CT

-

KAIST Holds Its Fourth Public Art Exhibition

KAIST hosted an opening ceremony for the annual art exhibition on December 3, 2015 at the KAIST Institute building. The KAIST Art and Design Committee first organized the event in 2012 to promote the integration of art and technology.

This year’s event entitled “Understanding the Purpose of an Object” will display 20 art pieces under six themes. Artist Keumhong Lee, Haeyool Roh, Joon Kim, Kyung Lee, and Juhae Yang participated in the exhibition. The names of some of the art pieces include “Feedback Field” by Joon Kim, “Self Action” by Haeyool Roh, and “Net of Time” by Juhae Yang.

Juhae Yang believes that, in the digital age, an identity of an object is defined by the traces of light which we read in the information hidden in the barcodes. Based on this interpretation, she transforms the black bars and white spaces into a harmony of colors and sounds. The continuum of colors and sounds in her work arouses time-space synesthesia.

Professor Sangmin Bae of the Industrial Design Department, the Director of the KAIST Art and Design Committee, hopes that the exhibition will inspire novel scientific ideas and artistic spirits.

The exhibition will remain open to the public until December 20, 2015.

2015.12.03 View 9195

KAIST Holds Its Fourth Public Art Exhibition

KAIST hosted an opening ceremony for the annual art exhibition on December 3, 2015 at the KAIST Institute building. The KAIST Art and Design Committee first organized the event in 2012 to promote the integration of art and technology.

This year’s event entitled “Understanding the Purpose of an Object” will display 20 art pieces under six themes. Artist Keumhong Lee, Haeyool Roh, Joon Kim, Kyung Lee, and Juhae Yang participated in the exhibition. The names of some of the art pieces include “Feedback Field” by Joon Kim, “Self Action” by Haeyool Roh, and “Net of Time” by Juhae Yang.

Juhae Yang believes that, in the digital age, an identity of an object is defined by the traces of light which we read in the information hidden in the barcodes. Based on this interpretation, she transforms the black bars and white spaces into a harmony of colors and sounds. The continuum of colors and sounds in her work arouses time-space synesthesia.

Professor Sangmin Bae of the Industrial Design Department, the Director of the KAIST Art and Design Committee, hopes that the exhibition will inspire novel scientific ideas and artistic spirits.

The exhibition will remain open to the public until December 20, 2015.

2015.12.03 View 9195 -

KAIST's Top 10 Contributions to Korea and the World

Established in 1971, the Korea Advanced Institute of Science and Technology (KAIST) started off as a relatively modest graduate school in a few disciplines in science and technology, but has gradually expanded into a full-fledged research university over the years.

From the beginning, KAIST was intended to offer an elite science education, setting it apart from other universities in Korea. A majority of its graduates have contributed to the development of, what the world now praises, Korean industry and economy, and have led the Korean scientific community for several decades. The university has also advanced the frontiers of knowledge, conducting the lion’s share of the nation’s private research and development in basic and applied science, leading to innovations and technologies essential to the growth of today’s Korea.

As it establishes international benchmarks of success, KAIST has acquired a global reputation for delivering the highest level of science and engineering education, while performing cutting-edge research and serving as a crucial driver to generate new knowledge and innovation beneficial not only to Korea but also to the world. The university has consistently ranked in the top 100 research universities for over more than a decade, according to the world university rankings published by international ranking institutions for higher education, among others, Quacquarelli Symonds and the Times Higher Education.

KAIST will mark its 45th anniversary next year. It plans to celebrate the anniversary, and here are some of the reasons why:

KAIST’s Win at the DARPA Robotics Challenge (DRC) 2015

Team KAIST, consisted of 29 members (students and researchers) led by Professors Jun-Ho Oh of the Mechanical Engineering Department and In-So Kweon of the Electrical Engineering Department, won the international humanoid robotics competition hosted by the United States (US) Defense Advanced Research Projects Agency (DARPA). Upon completion of the first and second competitions, the finals were held on June 5-6, 2015, at the Fairplex in Pomona, California. DARPA hosted the event to spur the development of humanoid robots to assist rescue and relief efforts in dangerous environments such as the Fukushima Daiichi nuclear incident in 2011. With 24 international teams participating in the finals from the US, Japan, Germany, China, Italy, and Korea, Team KAIST’s humanoid robot, DRC-HUBO, completed all eight tasks in 44 minutes and 28 seconds, six minutes earlier than the runner-up, and almost eleven minutes earlier than the third-place team, walking away with the grand prize of USD 2 million.

Hitting a Grand Slam to Win Major International Design Awards

Professor Sang-Min Bae of the Industrial Design Department achieved a grand slam in international design awards with his work HEARTea, an interactive tumbler, winning four major design competitions in the world: the iF Design Award, the International Design Excellence Awards, the Red Dot Design Award, and the Good Design Award. Released in 2010, HEARTea swept prizes from the four awards which were held during the period of the year 2010-2011. The tumbler displays the temperature of liquid contained inside in three degrees (cool, warm, and hot) by showing different colored lights on the surface of the tumbler based on the liquid temperature (see picture below). In 2015, Professor Bae and his research team won three awards from the 2015 Red Dot Design Award: the Best of the Best Award and two Red Dot Design Concept Awards. The team received the Best of the Best Award, the most prestigious award among the Red Dot Design awards, for Boxchool, a modular classroom built on shipping containers, which offers underprivileged children better opportunities for learning. With greater mobility, Boxchool can be easily installed in any setting, including remote areas where children do not have access to regular school facilities.

Glass Fabric Thermoelectric Generator, the Grand Prize Winner at the Netexplo Forum 2015

Professor Byung-Jin Cho of the Electrical Engineering Department received the grand prize at the Netexplo Forum 2015 held in partnership with the United Nations Educational, Scientific, and Cultural Organization (UNESCO) on February 4-5, 2015, at the UNESCO House in Paris. Established in 2007, the Netexplo Forum is an annual international conference hosted by the Netexplo Observatory, a non-profit organization sponsored by the French Senate and the French Ministry for the Digital Economy, which studies the impact of digital technology on society and business. Each year, the Netexplo Forum highlights major trends in digital technology and innovation worldwide and lists the top ten most promising technologies that it considers will greatly impact the world. Among the list for this year, Professor Cho’s glass fabric-based thermoelectric (TE) generator received the grand prize. Using a screen-printing technique, Professor Cho printed TE liquid materials onto a glass fabric to generate electricity through the thermoelectric effect, that is, by generating electricity from temperature difference. Since the glass fabric is light and flexible, this technology is expected to have a wide range of applications in wearable computers and devices.

Charging on the Go: Online Electric Vehicle System

KAIST’s Online Electric Vehicle (OLEV) is a system that charges electric vehicles while stationary or driving, thus removing the need to stop for charges. Developed by Professor Dong-Ho Cho of the Electrical Engineering Department and his research team, OLEV receives power wirelessly through a new application called “Shaped Magnetic Field in Resonance technology (SMFIR).” Electrical cables buried underneath roads create magnetic fields, and a receiving device installed underneath the electric vehicle collects the fields and converts them into electricity. Time, a US weekly magazine, listed OLEV as one of the 50 Greatest Inventions of the Year 2010 in its November 22nd issue. Since 2012, several OLEV buses have been operating daily to provide citizens with transportation in cities such as Yeosu, Gumi, and Sejong in Korea. In April 2015, Professor Cho signed a memorandum of understanding with the city government of Medellín, the second largest city in Colombia, to provide two OLEV buses for inner-city transportation services. The research team also developed OLEV for a high capacity transit system including trams and high-speed trains, successfully showcasing 60 kHz of power transferred wirelessly to trams and trains in 2013 and 2014, respectively.

Pioneer in the Development of Functional Mesoporous Materials and Zeolites

On September 25, 2014, Thomson Reuters announced the “2014 Citation Laureates,” a list of candidates considered likely to win the Nobel Prize in the fields of physics, chemistry, physiology or medicine, and economics. Distinguished Professor Ryong Ryoo of the Department of Chemistry was named the 2014 Thomson Reuters Citation Laureates in Chemistry in recognition of his significant contribution to the advancement of designing functional mesoporous materials. He is the first Korean scientist to make the list. Professor Ryoo has pioneered the field of functional mesoporous materials and zeolites which are widely used as catalysts and sorbents. In 1999, he developed a nanocasting method, and with the technique, was able to synthesize ordered mesoporous carbon materials, for the first time in the world. Today, ordered mesoporous carbon materials have widespread applications in many areas such as adsorbents, catalysts and supports, gas-storage hosts, and electrode materials. Since 2006, using zeolite frameworks, Professor Ryoo has led the development of new methods to synthesize mesoporous materials whose molecules are designed to have a hierarchical structure of microspores and mesopores. He has published 255 research papers in renowned academic journals including Nature and Science. In December 2011, Science highlighted his research as one of the top ten breakthroughs in the year of 2011 in an article entitled “Directing Zeolite Structures into Hierarchically Nanoporous Architectures.” Professor Ryoo received numerous awards and honors including the World’s Top 100 Chemists over the Past 11 Years (2000-2010) by UNESCO and IUPAC (International Union of Pure and Applied Chemistry), the Breck Award by International Zeolite Association, and the Ho-Am prize in Science.

The Launch of Korea’s First Satellites into Space

Founded in 1989, the Satellite Technology Research Center (SaTReC) at KAIST has led the development of a series of Korean-made satellites over the past 26 years. The first satellite, the Korea Institute of Technology Satellite-1 (KITSAT-1), was launched on August 11, 1992, at the Guiana Space Center in Kourou, French Guiana. KITSAT-1 was designed in collaboration with a British university, the University of Surrey in Guildford. The success of KITSAT-1 sparked nation-wide interest in the development of space technology and led to the subsequent launches of 18 satellites and three carrier rockets such as KITSAT-2 and 3 (meteorological satellites); KSR-1, 2, and 3 (carrier rockets); KOREASAT-1, 2, 3, 5, and 6 (communication satellites); KOMPSAT-1, 2, 3, and 5 (multipurpose satellites); STSAT-1, 2C, and 3 (scientific satellites); and COMS-1 (navigation satellite). The latest scientific satellite, STSAT-3, and an earth observation satellite, KOMPSAT-3A, were launched in 2013 and 2015, respectively. The STSAT-2C, exclusively developed by SaTReC, was launched in January 2013 and transmitted data on the observation of space environments to the ground station located on KAIST’s campus for 14 months. The STSAT-2C was the first satellite developed solely with Korean technology. On June 30, 2009, the Korean government also established a spaceport in South Jeolla’s Goheung County, the Naro Space Center to launch satellites and spacecraft.

KAIST: Major Feeder for Startups in Korea

As seen in its core values of promoting creativity and a challenging spirit, KAIST has always encouraged startups and technology transfers led by university members including students and faculty. In the past four years from 2011 to 2014, students and faculty members have created 104 startups based on technology innovation and research outcomes, with an average of 26 new companies started per year. This is the highest number of university-led startups in Korea. As of 2013, KAIST graduates founded a total of 1,245 companies, generating approximately USD 1.5 billion sales and creating 34,000 jobs. KAIST has provided a variety of programs and facilities to build a startup-friendly campus culture and support student- and faculty-led entrepreneurship, for example, the End-Run Policy, Startup KAIST Studio, the Institute of Startup and Entrepreneurship, and the Startup Incubation Center. In particular, KAIST Idea Factory, a startup laboratory established last year, where students play around with ideas by conducting new experiments or building test products, created 3-D printers this year, producing 20 prototypes and filing four pending patents. Recently, KAIST has registered four proprietary standard patents with MPEG (Moving Picture Experts Group)-LA’s HEVC (High Efficiency Video Coding) Patent Portfolio License, which provides access to essential patent rights for the HEVC digital video coding standard. KAIST expects to acquire more than 50 proprietary standard patents within two years, generating close to UDS 1 million in income.

The Number of KAIST Doctoral Graduates Reaches Over 10,000

Since the establishment of KAIST forty-four years ago, more than ten thousand alumni have received their doctorates. The university’s 2015 Commencement ceremony took place on February 13, 2015, at the Sports Complex on campus, awarding Dr. Sun-Mi Cho of the Department of Biological Sciences the 10,000th doctoral degree. She also received her Bachelor’s and Master’s degrees from KAIST. In 1978, KAIST had only two doctoral graduates, but since 1987, there have been more than one hundred graduates each year, two hundred since 1994, and four hundred since 2000. In 2015 alone, 522 doctoral students graduated. One of the first doctoral graduates, Dr. Dong-Yol Yang (Class of 1978 in the Mechanical Engineering Department) became a professor in the same department of KAIST. In the early 1970s, many Koreans preferred to go abroad for Ph.D. degrees, but this changed when KAIST began to select candidates for master’s degrees in 1973, and doctoral degrees in 1975. Talented Korean students began to work in KAIST laboratories, and its graduates were known for their knowledge and skills. Now, KAIST receives many applications from talented foreign students as well. At the 2015 Commencement, KAIST conferred 522 Doctoral, 1,241 Master’s, and 915 Bachelor of Science degrees. Since its inception in 1971, KAIST has granted 10,403 doctoral degrees, 26,402 master’s degrees, and 51,412 bachelor’s degrees.

Fostering a New Learning Model: The Education 3.0 Program

KAIST undertook a bold initiative to improve its education system that would address more effectively the needs of today’s higher education to foster talents with creative and critical thinking skills. It introduced a new pedagogical model, the Education 3.0 program, to the campus in the spring of 2012, which was then an extremely rare movement taken by universities around the world. The Education 3.0 program incorporates flipped learning and smart classrooms. This means there are no formal lectures while in-class time is devoted to problem solving, exercises, projects, or discussions. The program provided students with greater opportunity to control their learning and interact more with professors and peers. Originally started with three general courses in physics, chemistry, and biology, the Education 3.0 is now offered in 50-60 courses per semester. In 2013 alone, approximately 2,000 KAIST students took the Education 3.0 courses. The university has also developed and implemented an e-Learning system to provide online courses, as well as participated in the Massive Open Online Course (MOOC). Partnering with Coursera since 2013, KAIST has offered three MOOCs in engineering and business management to the global community. Leading the efforts to create Korean MOOCs (K-MOOCs), KAIST agreed with other Korean universities in October 2015 to create online courses in basic subjects of physics, chemistry, mathematics, life science, mechanical engineering, and material science. K-MOOCs will be available in the summer of 2016.

Holistic Admissions for Undergraduates

Korean universities traditionally put an emphasis on students’ empirical data such as a GPA or the national College Scholastic Ability Test (CSAT) when reviewing applicants for the undergraduate admission. This practice, however, has posed serious challenges, most notably with CSAT’s requirement that the test takes place only once a year. It was simply impossible and unfair to assess students’ capability from the scores of a high-pressure, high-stakes standardized test. In 2009, KAIST changed its undergraduate admission process to consider the whole applicant’s profile, not just looking for students with good grades, but interesting and promising students who would contribute to the campus community in different and diverse ways. KAIST’s admissions officers have taken into account applicants’ interests, passions, special talents, and personality through their personal essays, recommendation letters, extracurricular activities, and intensive interviews. Prior to KAIST’s new policy, no other university in the nation had ever incorporated such a holistic approach to review student applications. Today, most Korean universities have adopted this admission policy. In addition, for the first time in Korea, KAIST offered all freshmen the option to defer the decision on majors, thereby allowing them to explore their interests more freely. Even after declaring majors as sophomores and higher classes, KAIST students can easily change their majors, and undergraduate students can actually create and lead their own research projects. As such, KAIST has continued to offer innovations to provide students with a quality education to foster their potential.

2015.11.27 View 18599

KAIST's Top 10 Contributions to Korea and the World

Established in 1971, the Korea Advanced Institute of Science and Technology (KAIST) started off as a relatively modest graduate school in a few disciplines in science and technology, but has gradually expanded into a full-fledged research university over the years.

From the beginning, KAIST was intended to offer an elite science education, setting it apart from other universities in Korea. A majority of its graduates have contributed to the development of, what the world now praises, Korean industry and economy, and have led the Korean scientific community for several decades. The university has also advanced the frontiers of knowledge, conducting the lion’s share of the nation’s private research and development in basic and applied science, leading to innovations and technologies essential to the growth of today’s Korea.

As it establishes international benchmarks of success, KAIST has acquired a global reputation for delivering the highest level of science and engineering education, while performing cutting-edge research and serving as a crucial driver to generate new knowledge and innovation beneficial not only to Korea but also to the world. The university has consistently ranked in the top 100 research universities for over more than a decade, according to the world university rankings published by international ranking institutions for higher education, among others, Quacquarelli Symonds and the Times Higher Education.

KAIST will mark its 45th anniversary next year. It plans to celebrate the anniversary, and here are some of the reasons why:

KAIST’s Win at the DARPA Robotics Challenge (DRC) 2015

Team KAIST, consisted of 29 members (students and researchers) led by Professors Jun-Ho Oh of the Mechanical Engineering Department and In-So Kweon of the Electrical Engineering Department, won the international humanoid robotics competition hosted by the United States (US) Defense Advanced Research Projects Agency (DARPA). Upon completion of the first and second competitions, the finals were held on June 5-6, 2015, at the Fairplex in Pomona, California. DARPA hosted the event to spur the development of humanoid robots to assist rescue and relief efforts in dangerous environments such as the Fukushima Daiichi nuclear incident in 2011. With 24 international teams participating in the finals from the US, Japan, Germany, China, Italy, and Korea, Team KAIST’s humanoid robot, DRC-HUBO, completed all eight tasks in 44 minutes and 28 seconds, six minutes earlier than the runner-up, and almost eleven minutes earlier than the third-place team, walking away with the grand prize of USD 2 million.

Hitting a Grand Slam to Win Major International Design Awards

Professor Sang-Min Bae of the Industrial Design Department achieved a grand slam in international design awards with his work HEARTea, an interactive tumbler, winning four major design competitions in the world: the iF Design Award, the International Design Excellence Awards, the Red Dot Design Award, and the Good Design Award. Released in 2010, HEARTea swept prizes from the four awards which were held during the period of the year 2010-2011. The tumbler displays the temperature of liquid contained inside in three degrees (cool, warm, and hot) by showing different colored lights on the surface of the tumbler based on the liquid temperature (see picture below). In 2015, Professor Bae and his research team won three awards from the 2015 Red Dot Design Award: the Best of the Best Award and two Red Dot Design Concept Awards. The team received the Best of the Best Award, the most prestigious award among the Red Dot Design awards, for Boxchool, a modular classroom built on shipping containers, which offers underprivileged children better opportunities for learning. With greater mobility, Boxchool can be easily installed in any setting, including remote areas where children do not have access to regular school facilities.

Glass Fabric Thermoelectric Generator, the Grand Prize Winner at the Netexplo Forum 2015

Professor Byung-Jin Cho of the Electrical Engineering Department received the grand prize at the Netexplo Forum 2015 held in partnership with the United Nations Educational, Scientific, and Cultural Organization (UNESCO) on February 4-5, 2015, at the UNESCO House in Paris. Established in 2007, the Netexplo Forum is an annual international conference hosted by the Netexplo Observatory, a non-profit organization sponsored by the French Senate and the French Ministry for the Digital Economy, which studies the impact of digital technology on society and business. Each year, the Netexplo Forum highlights major trends in digital technology and innovation worldwide and lists the top ten most promising technologies that it considers will greatly impact the world. Among the list for this year, Professor Cho’s glass fabric-based thermoelectric (TE) generator received the grand prize. Using a screen-printing technique, Professor Cho printed TE liquid materials onto a glass fabric to generate electricity through the thermoelectric effect, that is, by generating electricity from temperature difference. Since the glass fabric is light and flexible, this technology is expected to have a wide range of applications in wearable computers and devices.

Charging on the Go: Online Electric Vehicle System

KAIST’s Online Electric Vehicle (OLEV) is a system that charges electric vehicles while stationary or driving, thus removing the need to stop for charges. Developed by Professor Dong-Ho Cho of the Electrical Engineering Department and his research team, OLEV receives power wirelessly through a new application called “Shaped Magnetic Field in Resonance technology (SMFIR).” Electrical cables buried underneath roads create magnetic fields, and a receiving device installed underneath the electric vehicle collects the fields and converts them into electricity. Time, a US weekly magazine, listed OLEV as one of the 50 Greatest Inventions of the Year 2010 in its November 22nd issue. Since 2012, several OLEV buses have been operating daily to provide citizens with transportation in cities such as Yeosu, Gumi, and Sejong in Korea. In April 2015, Professor Cho signed a memorandum of understanding with the city government of Medellín, the second largest city in Colombia, to provide two OLEV buses for inner-city transportation services. The research team also developed OLEV for a high capacity transit system including trams and high-speed trains, successfully showcasing 60 kHz of power transferred wirelessly to trams and trains in 2013 and 2014, respectively.

Pioneer in the Development of Functional Mesoporous Materials and Zeolites

On September 25, 2014, Thomson Reuters announced the “2014 Citation Laureates,” a list of candidates considered likely to win the Nobel Prize in the fields of physics, chemistry, physiology or medicine, and economics. Distinguished Professor Ryong Ryoo of the Department of Chemistry was named the 2014 Thomson Reuters Citation Laureates in Chemistry in recognition of his significant contribution to the advancement of designing functional mesoporous materials. He is the first Korean scientist to make the list. Professor Ryoo has pioneered the field of functional mesoporous materials and zeolites which are widely used as catalysts and sorbents. In 1999, he developed a nanocasting method, and with the technique, was able to synthesize ordered mesoporous carbon materials, for the first time in the world. Today, ordered mesoporous carbon materials have widespread applications in many areas such as adsorbents, catalysts and supports, gas-storage hosts, and electrode materials. Since 2006, using zeolite frameworks, Professor Ryoo has led the development of new methods to synthesize mesoporous materials whose molecules are designed to have a hierarchical structure of microspores and mesopores. He has published 255 research papers in renowned academic journals including Nature and Science. In December 2011, Science highlighted his research as one of the top ten breakthroughs in the year of 2011 in an article entitled “Directing Zeolite Structures into Hierarchically Nanoporous Architectures.” Professor Ryoo received numerous awards and honors including the World’s Top 100 Chemists over the Past 11 Years (2000-2010) by UNESCO and IUPAC (International Union of Pure and Applied Chemistry), the Breck Award by International Zeolite Association, and the Ho-Am prize in Science.

The Launch of Korea’s First Satellites into Space

Founded in 1989, the Satellite Technology Research Center (SaTReC) at KAIST has led the development of a series of Korean-made satellites over the past 26 years. The first satellite, the Korea Institute of Technology Satellite-1 (KITSAT-1), was launched on August 11, 1992, at the Guiana Space Center in Kourou, French Guiana. KITSAT-1 was designed in collaboration with a British university, the University of Surrey in Guildford. The success of KITSAT-1 sparked nation-wide interest in the development of space technology and led to the subsequent launches of 18 satellites and three carrier rockets such as KITSAT-2 and 3 (meteorological satellites); KSR-1, 2, and 3 (carrier rockets); KOREASAT-1, 2, 3, 5, and 6 (communication satellites); KOMPSAT-1, 2, 3, and 5 (multipurpose satellites); STSAT-1, 2C, and 3 (scientific satellites); and COMS-1 (navigation satellite). The latest scientific satellite, STSAT-3, and an earth observation satellite, KOMPSAT-3A, were launched in 2013 and 2015, respectively. The STSAT-2C, exclusively developed by SaTReC, was launched in January 2013 and transmitted data on the observation of space environments to the ground station located on KAIST’s campus for 14 months. The STSAT-2C was the first satellite developed solely with Korean technology. On June 30, 2009, the Korean government also established a spaceport in South Jeolla’s Goheung County, the Naro Space Center to launch satellites and spacecraft.

KAIST: Major Feeder for Startups in Korea

As seen in its core values of promoting creativity and a challenging spirit, KAIST has always encouraged startups and technology transfers led by university members including students and faculty. In the past four years from 2011 to 2014, students and faculty members have created 104 startups based on technology innovation and research outcomes, with an average of 26 new companies started per year. This is the highest number of university-led startups in Korea. As of 2013, KAIST graduates founded a total of 1,245 companies, generating approximately USD 1.5 billion sales and creating 34,000 jobs. KAIST has provided a variety of programs and facilities to build a startup-friendly campus culture and support student- and faculty-led entrepreneurship, for example, the End-Run Policy, Startup KAIST Studio, the Institute of Startup and Entrepreneurship, and the Startup Incubation Center. In particular, KAIST Idea Factory, a startup laboratory established last year, where students play around with ideas by conducting new experiments or building test products, created 3-D printers this year, producing 20 prototypes and filing four pending patents. Recently, KAIST has registered four proprietary standard patents with MPEG (Moving Picture Experts Group)-LA’s HEVC (High Efficiency Video Coding) Patent Portfolio License, which provides access to essential patent rights for the HEVC digital video coding standard. KAIST expects to acquire more than 50 proprietary standard patents within two years, generating close to UDS 1 million in income.

The Number of KAIST Doctoral Graduates Reaches Over 10,000

Since the establishment of KAIST forty-four years ago, more than ten thousand alumni have received their doctorates. The university’s 2015 Commencement ceremony took place on February 13, 2015, at the Sports Complex on campus, awarding Dr. Sun-Mi Cho of the Department of Biological Sciences the 10,000th doctoral degree. She also received her Bachelor’s and Master’s degrees from KAIST. In 1978, KAIST had only two doctoral graduates, but since 1987, there have been more than one hundred graduates each year, two hundred since 1994, and four hundred since 2000. In 2015 alone, 522 doctoral students graduated. One of the first doctoral graduates, Dr. Dong-Yol Yang (Class of 1978 in the Mechanical Engineering Department) became a professor in the same department of KAIST. In the early 1970s, many Koreans preferred to go abroad for Ph.D. degrees, but this changed when KAIST began to select candidates for master’s degrees in 1973, and doctoral degrees in 1975. Talented Korean students began to work in KAIST laboratories, and its graduates were known for their knowledge and skills. Now, KAIST receives many applications from talented foreign students as well. At the 2015 Commencement, KAIST conferred 522 Doctoral, 1,241 Master’s, and 915 Bachelor of Science degrees. Since its inception in 1971, KAIST has granted 10,403 doctoral degrees, 26,402 master’s degrees, and 51,412 bachelor’s degrees.

Fostering a New Learning Model: The Education 3.0 Program

KAIST undertook a bold initiative to improve its education system that would address more effectively the needs of today’s higher education to foster talents with creative and critical thinking skills. It introduced a new pedagogical model, the Education 3.0 program, to the campus in the spring of 2012, which was then an extremely rare movement taken by universities around the world. The Education 3.0 program incorporates flipped learning and smart classrooms. This means there are no formal lectures while in-class time is devoted to problem solving, exercises, projects, or discussions. The program provided students with greater opportunity to control their learning and interact more with professors and peers. Originally started with three general courses in physics, chemistry, and biology, the Education 3.0 is now offered in 50-60 courses per semester. In 2013 alone, approximately 2,000 KAIST students took the Education 3.0 courses. The university has also developed and implemented an e-Learning system to provide online courses, as well as participated in the Massive Open Online Course (MOOC). Partnering with Coursera since 2013, KAIST has offered three MOOCs in engineering and business management to the global community. Leading the efforts to create Korean MOOCs (K-MOOCs), KAIST agreed with other Korean universities in October 2015 to create online courses in basic subjects of physics, chemistry, mathematics, life science, mechanical engineering, and material science. K-MOOCs will be available in the summer of 2016.

Holistic Admissions for Undergraduates

Korean universities traditionally put an emphasis on students’ empirical data such as a GPA or the national College Scholastic Ability Test (CSAT) when reviewing applicants for the undergraduate admission. This practice, however, has posed serious challenges, most notably with CSAT’s requirement that the test takes place only once a year. It was simply impossible and unfair to assess students’ capability from the scores of a high-pressure, high-stakes standardized test. In 2009, KAIST changed its undergraduate admission process to consider the whole applicant’s profile, not just looking for students with good grades, but interesting and promising students who would contribute to the campus community in different and diverse ways. KAIST’s admissions officers have taken into account applicants’ interests, passions, special talents, and personality through their personal essays, recommendation letters, extracurricular activities, and intensive interviews. Prior to KAIST’s new policy, no other university in the nation had ever incorporated such a holistic approach to review student applications. Today, most Korean universities have adopted this admission policy. In addition, for the first time in Korea, KAIST offered all freshmen the option to defer the decision on majors, thereby allowing them to explore their interests more freely. Even after declaring majors as sophomores and higher classes, KAIST students can easily change their majors, and undergraduate students can actually create and lead their own research projects. As such, KAIST has continued to offer innovations to provide students with a quality education to foster their potential.

2015.11.27 View 18599 -

Dr. Ryu of KAIST Receives the S-Oil Outstanding Paper Award

Dr. Je-Kyung Ryu of KAIST’s Department of Physics has been awarded the S-Oil Outstanding Paper Award for his doctoral dissertation’s originality and applicability.

Professor Tae-Young Yoon of Physics is his doctoral advisor.

The award ceremony took place on November 25, 2015 at the Press Center in Seoul.

This S-Oil Outstanding Paper Award, jointly sponsored by the Korean Academy of Science and Technology (KAST) and the Scholastic University Presidential Association, was established to foster young talented scientists in basic science and to advance the field.

The award is given every other year for each of the fields of physics, chemistry, mathematics, biology, and earth sciences.

With the award, Dr. Ryu received a research grant of USD 8,600.

He discovered, for the first time in the world, how NSF (N-ethylmaleimide-sensitive factor), a protein involved in a vesicular transport in cellular activities, disassembles a SNARE (soluble NSF attachment protein receptor) complex, using a unimolecular biophysics method.

Unlike the existing studies, he proposed a model in which NSF disassembles SNARE complexes at one step, and as a result, provided evidence of how the SNARE complex influenced the fusion of biological membranes.

His research was published in the scientific journal Science issued on March 27, 2015. The title of the paper is “Spring-loaded Unraveling of a Single SNARE Complex by NSF in One Round of ATP Turnover.”

2015.11.27 View 9865

Dr. Ryu of KAIST Receives the S-Oil Outstanding Paper Award

Dr. Je-Kyung Ryu of KAIST’s Department of Physics has been awarded the S-Oil Outstanding Paper Award for his doctoral dissertation’s originality and applicability.

Professor Tae-Young Yoon of Physics is his doctoral advisor.

The award ceremony took place on November 25, 2015 at the Press Center in Seoul.

This S-Oil Outstanding Paper Award, jointly sponsored by the Korean Academy of Science and Technology (KAST) and the Scholastic University Presidential Association, was established to foster young talented scientists in basic science and to advance the field.

The award is given every other year for each of the fields of physics, chemistry, mathematics, biology, and earth sciences.

With the award, Dr. Ryu received a research grant of USD 8,600.

He discovered, for the first time in the world, how NSF (N-ethylmaleimide-sensitive factor), a protein involved in a vesicular transport in cellular activities, disassembles a SNARE (soluble NSF attachment protein receptor) complex, using a unimolecular biophysics method.

Unlike the existing studies, he proposed a model in which NSF disassembles SNARE complexes at one step, and as a result, provided evidence of how the SNARE complex influenced the fusion of biological membranes.

His research was published in the scientific journal Science issued on March 27, 2015. The title of the paper is “Spring-loaded Unraveling of a Single SNARE Complex by NSF in One Round of ATP Turnover.”

2015.11.27 View 9865 -

KAIST and Four Science and Technology Universities Host a Start-up Competition

KAIST and four other science and technology universities, such as Gwangju Institute of Science and Technology (GIST), Ulsan National Institute of Science and Technology (UNIST), Daegu Gyeongbuk Institute of Science and Technology (DGIST), and Pohang University of Science and Technology (POSTECH), hosted a startup competition on November 27, 2015 at the Dongdaemun Design Plaza in Seoul.

Approximately 150 participants including students from the five universities, "angel" investors, and entrepreneurs attended the competition.

The competition was held to promote startups that are based on research achievements in science and technology and to foster entrepreneurs with great potential.

Two hundred and sixty applicants from 81 teams competed this year. Only ten teams made it to the finals.

KAIST students presented two business plans: an experience-centered education platform and mobile taxi-pooling service. Students from other universities presented a brain-stimulating simulation software (GIST), handy smart health trainer (GIST), real-time reporting system for luggage (DGIST), a flower delivery system (UNIST), surveillance and alarm system for stock-related events via machinery studies (UNIST), augmented emotion toys using augmented reality (POSTECH), and a nasal spray for fine dust prevention (POSTECH).

KAIST also displayed an exhibition of “wearable haptic device for multimedia contents” and “next generation recommendation service platform based on one-on-one matching system with high expandability and improved user experience system.”

The winning team received an award from the Minister of Science, ICT and Future Planning of Korea, as well as an opportunity to participate in overseas startup programs over the course of ten days.

Joongmyeon Bae, Director of the KAIST Industry and University Cooperation, who organized the contest, said, “The alumni of Stanford University (USA) has annually created over 5.4 million jobs through startup activities. Likewise, we hope that our event will contribute to job creation by fostering innovative entrepreneurs.”

2015.11.26 View 11674

KAIST and Four Science and Technology Universities Host a Start-up Competition

KAIST and four other science and technology universities, such as Gwangju Institute of Science and Technology (GIST), Ulsan National Institute of Science and Technology (UNIST), Daegu Gyeongbuk Institute of Science and Technology (DGIST), and Pohang University of Science and Technology (POSTECH), hosted a startup competition on November 27, 2015 at the Dongdaemun Design Plaza in Seoul.

Approximately 150 participants including students from the five universities, "angel" investors, and entrepreneurs attended the competition.

The competition was held to promote startups that are based on research achievements in science and technology and to foster entrepreneurs with great potential.

Two hundred and sixty applicants from 81 teams competed this year. Only ten teams made it to the finals.

KAIST students presented two business plans: an experience-centered education platform and mobile taxi-pooling service. Students from other universities presented a brain-stimulating simulation software (GIST), handy smart health trainer (GIST), real-time reporting system for luggage (DGIST), a flower delivery system (UNIST), surveillance and alarm system for stock-related events via machinery studies (UNIST), augmented emotion toys using augmented reality (POSTECH), and a nasal spray for fine dust prevention (POSTECH).

KAIST also displayed an exhibition of “wearable haptic device for multimedia contents” and “next generation recommendation service platform based on one-on-one matching system with high expandability and improved user experience system.”

The winning team received an award from the Minister of Science, ICT and Future Planning of Korea, as well as an opportunity to participate in overseas startup programs over the course of ten days.

Joongmyeon Bae, Director of the KAIST Industry and University Cooperation, who organized the contest, said, “The alumni of Stanford University (USA) has annually created over 5.4 million jobs through startup activities. Likewise, we hope that our event will contribute to job creation by fostering innovative entrepreneurs.”

2015.11.26 View 11674 -

Professor Keon-Jae Lee Lectures at IEDM and ISSCC Forums

Professor Keon-Jae Lee of KAIST’s Materials Science and Engineering Department delivered a speech at the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Electron Devices Meeting (IEDM) held on December 7-9, 2015 in Washington, D.C.

He will also present a speech at the 2016 International Solid-State Circuits Conference scheduled on January 31-February 4, 2016 in San Francisco, California.

Both professional gatherings are considered the world’s most renowned forums in electronic devices and semiconductor technology. It is rare for a Korean researcher to be invited to speak at these global conferences.

Professor Lee was recognized for his research on flexible NAND chips. The Korea Times, an English language daily newspaper in Korea, reported on his participation in the forums and his recent work. An excerpt of the article follows below:

“KAIST Professor to Lecture at Renowned Tech Forums”

By Lee Min-hyung, The Korea Times, November 26, 2015

Recently he has focused on delivering technologies for producing flexible materials that can be applied to everyday life. The flexible NAND flash memory chips are expected to be widely used for developing flexible handsets. His latest research also includes flexible light-emitting diodes (LED) for implantable biomedical applications.

Lee is currently running a special laboratory focused on developing new flexible nano-materials. The research group is working to develop what it calls “self-powered flexible electronic systems” using nanomaterials and electronic technology.

Lee’s achievement with flexible NAND chips was published in the October edition of Nano Letters, the renowned U.S.-based scientific journal.

He said that flexible memory chips will be used to develop wearable computers that can be installed anywhere.

2015.11.26 View 12015

Professor Keon-Jae Lee Lectures at IEDM and ISSCC Forums

Professor Keon-Jae Lee of KAIST’s Materials Science and Engineering Department delivered a speech at the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Electron Devices Meeting (IEDM) held on December 7-9, 2015 in Washington, D.C.

He will also present a speech at the 2016 International Solid-State Circuits Conference scheduled on January 31-February 4, 2016 in San Francisco, California.

Both professional gatherings are considered the world’s most renowned forums in electronic devices and semiconductor technology. It is rare for a Korean researcher to be invited to speak at these global conferences.

Professor Lee was recognized for his research on flexible NAND chips. The Korea Times, an English language daily newspaper in Korea, reported on his participation in the forums and his recent work. An excerpt of the article follows below:

“KAIST Professor to Lecture at Renowned Tech Forums”

By Lee Min-hyung, The Korea Times, November 26, 2015

Recently he has focused on delivering technologies for producing flexible materials that can be applied to everyday life. The flexible NAND flash memory chips are expected to be widely used for developing flexible handsets. His latest research also includes flexible light-emitting diodes (LED) for implantable biomedical applications.

Lee is currently running a special laboratory focused on developing new flexible nano-materials. The research group is working to develop what it calls “self-powered flexible electronic systems” using nanomaterials and electronic technology.

Lee’s achievement with flexible NAND chips was published in the October edition of Nano Letters, the renowned U.S.-based scientific journal.

He said that flexible memory chips will be used to develop wearable computers that can be installed anywhere.

2015.11.26 View 12015 -

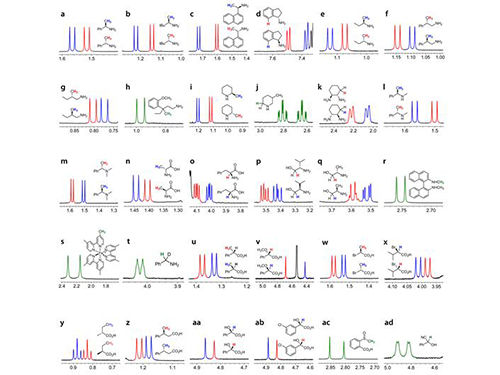

KAIST Develops New Technique for Chiral Activity in Molecules

Professor Hyunwoo Kim of the Chemistry Department and his research team have developed a technique that can easily analyze the optical activity of charged compounds by using nuclear magnetic resonance (NMR) spectroscopy. The research finding entitled “H NMR Chiral Analysis of Charged Molecules via Ion Pairing with Aluminum Complexes” was published online in the October 19th issue of The Journal of the American Chemical Society.

The technique relies on observation of the behavior of optical isomers. Molecules with the same composition that are mirror images of each other are optical isomers. For example, the building blocks of all living organisms, amino acids, are a single optical isomer. In our bodies, optical isomers bring different physiological changes due to their distinct optical activities. Therefore, controlling and analyzing the optical activities are critical when developing a new drug.

High-performance liquid chromatography (HPLC) is the de facto standard of analyzing the optical activity of a compound. However, HPLC is very expensive that many laboratories can’t afford to have. In addition, with the machine, one analysis may take 30 minutes to one hour to complete. It lacks in signal sensitivity and chemical decomposition, and the application is limited to nonpolar compounds.

Usually adopted in analyzing the structure of a chemical compound, NMR spectroscopy requires only one to five minutes per single analysis. Since it is essential for analyzing the molecular structure, many chemistry labs have NMR equipment. However, until this technique was invented, no other research team had reported an effective way of using the NMR spectroscopy to decompose the signal of chiral activity of a compound.

The research team uses negatively-charged metal compounds in NMR spectroscopy. The technique employs negatively-charged metal compounds which bond ionically to positively- and negatively-charged optical compounds. As a result, the NMR spectroscopy can distinguish the signal from chiral activity. Not only can it analyze various chemicals without structural constraints, but it can also be used for both nonpolar and polar solvents.

As many compounds for new drugs have functional groups, which can be charged, this analysis method can be directly employed in the development process of drugs. Professor Kim said, “A revolutionary analysis method has been developed using simple chemical principles. I hope that our method will be applied to the development of new medicine.”

This research was sponsored by the Center for Nanomaterials and Chemical Reactions at the Institute for Basic Science and the Supercomputing Research Center of KAIST.

Picture 1: Separations of NMR Signals of Chemicals due to Interaction with Metal Compounds

Picture 2: Separations of NMR Signals in Different Chemicals

2015.11.20 View 12053

KAIST Develops New Technique for Chiral Activity in Molecules

Professor Hyunwoo Kim of the Chemistry Department and his research team have developed a technique that can easily analyze the optical activity of charged compounds by using nuclear magnetic resonance (NMR) spectroscopy. The research finding entitled “H NMR Chiral Analysis of Charged Molecules via Ion Pairing with Aluminum Complexes” was published online in the October 19th issue of The Journal of the American Chemical Society.

The technique relies on observation of the behavior of optical isomers. Molecules with the same composition that are mirror images of each other are optical isomers. For example, the building blocks of all living organisms, amino acids, are a single optical isomer. In our bodies, optical isomers bring different physiological changes due to their distinct optical activities. Therefore, controlling and analyzing the optical activities are critical when developing a new drug.

High-performance liquid chromatography (HPLC) is the de facto standard of analyzing the optical activity of a compound. However, HPLC is very expensive that many laboratories can’t afford to have. In addition, with the machine, one analysis may take 30 minutes to one hour to complete. It lacks in signal sensitivity and chemical decomposition, and the application is limited to nonpolar compounds.

Usually adopted in analyzing the structure of a chemical compound, NMR spectroscopy requires only one to five minutes per single analysis. Since it is essential for analyzing the molecular structure, many chemistry labs have NMR equipment. However, until this technique was invented, no other research team had reported an effective way of using the NMR spectroscopy to decompose the signal of chiral activity of a compound.

The research team uses negatively-charged metal compounds in NMR spectroscopy. The technique employs negatively-charged metal compounds which bond ionically to positively- and negatively-charged optical compounds. As a result, the NMR spectroscopy can distinguish the signal from chiral activity. Not only can it analyze various chemicals without structural constraints, but it can also be used for both nonpolar and polar solvents.

As many compounds for new drugs have functional groups, which can be charged, this analysis method can be directly employed in the development process of drugs. Professor Kim said, “A revolutionary analysis method has been developed using simple chemical principles. I hope that our method will be applied to the development of new medicine.”

This research was sponsored by the Center for Nanomaterials and Chemical Reactions at the Institute for Basic Science and the Supercomputing Research Center of KAIST.

Picture 1: Separations of NMR Signals of Chemicals due to Interaction with Metal Compounds

Picture 2: Separations of NMR Signals in Different Chemicals

2015.11.20 View 12053 -

Open KAIST 2015

KAIST’s research environment and its most recent achievements were open to the public.

KAIST hosted “Open KAIST 2015” over two days from November 5-6, 2015 in which its 17 departments and three research centers were open to the public. The event is one of the largest events that KAIST holds, which permits such public viewings of its facilities. It is the eighth time it has taken place.

During this event, the departments and centers offered 64 programs including laboratory tours, research achievement exhibitions, department introductions, and special lectures.

The “Motion Capture System”of Professor Jun-Yong Noh’s lab (Graduate School of Culture Technology) drew particular attention.

The “Motion Capture System” expresses human and animal motion in three-dimensional (3D) space using infrared cameras and optic markers, which can then be applied to various industries such as movies, games, and animation. During the program, researchers themselves demonstrated the recording of the movement and its conversion into 3D characters.

Professor Yong-Hoon Cho’s laboratory introduced the scientific mechanism behind the Light Emitting Diode (LED) as well as its manufacturing process under the topic:“A to Z of LED Production.” The reserachers explained that how green LED is much more efficient compared to previous light sources and presented applications that how it is widely used in everyday life in smart phones, electronic displays, and other mobile gadgets.

Professor Jun-tani of the Department of Electronic and Electrical Engineering introduced “Humanoid Robot Nao’s Imitation of Human Motions.” Nao is an autonomous, programmable humanoid robot developed by a French robotics company based in Paris. Nao has an artificial neural circuit, which is the functional equivalent of a human brain, and can thus mimic the subject’s motions through learning.

In addition, Professor Hyo-Choong Bang (Department of Aerospace Engineering) in his lecture on “Unmanned Vehicle Research and Nano Satellites” and Professor Hyun Myung (Department of Civil and Environmental Engineering) on his lecture on “Future Civilization Robot System: the Jellyfish Elimination Robotic Swarm and the Wall-Climbing Drone” provided information on the progress of their respective research.

KAIST also displayed its most recent research achievements. A lecture on “Information Technology Convergence” offered a showroom for “Dr. M,” which is a mobile healthcare platform. Dr. M is a mobile healthcare system that collects and analyzes biosignals via a smart sensor attached to the human body that shows around 20 advanced technologies.

The Satellite Technology Research Center introduced the public to its “Get to Know Satellites” program on Korea’s first satellite “Our Star 1” in addition to showing the satellite assembly room and the satellite communication center.

Special lectures were also held for visitors. Professor Min-Hyuk Kim and Hye-Yeon Oh of the School of Computing talked about “Computer Graphics and Advanced Video Technology” and “Man and the Computer,” respectively, from the perspective of non-experts.

Another interesting feature was the “Wearable Computer Competition” in which college students held fashion shows with computers attached to their clothes.

Professor Jung Kwon Lee, the Dean of the College of Engineering, who led this event, said that “the Open KAIST, which is being held for the eighth time this year, is an excellent opportunity for the general public to experience KAIST’s research environment.” He hoped this could motivate young adults to widen their spectrum of scientific knowledge and raise affection for science.

2015.11.13 View 11395

Open KAIST 2015

KAIST’s research environment and its most recent achievements were open to the public.

KAIST hosted “Open KAIST 2015” over two days from November 5-6, 2015 in which its 17 departments and three research centers were open to the public. The event is one of the largest events that KAIST holds, which permits such public viewings of its facilities. It is the eighth time it has taken place.

During this event, the departments and centers offered 64 programs including laboratory tours, research achievement exhibitions, department introductions, and special lectures.

The “Motion Capture System”of Professor Jun-Yong Noh’s lab (Graduate School of Culture Technology) drew particular attention.

The “Motion Capture System” expresses human and animal motion in three-dimensional (3D) space using infrared cameras and optic markers, which can then be applied to various industries such as movies, games, and animation. During the program, researchers themselves demonstrated the recording of the movement and its conversion into 3D characters.

Professor Yong-Hoon Cho’s laboratory introduced the scientific mechanism behind the Light Emitting Diode (LED) as well as its manufacturing process under the topic:“A to Z of LED Production.” The reserachers explained that how green LED is much more efficient compared to previous light sources and presented applications that how it is widely used in everyday life in smart phones, electronic displays, and other mobile gadgets.

Professor Jun-tani of the Department of Electronic and Electrical Engineering introduced “Humanoid Robot Nao’s Imitation of Human Motions.” Nao is an autonomous, programmable humanoid robot developed by a French robotics company based in Paris. Nao has an artificial neural circuit, which is the functional equivalent of a human brain, and can thus mimic the subject’s motions through learning.

In addition, Professor Hyo-Choong Bang (Department of Aerospace Engineering) in his lecture on “Unmanned Vehicle Research and Nano Satellites” and Professor Hyun Myung (Department of Civil and Environmental Engineering) on his lecture on “Future Civilization Robot System: the Jellyfish Elimination Robotic Swarm and the Wall-Climbing Drone” provided information on the progress of their respective research.

KAIST also displayed its most recent research achievements. A lecture on “Information Technology Convergence” offered a showroom for “Dr. M,” which is a mobile healthcare platform. Dr. M is a mobile healthcare system that collects and analyzes biosignals via a smart sensor attached to the human body that shows around 20 advanced technologies.

The Satellite Technology Research Center introduced the public to its “Get to Know Satellites” program on Korea’s first satellite “Our Star 1” in addition to showing the satellite assembly room and the satellite communication center.

Special lectures were also held for visitors. Professor Min-Hyuk Kim and Hye-Yeon Oh of the School of Computing talked about “Computer Graphics and Advanced Video Technology” and “Man and the Computer,” respectively, from the perspective of non-experts.

Another interesting feature was the “Wearable Computer Competition” in which college students held fashion shows with computers attached to their clothes.

Professor Jung Kwon Lee, the Dean of the College of Engineering, who led this event, said that “the Open KAIST, which is being held for the eighth time this year, is an excellent opportunity for the general public to experience KAIST’s research environment.” He hoped this could motivate young adults to widen their spectrum of scientific knowledge and raise affection for science.

2015.11.13 View 11395 -

Public Lectures by KAIST's Humanities and Social Sciences Research Center

The Humanities and Social Sciences Research Center at KAIST offers public lectures at the International Seminar Hall of the Humanities and Social Sciences building on campus from November 12, 2015 to December 10, 2015. There will be four lectures, all of which will be available in Korean only.

The theme of the lectures is “social issues and strategic solutions.” Experts in various fields including women’s studies, criminal psychology, Go (a Chinese board game) and its philosophy, and Korean studies will participate, offering multifaceted analysis and solutions for social issues in Korea.

Joo-Hee Kim, a researcher at the Korean Women’s Institute of Ewha Women’s University, will lecture on “Problems of Loan Products Exclusively for Women” and discuss the background of "micro-loans" which are often targeted at women, while evaluating the logic of financial corporations behind marketing such products.

Lectures by Professor Ji-Sun Park from the Department of Social Psychology at Ewha Women’s University on “Understanding of Criminal Psychology from Letters,” Professor Soo-Hyun Jeong from the Department of Go at Myeongji University on “Life Lessons and Strategies from Playing Go,” and Professor Seung-Taek Ahn from Kyujanggak Institute for Korean Studies of Seoul National University on “Community Problems in Folk Culture” will follow.

The organizer of the lectures, Professor Jung-Hoon Kim of the Department of Humanities and Social Sciences at KAIST said,

“These lectures will provide local citizens and the KAIST family a wonderful opportunity to understand important social issues from the perspective of social science. It will also serve as a valuable time to think about how our social conflicts could differ from those of other countries, helping us to find solutions.”

To register for these free lectures, go to http://hss.kaist.ac.kr by November 9, 2015.

2015.11.06 View 7328

Public Lectures by KAIST's Humanities and Social Sciences Research Center

The Humanities and Social Sciences Research Center at KAIST offers public lectures at the International Seminar Hall of the Humanities and Social Sciences building on campus from November 12, 2015 to December 10, 2015. There will be four lectures, all of which will be available in Korean only.

The theme of the lectures is “social issues and strategic solutions.” Experts in various fields including women’s studies, criminal psychology, Go (a Chinese board game) and its philosophy, and Korean studies will participate, offering multifaceted analysis and solutions for social issues in Korea.

Joo-Hee Kim, a researcher at the Korean Women’s Institute of Ewha Women’s University, will lecture on “Problems of Loan Products Exclusively for Women” and discuss the background of "micro-loans" which are often targeted at women, while evaluating the logic of financial corporations behind marketing such products.

Lectures by Professor Ji-Sun Park from the Department of Social Psychology at Ewha Women’s University on “Understanding of Criminal Psychology from Letters,” Professor Soo-Hyun Jeong from the Department of Go at Myeongji University on “Life Lessons and Strategies from Playing Go,” and Professor Seung-Taek Ahn from Kyujanggak Institute for Korean Studies of Seoul National University on “Community Problems in Folk Culture” will follow.

The organizer of the lectures, Professor Jung-Hoon Kim of the Department of Humanities and Social Sciences at KAIST said,

“These lectures will provide local citizens and the KAIST family a wonderful opportunity to understand important social issues from the perspective of social science. It will also serve as a valuable time to think about how our social conflicts could differ from those of other countries, helping us to find solutions.”

To register for these free lectures, go to http://hss.kaist.ac.kr by November 9, 2015.

2015.11.06 View 7328 -

KAIST and University of Illinois at Urbana-Champaign Sign a MOU

KAIST and the University of Illinois at Urbana-Champaign (UIUC) signed a memorandum of understanding on collaboration of research and education on November 5, 2015, at the UIUC campus.

The agreement was made at the request of UIUC, under which the two institutions will exchange students and faculty and implement joint research projects.

President Steve Kang of KAIST said, “With this partnership, KAIST and the University of Illinois at Urbana-Champaign will move forward to advance the fields of medical engineering, life sciences, electrical engineering, and computer science.”

In the picture below, President Steve Kang (second from the right) and Associate Vice President of International Office, Sung-Hyon Myaeng (far right), hold the MOU with UIUC representatives.

2015.11.05 View 5619

KAIST and University of Illinois at Urbana-Champaign Sign a MOU

KAIST and the University of Illinois at Urbana-Champaign (UIUC) signed a memorandum of understanding on collaboration of research and education on November 5, 2015, at the UIUC campus.

The agreement was made at the request of UIUC, under which the two institutions will exchange students and faculty and implement joint research projects.

President Steve Kang of KAIST said, “With this partnership, KAIST and the University of Illinois at Urbana-Champaign will move forward to advance the fields of medical engineering, life sciences, electrical engineering, and computer science.”

In the picture below, President Steve Kang (second from the right) and Associate Vice President of International Office, Sung-Hyon Myaeng (far right), hold the MOU with UIUC representatives.

2015.11.05 View 5619 -

KAIST Hosts the Wearable Computer Contest 2015

“What you see is a compact electronic system on a dust mask, which monitors the amount of dust taken in by a worker and lets other workers know if the person is injured in an industrial site,” said Bum Taek Jung, a Master’s candidate from Sungkyunkwan University during the Wearable Computer Contest 2015 held in KI building of KAIST on November 5, 2015.

He explained his interest in developing this system, “Dust-related respiratory diseases and falling accidents are still prevalent in industrial sites.” He added, “Using the smart dust mask helps monitoring workers’ physical condition in real time, allowing us to cope with accidents in a much more timely manner.” A smart dust mask is a portable device that alerts the user with orange or red light signs when the amount of dust inhaled by the user is higher than the threshold. Its application on a smartphone can also allow project managers to alert the risk of falling accidents to workers by employing a gyroscope and an accelerometer on the mask.

The Wearable Computer Contest 2015 met for the eleventh time at KAIST on November 5-6, 2015. A wearable computer refers to a portable device which users can wear directly on the body or on their clothes while moving. Products that can provide various services by connecting to a smartphone have become increasingly popular. The contest is an excellent opportunity for university students to design creative wearable systems similar to those often depicted in movies and comics.

This year 102 teams from universities all over the nation participated. After screening and evaluation of their presentations, only 8 teams in the product section and 3 teams in the ideas section were selected for the finals. Of the many entries to the contest, the ECG security system caught many people’s attention. The wearable, which attaches to a shirt, acts like an electrocardiogram. By comparing the ECG reading with the one stored in the data server, the wearable can authenticate the user. The system could be widely used by enterprises and financial companies where tight security and authentication are crucial.

The winners of the product and the ideas sections received USD 4,300 and usd 860 respectively along with Minister Prizes from the Minister of Science, ICT and Future Planning of Korea. The Chairman of the contest, Professor Hoi-Jun Yoo from the Electrical Engineering Department of KAIST said, “The contest will be a great opportunity for anyone to have a look at advanced wearable devices developed through close integration of state-of-the-art technologies and creative ideas from young minds.”

2015.11.05 View 8734

KAIST Hosts the Wearable Computer Contest 2015

“What you see is a compact electronic system on a dust mask, which monitors the amount of dust taken in by a worker and lets other workers know if the person is injured in an industrial site,” said Bum Taek Jung, a Master’s candidate from Sungkyunkwan University during the Wearable Computer Contest 2015 held in KI building of KAIST on November 5, 2015.

He explained his interest in developing this system, “Dust-related respiratory diseases and falling accidents are still prevalent in industrial sites.” He added, “Using the smart dust mask helps monitoring workers’ physical condition in real time, allowing us to cope with accidents in a much more timely manner.” A smart dust mask is a portable device that alerts the user with orange or red light signs when the amount of dust inhaled by the user is higher than the threshold. Its application on a smartphone can also allow project managers to alert the risk of falling accidents to workers by employing a gyroscope and an accelerometer on the mask.

The Wearable Computer Contest 2015 met for the eleventh time at KAIST on November 5-6, 2015. A wearable computer refers to a portable device which users can wear directly on the body or on their clothes while moving. Products that can provide various services by connecting to a smartphone have become increasingly popular. The contest is an excellent opportunity for university students to design creative wearable systems similar to those often depicted in movies and comics.

This year 102 teams from universities all over the nation participated. After screening and evaluation of their presentations, only 8 teams in the product section and 3 teams in the ideas section were selected for the finals. Of the many entries to the contest, the ECG security system caught many people’s attention. The wearable, which attaches to a shirt, acts like an electrocardiogram. By comparing the ECG reading with the one stored in the data server, the wearable can authenticate the user. The system could be widely used by enterprises and financial companies where tight security and authentication are crucial.

The winners of the product and the ideas sections received USD 4,300 and usd 860 respectively along with Minister Prizes from the Minister of Science, ICT and Future Planning of Korea. The Chairman of the contest, Professor Hoi-Jun Yoo from the Electrical Engineering Department of KAIST said, “The contest will be a great opportunity for anyone to have a look at advanced wearable devices developed through close integration of state-of-the-art technologies and creative ideas from young minds.”

2015.11.05 View 8734 -

Partnership with École Centrale Paris

Courtesy of École Centrale Paris News: http://www.ecp.fr/lang/en/home/news?actuID=48892

Strengthening of the partnership betwenn CentraleSupélec and KAIST University, South Korea

The two institutions signed a new agreement.

Hervé Biausser (left in the picture), Director of CentraleSupélec, has met Sung-Mo Steve Kang (right in the picture), the President of the Korea Advanced Institute of Science and Technology (KAIST). They signed an agreement aiming to strengthen the partnership between the two institutions concerning research and higher education.

CentraleSupélec and KAIST have cooperated since 2010 on research projects in the context of the Erasmus Mundus BEAM and EASED programs, which are coordinated by CentraleSupélec.

The next step is now the application of graduate academic mobility in the common fields of excellency of the institutions: energy, electronic, physics and mathematics.

2015.11.02 View 6049

Partnership with École Centrale Paris

Courtesy of École Centrale Paris News: http://www.ecp.fr/lang/en/home/news?actuID=48892

Strengthening of the partnership betwenn CentraleSupélec and KAIST University, South Korea

The two institutions signed a new agreement.

Hervé Biausser (left in the picture), Director of CentraleSupélec, has met Sung-Mo Steve Kang (right in the picture), the President of the Korea Advanced Institute of Science and Technology (KAIST). They signed an agreement aiming to strengthen the partnership between the two institutions concerning research and higher education.

CentraleSupélec and KAIST have cooperated since 2010 on research projects in the context of the Erasmus Mundus BEAM and EASED programs, which are coordinated by CentraleSupélec.

The next step is now the application of graduate academic mobility in the common fields of excellency of the institutions: energy, electronic, physics and mathematics.

2015.11.02 View 6049 -

KAIST Invites Entrepreneurs and Experts to Participate in a Social Technology Innovation Symposium

The Research Institute for Social Technology and Innovation (RISTI) at KAIST hosted the Social Technology Innovation Symposium on November 4, 2015 in KI building, to which 100 social business entrepreneurs and experts in the field were invited.

Social businesses refer to activities of companies, which strive to resolve social problems such as environmental issues, income inequality, and aging societies while seeking profit at the same time. This is different from companies taking social responsibility and non-profit organization serving the community in that they attempt to solve social problems through a sustainable business model.

Held under the theme of “technology capabilities of companies and social business strategies,” this symposium was the first to gather representatives from social venture companies, medium-sized enterprises, and major companies at one place to share their experiences in a social business and to discuss future tasks.

The symposium was divided into sessions with three different topics ranging from social business strategies using information technology, a social business and its business model, and social business strategies of major companies.

The symposium started with keynote speeches delivered by Professor HongKyu Lee, RISTI, and Professor Hong-Tak Lim, RISTI, who discussed the role of technology in a social business. It was followed by plenary sessions led by CEOs who are running social businesses such as the Sharing and Technologies Incorporated Project, Simwon Technology, Ecojun Company, Underdogs, and the Farming Fund as well as by representatives from a social responsibility section of CJ management team and the social responsibility council of SK. In the future, these talks will serve as a medium to share their experiences in social businesses and to discuss the role of technology in the business. Some talks touched upon topics such as development of platforms for social innovation, social businesses employing disabled workers, and crowd funding for farming.

The Director of RISTI, Professor HongKyu Lee said, “The symposium will be the first to have people from leading companies in social businesses in Korea in one place.” He added, “This will be a great opportunity for anyone to know what will be the future of social businesses, which were created to solve the social problems caused by capitalism.”

The symposium was sponsored by the Ministry of Trade, Industry, and Energy of Korea.

2015.10.30 View 9249

KAIST Invites Entrepreneurs and Experts to Participate in a Social Technology Innovation Symposium

The Research Institute for Social Technology and Innovation (RISTI) at KAIST hosted the Social Technology Innovation Symposium on November 4, 2015 in KI building, to which 100 social business entrepreneurs and experts in the field were invited.

Social businesses refer to activities of companies, which strive to resolve social problems such as environmental issues, income inequality, and aging societies while seeking profit at the same time. This is different from companies taking social responsibility and non-profit organization serving the community in that they attempt to solve social problems through a sustainable business model.

Held under the theme of “technology capabilities of companies and social business strategies,” this symposium was the first to gather representatives from social venture companies, medium-sized enterprises, and major companies at one place to share their experiences in a social business and to discuss future tasks.

The symposium was divided into sessions with three different topics ranging from social business strategies using information technology, a social business and its business model, and social business strategies of major companies.

The symposium started with keynote speeches delivered by Professor HongKyu Lee, RISTI, and Professor Hong-Tak Lim, RISTI, who discussed the role of technology in a social business. It was followed by plenary sessions led by CEOs who are running social businesses such as the Sharing and Technologies Incorporated Project, Simwon Technology, Ecojun Company, Underdogs, and the Farming Fund as well as by representatives from a social responsibility section of CJ management team and the social responsibility council of SK. In the future, these talks will serve as a medium to share their experiences in social businesses and to discuss the role of technology in the business. Some talks touched upon topics such as development of platforms for social innovation, social businesses employing disabled workers, and crowd funding for farming.

The Director of RISTI, Professor HongKyu Lee said, “The symposium will be the first to have people from leading companies in social businesses in Korea in one place.” He added, “This will be a great opportunity for anyone to know what will be the future of social businesses, which were created to solve the social problems caused by capitalism.”

The symposium was sponsored by the Ministry of Trade, Industry, and Energy of Korea.

2015.10.30 View 9249