AT

-

Deep Learning-Powered 'DeepEC' Helps Accurately Understand Enzyme Functions

(Figure: Overall scheme of DeepEC)

A deep learning-powered computational framework, ‘DeepEC,’ will allow the high-quality and high-throughput prediction of enzyme commission numbers, which is essential for the accurate understanding of enzyme functions.

A team of Dr. Jae Yong Ryu, Professor Hyun Uk Kim, and Distinguished Professor Sang Yup Lee at KAIST reported the computational framework powered by deep learning that predicts enzyme commission (EC) numbers with high precision in a high-throughput manner.

DeepEC takes a protein sequence as an input and accurately predicts EC numbers as an output. Enzymes are proteins that catalyze biochemical reactions and EC numbers consisting of four level numbers (i.e., a.b.c.d) indicate biochemical reactions. Thus, the identification of EC numbers is critical for accurately understanding enzyme functions and metabolism.

EC numbers are usually given to a protein sequence encoding an enzyme during a genome annotation procedure. Because of the importance of EC numbers, several EC number prediction tools have been developed, but they have room for further improvement with respect to computation time, precision, coverage, and the total size of the files needed for the EC number prediction.

DeepEC uses three convolutional neural networks (CNNs) as a major engine for the prediction of EC numbers, and also implements homology analysis for EC numbers if the three CNNs do not produce reliable EC numbers for a given protein sequence. DeepEC was developed by using a gold standard dataset covering 1,388,606 protein sequences and 4,669 EC numbers.

In particular, benchmarking studies of DeepEC and five other representative EC number prediction tools showed that DeepEC made the most precise and fastest predictions for EC numbers. DeepEC also required the smallest disk space for implementation, which makes it an ideal third-party software component.

Furthermore, DeepEC was the most sensitive in detecting enzymatic function loss as a result of mutations in domains/binding site residue of protein sequences; in this comparative analysis, all the domains or binding site residue were substituted with L-alanine residue in order to remove the protein function, which is known as the L-alanine scanning method.

This study was published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on June 20, 2019, entitled “Deep learning enables high-quality and high-throughput prediction of enzyme commission numbers.”

“DeepEC can be used as an independent tool and also as a third-party software component in combination with other computational platforms that examine metabolic reactions. DeepEC is freely available online,” said Professor Kim.

Distinguished Professor Lee said, “With DeepEC, it has become possible to process ever-increasing volumes of protein sequence data more efficiently and more accurately.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea. This work was also funded by the Bio & Medical Technology Development Program of the National Research Foundation of Korea funded by the Korean government, the Ministry of Science and ICT.

Profile:

-Professor Hyun Uk Kim (ehukim@kaist.ac.kr)

https://sites.google.com/view/ehukim

Department of Chemical and Biomolecular Engineering

-Distinguished Professor Sang Yup Lee (leesy@kaist.ac.kr)

Department of Chemical and Biomolecular Engineering

http://mbel.kaist.ac.kr

2019.07.09 View 39606

Deep Learning-Powered 'DeepEC' Helps Accurately Understand Enzyme Functions

(Figure: Overall scheme of DeepEC)

A deep learning-powered computational framework, ‘DeepEC,’ will allow the high-quality and high-throughput prediction of enzyme commission numbers, which is essential for the accurate understanding of enzyme functions.

A team of Dr. Jae Yong Ryu, Professor Hyun Uk Kim, and Distinguished Professor Sang Yup Lee at KAIST reported the computational framework powered by deep learning that predicts enzyme commission (EC) numbers with high precision in a high-throughput manner.

DeepEC takes a protein sequence as an input and accurately predicts EC numbers as an output. Enzymes are proteins that catalyze biochemical reactions and EC numbers consisting of four level numbers (i.e., a.b.c.d) indicate biochemical reactions. Thus, the identification of EC numbers is critical for accurately understanding enzyme functions and metabolism.

EC numbers are usually given to a protein sequence encoding an enzyme during a genome annotation procedure. Because of the importance of EC numbers, several EC number prediction tools have been developed, but they have room for further improvement with respect to computation time, precision, coverage, and the total size of the files needed for the EC number prediction.

DeepEC uses three convolutional neural networks (CNNs) as a major engine for the prediction of EC numbers, and also implements homology analysis for EC numbers if the three CNNs do not produce reliable EC numbers for a given protein sequence. DeepEC was developed by using a gold standard dataset covering 1,388,606 protein sequences and 4,669 EC numbers.

In particular, benchmarking studies of DeepEC and five other representative EC number prediction tools showed that DeepEC made the most precise and fastest predictions for EC numbers. DeepEC also required the smallest disk space for implementation, which makes it an ideal third-party software component.

Furthermore, DeepEC was the most sensitive in detecting enzymatic function loss as a result of mutations in domains/binding site residue of protein sequences; in this comparative analysis, all the domains or binding site residue were substituted with L-alanine residue in order to remove the protein function, which is known as the L-alanine scanning method.

This study was published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on June 20, 2019, entitled “Deep learning enables high-quality and high-throughput prediction of enzyme commission numbers.”

“DeepEC can be used as an independent tool and also as a third-party software component in combination with other computational platforms that examine metabolic reactions. DeepEC is freely available online,” said Professor Kim.

Distinguished Professor Lee said, “With DeepEC, it has become possible to process ever-increasing volumes of protein sequence data more efficiently and more accurately.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea. This work was also funded by the Bio & Medical Technology Development Program of the National Research Foundation of Korea funded by the Korean government, the Ministry of Science and ICT.

Profile:

-Professor Hyun Uk Kim (ehukim@kaist.ac.kr)

https://sites.google.com/view/ehukim

Department of Chemical and Biomolecular Engineering

-Distinguished Professor Sang Yup Lee (leesy@kaist.ac.kr)

Department of Chemical and Biomolecular Engineering

http://mbel.kaist.ac.kr

2019.07.09 View 39606 -

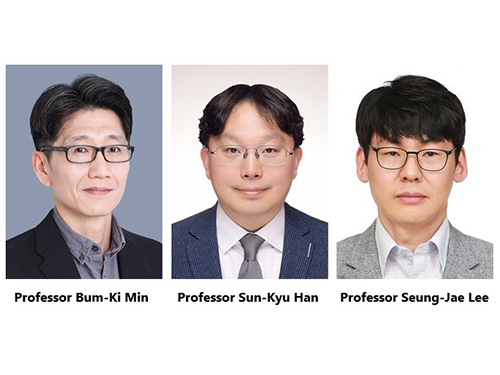

Three Professors Receive Han Sung Science Awards

Three KAIST professors swept the 2nd Han Sung Science Awards. Professor Bum-Ki Min from the Departments of Mechanical Engineering and Physics, Professor Sun-Kyu Han from the Department of Chemistry, and Professor Seung-Jae Lee from the Department of Biological Sciences won all three awards presented by the Han Sung Scholarship Foundation, which recognizes promising mid-career scientists in the fields of physics, chemistry, and biological sciences. The awards ceremony will take place on August 16 in Hwaseong.

Professor Min was declared as the winner of the physics field in recognition of his outstanding research activities including searching for new application areas for metamaterials and investigating their unexplored functionalities. The metamaterials with a high index of refraction developed by Professor Min’s research team have caught the attention of scientists worldwide, as they can help develop high-resolution imaging systems and ultra-small, hyper-sensitive optical devices.

The chemistry field winner, Professor Han, is the youngest awardee so far at 36 years of age. He is often described as one of the most promising next-generation Korean scientists in the field of the total synthesis of complex natural products. Given the fact that this field takes very long-term research, he is making unprecedented research achievements. He is focusing on convergent and flexible synthetic approaches that enable access to not only a single target but various natural products with structural and biosynthetic relevance as well as unnatural products with higher biological potency.

Professor Lee was recognized for his contributions to the advancement of biological sciences, especially in aging research. Professor Lee’s team is taking a novel approach by further investigating complex interactions between genetic and environmental factors that affect aging, and identifying genes that mediate the effects. The team has been conducting large-scale gene discovery efforts by employing RNA sequencing analysis, RNAi screening, and chemical mutagenesis screening. They are striving to determine the functional significance of candidate genes obtained from these experiments and mechanistically characterize these genes.

(END)

2019.07.03 View 11157

Three Professors Receive Han Sung Science Awards

Three KAIST professors swept the 2nd Han Sung Science Awards. Professor Bum-Ki Min from the Departments of Mechanical Engineering and Physics, Professor Sun-Kyu Han from the Department of Chemistry, and Professor Seung-Jae Lee from the Department of Biological Sciences won all three awards presented by the Han Sung Scholarship Foundation, which recognizes promising mid-career scientists in the fields of physics, chemistry, and biological sciences. The awards ceremony will take place on August 16 in Hwaseong.

Professor Min was declared as the winner of the physics field in recognition of his outstanding research activities including searching for new application areas for metamaterials and investigating their unexplored functionalities. The metamaterials with a high index of refraction developed by Professor Min’s research team have caught the attention of scientists worldwide, as they can help develop high-resolution imaging systems and ultra-small, hyper-sensitive optical devices.

The chemistry field winner, Professor Han, is the youngest awardee so far at 36 years of age. He is often described as one of the most promising next-generation Korean scientists in the field of the total synthesis of complex natural products. Given the fact that this field takes very long-term research, he is making unprecedented research achievements. He is focusing on convergent and flexible synthetic approaches that enable access to not only a single target but various natural products with structural and biosynthetic relevance as well as unnatural products with higher biological potency.

Professor Lee was recognized for his contributions to the advancement of biological sciences, especially in aging research. Professor Lee’s team is taking a novel approach by further investigating complex interactions between genetic and environmental factors that affect aging, and identifying genes that mediate the effects. The team has been conducting large-scale gene discovery efforts by employing RNA sequencing analysis, RNAi screening, and chemical mutagenesis screening. They are striving to determine the functional significance of candidate genes obtained from these experiments and mechanistically characterize these genes.

(END)

2019.07.03 View 11157 -

Micropatch Made of DNA

Researchers reported the fabrication of microstructure arrays of DNA materials using topographic control. This method provides a platform for forming multiscale hierarchical orientations of soft and biomaterials using a process of simple shearing and controlled evaporation on a patterned substrate. This approach enables the potential of patterning applications using DNA or other anisotropic biomaterials.

DNA is one of the most abundant biomaterials found in all living organisms in nature. It has unique characteristics of fine feature size and liquid crystalline phase, enabling to create various kinds of microstructure DNA arrays. Based on these characteristics, DNA has been used as a building block for “origami” and textile art at the nanometer scale.

A KAIST research team led by Professors Dong Ki Yoon and Hyungsoo Kim fabricated a DNA-based micropatch using the “coffee ring effect” and its multi-angle control technology, which was published online in Nature Communications on June 7.

The research team used cheap DNA material extracted from salmon to realize the micropatch structure with well-aligned knit or ice cream cone shapes. When the DNA material in an aqueous solution is rubbed between two solid substrates while water is evaporating, DNA chains are unidirectionally aligned to make a thin film such as in LCD display devices. The DNA chains can make more complex microstructures such as knit or a texture with ice cream cone shapes when the same procedure is carried out in topographical patterns like microposts (Figure 1). This can be applied to make metamaterials by mixing with functionalized gold nanorods to show plasmonic color.

Plasmon resonance is a phenomenon in which electrons vibrate uniformly on the surface of a substrate made of metal, reacting only to light that matches a specific energy to enhance the clarity and expression of colors. For this, the most important factor is the orientation in which the gold nanorods align. That is, when the rods are aligned side by side in one direction, the optical and electrical characteristics are maximized. The research team focused on this point and made the DNA micropatch as a frame to orient the gold nanorods in a unique shape and fabricated a plasmonic color film (Figure 2).

Professor Yoon said this study is meaningful in that it deals with the evaporation phenomenon, which has not been studied much in the field of polymers and biopolymers in terms of basic science. He explained, “This will also help maximize the efficiency of polymeric materials that can be orientated in coating, 2D, and 3D printing applications. Furthermore, DNA that exists infinitely in nature can be expected to have industrial application value as a new material since it can easily form complexes with other materials as described in this study.”

(Figure 1. The DNA micropatch using topographic control. (a) The experimental scheme.

(b) Enlarged image of (e). (c-e) Different micropatches made of DNA using different shearing directions.)

(Figure 2. The knit-like structures made of DNA-gold nanorod complex. (a,b) Optical

and polarized optical microscopy images. (c-f) Plasmonic colors reflected from aligned DNA-gold nanorod complex depending on the sample rotation.)

2019.07.01 View 35570

Micropatch Made of DNA

Researchers reported the fabrication of microstructure arrays of DNA materials using topographic control. This method provides a platform for forming multiscale hierarchical orientations of soft and biomaterials using a process of simple shearing and controlled evaporation on a patterned substrate. This approach enables the potential of patterning applications using DNA or other anisotropic biomaterials.

DNA is one of the most abundant biomaterials found in all living organisms in nature. It has unique characteristics of fine feature size and liquid crystalline phase, enabling to create various kinds of microstructure DNA arrays. Based on these characteristics, DNA has been used as a building block for “origami” and textile art at the nanometer scale.

A KAIST research team led by Professors Dong Ki Yoon and Hyungsoo Kim fabricated a DNA-based micropatch using the “coffee ring effect” and its multi-angle control technology, which was published online in Nature Communications on June 7.

The research team used cheap DNA material extracted from salmon to realize the micropatch structure with well-aligned knit or ice cream cone shapes. When the DNA material in an aqueous solution is rubbed between two solid substrates while water is evaporating, DNA chains are unidirectionally aligned to make a thin film such as in LCD display devices. The DNA chains can make more complex microstructures such as knit or a texture with ice cream cone shapes when the same procedure is carried out in topographical patterns like microposts (Figure 1). This can be applied to make metamaterials by mixing with functionalized gold nanorods to show plasmonic color.

Plasmon resonance is a phenomenon in which electrons vibrate uniformly on the surface of a substrate made of metal, reacting only to light that matches a specific energy to enhance the clarity and expression of colors. For this, the most important factor is the orientation in which the gold nanorods align. That is, when the rods are aligned side by side in one direction, the optical and electrical characteristics are maximized. The research team focused on this point and made the DNA micropatch as a frame to orient the gold nanorods in a unique shape and fabricated a plasmonic color film (Figure 2).

Professor Yoon said this study is meaningful in that it deals with the evaporation phenomenon, which has not been studied much in the field of polymers and biopolymers in terms of basic science. He explained, “This will also help maximize the efficiency of polymeric materials that can be orientated in coating, 2D, and 3D printing applications. Furthermore, DNA that exists infinitely in nature can be expected to have industrial application value as a new material since it can easily form complexes with other materials as described in this study.”

(Figure 1. The DNA micropatch using topographic control. (a) The experimental scheme.

(b) Enlarged image of (e). (c-e) Different micropatches made of DNA using different shearing directions.)

(Figure 2. The knit-like structures made of DNA-gold nanorod complex. (a,b) Optical

and polarized optical microscopy images. (c-f) Plasmonic colors reflected from aligned DNA-gold nanorod complex depending on the sample rotation.)

2019.07.01 View 35570 -

Professor Lee Elected as a Council Member of ION

< Professor Jiyun Lee >

Professor Jiyun Lee from the Department of Aerospace Engineering became the first professor of Korean university to be selected as a council member of the Institute of Navigation (ION), serving specifically as a technical representative.

ION is a world-leading organization established in 1945 and dedicated to advancing Positioning, Navigation and Timing (PNT) technologies. ION’s international membership is drawn not only from professionals in the fields of navigation, engineering, astronomy, education, and general aviation and the airline industry, but also from various supporting institutions, corporations, and government agencies.

Professor Lee has been actively engaged in the Institute’s academic and community activities as a technical advisor for the Satellite Division in the Asia-Pacific region, a chair of the International Technical Meeting, as well as a section chair of the Global Navigation Satellite System (GNSS+) Conference. She has also published 34 papers in numerous ION journals and conference proceedings over the past 10 years while serving as an associate editor of the ION Navigation Journal.

From these activities, Professor Lee was recognized for her academic achievements and committed leadership, which led her to be appointed as the first professor from a Korean university to participate on the Council. She will serve her term over the next two years, and conduct day-to-day operations for the Institute mainly related to developing new programs and strategies for the advancement of PNT technologies and discovering new distinguished members.

2019.06.27 View 8380

Professor Lee Elected as a Council Member of ION

< Professor Jiyun Lee >

Professor Jiyun Lee from the Department of Aerospace Engineering became the first professor of Korean university to be selected as a council member of the Institute of Navigation (ION), serving specifically as a technical representative.

ION is a world-leading organization established in 1945 and dedicated to advancing Positioning, Navigation and Timing (PNT) technologies. ION’s international membership is drawn not only from professionals in the fields of navigation, engineering, astronomy, education, and general aviation and the airline industry, but also from various supporting institutions, corporations, and government agencies.

Professor Lee has been actively engaged in the Institute’s academic and community activities as a technical advisor for the Satellite Division in the Asia-Pacific region, a chair of the International Technical Meeting, as well as a section chair of the Global Navigation Satellite System (GNSS+) Conference. She has also published 34 papers in numerous ION journals and conference proceedings over the past 10 years while serving as an associate editor of the ION Navigation Journal.

From these activities, Professor Lee was recognized for her academic achievements and committed leadership, which led her to be appointed as the first professor from a Korean university to participate on the Council. She will serve her term over the next two years, and conduct day-to-day operations for the Institute mainly related to developing new programs and strategies for the advancement of PNT technologies and discovering new distinguished members.

2019.06.27 View 8380 -

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 42523

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 42523 -

Anti-drone Technology for Anti-Terrorism Applications

(from top right clockwise: Professor Yongdae Kim,

PhD Candidates Yujin Kwon, Juhwan Noh, Hocheol Shin, and Dohyun Kim)

KAIST researchers have developed anti-drone technology that can hijack other drones by spoofing its location using fake GPS signals. This technology can safely guide a drone to a desired location without any sudden change in direction in emergency situations, and thus respond effectively to dangerous drones such as those intending to carry out acts of terrorism.

Advancements in the drone industry have led to the wider use of drones in our daily lives in areas of reconnaissance, searching and rescuing, disaster prevention and response, and delivery services. At the same time, there has also been a growing concern about privacy, safety, and security issues regarding drones, especially those arising from intrusion into private property and secure facilities. Therefore, the anti-drone industry is rapidly expanding to detect and respond to this possible drone invasion.

The current anti-drone systems used in airports and other key locations utilize electronic jamming signals, high-power lasers, or nets to neutralize drones. For example, drones trespassing on airports are often countered with simple jamming signals that can prevent the drones from moving and changing position, but this may result in a prolonged delay in flight departures and arrivals at the airports. Drones used for terrorist attacks – armed with explosives or weapons – must also be neutralized a safe distance from the public and vital infrastructure to minimize any damage.

Due to this need for a new anti-drone technology to counter these threats, a KAIST research team led by Professor Yongdae Kim from the School of Electrical Engineering has developed technology that securely thwarts drones by tricking them with fake GPS signals.

Fake GPS signals have been used in previous studies to cause confusion inside the drone regarding its location, making the drone drift from its position or path. However, such attack tactics cannot be applied in GPS safety mode. GPS safety mode is an emergency mode that ensures drone safety when the signal is cut or location accuracy is low due to a fake GPS signals. This mode differs between models and manufacturers.

Professor Kim’s team analyzed the GPS safety mode of different drone models made from major drone manufacturers such as DJI and Parrot, made classification systems, and designed a drone abduction technique that covers almost all the types of drone GPS safety modes, and is universally applicable to any drone that uses GPS regardless of model or manufacturer. The research team applied their new technique to four different drones and have proven that the drones can be safely hijacked and guided to the direction of intentional abduction within a small margin of error.

Professor Kim said, “Conventional consumer drones equipped with GPS safety mode seem to be safe from fake GPS signals, however, most of these drones are able to be detoured since they detect GPS errors in a rudimentary manner.” He continued, “This technology can contribute particularly to reducing damage to airports and the airline industry caused by illegal drone flights.”

The research team is planning to commercialize the developed technology by applying it to existing anti-drone solutions through technology transfer.” This research, featured in the ACM Transactions on Privacy and Security (TOPS) on April 9, was supported by the Defense Acquisition Program Administration (DAPA) and the Agency for Defense Development (ADD).

Image 1.

Experimental environment in which a fake GPS signal was produced from a PC and injected into the drone signal using directional antennae

Publication:

Juhwan Noh, Yujin Kwon, Yunmok Son, Hocheol Shin, Dohyun Kim, Jaeyeong Choi, and Yongdae Kim. 2019. Tractor Beam: Safe-hijacking of Consumer Drones with Adaptive GPS Spoofing. ACM Transactions on Privacy and Security. New York, NY, USA, Vol. 22, No. 2, Article 12, 26 pages. https://doi.org/10.1145/3309735

Profile: Prof. Yongdae Kim, MS, PhD

yongdaek@kaist.ac.kr

https://www.syssec.kr/

Professor

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Juhwan Noh, PhD Candidate

juhwan@kaist.ac.kr

PhD Candidate

System Security (SysSec) Lab

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

(END)

2019.06.25 View 45368

Anti-drone Technology for Anti-Terrorism Applications

(from top right clockwise: Professor Yongdae Kim,

PhD Candidates Yujin Kwon, Juhwan Noh, Hocheol Shin, and Dohyun Kim)

KAIST researchers have developed anti-drone technology that can hijack other drones by spoofing its location using fake GPS signals. This technology can safely guide a drone to a desired location without any sudden change in direction in emergency situations, and thus respond effectively to dangerous drones such as those intending to carry out acts of terrorism.

Advancements in the drone industry have led to the wider use of drones in our daily lives in areas of reconnaissance, searching and rescuing, disaster prevention and response, and delivery services. At the same time, there has also been a growing concern about privacy, safety, and security issues regarding drones, especially those arising from intrusion into private property and secure facilities. Therefore, the anti-drone industry is rapidly expanding to detect and respond to this possible drone invasion.

The current anti-drone systems used in airports and other key locations utilize electronic jamming signals, high-power lasers, or nets to neutralize drones. For example, drones trespassing on airports are often countered with simple jamming signals that can prevent the drones from moving and changing position, but this may result in a prolonged delay in flight departures and arrivals at the airports. Drones used for terrorist attacks – armed with explosives or weapons – must also be neutralized a safe distance from the public and vital infrastructure to minimize any damage.

Due to this need for a new anti-drone technology to counter these threats, a KAIST research team led by Professor Yongdae Kim from the School of Electrical Engineering has developed technology that securely thwarts drones by tricking them with fake GPS signals.

Fake GPS signals have been used in previous studies to cause confusion inside the drone regarding its location, making the drone drift from its position or path. However, such attack tactics cannot be applied in GPS safety mode. GPS safety mode is an emergency mode that ensures drone safety when the signal is cut or location accuracy is low due to a fake GPS signals. This mode differs between models and manufacturers.

Professor Kim’s team analyzed the GPS safety mode of different drone models made from major drone manufacturers such as DJI and Parrot, made classification systems, and designed a drone abduction technique that covers almost all the types of drone GPS safety modes, and is universally applicable to any drone that uses GPS regardless of model or manufacturer. The research team applied their new technique to four different drones and have proven that the drones can be safely hijacked and guided to the direction of intentional abduction within a small margin of error.

Professor Kim said, “Conventional consumer drones equipped with GPS safety mode seem to be safe from fake GPS signals, however, most of these drones are able to be detoured since they detect GPS errors in a rudimentary manner.” He continued, “This technology can contribute particularly to reducing damage to airports and the airline industry caused by illegal drone flights.”

The research team is planning to commercialize the developed technology by applying it to existing anti-drone solutions through technology transfer.” This research, featured in the ACM Transactions on Privacy and Security (TOPS) on April 9, was supported by the Defense Acquisition Program Administration (DAPA) and the Agency for Defense Development (ADD).

Image 1.

Experimental environment in which a fake GPS signal was produced from a PC and injected into the drone signal using directional antennae

Publication:

Juhwan Noh, Yujin Kwon, Yunmok Son, Hocheol Shin, Dohyun Kim, Jaeyeong Choi, and Yongdae Kim. 2019. Tractor Beam: Safe-hijacking of Consumer Drones with Adaptive GPS Spoofing. ACM Transactions on Privacy and Security. New York, NY, USA, Vol. 22, No. 2, Article 12, 26 pages. https://doi.org/10.1145/3309735

Profile: Prof. Yongdae Kim, MS, PhD

yongdaek@kaist.ac.kr

https://www.syssec.kr/

Professor

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Juhwan Noh, PhD Candidate

juhwan@kaist.ac.kr

PhD Candidate

System Security (SysSec) Lab

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

(END)

2019.06.25 View 45368 -

Hydrogen-Natural Gas Hydrates Harvested by Natural Gas

A hydrogen-natural gas blend (HNGB) can be a game changer only if it can be stored safely and used as a sustainable clean energy resource. A recent study has suggested a new strategy for stably storing hydrogen, using natural gas as a stabilizer. The research proposed a practical gas phase modulator based synthesis of HNGB without generating chemical waste after dissociation for the immediate service.

The research team of Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering in collaboration with the Gwangju Institute of Science and Technology (GIST) demonstrated that the natural gas modulator based synthesis leads to significantly reduced synthesis pressure simultaneously with the formation of hydrogen clusters in the confined nanoporous cages of clathrate hydrates. This approach minimizes the environmental impact and reduces operation costs since clathrate hydrates do not generate any chemical waste in both the synthesis and decomposition processes.

For the efficient storage and transportation of hydrogen, numerous materials have been investigated. Among others, clathrate hydrates offer distinct benefits. Clathrate hydrates are nanoporous inclusion compounds composed of a 3D network of polyhedral cages made of hydrogen-bonded ‘host’ water molecules and captured ‘guest’ gas or liquid molecules.

In this study, the research team used two gases, methane and ethane, which have lower equilibrium conditions compared to hydrogen as thermodynamic stabilizers. As a result, they succeeded in stably storing the hydrogen-natural gas compound in hydrates. According to the composition ratio of methane and ethane, structure I or II hydrates can be formed, both of which can stably store hydrogen-natural gas in low-pressure conditions.

The research team found that two hydrogen molecules are stored in small cages in tuned structure I hydrates, while up to three hydrogen molecules can be stored in both small and large cages in tuned structure II hydrates. Hydrates can store gas up to about 170-times its volume and the natural gas used as thermodynamic stabilizers in this study can also be used as an energy source.

The research team developed technology to produce hydrates from ice, produced hydrogen-natural gas hydrates by substitution, and successfully observed that the tuning phenomenon only occurs when hydrogen is involved in hydrate formation from the start for both structures of hydrates.

They expect that the findings can be applied to not only an energy-efficient gas storage material, but also a smart platform to utilize hydrogen natural gas blends, which can serve as a new alternative energy source with targeted hydrogen contents by designing synthetic pathways of mixed gas hydrates.

The research was published online in Energy Storage Materials on June 6, with the title ‘One-step formation of hydrogen clusters in clathrate hydrates stabilized via natural gas blending’.

Professor Lee said, “HNGB will utilize the existing natural gas infrastructure for transportation, so it is very likely that we can commercialize this hydrate system. We are investigating the kinetic performance through a follow-up strategy to increase the volume of gas storage.

This study was funded by the National Research Foundation of Korea and BK21 plus program.

(Figure1. Schematics showing the storage method for hydrogen in a natural gas hydrate using a substitution method and storage method directly from ice to a hydrogen-natural gas hydrate.)

(Figure 2. Artificially synthesized and dissociated hydrogen-natural gas hydrates. The Raman spectra of tuned sI and sII hydrate showing the hydrogen clusters in each cage.)

2019.06.21 View 42768

Hydrogen-Natural Gas Hydrates Harvested by Natural Gas

A hydrogen-natural gas blend (HNGB) can be a game changer only if it can be stored safely and used as a sustainable clean energy resource. A recent study has suggested a new strategy for stably storing hydrogen, using natural gas as a stabilizer. The research proposed a practical gas phase modulator based synthesis of HNGB without generating chemical waste after dissociation for the immediate service.

The research team of Professor Jae Woo Lee from the Department of Chemical and Biomolecular Engineering in collaboration with the Gwangju Institute of Science and Technology (GIST) demonstrated that the natural gas modulator based synthesis leads to significantly reduced synthesis pressure simultaneously with the formation of hydrogen clusters in the confined nanoporous cages of clathrate hydrates. This approach minimizes the environmental impact and reduces operation costs since clathrate hydrates do not generate any chemical waste in both the synthesis and decomposition processes.

For the efficient storage and transportation of hydrogen, numerous materials have been investigated. Among others, clathrate hydrates offer distinct benefits. Clathrate hydrates are nanoporous inclusion compounds composed of a 3D network of polyhedral cages made of hydrogen-bonded ‘host’ water molecules and captured ‘guest’ gas or liquid molecules.

In this study, the research team used two gases, methane and ethane, which have lower equilibrium conditions compared to hydrogen as thermodynamic stabilizers. As a result, they succeeded in stably storing the hydrogen-natural gas compound in hydrates. According to the composition ratio of methane and ethane, structure I or II hydrates can be formed, both of which can stably store hydrogen-natural gas in low-pressure conditions.

The research team found that two hydrogen molecules are stored in small cages in tuned structure I hydrates, while up to three hydrogen molecules can be stored in both small and large cages in tuned structure II hydrates. Hydrates can store gas up to about 170-times its volume and the natural gas used as thermodynamic stabilizers in this study can also be used as an energy source.

The research team developed technology to produce hydrates from ice, produced hydrogen-natural gas hydrates by substitution, and successfully observed that the tuning phenomenon only occurs when hydrogen is involved in hydrate formation from the start for both structures of hydrates.

They expect that the findings can be applied to not only an energy-efficient gas storage material, but also a smart platform to utilize hydrogen natural gas blends, which can serve as a new alternative energy source with targeted hydrogen contents by designing synthetic pathways of mixed gas hydrates.

The research was published online in Energy Storage Materials on June 6, with the title ‘One-step formation of hydrogen clusters in clathrate hydrates stabilized via natural gas blending’.

Professor Lee said, “HNGB will utilize the existing natural gas infrastructure for transportation, so it is very likely that we can commercialize this hydrate system. We are investigating the kinetic performance through a follow-up strategy to increase the volume of gas storage.

This study was funded by the National Research Foundation of Korea and BK21 plus program.

(Figure1. Schematics showing the storage method for hydrogen in a natural gas hydrate using a substitution method and storage method directly from ice to a hydrogen-natural gas hydrate.)

(Figure 2. Artificially synthesized and dissociated hydrogen-natural gas hydrates. The Raman spectra of tuned sI and sII hydrate showing the hydrogen clusters in each cage.)

2019.06.21 View 42768 -

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 51376

Efficiently Producing Fatty Acids and Biofuels from Glucose

Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.

The newly developed strain, created by Distinguished Professor Sang Yup Lee and his team, showed the highest efficiency in producing fatty acids and biodiesels ever reported. It will be expected to serve as a new platform to sustainably produce a wide array of fatty acid-based products from glucose and other carbon substrates.

Fossil fuels, which have long been energy resources for our daily lives, are now facing serious challenges: depletion of their reserves and their role in global warming. The production of sustainable bio-based renewable energy has emerged as an essential alternative and many studies to replace fossil fuels are underway. One of the representative examples is biodiesel. Currently, it is mainly being produced through the transesterification of vegetable oils or animal fats.

The research team engineered oleaginous microorganisms, Rhodococcus opacus, to produce fatty acids and their derivatives that can be used as biodiesel from glucose, one of the most abundant and cheap sugars derived from non-edible biomass.

Professor Lee’s team has already engineered Escherichia coli to produce short-chain hydrocarbons, which can be used as gasoline (published in Nature as the cover paper in 2013). However, the production efficiency of the short-chain hydrocarbons using E. coli (0.58 g/L) fell short of the levels required for commercialization.

To overcome these issues, the team employed oil-accumulating Rhodococcus opacus as a host strain in this study. First, the team optimized the cultivation conditions of Rhodococcus opacus to maximize the accumulation of oil (triacylglycerol), which serves as a precursor for the biosynthesis of fatty acids and their derivatives. Then, they systematically analyzed the metabolism of the strain and redesigned it to enable higher levels of fatty acids and two kinds of fatty acid-derived biodiesels (fatty acid ethyl esters and long-chain hydrocarbons) to be produced.

They found that the resulting strains produced 50.2, 21.3, and 5.2 g/L of fatty acids, fatty acid ethyl esters, and long-chain hydrocarbons, respectively. These are all the highest concentrations ever reported by microbial fermentations. It is expected that these strains can contribute to the future industrialization of microbial-based biodiesel production.

“This technology creates fatty acids and biodiesel with high efficiency by utilizing lignocellulose, one of the most abundant resources on the Earth, without depending on fossil fuels and vegetable or animal oils. This will provide new opportunities for oil and petroleum industries, which have long relied on fossil fuels, to turn to sustainable and eco-friendly biotechnologies,” said Professor Lee.

This paper titled “Engineering of an oleaginous bacterium for the production of fatty acids and fuels” was published in Nature Chemical Biology on June 17.

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea (NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557).

(Figure: Metabolic engineering for the production of free fatty acids (FFAs), fatty acid ethyl esters (FAEEs), and long-chain hydrocarbons (LCHCs) in Rhodococcus opacus PD630. Researchers have presented a new strategy for efficiently producing fatty acids and biofuels that can transform glucose and oleaginous microorganisms into microbial diesel fuel, with one-step direct fermentative production.)

# # #

Source:

Hye Mi Kim, Tong Un Chae, So Young Choi, Won Jun Kim and Sang Yup Lee. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nature Chemical Biology ( https://www.nature.com/nchembio/ ) DOI: 10.1038/s41589-019-0295-5

Profile

Dr. Sang Yup Lee

leesy@kaist.ac.kr

Distinguished Professor at the Department of Chemical and Biomolecular Engineering

KAIST

2019.06.19 View 51376 -

Real-Time Analysis of MOF Adsorption Behavior

Researchers have developed a technology to analyze the adsorption behavior of molecules in each individual pore of a metal organic framework (MOF). This system has large specific surface areas, allowing for the real-time observation of the adsorption process of an MOF, a new material effective for sorting carbon dioxide, hydrogen, and methane.

Accurate measurements and assessments of gas adsorption isotherms are important for characterizing porous materials and developing their applications. The existing technology is only able to measure the amount of gas molecules adsorbed to the material, without directly observing the adsorption behavior.

The research team led by Professor Jeung Ku Kang from the Graduate School of Energy, Environment, Water and Sustainability (EEWS) prescribed a real time gas adsorption crystallography system by integrating an existing X-ray diffraction (XRD) measurement device that can provide structural information and a gas adsorption measurement device.

Specifically, the system allowed the observation of a mesoporous MOF that has multiple pores rather than a single pore structure. The research team categorized the adsorption behaviors of MOF molecules by pore type, followed by observations and measurements, resulting in the identification of a stepwise adsorption process that was previously not possible to analyze.

Further, the team systematically and quantitatively analyzed how the pore structure and the type of adsorption molecule affect the adsorption behavior to suggest what type of MOF structure is appropriate as a storage material for each type of adsorption behavior.

Professor Kang said, “We quantitatively analyzed each pore molecule in real time to identify the effects of chemical and structural properties of pores on adsorption behavior.” He continued, “By understanding the real-time adsorption behavior of molecules at the level of the pores that form the material, rather than the whole material, we will be able to apply this technology to develop a new high-capacity storage material.”

This research was published in Nature Chemistry online on May 13, 2019 under the title ‘Isotherms of Individual Pores by Gas Adsorption Crystallography’.

(Figure. Schematic illustration of molecules adsorbed on metal organic frameworks with different pores of various structures, where the In-situ X-ray crystallography has been developed to classify each pore structure and analyze the position of the molecule to determine the amount of molecules adsorbed to each pore.)

2019.06.18 View 39959

Real-Time Analysis of MOF Adsorption Behavior

Researchers have developed a technology to analyze the adsorption behavior of molecules in each individual pore of a metal organic framework (MOF). This system has large specific surface areas, allowing for the real-time observation of the adsorption process of an MOF, a new material effective for sorting carbon dioxide, hydrogen, and methane.

Accurate measurements and assessments of gas adsorption isotherms are important for characterizing porous materials and developing their applications. The existing technology is only able to measure the amount of gas molecules adsorbed to the material, without directly observing the adsorption behavior.

The research team led by Professor Jeung Ku Kang from the Graduate School of Energy, Environment, Water and Sustainability (EEWS) prescribed a real time gas adsorption crystallography system by integrating an existing X-ray diffraction (XRD) measurement device that can provide structural information and a gas adsorption measurement device.

Specifically, the system allowed the observation of a mesoporous MOF that has multiple pores rather than a single pore structure. The research team categorized the adsorption behaviors of MOF molecules by pore type, followed by observations and measurements, resulting in the identification of a stepwise adsorption process that was previously not possible to analyze.

Further, the team systematically and quantitatively analyzed how the pore structure and the type of adsorption molecule affect the adsorption behavior to suggest what type of MOF structure is appropriate as a storage material for each type of adsorption behavior.

Professor Kang said, “We quantitatively analyzed each pore molecule in real time to identify the effects of chemical and structural properties of pores on adsorption behavior.” He continued, “By understanding the real-time adsorption behavior of molecules at the level of the pores that form the material, rather than the whole material, we will be able to apply this technology to develop a new high-capacity storage material.”

This research was published in Nature Chemistry online on May 13, 2019 under the title ‘Isotherms of Individual Pores by Gas Adsorption Crystallography’.

(Figure. Schematic illustration of molecules adsorbed on metal organic frameworks with different pores of various structures, where the In-situ X-ray crystallography has been developed to classify each pore structure and analyze the position of the molecule to determine the amount of molecules adsorbed to each pore.)

2019.06.18 View 39959 -

Novel Via-Hole-Less Multilevel Metal Interconnection Methods

Forming reliable multi-level metal interconnections is a key technology for integrating devices into organic integrated circuits (ICs). The conventional approach, called “via-hole,” locally removes the insulator and utilizes metal interconnects through the holes. Due to the high sensitivity of organic materials to chemical solvents, heat, and photo-radiation used in conventional “via-hole” methods, alternative printing methods or laser drilling methods have been developed. However, finding a reliable and practical metal interconnection for organic ICs is still challenging.

The research team of KAIST Professor Sung Gap Im and Postech Professor Kim Jae-Joon reported a new interconnection method that does not require via-hole formation, “via-hole-less metal interconnection,” in Nature Communications on June 3.

Metal electrodes in different layers can be isolated from each other by patterned dielectric layers, where they then can be interconnected to others in the open area where the dielectric layer is not present. See the images below. Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Professor Kim explained, “Our proposed via-hole-less interconnect method using a selectively patterned dielectric overcomes the limitations of the previous time-consuming, one-by-one via-hole formation process and provides reliable methods for creating metal interconnects in organic ICs. We expect the via-hole-less scheme to bring advances to organic IC technology.”

2019.06.18 View 45306

Novel Via-Hole-Less Multilevel Metal Interconnection Methods

Forming reliable multi-level metal interconnections is a key technology for integrating devices into organic integrated circuits (ICs). The conventional approach, called “via-hole,” locally removes the insulator and utilizes metal interconnects through the holes. Due to the high sensitivity of organic materials to chemical solvents, heat, and photo-radiation used in conventional “via-hole” methods, alternative printing methods or laser drilling methods have been developed. However, finding a reliable and practical metal interconnection for organic ICs is still challenging.

The research team of KAIST Professor Sung Gap Im and Postech Professor Kim Jae-Joon reported a new interconnection method that does not require via-hole formation, “via-hole-less metal interconnection,” in Nature Communications on June 3.

Metal electrodes in different layers can be isolated from each other by patterned dielectric layers, where they then can be interconnected to others in the open area where the dielectric layer is not present. See the images below. Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Professor Kim explained, “Our proposed via-hole-less interconnect method using a selectively patterned dielectric overcomes the limitations of the previous time-consuming, one-by-one via-hole formation process and provides reliable methods for creating metal interconnects in organic ICs. We expect the via-hole-less scheme to bring advances to organic IC technology.”

2019.06.18 View 45306 -

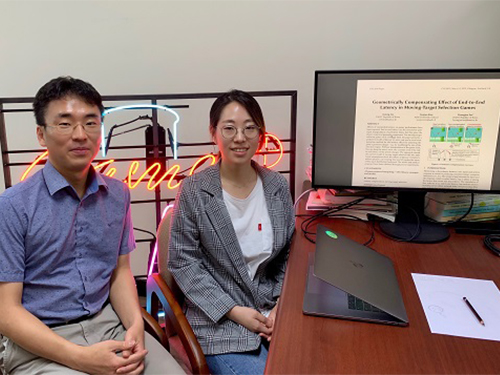

Play Games With No Latency

One of the most challenging issues for game players looks to be resolved soon with the introduction of a zero-latency gaming environment. A KAIST team developed a technology that helps game players maintain zero-latency performance. The new technology transforms the shapes of game design according to the amount of latency.

Latency in human-computer interactions is often caused by various factors related to the environment and performance of the devices, networks, and data processing. The term ‘lag’ is used to refer to any latency during gaming which impacts the user’s performance.

Professor Byungjoo Lee at the Graduate School of Culture Technology in collaboration with Aalto University in Finland presented a mathematical model for predicting players' behavior by understanding the effects of latency on players. This cognitive model is capable of predicting the success rate of a user when there is latency in a 'moving target selection' task which requires button input in a time constrained situation.

The model predicts the players’ task success rate when latency is added to the gaming environment. Using these predicted success rates, the design elements of the game are geometrically modified to help players maintain similar success rates as they would achieve in a zero-latency environment. In fact, this research succeeded in modifying the pillar heights of the Flappy Bird game, allowing the players to maintain their gaming performance regardless of the added latency.

Professor Lee said, "This technique is unique in the sense that it does not interfere with a player's gaming flow, unlike traditional methods which manipulate the game clock by the amount of latency. This study can be extended to various games such as reducing the size of obstacles in the latent computing environment.”

This research, in collaboration with Dr. Sunjun Kim from Aalto University and led by PhD candidate Injung Lee, was presented during the 2019 CHI Conference on Human Factors in Computing Systems last month in Glasgow in the UK.

This research was supported by the National Research Foundation of Korea (NRF) (2017R1C1B2002101, 2018R1A5A7025409), and the Aalto University Seed Funding Granted to the GamerLab respectively.

Figure 1. Overview of Geometric Compensation

Publication:

Injung Lee, Sunjun Kim, and Byungjoo Lee. 2019. Geometrically Compensating Effect of End-to-End Latency in Moving-Target Selection Games. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI’19) . ACM, New York, NY, USA, Article 560, 12 pages. https://doi.org/10.1145/3290605.3300790

Video Material:

https://youtu.be/TTi7dipAKJs

Profile: Prof. Byungjoo Lee, MD, PhD

byungjoo.lee@kaist.ac.kr

http://kiml.org/

Assistant Professor

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Injung Lee, PhD Candidate

edndn@kaist.ac.kr

PhD Candidate

Interactive Media Lab

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Postdoc. Sunjun Kim, MD, PhD

kuaa.net@gmail.com

Postdoctoral Researcher

User Interfaces Group

Aalto University

https://www.aalto.fi Espoo 02150, Finland

(END)

2019.06.11 View 48275

Play Games With No Latency

One of the most challenging issues for game players looks to be resolved soon with the introduction of a zero-latency gaming environment. A KAIST team developed a technology that helps game players maintain zero-latency performance. The new technology transforms the shapes of game design according to the amount of latency.

Latency in human-computer interactions is often caused by various factors related to the environment and performance of the devices, networks, and data processing. The term ‘lag’ is used to refer to any latency during gaming which impacts the user’s performance.

Professor Byungjoo Lee at the Graduate School of Culture Technology in collaboration with Aalto University in Finland presented a mathematical model for predicting players' behavior by understanding the effects of latency on players. This cognitive model is capable of predicting the success rate of a user when there is latency in a 'moving target selection' task which requires button input in a time constrained situation.

The model predicts the players’ task success rate when latency is added to the gaming environment. Using these predicted success rates, the design elements of the game are geometrically modified to help players maintain similar success rates as they would achieve in a zero-latency environment. In fact, this research succeeded in modifying the pillar heights of the Flappy Bird game, allowing the players to maintain their gaming performance regardless of the added latency.

Professor Lee said, "This technique is unique in the sense that it does not interfere with a player's gaming flow, unlike traditional methods which manipulate the game clock by the amount of latency. This study can be extended to various games such as reducing the size of obstacles in the latent computing environment.”

This research, in collaboration with Dr. Sunjun Kim from Aalto University and led by PhD candidate Injung Lee, was presented during the 2019 CHI Conference on Human Factors in Computing Systems last month in Glasgow in the UK.

This research was supported by the National Research Foundation of Korea (NRF) (2017R1C1B2002101, 2018R1A5A7025409), and the Aalto University Seed Funding Granted to the GamerLab respectively.

Figure 1. Overview of Geometric Compensation

Publication:

Injung Lee, Sunjun Kim, and Byungjoo Lee. 2019. Geometrically Compensating Effect of End-to-End Latency in Moving-Target Selection Games. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI’19) . ACM, New York, NY, USA, Article 560, 12 pages. https://doi.org/10.1145/3290605.3300790

Video Material:

https://youtu.be/TTi7dipAKJs

Profile: Prof. Byungjoo Lee, MD, PhD

byungjoo.lee@kaist.ac.kr

http://kiml.org/

Assistant Professor

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Injung Lee, PhD Candidate

edndn@kaist.ac.kr

PhD Candidate

Interactive Media Lab

Graduate School of Culture Technology (CT)

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Postdoc. Sunjun Kim, MD, PhD

kuaa.net@gmail.com

Postdoctoral Researcher

User Interfaces Group

Aalto University

https://www.aalto.fi Espoo 02150, Finland

(END)

2019.06.11 View 48275 -

Early Genome Catastrophes Can Cause Non-Smoking Lung Cancer

Some teenagers harbor catastrophic changes to their genomes that can lead to lung cancer later on in life, even if they never smoke

(Professor Young Seok Ju at the Graduate School of Medical Science and Engineering)

Catastrophic rearrangements in the genome occurring as early as childhood and adolescence can lead to the development of lung cancer in later years in non-smokers. This finding, published in Cell, helps explain how some non-smoking-related lung cancers develop.

Researchers at KAIST, Seoul National University and their collaborators confirmed that gene fusions in non-smokers mostly occur early on, sometimes as early as childhood or adolescence, and on average about three decades before cancer is diagnosed. The study showed that these mutant lung cells, harboring oncogenic seeds, remain dormant for several decades until a number of further mutations accumulate sufficiently for progression into cancer. This is the first study to reveal the landscape of genome structural variations in lung adenocarcinoma.

Lung cancer is the leading cause of cancer-related deaths worldwide, and lung adenocarcinoma is its most common type. Most lung adenocarcinomas are associated with chronic smoking, but about a fourth develop in non-smokers. Precisely what happens in non-smokers for this cancer to develop is not clearly understood.

Researchers analyzed the genomes of 138 lung adenocarcinoma patients, including smokers and non-smokers, with whole-genome sequencing technologies. They explored DNA damage that induced neoplastic transformation.

Lung adenocarcinomas that originated from chronic smoking, referred to as signature 4-high (S4-high) cancers in the study, showed several distinguishing features compared to smoking-unrelated cancers (S4-low).

People in the S4-high group were largely older, men and had more frequent mutations in a cancer-related gene called KRAS. Cancer genomes in the S4-high group were hypermutated with simple mutational classes, such as the substitution, insertion, or deletion of a single base, the building block of DNA.

But the story was very different in the S4-low group. Generally, mutational profiles in this group were much more silent than the S4-high group. However, all cancer-related gene fusions, which are abnormally activated from the merging of two originally separate genes, were exclusively observed in the S4-low group.

The patterns of genomic structural changes underlying gene fusions suggest that about three in four cases of gene fusions emerged from a single cellular crisis causing massive genomic fragmentation and subsequent imprecise repair in normal lung epithelium.

Most strikingly, these major genomic rearrangements, which led to the development of lung adenocarcinoma, are very likely to be acquired decades before cancer diagnosis. The researchers used genomic archaeology techniques to trace the timing of when the catastrophes took place.