TR

-

Professor YongKeun Park Elected as a Fellow of the Optical Society

Professor YongKeun Park, from the Department of Physics at KAIST, was elected as a fellow member of the Optical Society (OSA) in Washington, D.C. on September 12. Fellow membership is given to members who have made a significant contribution to the advancement of optics and photonics.

Professor Park was recognized for his research on digital holography and wavefront control technology.

Professor Park has been producing outstanding research outcomes in the field of holographic technology and light scattering control since joining KAIST in 2010. In particular, he developed and commercialized technology for a holographic telescope. He applied it to various medical and biological research projects, leading the field worldwide.

In the past, cells needed to be dyed with fluorescent materials to capture a 3-D image. However, Professor Park’s holotomography (HT) technology can capture 3-D images of living cells and tissues in real time without color dyeing. This technology allows diversified research in the biological and medical field.

Professor Park established a company, Tomocube, Inc. in 2015 to commercialize the technology. In 2016, he received funding from SoftBank Ventures and Hanmi Pharmaceutical. Currently, major institutes, including MIT, the University of Pittsburgh, the German Cancer Research Center, and Seoul National University Hospital are using his equipment.

Recently, Professor Park and his team developed technology based on light scattering measurements. With this technology, they established a company called The Wave Talk and received funding from various organizations, such as NAVER. Its first product is about to be released.

Professor Park said, “I am glad to become a fellow member based on the research outcomes I produced since I was appointed as a professor at KAIST. I would like to thank the excellent researchers as well as the school for its support. I will devote myself to continuously producing novel outcomes in both basic and applied fields.”

Professor Park has published nearly 100 papers in renowned journals including Nature Photonics, Nature Communications, Science Advances, and Physical Review Letters.

2017.10.18 View 14081

Professor YongKeun Park Elected as a Fellow of the Optical Society

Professor YongKeun Park, from the Department of Physics at KAIST, was elected as a fellow member of the Optical Society (OSA) in Washington, D.C. on September 12. Fellow membership is given to members who have made a significant contribution to the advancement of optics and photonics.

Professor Park was recognized for his research on digital holography and wavefront control technology.

Professor Park has been producing outstanding research outcomes in the field of holographic technology and light scattering control since joining KAIST in 2010. In particular, he developed and commercialized technology for a holographic telescope. He applied it to various medical and biological research projects, leading the field worldwide.

In the past, cells needed to be dyed with fluorescent materials to capture a 3-D image. However, Professor Park’s holotomography (HT) technology can capture 3-D images of living cells and tissues in real time without color dyeing. This technology allows diversified research in the biological and medical field.

Professor Park established a company, Tomocube, Inc. in 2015 to commercialize the technology. In 2016, he received funding from SoftBank Ventures and Hanmi Pharmaceutical. Currently, major institutes, including MIT, the University of Pittsburgh, the German Cancer Research Center, and Seoul National University Hospital are using his equipment.

Recently, Professor Park and his team developed technology based on light scattering measurements. With this technology, they established a company called The Wave Talk and received funding from various organizations, such as NAVER. Its first product is about to be released.

Professor Park said, “I am glad to become a fellow member based on the research outcomes I produced since I was appointed as a professor at KAIST. I would like to thank the excellent researchers as well as the school for its support. I will devote myself to continuously producing novel outcomes in both basic and applied fields.”

Professor Park has published nearly 100 papers in renowned journals including Nature Photonics, Nature Communications, Science Advances, and Physical Review Letters.

2017.10.18 View 14081 -

KAIST Partners with WEF to Prepare for the 4th Industrial Revolution

KAIST President Sung-Chul Shin and the Head of the World Economic Forum Center for the Fourth Industrial Revolution, Murat Sonmez, made a commitment to build cooperation in an active manner for addressing the ramifications of the Fourth Industrial Revolution.

The two signed an MOU to cooperate in research in related fields on October 13 after holding a roundtable discussion titled “The Future of Jobs and Inclusive Growth in Korea”. It is the first partnership that the WEF has sealed with an academic institution.The roundtable discussion brought together distinguished guests from politics, non-profit civic organizations, academia, and enterprises including Daejeon Mayor Seon-Taek Kwon, Doosan Group Vice Chairman Lee Hyun-Soon, and Korean Venture Business Association President Ahn Keon-Joon.

During the news conference, President Shin said, “This event means a lot because it explores ways in which inclusive growth and job creation can be realized in Korea. To move forward in the new age of the Fourth Industrial Revolution, every country needs to adopt appropriate new policies suitable for their specific market environments. KAIST will contribute to this process for Korea as well as for the global community.”

President Shin also said, “Korea has been a fast follower in previous industrial revolutions. Now, we have the momentum to seize the opportunities in the wake of this revolution. KAIST is dedicated to leading Korea into becoming a first mover in the Fourth Industrial Revolution by cooperating with the WEF.”

“Two decades later, we will live with considerable number of robots around us. It is possible that our societies in the future will consist of Homo sapiens and Robo sapiens. We need to create new jobs for Homo sapiens to prepare for a society that we will have to coexist with a new industrial tribe. Industries need continuing education to retrain workers for the ever evolving industrial landscape of the future,” President Shin emphasized.

Meanwhile, Sonmez pointed out that all stakeholders should participate in understanding the new industrial environment’s ramifications, saying “Societies, governments, public and private sectors, startups, and academia should co-design inclusive models through global efforts. Ethics and influences on the job market should also be taken into consideration.”

Sonmez said nine factors such as blockchains, internet of things, artificial intelligence, machine learning, cross-border data blow, drones, 3D printing, autonomous driving, the environment, and precision medicine will take center stage in the Fourth Industrial Revolution, In particular, he said that blockchains, which are a cybersecurity technology for online financial transactions, will bring even bigger changes than the ‘World Wide Web’ has done over the past three decades.

“To this end, we will have to work closely with major academic institutes. Through this partnership with KAIST, we will make the fruits of the new industrial environment benefit Koreans and Korean society,” Sonmez added.

2017.10.14 View 10019

KAIST Partners with WEF to Prepare for the 4th Industrial Revolution

KAIST President Sung-Chul Shin and the Head of the World Economic Forum Center for the Fourth Industrial Revolution, Murat Sonmez, made a commitment to build cooperation in an active manner for addressing the ramifications of the Fourth Industrial Revolution.

The two signed an MOU to cooperate in research in related fields on October 13 after holding a roundtable discussion titled “The Future of Jobs and Inclusive Growth in Korea”. It is the first partnership that the WEF has sealed with an academic institution.The roundtable discussion brought together distinguished guests from politics, non-profit civic organizations, academia, and enterprises including Daejeon Mayor Seon-Taek Kwon, Doosan Group Vice Chairman Lee Hyun-Soon, and Korean Venture Business Association President Ahn Keon-Joon.

During the news conference, President Shin said, “This event means a lot because it explores ways in which inclusive growth and job creation can be realized in Korea. To move forward in the new age of the Fourth Industrial Revolution, every country needs to adopt appropriate new policies suitable for their specific market environments. KAIST will contribute to this process for Korea as well as for the global community.”

President Shin also said, “Korea has been a fast follower in previous industrial revolutions. Now, we have the momentum to seize the opportunities in the wake of this revolution. KAIST is dedicated to leading Korea into becoming a first mover in the Fourth Industrial Revolution by cooperating with the WEF.”

“Two decades later, we will live with considerable number of robots around us. It is possible that our societies in the future will consist of Homo sapiens and Robo sapiens. We need to create new jobs for Homo sapiens to prepare for a society that we will have to coexist with a new industrial tribe. Industries need continuing education to retrain workers for the ever evolving industrial landscape of the future,” President Shin emphasized.

Meanwhile, Sonmez pointed out that all stakeholders should participate in understanding the new industrial environment’s ramifications, saying “Societies, governments, public and private sectors, startups, and academia should co-design inclusive models through global efforts. Ethics and influences on the job market should also be taken into consideration.”

Sonmez said nine factors such as blockchains, internet of things, artificial intelligence, machine learning, cross-border data blow, drones, 3D printing, autonomous driving, the environment, and precision medicine will take center stage in the Fourth Industrial Revolution, In particular, he said that blockchains, which are a cybersecurity technology for online financial transactions, will bring even bigger changes than the ‘World Wide Web’ has done over the past three decades.

“To this end, we will have to work closely with major academic institutes. Through this partnership with KAIST, we will make the fruits of the new industrial environment benefit Koreans and Korean society,” Sonmez added.

2017.10.14 View 10019 -

KAIST-WEF Roundtable on Inclusive Growth and Job Creation

The World Economic Forum (WEF) will join KAIST in an effort to address sweeping global problems in the wake of the Fourth Industrial Revolution. The two will co-host a roundtable on ‘Shaping Korea’s Priorities for Inclusive Growth and Job Creation in the Fourth Industrial Revolution’ on October 13 at Lotte Hotel in Seoul.

The roundtable will bring together leaders from government, industry, universities, and non-profit civic organizations to have an in-depth discussion on a thought-provoking agenda of inclusive growth and job creation which scientific and technological changes will bring about. The event will provide a platform to explore practical collaboration and innovative strategies for better job creation and innovation ecosystems.

The two will also sign an MOU for collaboration between the Fourth Industrial Revolution Information Center (FIRIC) of KAIST and the WEF Center for the Fourth Industrial Revolution (C4IR).

President Sung-Chul Shin of KAIST and the Head of the WEF Center for the Fourth Industrial Revolution, Murat Sonmez, will lead the panel discussion titled ‘Inclusive Growth and the Fourth Industrial Revolution’ which will be attended by leaders from government, industry, and non-profit civic organizations.

At the breakout sessions, the topics will be “Future Jobs” and the “Creation of Innovation Ecosystems”. Additionally, a discussion on the “SME 4.0 Initiative”, which is a program pushed forward by KAIST in collaboration with local governments, will talk about job creation through innovation in small and medium-sized enterprises (SMEs). The WEF will introduce their two-year activities and research on the Fourth Industrial Revolution, which have great potential and a high possibility of successfully undergoing the revolution, to Korea.

Since WEF Executive Chairman Klaus Schwab brought up the topic of the Fourth Industrial Revolution, the WEF has been leading agenda topics and discussions on high-profile matters, including ‘technology-driven but human-centered inclusive growth’ in predicting the future of jobs.

The WEF is a nonprofit organization committed to addressing the world’s weightiest problems. It is best known for its annual meetings in Davos, Switzerland, which attracts leaders from around the world. KAIST has been participating in this summit since 2009. President Shin will also attend the upcoming Davos summit next January. Distinguished Professor Sang Yup Lee who heads the KAIST Institute and the FIRIC is the co-chair of the Global Council on Biotechnology and a member of the Global Future Council on the Fourth Industrial Revolution at the WEF.

Moreover, President Shin and Mr. Sonmez will explain the background of the roundtable and share the results of the sessions at a joint news conference.

2017.09.28 View 11339

KAIST-WEF Roundtable on Inclusive Growth and Job Creation

The World Economic Forum (WEF) will join KAIST in an effort to address sweeping global problems in the wake of the Fourth Industrial Revolution. The two will co-host a roundtable on ‘Shaping Korea’s Priorities for Inclusive Growth and Job Creation in the Fourth Industrial Revolution’ on October 13 at Lotte Hotel in Seoul.

The roundtable will bring together leaders from government, industry, universities, and non-profit civic organizations to have an in-depth discussion on a thought-provoking agenda of inclusive growth and job creation which scientific and technological changes will bring about. The event will provide a platform to explore practical collaboration and innovative strategies for better job creation and innovation ecosystems.

The two will also sign an MOU for collaboration between the Fourth Industrial Revolution Information Center (FIRIC) of KAIST and the WEF Center for the Fourth Industrial Revolution (C4IR).

President Sung-Chul Shin of KAIST and the Head of the WEF Center for the Fourth Industrial Revolution, Murat Sonmez, will lead the panel discussion titled ‘Inclusive Growth and the Fourth Industrial Revolution’ which will be attended by leaders from government, industry, and non-profit civic organizations.

At the breakout sessions, the topics will be “Future Jobs” and the “Creation of Innovation Ecosystems”. Additionally, a discussion on the “SME 4.0 Initiative”, which is a program pushed forward by KAIST in collaboration with local governments, will talk about job creation through innovation in small and medium-sized enterprises (SMEs). The WEF will introduce their two-year activities and research on the Fourth Industrial Revolution, which have great potential and a high possibility of successfully undergoing the revolution, to Korea.

Since WEF Executive Chairman Klaus Schwab brought up the topic of the Fourth Industrial Revolution, the WEF has been leading agenda topics and discussions on high-profile matters, including ‘technology-driven but human-centered inclusive growth’ in predicting the future of jobs.

The WEF is a nonprofit organization committed to addressing the world’s weightiest problems. It is best known for its annual meetings in Davos, Switzerland, which attracts leaders from around the world. KAIST has been participating in this summit since 2009. President Shin will also attend the upcoming Davos summit next January. Distinguished Professor Sang Yup Lee who heads the KAIST Institute and the FIRIC is the co-chair of the Global Council on Biotechnology and a member of the Global Future Council on the Fourth Industrial Revolution at the WEF.

Moreover, President Shin and Mr. Sonmez will explain the background of the roundtable and share the results of the sessions at a joint news conference.

2017.09.28 View 11339 -

Semiconductor Patterning of Seven Nanometers Technology Using a Camera Flash

A research team led by Professor Sang Ouk Kim in the Department of Materials Science and Engineering at KAIST has developed semiconductor manufacturing technology using a camera flash.

This technology can manufacture ultra-fine patterns over a large area by irradiating a single flash with a seven-nanometer patterning technique for semiconductors. It can facilitate the manufacturing of highly efficient, integrated semiconductor devices in the future.

Technology for the Artificial Intelligence (AI), the Internet of Things (IoTs), and big data, which are the major keys for the fourth Industrial Revolution, require high-capacity, high-performance semiconductor devices. It is necessary to develop lithography technology to produce such next-generation, highly integrated semiconductor devices.

Although related industries have been using conventional photolithography for small patterns, this technique has limitations for forming a pattern of sub-10 nm patterns.

Molecular assembly patterning technology using polymers has been in the spotlight as the next generation technology to replace photolithography because it is inexpensive to produce and can easily form sub-10 nm patterns. However, since it generally takes a long time for heat treatment at high-temperature or toxic solvent vapor treatment, mass production is difficult and thus its commercialization has been limited.

The research team introduced a camera flash that instantly emits strong light to solve the issues of polymer molecular assembly patterning. Using a flash can possibly achieve a semiconductor patterning of seven nanometers within 15 milliseconds (1 millisecond = 1/1,000 second), which can generate a temperature of several hundred degrees Celsius in several tens of milliseconds.

The team has demonstrated that applying this technology to polymer molecular assembly allows a single flash of light to form molecular assembly patterns.

The team also identified its compatibility with polymer flexible substrates, which are impossible to process at high temperatures. Through these findings, the technology can be applied to the fabrication of next-generation, flexible semiconductors.

The researchers said the camera flash photo-thermal process will be introduced into molecular assembly technology and this highly-efficiency technology can accelerate the realization of molecular assembly semiconductor technology.

Professor Kim, who led the research, said, “Despite its potential, molecular assembly semiconductor technology has remained a big challenge in improving process efficiency.” “This technology will be a breakthrough for the practical use of molecular assembly-based semiconductors.”

The paper was published in the international journal, Advanced Materials on August 21 with first authors, researcher Hyeong Min Jin and PhD candidate Dae Yong Park.

The research, sponsored by the Ministry of Science and ICT, was co-led Professor by Keon Jae Lee in the Department of Materials Science and Engineering at KAIST, and Professor Kwang Ho Kim in the School of Materials Science and Engineering at Pusan National University.

(1. Formation of semiconductor patterns using a camera flash)

(Schematic diagram of molecular assembly pattern using a camera flash)

(Self-assembled patterns)

2017.09.18 View 12289

Semiconductor Patterning of Seven Nanometers Technology Using a Camera Flash

A research team led by Professor Sang Ouk Kim in the Department of Materials Science and Engineering at KAIST has developed semiconductor manufacturing technology using a camera flash.

This technology can manufacture ultra-fine patterns over a large area by irradiating a single flash with a seven-nanometer patterning technique for semiconductors. It can facilitate the manufacturing of highly efficient, integrated semiconductor devices in the future.

Technology for the Artificial Intelligence (AI), the Internet of Things (IoTs), and big data, which are the major keys for the fourth Industrial Revolution, require high-capacity, high-performance semiconductor devices. It is necessary to develop lithography technology to produce such next-generation, highly integrated semiconductor devices.

Although related industries have been using conventional photolithography for small patterns, this technique has limitations for forming a pattern of sub-10 nm patterns.

Molecular assembly patterning technology using polymers has been in the spotlight as the next generation technology to replace photolithography because it is inexpensive to produce and can easily form sub-10 nm patterns. However, since it generally takes a long time for heat treatment at high-temperature or toxic solvent vapor treatment, mass production is difficult and thus its commercialization has been limited.

The research team introduced a camera flash that instantly emits strong light to solve the issues of polymer molecular assembly patterning. Using a flash can possibly achieve a semiconductor patterning of seven nanometers within 15 milliseconds (1 millisecond = 1/1,000 second), which can generate a temperature of several hundred degrees Celsius in several tens of milliseconds.

The team has demonstrated that applying this technology to polymer molecular assembly allows a single flash of light to form molecular assembly patterns.

The team also identified its compatibility with polymer flexible substrates, which are impossible to process at high temperatures. Through these findings, the technology can be applied to the fabrication of next-generation, flexible semiconductors.

The researchers said the camera flash photo-thermal process will be introduced into molecular assembly technology and this highly-efficiency technology can accelerate the realization of molecular assembly semiconductor technology.

Professor Kim, who led the research, said, “Despite its potential, molecular assembly semiconductor technology has remained a big challenge in improving process efficiency.” “This technology will be a breakthrough for the practical use of molecular assembly-based semiconductors.”

The paper was published in the international journal, Advanced Materials on August 21 with first authors, researcher Hyeong Min Jin and PhD candidate Dae Yong Park.

The research, sponsored by the Ministry of Science and ICT, was co-led Professor by Keon Jae Lee in the Department of Materials Science and Engineering at KAIST, and Professor Kwang Ho Kim in the School of Materials Science and Engineering at Pusan National University.

(1. Formation of semiconductor patterns using a camera flash)

(Schematic diagram of molecular assembly pattern using a camera flash)

(Self-assembled patterns)

2017.09.18 View 12289 -

Professor Jun Ho Oh's Total Solar Eclipse Featured in the APOD, NASA

(Professor Jun Ho Oh)

A video of a total solar eclipse, filmed in Warm Springs, Oregon by Professor Jun Ho Oh of the Department of Mechanical Engineering, was selected as the Astronomy Picture of the Day (APOD).

APOD, is a NASA website specializing in astronomy pictures. It features astronomical observations recorded by the Hubble Space Telescope or photos taken by astronomical observers from around the world.

Professor Oh is now the second Korean and the first amateur photographer whose photo was selected as the APOD.

According to the website, ‘the video frames were acquired with equipment specifically designed by Jun Ho Oh to track a close-up of the Sun’s periphery during the eclipse.’

Also, Digital Photography Review (dpreview.com) introduced observation points of the eclipse in his three-minute video, including solar prominences, corona, and Baily’s beads.

Professor Oh, the creator of the bipedal walking humanoid robot named Hubo, has been chasing eclipse since his first trip to Turkey in 1999.

“After numerous trials and failures over the last 18 years, I was finally able to capture every single breath-taking moment of the total eclipse,” said the professor.

He’s already planning for the next total eclipse in Chile on July 2, 2019.

Click the link to watch the video https://apod.nasa.gov/apod/ap170912.html

(#1 Photo of solar eclipse)

(#2 Photo of solar eclipse)

2017.09.14 View 7766

Professor Jun Ho Oh's Total Solar Eclipse Featured in the APOD, NASA

(Professor Jun Ho Oh)

A video of a total solar eclipse, filmed in Warm Springs, Oregon by Professor Jun Ho Oh of the Department of Mechanical Engineering, was selected as the Astronomy Picture of the Day (APOD).

APOD, is a NASA website specializing in astronomy pictures. It features astronomical observations recorded by the Hubble Space Telescope or photos taken by astronomical observers from around the world.

Professor Oh is now the second Korean and the first amateur photographer whose photo was selected as the APOD.

According to the website, ‘the video frames were acquired with equipment specifically designed by Jun Ho Oh to track a close-up of the Sun’s periphery during the eclipse.’

Also, Digital Photography Review (dpreview.com) introduced observation points of the eclipse in his three-minute video, including solar prominences, corona, and Baily’s beads.

Professor Oh, the creator of the bipedal walking humanoid robot named Hubo, has been chasing eclipse since his first trip to Turkey in 1999.

“After numerous trials and failures over the last 18 years, I was finally able to capture every single breath-taking moment of the total eclipse,” said the professor.

He’s already planning for the next total eclipse in Chile on July 2, 2019.

Click the link to watch the video https://apod.nasa.gov/apod/ap170912.html

(#1 Photo of solar eclipse)

(#2 Photo of solar eclipse)

2017.09.14 View 7766 -

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 28886

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 28886 -

Research Center for Smart Submerged Floating Tunnel Systems Opens

(Distinguished guests including President Shin (fourth from the right) and Director Lee (third from left) at the opening ceremony)

The Research Center for a Smart Submerged Floating Tunnel Systems was recently established at KAIST with the purpose of taking the lead in developing fundamental and applicable technology for submerged floating tunnels as well as fostering creative and talented people. Haeng-Ki Lee, a professor in the Department of Civil & Environmental Engineering at KAIST is heading the center.

KAIST held its opening ceremony on September 7, 2017 in the Applied Engineering Building located on the main campus.

Distinguished guests, including KAIST president Sung-Chul Shin, the President of the Korea Institute of Ocean Science and Technology Gi-Hoon Hong, the President of the Korean Society of Civil Engineering Young-Seok Park, and the Director in the Division of Engineering at the National Research Foundation of Korea Joong-Kon Park attended the ceremony.

The National Research Foundation of Korea provides Engineering Research Center (ERC) projects which find and foster groups with outstanding research performance in a field of engineering. The projects support these groups so that they can strengthen their global competitiveness while enhancing national competence in basic research.

The ‘Research Center for Smart Submerged Floating Tunnel Systems’ was selected as one of the ERC projects in 2017. For the next seven years, the research center will work to develop a submerged floating tunnel system resistant depths greater than 100 meters.

To achieve its goal, the center has defined crucial research topics including: i) a structural analysis program and integrated design technology specific for submerged floating tunnel systems, ii) high-durability marine construction materials and submerged construction integrated systems, and iii) safety and maintenance integrated technology for smart submerged floating tunnel systems.

The ‘Research Center for Smart Submerged Floating Tunnel Systems’ will devote itself to developing a variety of fundamental and applicable technology that will be leading global maritime construction. Moreover, it will concentrate on fostering professional research manpower in related areas.

The Director of the Center Lee said, “The center will cooperate with KAIST researchers who are experts in various fields, including structures, materials, construction, and maritime research. Based on this collaboration, the center will contribute to achieving autonomous technologies by developing fundamental and applicable technology related with submerged floating tunnel systems. It will also take the role of a leading global research hub in the field of submerged floating tunnels as well as construction technologies.”

2017.09.07 View 11080

Research Center for Smart Submerged Floating Tunnel Systems Opens

(Distinguished guests including President Shin (fourth from the right) and Director Lee (third from left) at the opening ceremony)

The Research Center for a Smart Submerged Floating Tunnel Systems was recently established at KAIST with the purpose of taking the lead in developing fundamental and applicable technology for submerged floating tunnels as well as fostering creative and talented people. Haeng-Ki Lee, a professor in the Department of Civil & Environmental Engineering at KAIST is heading the center.

KAIST held its opening ceremony on September 7, 2017 in the Applied Engineering Building located on the main campus.

Distinguished guests, including KAIST president Sung-Chul Shin, the President of the Korea Institute of Ocean Science and Technology Gi-Hoon Hong, the President of the Korean Society of Civil Engineering Young-Seok Park, and the Director in the Division of Engineering at the National Research Foundation of Korea Joong-Kon Park attended the ceremony.

The National Research Foundation of Korea provides Engineering Research Center (ERC) projects which find and foster groups with outstanding research performance in a field of engineering. The projects support these groups so that they can strengthen their global competitiveness while enhancing national competence in basic research.

The ‘Research Center for Smart Submerged Floating Tunnel Systems’ was selected as one of the ERC projects in 2017. For the next seven years, the research center will work to develop a submerged floating tunnel system resistant depths greater than 100 meters.

To achieve its goal, the center has defined crucial research topics including: i) a structural analysis program and integrated design technology specific for submerged floating tunnel systems, ii) high-durability marine construction materials and submerged construction integrated systems, and iii) safety and maintenance integrated technology for smart submerged floating tunnel systems.

The ‘Research Center for Smart Submerged Floating Tunnel Systems’ will devote itself to developing a variety of fundamental and applicable technology that will be leading global maritime construction. Moreover, it will concentrate on fostering professional research manpower in related areas.

The Director of the Center Lee said, “The center will cooperate with KAIST researchers who are experts in various fields, including structures, materials, construction, and maritime research. Based on this collaboration, the center will contribute to achieving autonomous technologies by developing fundamental and applicable technology related with submerged floating tunnel systems. It will also take the role of a leading global research hub in the field of submerged floating tunnels as well as construction technologies.”

2017.09.07 View 11080 -

Hyosung R&DB Labs to Teach Special Class on High Molecule Chemistry for the Fall Semester

The Department of Chemistry in collaboration with the Hyosung Group’s R&DB Labs will open a ‘special class on high molecule chemistry’ for Masters and Ph.D. candidates. The class, led by researchers at Hyosung’s R&D think tank, will provide the latest market and technology trends in the molecule chemical industry during the fall semester.

Hyosung joined this special industry program in an effort to enhance students’ hands-on understanding of new technologies that will emerge in the global market. During the semester, Hyosung plans to present the technology portfolios on their brand new materials of TAC film, membrane, and carbon fiber as well as the existing products leading the world in market share such as spandex, tire cords.

Hyosung plans to recruit students who previously took courses led by Hyosung researchers. President Tu-Won Chang of Hyosung R&DB said, “This program is designed to foster highly qualified R&D personnel especially catering to our company’s needs and market demands. We will continue to share our company’s market analysis and R&D know-how with outstanding universities.

2017.09.07 View 5918

Hyosung R&DB Labs to Teach Special Class on High Molecule Chemistry for the Fall Semester

The Department of Chemistry in collaboration with the Hyosung Group’s R&DB Labs will open a ‘special class on high molecule chemistry’ for Masters and Ph.D. candidates. The class, led by researchers at Hyosung’s R&D think tank, will provide the latest market and technology trends in the molecule chemical industry during the fall semester.

Hyosung joined this special industry program in an effort to enhance students’ hands-on understanding of new technologies that will emerge in the global market. During the semester, Hyosung plans to present the technology portfolios on their brand new materials of TAC film, membrane, and carbon fiber as well as the existing products leading the world in market share such as spandex, tire cords.

Hyosung plans to recruit students who previously took courses led by Hyosung researchers. President Tu-Won Chang of Hyosung R&DB said, “This program is designed to foster highly qualified R&D personnel especially catering to our company’s needs and market demands. We will continue to share our company’s market analysis and R&D know-how with outstanding universities.

2017.09.07 View 5918 -

Professor Dae-Sik Im to Head the Science, Technology and Innovation Office at the Ministry of Science & ICT

(Professor Dae-Sik Im of the Department of Biological Sciences)

Professor Dae-Sik Im of the Department of Biological Sciences, a renowned molecular cell biologist, was named to head the Science, Technology and Innovation Office in the Ministry of Science and ICT on August 31. He will be responsible for the oversight of national R&D projects as well as budget deliberation. Joining the KAIST faculty in 2002, he led the Creative Research Center of Cell Division and Differentiation at KAIST.

Announcing the nomination of Professor Im, Cheong Wa Dae spokesman Park Soo-Hyun said, “Professor Im will be the best person to lead the innovation of the research infrastructure system for basic research studies. We believe that his expertise and leadership will make a significant impact in enhancing the nation’s science and technology competitiveness. This vice minister position in the Ministry of Science and ICT was newly created in an effort to enhance national science and technology initiatives by President Moon Jae-In.

Professor Im said at the news conference, “I would like to make a sustainable, as well as credible, system ensuring the ingenuity of scientists in Korean labs. To this end, I will make every effort to enhance Korea’s innovative research environment in a way to maximize research achievements.”

2017.09.03 View 10509

Professor Dae-Sik Im to Head the Science, Technology and Innovation Office at the Ministry of Science & ICT

(Professor Dae-Sik Im of the Department of Biological Sciences)

Professor Dae-Sik Im of the Department of Biological Sciences, a renowned molecular cell biologist, was named to head the Science, Technology and Innovation Office in the Ministry of Science and ICT on August 31. He will be responsible for the oversight of national R&D projects as well as budget deliberation. Joining the KAIST faculty in 2002, he led the Creative Research Center of Cell Division and Differentiation at KAIST.

Announcing the nomination of Professor Im, Cheong Wa Dae spokesman Park Soo-Hyun said, “Professor Im will be the best person to lead the innovation of the research infrastructure system for basic research studies. We believe that his expertise and leadership will make a significant impact in enhancing the nation’s science and technology competitiveness. This vice minister position in the Ministry of Science and ICT was newly created in an effort to enhance national science and technology initiatives by President Moon Jae-In.

Professor Im said at the news conference, “I would like to make a sustainable, as well as credible, system ensuring the ingenuity of scientists in Korean labs. To this end, I will make every effort to enhance Korea’s innovative research environment in a way to maximize research achievements.”

2017.09.03 View 10509 -

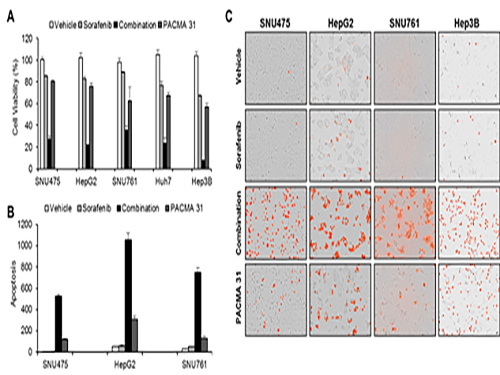

Discovery of an Optimal Drug Combination: Overcoming Resistance to Targeted Drugs for Liver Cancer

A KAIST research team presented a novel method for improving medication treatment for liver cancer using Systems Biology, combining research from information technology and the life sciences. Professor Kwang-Hyun Cho in the Department of Bio and Brain Engineering at KAIST conducted the research in collaboration with Professor Jung-Hwan Yoon in the Department of Internal Medicine at Seoul National University Hospital. This research was published in Hepatology in September 2017 (available online from August 24, 2017).

Liver cancer is the fifth and seventh most common cancer found in men and women throughout the world, which places it second in the cause of cancer deaths. In particular, Korea has 28.4 deaths from liver cancer per 100,000 persons, the highest death rate among OECD countries and twice that of Japan.

Each year in Korea, 16,000 people get liver cancer on average, yet the five-year survival rate stands below 12%. According to the National Cancer Information Center, lung cancer (17,399) took the highest portion of cancer-related deaths, followed by liver cancer (11,311) based on last year data.

Liver cancer is known to carry the highest social cost in comparison to other cancers and it causes the highest fatality in earlier age groups (40s-50s). In that sense, it is necessary to develop a new treatment that mitigates side effects yet elevates the survival rate.

There are ways in which liver cancer can be cured, such as surgery, embolization, and medication treatments; however, the options become limited for curing progressive cancer, a stage in which surgical methods cannot be executed.

Among anticancer medications, Sorafenib, a drug known for enhancing the survival rate of cancer patients, is a unique drug allowed for use as a targeted anticancer medication for progressive liver cancer patients. Its sales reached more than ten billion KRW annually in Korea, but its efficacy works on only about 20% of the treated patients. Also, acquired resistance to Sorafenib is emerging. Additionally, the action mechanism and resistance mechanism of Sorafenib is only vaguely identified.Although Sorafenib only extends the survival rate of terminal cancer patients less than three months on average, it is widely being used because drugs developed by global pharmaceutical companies failed to outperform its effectiveness.

Professor Cho’s research team analyzed the expression changes of genes in cell lines in response to Sorafenib in order to identify the effect and the resistance mechanism of Sorafenib.

As a result, the team discovered the resistance mechanism of Sorafenib using Systems Biology analysis. By combining computer simulations and biological experiments, it was revealed that protein disulfide isomerase (PDI) plays a crucial role in the resistance mechanism of Sorafenib and that its efficacy can be improved significantly by blocking PDI.

The research team used mice in the experiment and discovered the synergic effect of PDI inhibition with Sorafenib for reducing liver cancer cells, known as hepatocellular carcinoma. Also, more PDIs are shown in tissue from patients who possess a resistance to Sorafenib. From these findings, the team could identify the possibility of its clinical applications. The team also confirmed these findings from clinical data through a retrospective cohort study.

“Molecules that play an important role in cell lines are mostly put under complex regulation. For this reason, the existing biological research has a fundamental limitations for discovering its underlying principles,” Professor Cho said. “This research is a representative case of overcoming this limitation of traditional life science research by using a Systems Biology approach, combining IT and life science. It suggests the possibility of developing a new method that overcomes drug resistance with a network analysis of the targeted drug action mechanism of cancer.”

The research was supported by the National Research Foundation of Korea (NRF) and funded by the Ministry of Science and ICT.

(Figure 1. Simulation results from cellular experiments using hepatocellular carcinoma)

(Figure 2. Network analysis and computer simulation by using the endoplasmic reticulum (ER) stress network)

(Figure 3. ER stress network model)

2017.08.30 View 13126

Discovery of an Optimal Drug Combination: Overcoming Resistance to Targeted Drugs for Liver Cancer

A KAIST research team presented a novel method for improving medication treatment for liver cancer using Systems Biology, combining research from information technology and the life sciences. Professor Kwang-Hyun Cho in the Department of Bio and Brain Engineering at KAIST conducted the research in collaboration with Professor Jung-Hwan Yoon in the Department of Internal Medicine at Seoul National University Hospital. This research was published in Hepatology in September 2017 (available online from August 24, 2017).

Liver cancer is the fifth and seventh most common cancer found in men and women throughout the world, which places it second in the cause of cancer deaths. In particular, Korea has 28.4 deaths from liver cancer per 100,000 persons, the highest death rate among OECD countries and twice that of Japan.

Each year in Korea, 16,000 people get liver cancer on average, yet the five-year survival rate stands below 12%. According to the National Cancer Information Center, lung cancer (17,399) took the highest portion of cancer-related deaths, followed by liver cancer (11,311) based on last year data.

Liver cancer is known to carry the highest social cost in comparison to other cancers and it causes the highest fatality in earlier age groups (40s-50s). In that sense, it is necessary to develop a new treatment that mitigates side effects yet elevates the survival rate.

There are ways in which liver cancer can be cured, such as surgery, embolization, and medication treatments; however, the options become limited for curing progressive cancer, a stage in which surgical methods cannot be executed.

Among anticancer medications, Sorafenib, a drug known for enhancing the survival rate of cancer patients, is a unique drug allowed for use as a targeted anticancer medication for progressive liver cancer patients. Its sales reached more than ten billion KRW annually in Korea, but its efficacy works on only about 20% of the treated patients. Also, acquired resistance to Sorafenib is emerging. Additionally, the action mechanism and resistance mechanism of Sorafenib is only vaguely identified.Although Sorafenib only extends the survival rate of terminal cancer patients less than three months on average, it is widely being used because drugs developed by global pharmaceutical companies failed to outperform its effectiveness.

Professor Cho’s research team analyzed the expression changes of genes in cell lines in response to Sorafenib in order to identify the effect and the resistance mechanism of Sorafenib.

As a result, the team discovered the resistance mechanism of Sorafenib using Systems Biology analysis. By combining computer simulations and biological experiments, it was revealed that protein disulfide isomerase (PDI) plays a crucial role in the resistance mechanism of Sorafenib and that its efficacy can be improved significantly by blocking PDI.

The research team used mice in the experiment and discovered the synergic effect of PDI inhibition with Sorafenib for reducing liver cancer cells, known as hepatocellular carcinoma. Also, more PDIs are shown in tissue from patients who possess a resistance to Sorafenib. From these findings, the team could identify the possibility of its clinical applications. The team also confirmed these findings from clinical data through a retrospective cohort study.

“Molecules that play an important role in cell lines are mostly put under complex regulation. For this reason, the existing biological research has a fundamental limitations for discovering its underlying principles,” Professor Cho said. “This research is a representative case of overcoming this limitation of traditional life science research by using a Systems Biology approach, combining IT and life science. It suggests the possibility of developing a new method that overcomes drug resistance with a network analysis of the targeted drug action mechanism of cancer.”

The research was supported by the National Research Foundation of Korea (NRF) and funded by the Ministry of Science and ICT.

(Figure 1. Simulation results from cellular experiments using hepatocellular carcinoma)

(Figure 2. Network analysis and computer simulation by using the endoplasmic reticulum (ER) stress network)

(Figure 3. ER stress network model)

2017.08.30 View 13126 -

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 16613

The Medici Effect: Highly Flexible, Wearable Displays Born in KAIST

(Ph.D. candidate Seungyeop Choi)

How do you feel when technology you saw in a movie is made into reality? Collaboration between the electrical engineering and textile industries has made TVs or smartphone screens displaying on clothing a reality.

A research team led by Professor Kyung Cheol Choi at the School of Electrical Engineering presented wearable displays for various applications including fashion, IT, and healthcare. Integrating OLED (organic light-emitting diode) into fabrics, the team developed the most highly flexible and reliable technology for wearable displays in the world.

Recently, information displays have become increasingly important as they construct the external part of smart devices for the next generation. As world trends are focusing on the Internet of Things (IoTs) and wearable technology, the team drew a lot of attention by making great progress towards commercializing clothing-shaped ‘wearable displays’.

The research for realizing displays on clothing gained considerable attention from academia as well as industry when research on luminescence formed in fabrics was introduced in 2011; however, there was no technology for commercializing it due to its surface roughness and flexibility.

Because of this technical limitation, clothing-shaped wearable displays were thought to be unreachable technology. However, the KAIST team recently succeeded in developing the world’s most highly efficient, light-emitting clothes that can be commercialized.

The research team used two different approaches, fabric-type and fiber-type, in order to realize clothing-shaped wearable displays. In 2015, the team successfully laminated a thin planarization sheet thermally onto fabric to form a surface that is compatible with the OLEDs approximately 200 hundred nanometers thick. Also, the team reported their research outcomes on enhancing the reliability of operating fiber-based OLEDs. In 2016, the team introduced a dip-coating method, capable of uniformly depositing layers, to develop polymer light-emitting diodes, which show high luminance even on thin fabric.

Based on the research performance in 2015 and 2016, Ph.D. candidate Seungyeop Choi took the lead in the research team and succeeded in realizing fabric-based OLEDs, showing high luminance and efficiency while maintaining the flexibility of the fabric.

The long-term reliability of this wearable device that has the world’s best electrical and optical characteristics was verified through their self-developed, organic and inorganic encapsulation technology. According to the team, their wearable device facilitates the operation of OLEDs even at a bending radius of 2mm.

According to Choi, “Having wavy structures and empty spaces, fiber plays a significant role in lowering the mechanical stress on the OLEDs.”

“Screen displayed on our daily clothing is no longer a future technology,” said Professor Choi. “Light-emitting clothes will have considerable influence on not only the e-textile industry but also the automobile and healthcare industries.”

Moreover, the research team remarked, “It means a lot to realize clothing-shaped OLEDs that have the world’s best luminance and efficiency. It is the most flexible fabric-based light-emitting device among those reported. Moreover, noting that this research carried out an in-depth analysis of the mechanical characteristics of the clothing-spared, light-emitting device, the research performance will become a guideline for developing the fabric-based electronics industry.”

This research was funded by the Ministry of Trade, Industry and Energy and collaborated with KOLON Glotech, INC. The research performance was published in Scientific Reports in July.

(OLEDs operating in fabrics)

(Current-voltage-luminance and efficiency of the highly flexible, fabric-based OLEDs;Image of OLEDs after repetitive bending tests;Verification of flexibility through mechanical simulation)

2017.08.24 View 16613 -

KAIST Researchers Receive Awards at the 13th Asian Congress on Biotechnology

(From left: Seon Young Park, Dr. So Young Choi, and Yoojin Choi)

Researchers in the laboratory of KAIST Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering swept awards at the 13th Asian Congress on Biotechnology held in Thailand last month. The conference awarded a total of eight prizes in the areas of best research and best poster presentation. This is an exceptional case in which members of one research team received almost half of the awards at an international conference.

Dr. So Young Choi received the Best Research Award, while Ph.D. candidates Yoojin Choi and Seon Young Park each received the Best Poster Presentation Award at the conference held in Khon Kaen, Thailand from July 23 to 27.

The Asian Congress on Biotechnology is an international conference in which scientists and industry experts in Asia and from around the world gather to present recent research findings in the field of biotechnology. At the conference, around 400 researchers in biotechnology from 25 countries, including Korea, gathered to present and discuss various research findings under the theme of “Bioinnovation and Bioeconomy.”

Distinguished Professor Sang Yup Lee attended the conference to give the opening plenary lecture on the topic of ‘Systems Strategies in Biotechnology.’ Professor Lee announced, “I have attended international conferences with students for the last 20 years, but this is the first in which my team received three awards at an international conference that only honors a total of eight awards, three for Best Research and five for Best Presentation.”

Dr. Choi presented research results on poly (lactate-co-glycolate) (PLGA) synthesis through a biological method using micro-organisms and received the Best Research Award. PLGA is a random copolymer of DL-lactic and glycolic acids and is a biopolymer widely used for biomedical applications. PLGA is biodegradable, biocompatible, and nontoxic, and thus has been approved by the US Food and Drug Administration (FDA) for its use in implants, drug delivery, and sutures.

Dr. Choi’s research was deemed to be innovative for synthesizing PLGA from glucose and xylose in cells through metabolic engineering of E.Coli. Dr. Choi received her Ph.D. under the supervision of Distinguished Professor Lee this February and is currently conducting post-doc research.

Ph.D. candidate Choi presented her research on the use of recombinant E.Coli for the biological synthesis of various nanoparticles and received the Best Poster Presentation award. Choi used recombinant E.Coli-expressing proteins and peptides that adsorb to heavy metals to biologically synthesize diverse metal nanoparticles such as single-nanoparticle including gold and silver, quantum dots, and magnetic nanoparticles for the first time. The synthesized nanoparticles can be used in the fields of bio-imaging, diagnosis, environment, and energy.

Ph.D. candidate Park, who also received the Best Poster Presentation award, synthesized and increased production of astanxanthin, a strong antioxidant found in nature, in E.Coli using metabolic engineering. Astanxanthin is a carotenoid pigment found in salmon and shrimp that widely used in health products and cosmetics.

2017.08.01 View 16388

KAIST Researchers Receive Awards at the 13th Asian Congress on Biotechnology

(From left: Seon Young Park, Dr. So Young Choi, and Yoojin Choi)

Researchers in the laboratory of KAIST Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering swept awards at the 13th Asian Congress on Biotechnology held in Thailand last month. The conference awarded a total of eight prizes in the areas of best research and best poster presentation. This is an exceptional case in which members of one research team received almost half of the awards at an international conference.

Dr. So Young Choi received the Best Research Award, while Ph.D. candidates Yoojin Choi and Seon Young Park each received the Best Poster Presentation Award at the conference held in Khon Kaen, Thailand from July 23 to 27.

The Asian Congress on Biotechnology is an international conference in which scientists and industry experts in Asia and from around the world gather to present recent research findings in the field of biotechnology. At the conference, around 400 researchers in biotechnology from 25 countries, including Korea, gathered to present and discuss various research findings under the theme of “Bioinnovation and Bioeconomy.”

Distinguished Professor Sang Yup Lee attended the conference to give the opening plenary lecture on the topic of ‘Systems Strategies in Biotechnology.’ Professor Lee announced, “I have attended international conferences with students for the last 20 years, but this is the first in which my team received three awards at an international conference that only honors a total of eight awards, three for Best Research and five for Best Presentation.”

Dr. Choi presented research results on poly (lactate-co-glycolate) (PLGA) synthesis through a biological method using micro-organisms and received the Best Research Award. PLGA is a random copolymer of DL-lactic and glycolic acids and is a biopolymer widely used for biomedical applications. PLGA is biodegradable, biocompatible, and nontoxic, and thus has been approved by the US Food and Drug Administration (FDA) for its use in implants, drug delivery, and sutures.

Dr. Choi’s research was deemed to be innovative for synthesizing PLGA from glucose and xylose in cells through metabolic engineering of E.Coli. Dr. Choi received her Ph.D. under the supervision of Distinguished Professor Lee this February and is currently conducting post-doc research.

Ph.D. candidate Choi presented her research on the use of recombinant E.Coli for the biological synthesis of various nanoparticles and received the Best Poster Presentation award. Choi used recombinant E.Coli-expressing proteins and peptides that adsorb to heavy metals to biologically synthesize diverse metal nanoparticles such as single-nanoparticle including gold and silver, quantum dots, and magnetic nanoparticles for the first time. The synthesized nanoparticles can be used in the fields of bio-imaging, diagnosis, environment, and energy.

Ph.D. candidate Park, who also received the Best Poster Presentation award, synthesized and increased production of astanxanthin, a strong antioxidant found in nature, in E.Coli using metabolic engineering. Astanxanthin is a carotenoid pigment found in salmon and shrimp that widely used in health products and cosmetics.

2017.08.01 View 16388