UST

-

Experts to Help Asia Navigate the Post-COVID-19 and 4IR Eras

Risk Quotient 2020, an international conference co-hosted by KAIST and the National University of Singapore (NUS), will bring together world-leading experts from academia and industry to help Asia navigate the post-COVID-19 and Fourth Industrial Revolution (4IR) eras.

The online conference will be held on October 29 from 10 a.m. Korean time under the theme “COVID-19 Pandemic and A Brave New World”. It will be streamed live on YouTube at https://www.youtube.com/c/KAISTofficial and https://www.youtube.com/user/NUScast.

The Korea Policy Center for the Fourth Industrial Revolution (KPC4IR) at KAIST organized this conference in collaboration with the Lloyd's Register Foundation Institute for the Public Understanding of Risk (IPUR) at NUS.

During the conference, global leaders will examine the socioeconomic impacts of the COVID-19 pandemic on areas including digital innovation, education, the workforce, and the economy. They will then highlight digital and 4IR technologies that could be utilized to effectively mitigate the risks and challenges associated with the pandemic, while harnessing the opportunities that these socioeconomic effects may present. Their discussions will mainly focus on the Asian region.

In his opening remarks, KAIST President Sung-Chul Shin will express his appreciation for the Asian populations’ greater trust in and compliance with their governments, which have given the continent a leg up against the coronavirus. He will then emphasize that by working together through the exchange of ideas and global collaboration, we will be able to shape ‘a brave new world’ to better humanity. Welcoming remarks by Prof. Sang Yup Lee (Dean, KAIST Institutes) and Prof. Tze Yun Leong (Director, AI Technology at AI Singapore) will follow.

For the keynote speech, Prof. Lan Xue (Dean, Schwarzman College, Tsinghua University) will share China’s response to COVID-19 and lessons for crisis management. Prof. Danny Quah (Dean, Lee Kuan Yew School of Public Policy, NUS) will present possible ways to overcome these difficult times. Dr. Kak-Soo Shin (Senior Advisor, Shin & Kim LLC, Former Ambassador to the State of Israel and Japan, and Former First and Second Vice Minister of the Ministry of Foreign Affairs of the Republic of Korea) will stress the importance of the international community’s solidarity to ensure peace, prosperity, and safety in this new era.

Panel Session I will address the impact of COVID-19 on digital innovation. Dr. Carol Soon (Senior Research Fellow, Institute of Policy Studies, NUS) will present her interpretation of recent technological developments as both opportunities for our society as a whole and challenges for vulnerable groups such as low-income families. Dr. Christopher SungWook Chang (Managing Director, Kakao Mobility) will show how changes in mobility usage patterns can be captured by Kakao Mobility’s big data analysis. He will illustrate how the data can be used to interpret citizen’s behaviors and how risks can be transformed into opportunities by utilizing technology. Mr. Steve Ledzian’s (Vice President, Chief Technology Officer, FireEye) talk will discuss the dangers caused by threat actors and other cyber risk implications of COVID-19. Dr. June Sung Park (Chairman, Korea Software Technology Association (KOSTA)) will share how COVID-19 has accelerated digital transformations across all industries and why software education should be reformed to improve Korea’s competitiveness.

Panel Session II will examine the impact on education and the workforce. Dr. Sang-Jin Ban (President, Korean Educational Development Institute (KEDI)) will explain Korea’s educational response to the pandemic and the concept of “blended learning” as a new paradigm, and present both positive and negative impacts of online education on students’ learning experiences. Prof. Reuben Ng (Professor, Lee Kuan Yew School of Public Policy, NUS) will present on graduate underemployment, which seems to have worsened during COVID-19. Dr. Michael Fung’s presentation (Deputy Chief Executive (Industry), SkillsFuture SG) will introduce the promotion of lifelong learning in Singapore through a new national initiative known as the ‘SkillsFuture Movement’. This movement serves as an example of a national response to disruptions in the job market and the pace of skills obsolescence triggered by AI and COVID-19.

Panel Session III will touch on technology leadership and Asia’s digital economy and society. Prof. Naubahar Sharif (Professor, Division of Social Science and Division of Public Policy, Hong Kong University of Science and Technology (HKUST)) will share his views on the potential of China in taking over global technological leadership based on its massive domestic market, its government support, and the globalization process. Prof. Yee Kuang Heng (Professor, Graduate School of Public Policy, University of Tokyo) will illustrate how different legal and political needs in China and Japan have shaped the ways technologies have been deployed in responding to COVID-19. Dr. Hayun Kang (Head, International Cooperation Research Division, Korea Information Society Development Institute (KISDI)) will explain Korea’s relative success containing the pandemic compared to other countries, and how policy leaders and institutions that embrace digital technologies in the pursuit of public welfare objectives can produce positive outcomes while minimizing the side effects.

Prof. Kyung Ryul Park (Graduate School of Science and Technology Policy, KAIST) will be hosting the entire conference, whereas Prof. Alice Hae Yun Oh (Director, MARS Artificial Intelligence Research Center, KAIST), Prof. Wonjoon Kim (Dean, Graduate School of Innovation and Technology Management, College of Business, KAIST), Prof. Youngsun Kwon (Dean, KAIST Academy), and Prof. Taejun Lee (Korea Development Institute (KDI) School of Public Policy and Management) are to chair discussions with the keynote speakers and panelists.

Closing remarks will be delivered by Prof. Chan Ghee Koh (Director, NUS IPUR), Prof. So Young Kim (Director, KAIST KPC4IR), and Prof. Joungho Kim (Director, KAIST Global Strategy Institute (GSI)).

“This conference is expected to serve as a springboard to help Asian countries recover from global crises such as the COVID-19 pandemic through active cooperation and joint engagement among scholars, experts, and policymakers,” according to Director So Young Kim.

(END)

2020.10.22 View 17443

Experts to Help Asia Navigate the Post-COVID-19 and 4IR Eras

Risk Quotient 2020, an international conference co-hosted by KAIST and the National University of Singapore (NUS), will bring together world-leading experts from academia and industry to help Asia navigate the post-COVID-19 and Fourth Industrial Revolution (4IR) eras.

The online conference will be held on October 29 from 10 a.m. Korean time under the theme “COVID-19 Pandemic and A Brave New World”. It will be streamed live on YouTube at https://www.youtube.com/c/KAISTofficial and https://www.youtube.com/user/NUScast.

The Korea Policy Center for the Fourth Industrial Revolution (KPC4IR) at KAIST organized this conference in collaboration with the Lloyd's Register Foundation Institute for the Public Understanding of Risk (IPUR) at NUS.

During the conference, global leaders will examine the socioeconomic impacts of the COVID-19 pandemic on areas including digital innovation, education, the workforce, and the economy. They will then highlight digital and 4IR technologies that could be utilized to effectively mitigate the risks and challenges associated with the pandemic, while harnessing the opportunities that these socioeconomic effects may present. Their discussions will mainly focus on the Asian region.

In his opening remarks, KAIST President Sung-Chul Shin will express his appreciation for the Asian populations’ greater trust in and compliance with their governments, which have given the continent a leg up against the coronavirus. He will then emphasize that by working together through the exchange of ideas and global collaboration, we will be able to shape ‘a brave new world’ to better humanity. Welcoming remarks by Prof. Sang Yup Lee (Dean, KAIST Institutes) and Prof. Tze Yun Leong (Director, AI Technology at AI Singapore) will follow.

For the keynote speech, Prof. Lan Xue (Dean, Schwarzman College, Tsinghua University) will share China’s response to COVID-19 and lessons for crisis management. Prof. Danny Quah (Dean, Lee Kuan Yew School of Public Policy, NUS) will present possible ways to overcome these difficult times. Dr. Kak-Soo Shin (Senior Advisor, Shin & Kim LLC, Former Ambassador to the State of Israel and Japan, and Former First and Second Vice Minister of the Ministry of Foreign Affairs of the Republic of Korea) will stress the importance of the international community’s solidarity to ensure peace, prosperity, and safety in this new era.

Panel Session I will address the impact of COVID-19 on digital innovation. Dr. Carol Soon (Senior Research Fellow, Institute of Policy Studies, NUS) will present her interpretation of recent technological developments as both opportunities for our society as a whole and challenges for vulnerable groups such as low-income families. Dr. Christopher SungWook Chang (Managing Director, Kakao Mobility) will show how changes in mobility usage patterns can be captured by Kakao Mobility’s big data analysis. He will illustrate how the data can be used to interpret citizen’s behaviors and how risks can be transformed into opportunities by utilizing technology. Mr. Steve Ledzian’s (Vice President, Chief Technology Officer, FireEye) talk will discuss the dangers caused by threat actors and other cyber risk implications of COVID-19. Dr. June Sung Park (Chairman, Korea Software Technology Association (KOSTA)) will share how COVID-19 has accelerated digital transformations across all industries and why software education should be reformed to improve Korea’s competitiveness.

Panel Session II will examine the impact on education and the workforce. Dr. Sang-Jin Ban (President, Korean Educational Development Institute (KEDI)) will explain Korea’s educational response to the pandemic and the concept of “blended learning” as a new paradigm, and present both positive and negative impacts of online education on students’ learning experiences. Prof. Reuben Ng (Professor, Lee Kuan Yew School of Public Policy, NUS) will present on graduate underemployment, which seems to have worsened during COVID-19. Dr. Michael Fung’s presentation (Deputy Chief Executive (Industry), SkillsFuture SG) will introduce the promotion of lifelong learning in Singapore through a new national initiative known as the ‘SkillsFuture Movement’. This movement serves as an example of a national response to disruptions in the job market and the pace of skills obsolescence triggered by AI and COVID-19.

Panel Session III will touch on technology leadership and Asia’s digital economy and society. Prof. Naubahar Sharif (Professor, Division of Social Science and Division of Public Policy, Hong Kong University of Science and Technology (HKUST)) will share his views on the potential of China in taking over global technological leadership based on its massive domestic market, its government support, and the globalization process. Prof. Yee Kuang Heng (Professor, Graduate School of Public Policy, University of Tokyo) will illustrate how different legal and political needs in China and Japan have shaped the ways technologies have been deployed in responding to COVID-19. Dr. Hayun Kang (Head, International Cooperation Research Division, Korea Information Society Development Institute (KISDI)) will explain Korea’s relative success containing the pandemic compared to other countries, and how policy leaders and institutions that embrace digital technologies in the pursuit of public welfare objectives can produce positive outcomes while minimizing the side effects.

Prof. Kyung Ryul Park (Graduate School of Science and Technology Policy, KAIST) will be hosting the entire conference, whereas Prof. Alice Hae Yun Oh (Director, MARS Artificial Intelligence Research Center, KAIST), Prof. Wonjoon Kim (Dean, Graduate School of Innovation and Technology Management, College of Business, KAIST), Prof. Youngsun Kwon (Dean, KAIST Academy), and Prof. Taejun Lee (Korea Development Institute (KDI) School of Public Policy and Management) are to chair discussions with the keynote speakers and panelists.

Closing remarks will be delivered by Prof. Chan Ghee Koh (Director, NUS IPUR), Prof. So Young Kim (Director, KAIST KPC4IR), and Prof. Joungho Kim (Director, KAIST Global Strategy Institute (GSI)).

“This conference is expected to serve as a springboard to help Asian countries recover from global crises such as the COVID-19 pandemic through active cooperation and joint engagement among scholars, experts, and policymakers,” according to Director So Young Kim.

(END)

2020.10.22 View 17443 -

Fundraising for the 50th Anniversary Memorial Building Kicks Off

KAIST started the fundraising campaign to construct the 50th Anniversary Memorial Building. This is one of the projects and events the 50th Anniversary Commemorative Committee established to celebrate the anniversary.

The ground will be broken in 2022 after raising approximately 50 billion KRW through 2021. The five-story building will be the latest addition to the KAIST campus. To highlight the campus’s history, the new building will connect the N5 (Basic Experiment & Research) and N2 (Administration Branch) buildings, the first buildings on the main Daejeon campus after its main campus moved from Seoul in 1987. Currently, the College of Business remains at the Seoul campus.

The 50th Anniversary Memorial Building will connect the two buildings in the shape of C, and represent KAIST’s C3 core value of Challenging, Creating, and Caring. The concept of this building was designed by Professor Sang-Min Bae from the Department of Industrial Design.

The 50th Anniversary Commemorative Committee said the Memorial Building will reflect the spirit of its core values. The first floor will accommodate the auditorium and exhibition hall, showcasing the latest achievements in KAIST innovation and convergence research as well as alumni startups and companies. The second floor will be an education space for entrepreneurship and video studios. An area for delivering creative education platforms such as Education 4.0 will be prepared on the third floor. The fourth floor will be used for global leadership education. The fifth floor will house the KAIST Club, a lounge for alumni and the Global Strategy Institute.

Co-Chair of the Fundraising & PR Sub-Committee of the KAIST 50th Anniversary Commemorative Committee and Former Vice President for Planning and Budget Seung-Bin Park and current Vice President for Planning and Budget Suchan Chae reiterated the importance of extending the infrastructure of the campus, saying that investments in the infrastructure will expand the university’s future growth potential. In a letter to kick off the fundraising efforts last month, they called for support from the entire KAIST community to help construct the new memorial building that will produce global talents and help young scientists make their dreams come true.

To donate, click here

2020.10.07 View 9601

Fundraising for the 50th Anniversary Memorial Building Kicks Off

KAIST started the fundraising campaign to construct the 50th Anniversary Memorial Building. This is one of the projects and events the 50th Anniversary Commemorative Committee established to celebrate the anniversary.

The ground will be broken in 2022 after raising approximately 50 billion KRW through 2021. The five-story building will be the latest addition to the KAIST campus. To highlight the campus’s history, the new building will connect the N5 (Basic Experiment & Research) and N2 (Administration Branch) buildings, the first buildings on the main Daejeon campus after its main campus moved from Seoul in 1987. Currently, the College of Business remains at the Seoul campus.

The 50th Anniversary Memorial Building will connect the two buildings in the shape of C, and represent KAIST’s C3 core value of Challenging, Creating, and Caring. The concept of this building was designed by Professor Sang-Min Bae from the Department of Industrial Design.

The 50th Anniversary Commemorative Committee said the Memorial Building will reflect the spirit of its core values. The first floor will accommodate the auditorium and exhibition hall, showcasing the latest achievements in KAIST innovation and convergence research as well as alumni startups and companies. The second floor will be an education space for entrepreneurship and video studios. An area for delivering creative education platforms such as Education 4.0 will be prepared on the third floor. The fourth floor will be used for global leadership education. The fifth floor will house the KAIST Club, a lounge for alumni and the Global Strategy Institute.

Co-Chair of the Fundraising & PR Sub-Committee of the KAIST 50th Anniversary Commemorative Committee and Former Vice President for Planning and Budget Seung-Bin Park and current Vice President for Planning and Budget Suchan Chae reiterated the importance of extending the infrastructure of the campus, saying that investments in the infrastructure will expand the university’s future growth potential. In a letter to kick off the fundraising efforts last month, they called for support from the entire KAIST community to help construct the new memorial building that will produce global talents and help young scientists make their dreams come true.

To donate, click here

2020.10.07 View 9601 -

Professor Sukyung Park Named Presidential Science and Technology Adviser

Professor Sukyung Park from the Department of Mechanical Engineering was appointed as the science and technology adviser to the President Jae-in Moon on May 4. Professor Park, at the age of 47, became the youngest member of the president’s senior aide team at Chong Wa Dae.

A Chong Wa Dae spokesman said on May 4 while announcing the appointment, “Professor Park, a talent with a great deal of policymaking participation in science and technology, will contribute to accelerating the government’s push for science and technology innovation, especially in the information and communications technology (ICT) sector.”

Professor Park joined KAIST in 2004 as the first female professor of mechanical engineering. She is a biomechanics expert who has conducted extensive research on biometric mechanical behaviors. Professor Park is also a member of the KAIST Board of Trustees. Before that, she served as a senior researcher at the Korea Institute of Machinery and Materials (KIMM) as well as a member of the Presidential Advisory Council on Science and Technology.

After graduating from Seoul Science High School as the first ever two-year graduate, Professor Park earned a bachelor and master’s degrees in mechanical engineering at KAIST. She then finished her Ph.D. from the University of Michigan.

(END)

2020.05.06 View 16105

Professor Sukyung Park Named Presidential Science and Technology Adviser

Professor Sukyung Park from the Department of Mechanical Engineering was appointed as the science and technology adviser to the President Jae-in Moon on May 4. Professor Park, at the age of 47, became the youngest member of the president’s senior aide team at Chong Wa Dae.

A Chong Wa Dae spokesman said on May 4 while announcing the appointment, “Professor Park, a talent with a great deal of policymaking participation in science and technology, will contribute to accelerating the government’s push for science and technology innovation, especially in the information and communications technology (ICT) sector.”

Professor Park joined KAIST in 2004 as the first female professor of mechanical engineering. She is a biomechanics expert who has conducted extensive research on biometric mechanical behaviors. Professor Park is also a member of the KAIST Board of Trustees. Before that, she served as a senior researcher at the Korea Institute of Machinery and Materials (KIMM) as well as a member of the Presidential Advisory Council on Science and Technology.

After graduating from Seoul Science High School as the first ever two-year graduate, Professor Park earned a bachelor and master’s degrees in mechanical engineering at KAIST. She then finished her Ph.D. from the University of Michigan.

(END)

2020.05.06 View 16105 -

Former Minister of Science and Technology Woo Sik Kim Elected as New Chairman of Board of Trustees

Dr. Woo Sik Kim, former Minister of Science and Technology and Deputy Prime Minister, was elected as the new chairman of the KAIST Board of Trustees on March 26. Dr. Kim will succeed Chairman Jang-Mu Lee, whose three-year term expired last month.

Dr. Kim is a chemical engineering professor who spent most of his academic career at Yonsei University from 1968. In 2000, he held the office of president of Yonsei University for four years before moving to the Presidential Office of President Roh Moo-Hyun as his chief of staff in 2004. After serving in the Blue House for two years, he served as the Minister of Science and Technology from 2006 to 2008.

An emeritus fellow of the National Academy of Engineering of Korea (NAEK), Chairman Kim also taught at KAIST as an invited distinguished professor from 2008 to 2010. He is currently the chairman of the Creativity Engineering Institute (CEI).

(END)

2020.04.06 View 15219

Former Minister of Science and Technology Woo Sik Kim Elected as New Chairman of Board of Trustees

Dr. Woo Sik Kim, former Minister of Science and Technology and Deputy Prime Minister, was elected as the new chairman of the KAIST Board of Trustees on March 26. Dr. Kim will succeed Chairman Jang-Mu Lee, whose three-year term expired last month.

Dr. Kim is a chemical engineering professor who spent most of his academic career at Yonsei University from 1968. In 2000, he held the office of president of Yonsei University for four years before moving to the Presidential Office of President Roh Moo-Hyun as his chief of staff in 2004. After serving in the Blue House for two years, he served as the Minister of Science and Technology from 2006 to 2008.

An emeritus fellow of the National Academy of Engineering of Korea (NAEK), Chairman Kim also taught at KAIST as an invited distinguished professor from 2008 to 2010. He is currently the chairman of the Creativity Engineering Institute (CEI).

(END)

2020.04.06 View 15219 -

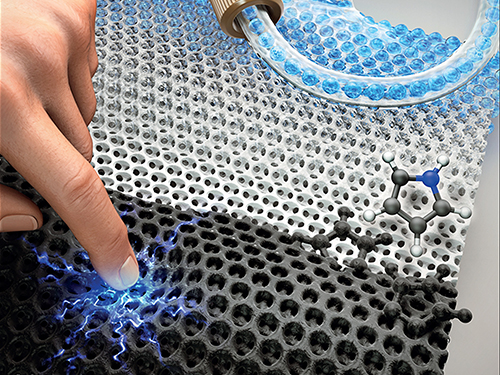

Highly Efficient and Stable Double Layer Solar Cell Developed

Solar cells convert light into energy, but they can be inefficient and vulnerable to the environment, degrading with, ironically, too much light or other factors, including moisture and low temperature. An international research team has developed a new type of solar cell that can both withstand environmental hazards and is 26.7% efficient in power conversion.

They published their results on March 26 in Science.

The researchers, led by Byungha Shin, a professor from the Department of Materials Science and Engineering at KAIST, focused on developing a new class of light-absorbing material, called a wide bandgap perovskite. The material has a highly effective crystal structure that can process the power needs, but it can become problematic when exposed to environmental hazards, such as moisture. Researchers have made some progress increasing the efficiency of solar cells based on perovskite, but the material has greater potential than what was previously achieved.

To achieve better performance, Shin and his team built a double layer solar cell, called tandem, in which two or more light absorbers are stacked together to better utilize solar energy. To use perovskite in these tandem devices, the scientists modified the material’s optical property, which allows it to absorb a wider range of solar energy. Without the adjustment, the material is not as useful in achieving high performing tandem solar cells. The modification of the optical property of perovskite, however, comes with a penalty — the material becomes hugely vulnerable to the environment, in particular, to light.

To counteract the wide bandgap perovskite’s delicate nature, the researchers engineered combinations of molecules composing a two-dimensional layer in the perovskite, stabilizing the solar cells.

“We developed a high-quality wide bandgap perovskite material and, in combination with silicon solar cells, achieved world-class perovskite-silicon tandem cells,” Shin said.

The development was only possible due to the engineering method, in which the mixing ratio of the molecules building the two-dimensional layer are carefully controlled. In this case, the perovskite material not only improved efficiency of the resulting solar cell but also gained durability, retaining 80% of its initial power conversion capability even after 1,000 hours of continuous illumination. This is the first time such a high efficiency has been achieved with a wide bandgap perovskite single layer alone, according to Shin.

“Such high-efficiency wide bandgap perovskite is an essential technology for achieving ultra-high efficiency of perovskite-silicon tandem (double layer) solar cells,” Shin said. “The results also show the importance of bandgap matching of upper and lower cells in these tandem solar cells.”

The researchers, having stabilized the wide bandgap perovskite material, are now focused on developing even more efficient tandem solar cells that are expected to have more than 30% of power conversion efficiency, something that no one has achieved yet,

“Our ultimate goal is to develop ultra-high-efficiency tandem solar cells that contribute to the increase of shared solar energy among all energy sources,” Shin said. “We want to contribute to making the planet healthier.”

This work was supported by the National Research Foundation of Korea, the Korea Institute of Energy Technology Evaluation and Planning, the Ministry of Trade Industry and Energy of Korea, and the U.S. Department of Energy.

Other contributors include Daehan Kim, Jekyung Kim, Passarut Boonmongkolras, Seong Ryul Pae and Minkyu Kim, all of whom affiliated with the Department of Materials Science and Engineering at KAIST. Other authors include Byron W. Larson, Sean P. Dunfield, Chuanxiao Xiao, Jinhui Tong, Fei Zhang, Joseph J. Berry, Kai Zhu and Dong Hoe Kim, all of who are affiliated with the National Renewable Energy Laboratory in Colorado. Dunfield is also affiliated with the Materials Science and Engineering Program at the University of Colorado; Berry is also affiliated with the Department of Physics and the Renewable and Sustainable Energy Institute at the University of Colorado Boulder; and Kim is also affiliated with the Department of Nanotechnology and Advanced Materials Engineering at Sejong University. Hee Joon Jung and Vinayak Dravid of the Department of Materials Science and Engineering at Northwestern University; Ik Jae Park, Su Geun Ji and Jin Young Kim of the Department of Materials Science and Engineering at Seoul National University; and Seok Beom Kang of the Department of Nanotechnology and Advanced Materials Engineering of Sejong University also contributed.

Image credit: Professor Byungha Shin, KAIST

Image usage restrictions: News organizations may use or redistribute this image, with proper attribution, as part of news coverage of this paper only.

Publication: Kim et al. (2020) “Efficient, stable silicon tandem cells enabled by anion-engineered wide band gap perovskites”. Science. Available online at https://doi.org/10.1126/science.aba3433

Profile:

Byungha Shin

Professor

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

Profile:

Daehan Kim

Ph.D. Candidate

zxzx4592@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

(END)

2020.03.27 View 24144

Highly Efficient and Stable Double Layer Solar Cell Developed

Solar cells convert light into energy, but they can be inefficient and vulnerable to the environment, degrading with, ironically, too much light or other factors, including moisture and low temperature. An international research team has developed a new type of solar cell that can both withstand environmental hazards and is 26.7% efficient in power conversion.

They published their results on March 26 in Science.

The researchers, led by Byungha Shin, a professor from the Department of Materials Science and Engineering at KAIST, focused on developing a new class of light-absorbing material, called a wide bandgap perovskite. The material has a highly effective crystal structure that can process the power needs, but it can become problematic when exposed to environmental hazards, such as moisture. Researchers have made some progress increasing the efficiency of solar cells based on perovskite, but the material has greater potential than what was previously achieved.

To achieve better performance, Shin and his team built a double layer solar cell, called tandem, in which two or more light absorbers are stacked together to better utilize solar energy. To use perovskite in these tandem devices, the scientists modified the material’s optical property, which allows it to absorb a wider range of solar energy. Without the adjustment, the material is not as useful in achieving high performing tandem solar cells. The modification of the optical property of perovskite, however, comes with a penalty — the material becomes hugely vulnerable to the environment, in particular, to light.

To counteract the wide bandgap perovskite’s delicate nature, the researchers engineered combinations of molecules composing a two-dimensional layer in the perovskite, stabilizing the solar cells.

“We developed a high-quality wide bandgap perovskite material and, in combination with silicon solar cells, achieved world-class perovskite-silicon tandem cells,” Shin said.

The development was only possible due to the engineering method, in which the mixing ratio of the molecules building the two-dimensional layer are carefully controlled. In this case, the perovskite material not only improved efficiency of the resulting solar cell but also gained durability, retaining 80% of its initial power conversion capability even after 1,000 hours of continuous illumination. This is the first time such a high efficiency has been achieved with a wide bandgap perovskite single layer alone, according to Shin.

“Such high-efficiency wide bandgap perovskite is an essential technology for achieving ultra-high efficiency of perovskite-silicon tandem (double layer) solar cells,” Shin said. “The results also show the importance of bandgap matching of upper and lower cells in these tandem solar cells.”

The researchers, having stabilized the wide bandgap perovskite material, are now focused on developing even more efficient tandem solar cells that are expected to have more than 30% of power conversion efficiency, something that no one has achieved yet,

“Our ultimate goal is to develop ultra-high-efficiency tandem solar cells that contribute to the increase of shared solar energy among all energy sources,” Shin said. “We want to contribute to making the planet healthier.”

This work was supported by the National Research Foundation of Korea, the Korea Institute of Energy Technology Evaluation and Planning, the Ministry of Trade Industry and Energy of Korea, and the U.S. Department of Energy.

Other contributors include Daehan Kim, Jekyung Kim, Passarut Boonmongkolras, Seong Ryul Pae and Minkyu Kim, all of whom affiliated with the Department of Materials Science and Engineering at KAIST. Other authors include Byron W. Larson, Sean P. Dunfield, Chuanxiao Xiao, Jinhui Tong, Fei Zhang, Joseph J. Berry, Kai Zhu and Dong Hoe Kim, all of who are affiliated with the National Renewable Energy Laboratory in Colorado. Dunfield is also affiliated with the Materials Science and Engineering Program at the University of Colorado; Berry is also affiliated with the Department of Physics and the Renewable and Sustainable Energy Institute at the University of Colorado Boulder; and Kim is also affiliated with the Department of Nanotechnology and Advanced Materials Engineering at Sejong University. Hee Joon Jung and Vinayak Dravid of the Department of Materials Science and Engineering at Northwestern University; Ik Jae Park, Su Geun Ji and Jin Young Kim of the Department of Materials Science and Engineering at Seoul National University; and Seok Beom Kang of the Department of Nanotechnology and Advanced Materials Engineering of Sejong University also contributed.

Image credit: Professor Byungha Shin, KAIST

Image usage restrictions: News organizations may use or redistribute this image, with proper attribution, as part of news coverage of this paper only.

Publication: Kim et al. (2020) “Efficient, stable silicon tandem cells enabled by anion-engineered wide band gap perovskites”. Science. Available online at https://doi.org/10.1126/science.aba3433

Profile:

Byungha Shin

Professor

byungha@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

Profile:

Daehan Kim

Ph.D. Candidate

zxzx4592@kaist.ac.kr

http://energymatlab.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

(END)

2020.03.27 View 24144 -

A System Controlling Road Active Noise to Hit the Road

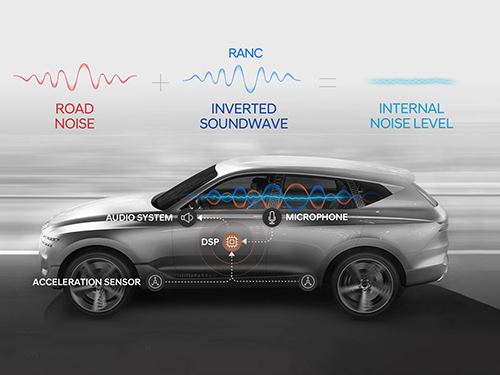

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 14041

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 14041 -

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 10227

Korea Policy Center for the Fourth Industrial Revolution Opens

The World Economic Forum’s Center for the Fourth Industrial Revolution opened its Korean affiliate center at KAIST on December 10. The Korea Policy Center for the 4th Industrial Revolution (KPC4IR) will develop policy norms and frameworks for accelerating the benefits of emerging technologies.

Many dignitaries including KAIST President Sung-Chul Shin, National Assemblyman Sang-Min Lee, Daejeon City Mayor Her Tae-Jeong, and Managing Director of the WEF Center for the Fourth Industrial Revolution Murat Sonmez attended the opening ceremony.

The center will play a vital role in helping to shape the development of national Fourth Industrial Revolution strategies and public-private initiatives. The Center will actively engage with the government on policy design and piloting activities.

The Center is the result of KAIST’s close partnership with the WEF and its Center for the Fourth Industrial Revolution in San Francisco. KAIST signed an MOU with the WEF in 2017 for this collaboration. Dr. Klaus Schwab expressed his high hopes many times regarding Korea’s potential in responding to the Fourth Industrial Revolution. In addition, he said that KAIST and the City of Daejeon would play a significant role in helping the Fourth Industrial Revolution move forward.

During a meeting with President Moon Jae-In last June, Dr. Schwab expressed his strong desire to collaborate with Korea, and the Korean government designated KAIST as an affiliate center of the WEF.

The KPC4IR had already begun conducting policy research in the areas of block chain and precision medicine even before making a partnership with the WEF. The director of the Center, Distinguished Professor Sang Yup Lee, said, “We have focused on the development of technology but rarely talk about governance. Technology should come with policy. We will conduct policy development on how to ensure inclusive growth capitalizing on emerging technologies. We will also make policy guidelines for technological applications after considering all the ethical perspectives.

President Shin also said in his opening remarks, “Korea has been a fast follower over the past decades in making economic development and innovations. I believe that the Fourth Industrial Revolution gives us the best opportunity to play the role of ‘first mover.’ I look forward to the KPC4IR serving as a ‘Think and Do’ tank, not limiting itself to the role of ‘think tank.’ We will continue to work closely with the WEF in the fields of AI, blockchain, and precision medicine.

2019.12.10 View 10227 -

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9804

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9804 -

KAIST and Google Jointly Develop AI Curricula

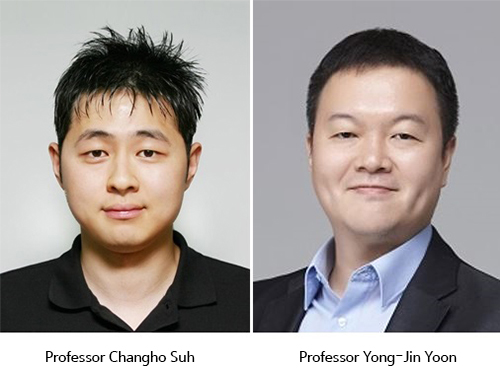

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 17387

KAIST and Google Jointly Develop AI Curricula

KAIST selected the two professors who will develop AI curriculum under the auspices of the KAIST-Google Partnership for AI Education and Research. The Graduate School of AI announced the two authors among the 20 applicants who will develop the curriculum next year. They will be provided 7,500 USD per subject.

Professor Changho Suh from the School of Electrical Engineering and Professor Yong-Jin Yoon from the Department of Mechanical Engineering will use Google technology such as TensorFlow, Google Cloud, and Android to create the curriculum.

Professor Suh’s “TensorFlow for Information Theory and Convex Optimization “will be used for curriculum in the graduate courses and Professor Yoon’s “AI Convergence Project Based Learning (PBL)” will be used for online courses. Professor Yoon’s course will explore and define problems by utilizing AI and experiencing the process of developing products that use AI through design thinking, which involves product design, production, and verification. Professor Suh’s course will discus“information theory and convergence,” which uses basic sciences and engineering as well as AI, machine learning, and deep learning.

2019.12.04 View 17387 -

A Mathematical Model Reveals Long-Distance Cell Communication Mechanism

How can tens of thousands of people in a large football stadium all clap together with the same beat even though they can only hear the people near them clapping?

A combination of a partial differential equation and a synthetic circuit in microbes answers this question. An interdisciplinary collaborative team of Professor Jae Kyoung Kim at KAIST, Professor Krešimir Josić at the University of Houston, and Professor Matt Bennett at Rice University has identified how a large community can communicate with each other almost simultaneously even with very short distance signaling. The research was reported at Nature Chemical Biology.

Cells often communicate using signaling molecules, which can travel only a short distance. Nevertheless, the cells can also communicate over large distances to spur collective action. The team revealed a cell communication mechanism that quickly forms a network of local interactions to spur collective action, even in large communities.

The research team used an engineered transcriptional circuit of combined positive and negative feedback loops in E. coli, which can periodically release two types of signaling molecules: activator and repressor. As the signaling molecules travel over a short distance, cells can only talk to their nearest neighbors. However, cell communities synchronize oscillatory gene expression in spatially extended systems as long as the transcriptional circuit contains a positive feedback loop for the activator.

Professor Kim said that analyzing and understanding such high-dimensional dynamics was extremely difficult. He explained, “That’s why we used high-dimensional partial differential equation to describe the system based on the interactions among various types of molecules.” Surprisingly, the mathematical model accurately simulates the synthesis of the signaling molecules in the cell and their spatial diffusion throughout the chamber and their effect on neighboring cells.

The team simplified the high-dimensional system into a one-dimensional orbit, noting that the system repeats periodically. This allowed them to discover that cells can make one voice when they lowered their own voice and listened to the others. “It turns out the positive feedback loop reduces the distance between moving points and finally makes them move all together. That’s why you clap louder when you hear applause from nearby neighbors and everyone eventually claps together at almost the same time,” said Professor Kim.

Professor Kim added, “Math is a powerful as it simplifies complex thing so that we can find an essential underlying property. This finding would not have been possible without the simplification of complex systems using mathematics."

The National Institutes of Health, the National Science Foundation, the Robert A. Welch Foundation, the Hamill Foundation, the National Research Foundation of Korea, and the T.J. Park Science Fellowship of POSCO supported the research.

(Figure: Complex molecular interactions among microbial consortia is simplified as interactions among points on a limit cycle (right).)

2019.10.15 View 30820

A Mathematical Model Reveals Long-Distance Cell Communication Mechanism

How can tens of thousands of people in a large football stadium all clap together with the same beat even though they can only hear the people near them clapping?

A combination of a partial differential equation and a synthetic circuit in microbes answers this question. An interdisciplinary collaborative team of Professor Jae Kyoung Kim at KAIST, Professor Krešimir Josić at the University of Houston, and Professor Matt Bennett at Rice University has identified how a large community can communicate with each other almost simultaneously even with very short distance signaling. The research was reported at Nature Chemical Biology.

Cells often communicate using signaling molecules, which can travel only a short distance. Nevertheless, the cells can also communicate over large distances to spur collective action. The team revealed a cell communication mechanism that quickly forms a network of local interactions to spur collective action, even in large communities.

The research team used an engineered transcriptional circuit of combined positive and negative feedback loops in E. coli, which can periodically release two types of signaling molecules: activator and repressor. As the signaling molecules travel over a short distance, cells can only talk to their nearest neighbors. However, cell communities synchronize oscillatory gene expression in spatially extended systems as long as the transcriptional circuit contains a positive feedback loop for the activator.

Professor Kim said that analyzing and understanding such high-dimensional dynamics was extremely difficult. He explained, “That’s why we used high-dimensional partial differential equation to describe the system based on the interactions among various types of molecules.” Surprisingly, the mathematical model accurately simulates the synthesis of the signaling molecules in the cell and their spatial diffusion throughout the chamber and their effect on neighboring cells.

The team simplified the high-dimensional system into a one-dimensional orbit, noting that the system repeats periodically. This allowed them to discover that cells can make one voice when they lowered their own voice and listened to the others. “It turns out the positive feedback loop reduces the distance between moving points and finally makes them move all together. That’s why you clap louder when you hear applause from nearby neighbors and everyone eventually claps together at almost the same time,” said Professor Kim.

Professor Kim added, “Math is a powerful as it simplifies complex thing so that we can find an essential underlying property. This finding would not have been possible without the simplification of complex systems using mathematics."

The National Institutes of Health, the National Science Foundation, the Robert A. Welch Foundation, the Hamill Foundation, the National Research Foundation of Korea, and the T.J. Park Science Fellowship of POSCO supported the research.

(Figure: Complex molecular interactions among microbial consortia is simplified as interactions among points on a limit cycle (right).)

2019.10.15 View 30820 -

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 8214

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 8214 -

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 30318

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 30318