.

The research team said they developed fast and low-power transistors that can replace conventional CMOS transistors. In particular, they solved problems that have degraded TFET operation speed and performance, paving the way to extend Moore’s Law.

In the study featured in Nature Nanotechnology last month, Professor Cho’s team reported a natural heterojunction TFET with spatially varying layer thickness in black phosphorous without interface problems. They achieved record-low average subthreshold swing values over 4-5 dec of current and record-high, on-state current, which allows the TFETs to operate as fast as conventional CMOS transistors with as much lower power consumption.

"We successfully developed the first transistor that achieved the essential criteria for fast, low-power switching. Our newly developed TFETs can replace CMOS transistors by solving a major issue regarding the performance degradation of TFETs,"Professor Cho said.

The continuous down-scaling of transistors has been the key to the successful development of current information technology. However, with Moore’s Law reaching its limits due to the increased power consumption, the development of new alternative transistor designs has emerged as an urgent need.

Reducing both switching and standby power consumption while further scaling transistors requires overcoming the thermionic limit of subthreshold swing, which is defined as the required voltage per ten-fold current increase in the subthreshold region. In order to reduce both the switching and standby power of CMOS circuits, it is critical to reduce the subthreshold swing of the transistors.

However, there is fundamental subthreshold swing limit of 60 mV/dec in CMOS transistors, which originates from thermal carrier injection. The International Roadmap for Devices and Systems has already predicted that new device geometries with new materials beyond CMOS will be required to address transistor scaling challenges in the near future. In particular, TFETs have been suggested as a major alternative to CMOS transistors, since the subthreshold swing in TFETs can be substantially reduced below the thermionic limit of 60 mV/dec. TFETs operate via quantum tunneling, which does not limit subthreshold swing as in thermal injection of CMOS transistors.

In particular, heterojunction TFETs hold significant promise for delivering both low subthreshold swing and high on-state current. High on-current is essential for the fast operation of transistors since charging a device to on state takes a longer time with lower currents. Unlike theoretical expectations, previously developed heterojunction TFETs show 100-100,000x lower on-state current (100-100,000x slower operation speeds) than CMOS transistors due to interface problems in the heterojunction. This low operation speed impedes the replacement of CMOS transistors with low-power TFETs.

Professor Cho said, “We have demonstrated for the first time, to the best of our knowledge, TFET optimization for both fast and ultra-low-power operations, which is essential to replace CMOS transistors for low-power applications.” He said he is very delighted to extend Moore’s Law, which may eventually affect almost every aspect of life and society. This study (https://doi.org/10.1038/s41565-019-0623-7) was supported by the National Research Foundation of Korea.

Publication:

Kim et al. (2020) Thickness-controlled black phosphorus tunnel field-effect transistor for low-power switches. Nature Nanotechnology. Available online at https://doi.org/10.1038/s41565-019-0623-7

Profile:

Professor Sungjae Cho

sungjae.cho@kaist.ac.kr

Department of Physics

http://qtak.kaist.ac.kr/

KAIST

Profile:

Seungho Kim, PhD Candidate

krksh21@kaist.ac.kr

Department of Physics

http://qtak.kaist.ac.kr/

KAIST

(END)

2020.02.21 View 12494 -

Jeju Inspired Packaging by ID+IM Design Lab Wins 2020 iF Design Award

A water bottle designed by researchers from the ID+IM Design Laboratory led by Professor Sangmin Bae from the Department of Industrial Design won the packaging section of the 2020 iF Design Award.

The iF Design Award, hosted by the Hannover Exhibition Center in Germany, is one of the three major international design competitions. It receives more than 7,000 submissions from participants representing 60 countries.

The Jeju Yong-Am-Soo (which means ‘volcanic mineral water’ in English) bottle design was a product of an academic-industrial cooperation project carried out by Professor Bae’s team and a Korean confectionery company, Orion Corporation, to create a design for a premium mineral water bottle.

The motif of the awarded design was the beautiful nature of Jeju Island in Korea. The columnar joints and the horizon of Jeju Island were each represented by horizontal and vertical lines, completing a simple yet sensuous design.

The mystical volcanic Mount Halla printed on the transparent front-label of the bottle represents the daytime of Jeju Island, while the rear-label design, which is reflected through the transparent front-label, symbolizes the nighttime of Jeju Island. By putting the Orion constellation, a symbol of tourist’s guide, right above the Orion Corporation’s brand logo, Professor Bae’s team ambiently promotes the company’s identity.

Although the design uses a significantly smaller amount of materials than traditional water bottles, it can withstand about four times the pressure and weight. The efficient structure therefore shows excellence in both aesthetic and functional areas.

Professor Bae said, “I am happy with the fact that the result of this academic-industrial cooperation project became mass-produced through commercialization and was recognized by an international design award.” He continued, “Even though it was difficult for my team to come up with the design that fits both manufacturing and the distribution processes, we worked hard to achieve the structural and functional aspects, while also expressing beauty through its appearance.”

(END)

2020.02.20 View 7218

Jeju Inspired Packaging by ID+IM Design Lab Wins 2020 iF Design Award

A water bottle designed by researchers from the ID+IM Design Laboratory led by Professor Sangmin Bae from the Department of Industrial Design won the packaging section of the 2020 iF Design Award.

The iF Design Award, hosted by the Hannover Exhibition Center in Germany, is one of the three major international design competitions. It receives more than 7,000 submissions from participants representing 60 countries.

The Jeju Yong-Am-Soo (which means ‘volcanic mineral water’ in English) bottle design was a product of an academic-industrial cooperation project carried out by Professor Bae’s team and a Korean confectionery company, Orion Corporation, to create a design for a premium mineral water bottle.

The motif of the awarded design was the beautiful nature of Jeju Island in Korea. The columnar joints and the horizon of Jeju Island were each represented by horizontal and vertical lines, completing a simple yet sensuous design.

The mystical volcanic Mount Halla printed on the transparent front-label of the bottle represents the daytime of Jeju Island, while the rear-label design, which is reflected through the transparent front-label, symbolizes the nighttime of Jeju Island. By putting the Orion constellation, a symbol of tourist’s guide, right above the Orion Corporation’s brand logo, Professor Bae’s team ambiently promotes the company’s identity.

Although the design uses a significantly smaller amount of materials than traditional water bottles, it can withstand about four times the pressure and weight. The efficient structure therefore shows excellence in both aesthetic and functional areas.

Professor Bae said, “I am happy with the fact that the result of this academic-industrial cooperation project became mass-produced through commercialization and was recognized by an international design award.” He continued, “Even though it was difficult for my team to come up with the design that fits both manufacturing and the distribution processes, we worked hard to achieve the structural and functional aspects, while also expressing beauty through its appearance.”

(END)

2020.02.20 View 7218 -

New Graphene-Based Metasurface Capable of Independent Amplitude and Phase Control of Light

Researchers described a new strategy of designing metamolecules that incorporates two independently controllable subwavelength meta-atoms. This two-parametric control of the metamolecule secures the complete control of both amplitude and the phase of light.

A KAIST research team in collaboration with the University of Wisconsin-Madison theoretically suggested a graphene-based active metasurface capable of independent amplitude and phase control of mid-infrared light. This research gives a new insight into modulating the mid-infrared wavefront with high resolution by solving the problem of the independent control of light amplitude and phase, which has remained a long-standing challenge.

Light modulation technology is essential for developing future optical devices such as holography, high-resolution imaging, and optical communication systems. Liquid crystals and a microelectromechanical system (MEMS) have previously been utilized to modulate light. However, both methods suffer from significantly limited driving speeds and unit pixel sizes larger than the diffraction limit, which consequently prevent their integration into photonic systems.

The metasurface platform is considered a strong candidate for the next generation of light modulation technology. Metasurfaces have optical properties that natural materials cannot have, and can overcome the limitations of conventional optical systems, such as forming a high-resolution image beyond the diffraction limit. In particular, the active metasurface is regarded as a technology with a wide range of applications due to its tunable optical characteristics with an electrical signal.

However, the previous active metasurfaces suffered from the inevitable correlation between light amplitude control and phase control. This problem is caused by the modulation mechanism of conventional metasurfaces. Conventional metasurfaces have been designed such that a metaatom only has one resonance condition, but a single resonant design inherently lacks the degrees of freedom to independently control the amplitude and phase of light.

The research team made a metaunit by combining two independently controllable metaatoms, dramatically improving the modulation range of active metasurfaces. The proposed metasurface can control the amplitude and phase of the mid-infrared light independently with a resolution beyond the diffraction limit, thus allowing complete control of the optical wavefront.

The research team theoretically confirmed the performance of the proposed active metasurface and the possibility of wavefront shaping using this design method. Furthermore, they developed an analytical method that can approximate the optical properties of metasurfaces without complex electromagnetic simulations. This analytical platform proposes a more intuitive and comprehensively applicable metasurface design guideline.

The proposed technology is expected to enable accurate wavefront shaping with a much higher spatial resolution than existing wavefront shaping technologies, which will be applied to active optical systems such as mid-infrared holography, high-speed beam steering devices that can be applied for LiDAR, and variable focus infrared lenses.

Professor Min Seok Jang commented, "This study showed the independent control amplitude and phase of light, which has been a long-standing quest in light modulator technology. The development of optical devices using complex wavefront control is expected to become more active in the future."

MS candidate Sangjun Han and Dr. Seyoon Kim of the University of Wisconsin-Madison are the co-first authors of the research, which was published and selected as the front cover of the January 28 edition of ACS Nano titled “Complete complex amplitude modulation with electronically tunable graphene plasmonic metamolecules.”

This research was funded by the Samsung Research Funding & Incubation Center for Future Technology.

Publication:

Han et al. (2020) Complete Complex Amplitude Modulation with Electronically Tunable Graphene Plasmonic Metamolecules. ACS Nano, Vol. 14, Issue 1, pp. 1166-1175. Available online at https://doi.org/10.1021/acsnano.9b09277

Profile: Prof. Min Seok Jang, MS, PhD

jang.minseok@kaist.ac.kr

http://jlab.kaist.ac.kr/

Associate Professor

Jang Research Group

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Sangjun Han

sangjun.han@kaist.ac.kr

MS Candidate

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.20 View 9774

New Graphene-Based Metasurface Capable of Independent Amplitude and Phase Control of Light

Researchers described a new strategy of designing metamolecules that incorporates two independently controllable subwavelength meta-atoms. This two-parametric control of the metamolecule secures the complete control of both amplitude and the phase of light.

A KAIST research team in collaboration with the University of Wisconsin-Madison theoretically suggested a graphene-based active metasurface capable of independent amplitude and phase control of mid-infrared light. This research gives a new insight into modulating the mid-infrared wavefront with high resolution by solving the problem of the independent control of light amplitude and phase, which has remained a long-standing challenge.

Light modulation technology is essential for developing future optical devices such as holography, high-resolution imaging, and optical communication systems. Liquid crystals and a microelectromechanical system (MEMS) have previously been utilized to modulate light. However, both methods suffer from significantly limited driving speeds and unit pixel sizes larger than the diffraction limit, which consequently prevent their integration into photonic systems.

The metasurface platform is considered a strong candidate for the next generation of light modulation technology. Metasurfaces have optical properties that natural materials cannot have, and can overcome the limitations of conventional optical systems, such as forming a high-resolution image beyond the diffraction limit. In particular, the active metasurface is regarded as a technology with a wide range of applications due to its tunable optical characteristics with an electrical signal.

However, the previous active metasurfaces suffered from the inevitable correlation between light amplitude control and phase control. This problem is caused by the modulation mechanism of conventional metasurfaces. Conventional metasurfaces have been designed such that a metaatom only has one resonance condition, but a single resonant design inherently lacks the degrees of freedom to independently control the amplitude and phase of light.

The research team made a metaunit by combining two independently controllable metaatoms, dramatically improving the modulation range of active metasurfaces. The proposed metasurface can control the amplitude and phase of the mid-infrared light independently with a resolution beyond the diffraction limit, thus allowing complete control of the optical wavefront.

The research team theoretically confirmed the performance of the proposed active metasurface and the possibility of wavefront shaping using this design method. Furthermore, they developed an analytical method that can approximate the optical properties of metasurfaces without complex electromagnetic simulations. This analytical platform proposes a more intuitive and comprehensively applicable metasurface design guideline.

The proposed technology is expected to enable accurate wavefront shaping with a much higher spatial resolution than existing wavefront shaping technologies, which will be applied to active optical systems such as mid-infrared holography, high-speed beam steering devices that can be applied for LiDAR, and variable focus infrared lenses.

Professor Min Seok Jang commented, "This study showed the independent control amplitude and phase of light, which has been a long-standing quest in light modulator technology. The development of optical devices using complex wavefront control is expected to become more active in the future."

MS candidate Sangjun Han and Dr. Seyoon Kim of the University of Wisconsin-Madison are the co-first authors of the research, which was published and selected as the front cover of the January 28 edition of ACS Nano titled “Complete complex amplitude modulation with electronically tunable graphene plasmonic metamolecules.”

This research was funded by the Samsung Research Funding & Incubation Center for Future Technology.

Publication:

Han et al. (2020) Complete Complex Amplitude Modulation with Electronically Tunable Graphene Plasmonic Metamolecules. ACS Nano, Vol. 14, Issue 1, pp. 1166-1175. Available online at https://doi.org/10.1021/acsnano.9b09277

Profile: Prof. Min Seok Jang, MS, PhD

jang.minseok@kaist.ac.kr

http://jlab.kaist.ac.kr/

Associate Professor

Jang Research Group

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Sangjun Han

sangjun.han@kaist.ac.kr

MS Candidate

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.20 View 9774 -

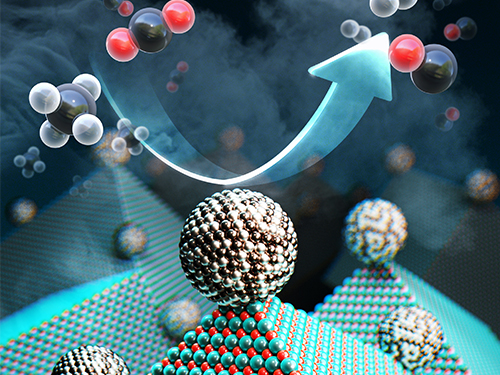

New Catalyst Recycles Greenhouse Gases into Fuel and Hydrogen Gas

< Professor Cafer T. Yavuz (left), PhD Candidate Youngdong Song (center), and Researcher Sreerangappa Ramesh (right) >

Scientists have taken a major step toward a circular carbon economy by developing a long-lasting, economical catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas, and other chemicals. The results could be revolutionary in the effort to reverse global warming, according to the researchers. The study was published on February 14 in Science.

“We set out to develop an effective catalyst that can convert large amounts of the greenhouse gases carbon dioxide and methane without failure,” said Cafer T. Yavuz, paper author and associate professor of chemical and biomolecular engineering and of chemistry at KAIST.

The catalyst, made from inexpensive and abundant nickel, magnesium, and molybdenum, initiates and speeds up the rate of reaction that converts carbon dioxide and methane into hydrogen gas. It can work efficiently for more than a month.

This conversion is called ‘dry reforming’, where harmful gases, such as carbon dioxide, are processed to produce more useful chemicals that could be refined for use in fuel, plastics, or even pharmaceuticals. It is an effective process, but it previously required rare and expensive metals such as platinum and rhodium to induce a brief and inefficient chemical reaction.

Other researchers had previously proposed nickel as a more economical solution, but carbon byproducts would build up and the surface nanoparticles would bind together on the cheaper metal, fundamentally changing the composition and geometry of the catalyst and rendering it useless.

“The difficulty arises from the lack of control on scores of active sites over the bulky catalysts surfaces because any refinement procedures attempted also change the nature of the catalyst itself,” Yavuz said.

The researchers produced nickel-molybdenum nanoparticles under a reductive environment in the presence of a single crystalline magnesium oxide. As the ingredients were heated under reactive gas, the nanoparticles moved on the pristine crystal surface seeking anchoring points. The resulting activated catalyst sealed its own high-energy active sites and permanently fixed the location of the nanoparticles — meaning that the nickel-based catalyst will not have a carbon build up, nor will the surface particles bind to one another.

“It took us almost a year to understand the underlying mechanism,” said first author Youngdong Song, a graduate student in the Department of Chemical and Biomolecular Engineering at KAIST. “Once we studied all the chemical events in detail, we were shocked.”

The researchers dubbed the catalyst Nanocatalysts on Single Crystal Edges (NOSCE). The magnesium-oxide nanopowder comes from a finely structured form of magnesium oxide, where the molecules bind continuously to the edge. There are no breaks or defects in the surface, allowing for uniform and predictable reactions.

“Our study solves a number of challenges the catalyst community faces,” Yavuz said. “We believe the NOSCE mechanism will improve other inefficient catalytic reactions and provide even further savings of greenhouse gas emissions.”

This work was supported, in part, by the Saudi-Aramco-KAIST CO2 Management Center and the National Research Foundation of Korea.

Other contributors include Ercan Ozdemir, Sreerangappa Ramesh, Aldiar Adishev, and Saravanan Subramanian, all of whom are affiliated with the Graduate School of Energy, Environment, Water and Sustainability at KAIST; Aadesh Harale, Mohammed Albuali, Bandar Abdullah Fadhel, and Aqil Jamal, all of whom are with the Research and Development Center in Saudi Arabia; and Dohyun Moon and Sun Hee Choi, both of whom are with the Pohang Accelerator Laboratory in Korea. Ozdemir is also affiliated with the Institute of Nanotechnology at the Gebze Technical University in Turkey; Fadhel and Jamal are also affiliated with the Saudi-Armco-KAIST CO2 Management Center in Korea.

<Newly developed catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas and other chemicals.>

Publication:

Song et al. (2020) Dry reforming of methane by stable Ni–Mo nanocatalysts on single-crystalline MgO. Science, Vol. 367, Issue 6479, pp. 777-781. Available online at http://dx.doi.org/10.1126/science.aav2412

Profile: Prof. Cafer T. Yavuz, MA, PhD

yavuz@kaist.ac.kr

http://yavuz.kaist.ac.kr/

Associate Professor

Oxide and Organic Nanomaterials for the Environment (ONE) Laboratory

Graduate School of Energy, Environment, Water and Sustainability (EEWS)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Youngdong Song ydsong88@kaist.ac.kr

Ph.D. Candidate

Department of Chemical and Biomolecular Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.17 View 17724

New Catalyst Recycles Greenhouse Gases into Fuel and Hydrogen Gas

< Professor Cafer T. Yavuz (left), PhD Candidate Youngdong Song (center), and Researcher Sreerangappa Ramesh (right) >

Scientists have taken a major step toward a circular carbon economy by developing a long-lasting, economical catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas, and other chemicals. The results could be revolutionary in the effort to reverse global warming, according to the researchers. The study was published on February 14 in Science.

“We set out to develop an effective catalyst that can convert large amounts of the greenhouse gases carbon dioxide and methane without failure,” said Cafer T. Yavuz, paper author and associate professor of chemical and biomolecular engineering and of chemistry at KAIST.

The catalyst, made from inexpensive and abundant nickel, magnesium, and molybdenum, initiates and speeds up the rate of reaction that converts carbon dioxide and methane into hydrogen gas. It can work efficiently for more than a month.

This conversion is called ‘dry reforming’, where harmful gases, such as carbon dioxide, are processed to produce more useful chemicals that could be refined for use in fuel, plastics, or even pharmaceuticals. It is an effective process, but it previously required rare and expensive metals such as platinum and rhodium to induce a brief and inefficient chemical reaction.

Other researchers had previously proposed nickel as a more economical solution, but carbon byproducts would build up and the surface nanoparticles would bind together on the cheaper metal, fundamentally changing the composition and geometry of the catalyst and rendering it useless.

“The difficulty arises from the lack of control on scores of active sites over the bulky catalysts surfaces because any refinement procedures attempted also change the nature of the catalyst itself,” Yavuz said.

The researchers produced nickel-molybdenum nanoparticles under a reductive environment in the presence of a single crystalline magnesium oxide. As the ingredients were heated under reactive gas, the nanoparticles moved on the pristine crystal surface seeking anchoring points. The resulting activated catalyst sealed its own high-energy active sites and permanently fixed the location of the nanoparticles — meaning that the nickel-based catalyst will not have a carbon build up, nor will the surface particles bind to one another.

“It took us almost a year to understand the underlying mechanism,” said first author Youngdong Song, a graduate student in the Department of Chemical and Biomolecular Engineering at KAIST. “Once we studied all the chemical events in detail, we were shocked.”

The researchers dubbed the catalyst Nanocatalysts on Single Crystal Edges (NOSCE). The magnesium-oxide nanopowder comes from a finely structured form of magnesium oxide, where the molecules bind continuously to the edge. There are no breaks or defects in the surface, allowing for uniform and predictable reactions.

“Our study solves a number of challenges the catalyst community faces,” Yavuz said. “We believe the NOSCE mechanism will improve other inefficient catalytic reactions and provide even further savings of greenhouse gas emissions.”

This work was supported, in part, by the Saudi-Aramco-KAIST CO2 Management Center and the National Research Foundation of Korea.

Other contributors include Ercan Ozdemir, Sreerangappa Ramesh, Aldiar Adishev, and Saravanan Subramanian, all of whom are affiliated with the Graduate School of Energy, Environment, Water and Sustainability at KAIST; Aadesh Harale, Mohammed Albuali, Bandar Abdullah Fadhel, and Aqil Jamal, all of whom are with the Research and Development Center in Saudi Arabia; and Dohyun Moon and Sun Hee Choi, both of whom are with the Pohang Accelerator Laboratory in Korea. Ozdemir is also affiliated with the Institute of Nanotechnology at the Gebze Technical University in Turkey; Fadhel and Jamal are also affiliated with the Saudi-Armco-KAIST CO2 Management Center in Korea.

<Newly developed catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas and other chemicals.>

Publication:

Song et al. (2020) Dry reforming of methane by stable Ni–Mo nanocatalysts on single-crystalline MgO. Science, Vol. 367, Issue 6479, pp. 777-781. Available online at http://dx.doi.org/10.1126/science.aav2412

Profile: Prof. Cafer T. Yavuz, MA, PhD

yavuz@kaist.ac.kr

http://yavuz.kaist.ac.kr/

Associate Professor

Oxide and Organic Nanomaterials for the Environment (ONE) Laboratory

Graduate School of Energy, Environment, Water and Sustainability (EEWS)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Youngdong Song ydsong88@kaist.ac.kr

Ph.D. Candidate

Department of Chemical and Biomolecular Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.17 View 17724 -

What Fuels a “Domino Effect” in Cancer Drug Resistance?

KAIST researchers have identified mechanisms that relay prior acquired resistance to the first-line chemotherapy to the second-line targeted therapy, fueling a “domino effect” in cancer drug resistance. Their study featured in the February 7 edition of Science Advances suggests a new strategy for improving the second-line setting of cancer treatment for patients who showed resistance to anti-cancer drugs.

Resistance to cancer drugs is often managed in the clinic by chemotherapy and targeted therapy. Unlike chemotherapy that works by repressing fast-proliferating cells, targeted therapy blocks a single oncogenic pathway to halt tumor growth. In many cases, targeted therapy is engaged as a maintenance therapy or employed in the second-line after front-line chemotherapy.

A team of researchers led by Professor Yoosik Kim from the Department of Chemical and Biomolecular Engineering and the KAIST Institute for Health Science and Technology (KIHST) has discovered an unexpected resistance signature that occurs between chemotherapy and targeted therapy. The team further identified a set of integrated mechanisms that promotes this kind of sequential therapy resistance.

“There have been multiple clinical accounts reflecting that targeted therapies tend to be least successful in patients who have exhausted all standard treatments,” said the first author of the paper Mark Borris D. Aldonza. He continued, “These accounts ignited our hypothesis that failed responses to some chemotherapies might speed up the evolution of resistance to other drugs, particularly those with specific targets.”

Aldonza and his colleagues extracted large amounts of drug-resistance information from the open-source database the Genomics of Drug Sensitivity in Cancer (GDSC), which contains thousands of drug response data entries from various human cancer cell lines. Their big data analysis revealed that cancer cell lines resistant to chemotherapies classified as anti-mitotic drugs (AMDs), toxins that inhibit overacting cell division, are also resistant to a class of targeted therapies called epidermal growth factor receptor-tyrosine kinase inhibitors (EGFR-TKIs).

In all of the cancer types analyzed, more than 84 percent of those resistant to AMDs, representatively ‘paclitaxel’, were also resistant to at least nine EGFR-TKIs. In lung, pancreatic, and breast cancers where paclitaxel is often used as a first-line, standard-of-care regimen, greater than 92 percent showed resistance to EGFR-TKIs. Professor Kim said, “It is surprising to see that such collateral resistance can occur specifically between two chemically different classes of drugs.”

To figure out how failed responses to paclitaxel leads to resistance to EGFR-TKIs, the team validated co-resistance signatures that they found in the database by generating and analyzing a subset of slow-doubling, paclitaxel-resistant cancer models called ‘persisters’.

The results demonstrated that paclitaxel-resistant cancers remodel their stress response by first becoming more stem cell-like, evolving the ability to self-renew to adapt to more stressful conditions like drug exposures. More surprisingly, when the researchers characterized the metabolic state of the cells, EGFR-TKI persisters derived from paclitaxel-resistant cancer cells showed high dependencies to energy-producing processes such as glycolysis and glutaminolysis.

“We found that, without an energy stimulus like glucose, these cells transform to becoming more senescent, a characteristic of cells that have arrested cell division. However, this senescence is controlled by stem cell factors, which the paclitaxel-resistant cancers use to escape from this arrested state given a favorable condition to re-grow,” said Aldonza.

Professor Kim explained, “Before this research, there was no reason to expect that acquiring the cancer stem cell phenotype that dramatically leads to a cascade of changes in cellular states affecting metabolism and cell death is linked with drug-specific sequential resistance between two classes of therapies.”

He added, “The expansion of our work to other working models of drug resistance in a much more clinically-relevant setting, perhaps in clinical trials, will take on increasing importance, as sequential treatment strategies will continue to be adapted to various forms of anti-cancer therapy regimens.”

This study was supported by the Basic Science Research Program of the National Research Foundation of Korea (NRF-2016R1C1B2009886), and the KAIST Future Systems Healthcare Project (KAISTHEALTHCARE42) funded by the Korean Ministry of Science and ICT (MSIT). Undergraduate student Aldonza participated in this research project and presented the findings as the lead author as part of the Undergraduate Research Participation (URP) Program at KAIST.

< Figure 1. Schematic overview of the study. >

< Figure 2. Big data analysis revealing co-resistance signatures between classes of anti-cancer drugs. >

Publication:

Aldonza et al. (2020) Prior acquired resistance to paclitaxel relays diverse EGFR-targeted therapy persistence mechanisms. Science Advances, Vol. 6, No. 6, eaav7416. Available online at http://dx.doi.org/10.1126/sciadv.aav7416

Profile: Prof. Yoosik Kim, MA, PhD

ysyoosik@kaist.ac.kr

https://qcbio.kaist.ac.kr/

Assistant Professor

Bio Network Analysis Laboratory

Department of Chemical and Biomolecular Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Mark Borris D. Aldonza

borris@kaist.ac.kr

Undergraduate Student

Department of Biological Sciences

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.10 View 14856

What Fuels a “Domino Effect” in Cancer Drug Resistance?

KAIST researchers have identified mechanisms that relay prior acquired resistance to the first-line chemotherapy to the second-line targeted therapy, fueling a “domino effect” in cancer drug resistance. Their study featured in the February 7 edition of Science Advances suggests a new strategy for improving the second-line setting of cancer treatment for patients who showed resistance to anti-cancer drugs.

Resistance to cancer drugs is often managed in the clinic by chemotherapy and targeted therapy. Unlike chemotherapy that works by repressing fast-proliferating cells, targeted therapy blocks a single oncogenic pathway to halt tumor growth. In many cases, targeted therapy is engaged as a maintenance therapy or employed in the second-line after front-line chemotherapy.

A team of researchers led by Professor Yoosik Kim from the Department of Chemical and Biomolecular Engineering and the KAIST Institute for Health Science and Technology (KIHST) has discovered an unexpected resistance signature that occurs between chemotherapy and targeted therapy. The team further identified a set of integrated mechanisms that promotes this kind of sequential therapy resistance.

“There have been multiple clinical accounts reflecting that targeted therapies tend to be least successful in patients who have exhausted all standard treatments,” said the first author of the paper Mark Borris D. Aldonza. He continued, “These accounts ignited our hypothesis that failed responses to some chemotherapies might speed up the evolution of resistance to other drugs, particularly those with specific targets.”

Aldonza and his colleagues extracted large amounts of drug-resistance information from the open-source database the Genomics of Drug Sensitivity in Cancer (GDSC), which contains thousands of drug response data entries from various human cancer cell lines. Their big data analysis revealed that cancer cell lines resistant to chemotherapies classified as anti-mitotic drugs (AMDs), toxins that inhibit overacting cell division, are also resistant to a class of targeted therapies called epidermal growth factor receptor-tyrosine kinase inhibitors (EGFR-TKIs).

In all of the cancer types analyzed, more than 84 percent of those resistant to AMDs, representatively ‘paclitaxel’, were also resistant to at least nine EGFR-TKIs. In lung, pancreatic, and breast cancers where paclitaxel is often used as a first-line, standard-of-care regimen, greater than 92 percent showed resistance to EGFR-TKIs. Professor Kim said, “It is surprising to see that such collateral resistance can occur specifically between two chemically different classes of drugs.”

To figure out how failed responses to paclitaxel leads to resistance to EGFR-TKIs, the team validated co-resistance signatures that they found in the database by generating and analyzing a subset of slow-doubling, paclitaxel-resistant cancer models called ‘persisters’.

The results demonstrated that paclitaxel-resistant cancers remodel their stress response by first becoming more stem cell-like, evolving the ability to self-renew to adapt to more stressful conditions like drug exposures. More surprisingly, when the researchers characterized the metabolic state of the cells, EGFR-TKI persisters derived from paclitaxel-resistant cancer cells showed high dependencies to energy-producing processes such as glycolysis and glutaminolysis.

“We found that, without an energy stimulus like glucose, these cells transform to becoming more senescent, a characteristic of cells that have arrested cell division. However, this senescence is controlled by stem cell factors, which the paclitaxel-resistant cancers use to escape from this arrested state given a favorable condition to re-grow,” said Aldonza.

Professor Kim explained, “Before this research, there was no reason to expect that acquiring the cancer stem cell phenotype that dramatically leads to a cascade of changes in cellular states affecting metabolism and cell death is linked with drug-specific sequential resistance between two classes of therapies.”

He added, “The expansion of our work to other working models of drug resistance in a much more clinically-relevant setting, perhaps in clinical trials, will take on increasing importance, as sequential treatment strategies will continue to be adapted to various forms of anti-cancer therapy regimens.”