device

-

Flexible User Interface Distribution for Ubiquitous Multi-Device Interaction

< Research Group of Professor Insik Shin (center) >

KAIST researchers have developed mobile software platform technology that allows a mobile application (app) to be executed simultaneously and more dynamically on multiple smart devices. Its high flexibility and broad applicability can help accelerate a shift from the current single-device paradigm to a multiple one, which enables users to utilize mobile apps in ways previously unthinkable.

Recent trends in mobile and IoT technologies in this era of 5G high-speed wireless communication have been hallmarked by the emergence of new display hardware and smart devices such as dual screens, foldable screens, smart watches, smart TVs, and smart cars. However, the current mobile app ecosystem is still confined to the conventional single-device paradigm in which users can employ only one screen on one device at a time. Due to this limitation, the real potential of multi-device environments has not been fully explored.

A KAIST research team led by Professor Insik Shin from the School of Computing, in collaboration with Professor Steve Ko’s group from the State University of New York at Buffalo, has developed mobile software platform technology named FLUID that can flexibly distribute the user interfaces (UIs) of an app to a number of other devices in real time without needing any modifications. The proposed technology provides single-device virtualization, and ensures that the interactions between the distributed UI elements across multiple devices remain intact.

This flexible multimodal interaction can be realized in diverse ubiquitous user experiences (UX), such as using live video steaming and chatting apps including YouTube, LiveMe, and AfreecaTV. FLUID can ensure that the video is not obscured by the chat window by distributing and displaying them separately on different devices respectively, which lets users enjoy the chat function while watching the video at the same time.

In addition, the UI for the destination input on a navigation app can be migrated into the passenger’s device with the help of FLUID, so that the destination can be easily and safely entered by the passenger while the driver is at the wheel.

FLUID can also support 5G multi-view apps – the latest service that allows sports or games to be viewed from various angles on a single device. With FLUID, the user can watch the event simultaneously from different viewpoints on multiple devices without switching between viewpoints on a single screen.

PhD candidate Sangeun Oh, who is the first author, and his team implemented the prototype of FLUID on the leading open-source mobile operating system, Android, and confirmed that it can successfully deliver the new UX to 20 existing legacy apps.

“This new technology can be applied to next-generation products from South Korean companies such as LG’s dual screen phone and Samsung’s foldable phone and is expected to embolden their competitiveness by giving them a head-start in the global market.” said Professor Shin.

This study will be presented at the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019) October 21 through 25 in Los Cabos, Mexico. The research was supported by the National Science Foundation (NSF) (CNS-1350883 (CAREER) and CNS-1618531).

Figure 1. Live video streaming and chatting app scenario

Figure 2. Navigation app scenario

Figure 3. 5G multi-view app scenario

Publication: Sangeun Oh, Ahyeon Kim, Sunjae Lee, Kilho Lee, Dae R. Jeong, Steven Y. Ko, and Insik Shin. 2019. FLUID: Flexible User Interface Distribution for Ubiquitous Multi-device Interaction. To be published in Proceedings of the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019). ACM, New York, NY, USA. Article Number and DOI Name TBD.

Video Material:

https://youtu.be/lGO4GwH4enA

Profile: Prof. Insik Shin, MS, PhD

ishin@kaist.ac.kr

https://cps.kaist.ac.kr/~ishin

Professor

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Sangeun Oh, PhD Candidate

ohsang1213@kaist.ac.kr

https://cps.kaist.ac.kr/

PhD Candidate

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Steve Ko, PhD

stevko@buffalo.edu

https://nsr.cse.buffalo.edu/?page_id=272

Associate Professor

Networked Systems Research Group

Department of Computer Science and Engineering

State University of New York at Buffalo

http://www.buffalo.edu/ Buffalo 14260, USA

(END)

2019.07.20 View 42270

Flexible User Interface Distribution for Ubiquitous Multi-Device Interaction

< Research Group of Professor Insik Shin (center) >

KAIST researchers have developed mobile software platform technology that allows a mobile application (app) to be executed simultaneously and more dynamically on multiple smart devices. Its high flexibility and broad applicability can help accelerate a shift from the current single-device paradigm to a multiple one, which enables users to utilize mobile apps in ways previously unthinkable.

Recent trends in mobile and IoT technologies in this era of 5G high-speed wireless communication have been hallmarked by the emergence of new display hardware and smart devices such as dual screens, foldable screens, smart watches, smart TVs, and smart cars. However, the current mobile app ecosystem is still confined to the conventional single-device paradigm in which users can employ only one screen on one device at a time. Due to this limitation, the real potential of multi-device environments has not been fully explored.

A KAIST research team led by Professor Insik Shin from the School of Computing, in collaboration with Professor Steve Ko’s group from the State University of New York at Buffalo, has developed mobile software platform technology named FLUID that can flexibly distribute the user interfaces (UIs) of an app to a number of other devices in real time without needing any modifications. The proposed technology provides single-device virtualization, and ensures that the interactions between the distributed UI elements across multiple devices remain intact.

This flexible multimodal interaction can be realized in diverse ubiquitous user experiences (UX), such as using live video steaming and chatting apps including YouTube, LiveMe, and AfreecaTV. FLUID can ensure that the video is not obscured by the chat window by distributing and displaying them separately on different devices respectively, which lets users enjoy the chat function while watching the video at the same time.

In addition, the UI for the destination input on a navigation app can be migrated into the passenger’s device with the help of FLUID, so that the destination can be easily and safely entered by the passenger while the driver is at the wheel.

FLUID can also support 5G multi-view apps – the latest service that allows sports or games to be viewed from various angles on a single device. With FLUID, the user can watch the event simultaneously from different viewpoints on multiple devices without switching between viewpoints on a single screen.

PhD candidate Sangeun Oh, who is the first author, and his team implemented the prototype of FLUID on the leading open-source mobile operating system, Android, and confirmed that it can successfully deliver the new UX to 20 existing legacy apps.

“This new technology can be applied to next-generation products from South Korean companies such as LG’s dual screen phone and Samsung’s foldable phone and is expected to embolden their competitiveness by giving them a head-start in the global market.” said Professor Shin.

This study will be presented at the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019) October 21 through 25 in Los Cabos, Mexico. The research was supported by the National Science Foundation (NSF) (CNS-1350883 (CAREER) and CNS-1618531).

Figure 1. Live video streaming and chatting app scenario

Figure 2. Navigation app scenario

Figure 3. 5G multi-view app scenario

Publication: Sangeun Oh, Ahyeon Kim, Sunjae Lee, Kilho Lee, Dae R. Jeong, Steven Y. Ko, and Insik Shin. 2019. FLUID: Flexible User Interface Distribution for Ubiquitous Multi-device Interaction. To be published in Proceedings of the 25th Annual International Conference on Mobile Computing and Networking (ACM MobiCom 2019). ACM, New York, NY, USA. Article Number and DOI Name TBD.

Video Material:

https://youtu.be/lGO4GwH4enA

Profile: Prof. Insik Shin, MS, PhD

ishin@kaist.ac.kr

https://cps.kaist.ac.kr/~ishin

Professor

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Sangeun Oh, PhD Candidate

ohsang1213@kaist.ac.kr

https://cps.kaist.ac.kr/

PhD Candidate

Cyber-Physical Systems (CPS) Lab

School of Computing

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Steve Ko, PhD

stevko@buffalo.edu

https://nsr.cse.buffalo.edu/?page_id=272

Associate Professor

Networked Systems Research Group

Department of Computer Science and Engineering

State University of New York at Buffalo

http://www.buffalo.edu/ Buffalo 14260, USA

(END)

2019.07.20 View 42270 -

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 43386

Wearable Robot 'WalkON Suit' Off to Cybathlon 2020

Standing upright and walking alone are very simple but noble motions that separate humans from many other creatures. Wearable and prosthetic technologies have emerged to augment human function in locomotion and manipulation. However, advances in wearable robot technology have been especially momentous to Byoung-Wook Kim, a triplegic for 22 years following a devastating car accident.

Kim rejoiced after standing upright and walking again by putting on the ‘WalkON Suit,’ the wearable robot developed by Professor Kyoungchul Kong’s team. Even more, Kim won third prize in the powered exoskeleton race at Cybathlon 2016, an international cyborg Olympics hosted by ETH Zurich.

Now Kim and Professor Kong’s team are all geared up for the Cybathlon Championship 2020. Professor Kong and his startup, Angel Robotics, held a kickoff ceremony for Cybathlon 2020 at KAIST on June 24. The 2020 championship will take place in Switzerland.

Only pilots with complete paralysis of the legs resulting from spinal cord injuries are eligible to participate in the Cybathlon, which takes place every four years. Pilots compete against each other while completing everyday tasks using technical assistance systems in six different disciplines: a brain-computer interface race, a functional electrical stimulation bike race, a powered arm prosthesis race, a powered leg prosthesis race, a powered exoskeleton race, and a powered wheelchair race. The 2016 championship drew 66 pilots from 56 teams representing 25 countries.

In the powered exoskeleton race, pilots complete everyday activities such as getting up from a sofa and overcoming obstacles such as stairs, ramps, or slopes and up to four pilots compete simultaneously on tracks to solve six tasks; and the pilot that solves the most tasks in the least amount of time wins the race.

(Kim, a triplegic for 22 years demonstrates walking and climbing the stairs (below photo) wearing the WalkOn Suit during the media day on June 21 at KAIST.)

Kim, who demonstrated walking and climbing the stairs wearing the WalkON Suit during the media day for the Cybathlon 2020 kickoff ceremony on June 21 at KAIST, said, “I have been confined to a wheelchair for more than 20 years. I am used to it so I feel like the wheelchair is one of my body parts. Actually, I don’t feel any big difficulties in doing everyday tasks in wheelchair. But whenever I face the fact that I will never be able to stand up with my own two legs again, I am so devastated.” He continued, “I still remember the day when I stood up with my own two legs by myself after 22 years. It was beyond description.”

The market for wearable robots, especially for exoskeleton robots, is continuing to grow as the aging population has been a major challenge in almost every advanced country. The global market for these robots expects to see annual growth of 41.2% to 8.3 billion US dollars by 2025. Healthcare wearable robots for the elderly and rehabilitation take up the half of the market share followed by wearable robots for industrial and defense purposes.

Professor Kong from the Department of Mechanical Engineering and his colleagues have developed two wearable robot systems in 2014: The "WalkON Suit" for complete paraplegics and “Angel Suit” for those with partial impairment in walking ability such as the elderly and rehabilitation patients.

Professor Kong said after 15 years of basic research, the team is now able to develop its own distinct technologies. He said their robots are powered by non-resistant precision drives with algorithms recognizing the user’s moving intention. Incorporated with prosthetic devices technology from the Severance Rehabilitation Hospital, their control technology has led to the production of a customizable robot suit optimized for each user’s physical condition.

The WalkON Suit, which boasts a maximum force of 250 Nm and maximum rotation speed of 45 RPM, gives the user high-energy efficiency modeled after the physiology of the human leg. It allows users to walk on flat ground and down stairs, climb up and down inclines, and sit and lie down. Currently the battery lasts five to six hours for locomotion and the approximate 25 kg of robot weight still remains a technical challenge to upgrade.

Professor Kong’s team has grafted AR glass technology into the WalkOn Suit that one of his pilots put on for the torch relay of the PyongChang Paralympics in 2018. His team is now upgrading the WalkON Suit 4.0 for next year’s competition. Severance Rehabilitation Hospital will help the seven pilots with their training.

Professor Kong said his goal is to make robots that can make people with disabilities much more independent. He stressed, “Wearable robots should be designed for each single user. We provide a very good graphical user interface so that we can design, check, and also verify our optimized design for users’ best performance.”

(Seven pilots and Professor Kong (fifth from left in second row) pose with guests who joined the Cybathlon 2020 kickoff ceremony. President Shin (fifth from right) made a congratulatory remarks during the ceremony.)

2019.06.25 View 43386 -

Novel Via-Hole-Less Multilevel Metal Interconnection Methods

Forming reliable multi-level metal interconnections is a key technology for integrating devices into organic integrated circuits (ICs). The conventional approach, called “via-hole,” locally removes the insulator and utilizes metal interconnects through the holes. Due to the high sensitivity of organic materials to chemical solvents, heat, and photo-radiation used in conventional “via-hole” methods, alternative printing methods or laser drilling methods have been developed. However, finding a reliable and practical metal interconnection for organic ICs is still challenging.

The research team of KAIST Professor Sung Gap Im and Postech Professor Kim Jae-Joon reported a new interconnection method that does not require via-hole formation, “via-hole-less metal interconnection,” in Nature Communications on June 3.

Metal electrodes in different layers can be isolated from each other by patterned dielectric layers, where they then can be interconnected to others in the open area where the dielectric layer is not present. See the images below. Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Professor Kim explained, “Our proposed via-hole-less interconnect method using a selectively patterned dielectric overcomes the limitations of the previous time-consuming, one-by-one via-hole formation process and provides reliable methods for creating metal interconnects in organic ICs. We expect the via-hole-less scheme to bring advances to organic IC technology.”

2019.06.18 View 45965

Novel Via-Hole-Less Multilevel Metal Interconnection Methods

Forming reliable multi-level metal interconnections is a key technology for integrating devices into organic integrated circuits (ICs). The conventional approach, called “via-hole,” locally removes the insulator and utilizes metal interconnects through the holes. Due to the high sensitivity of organic materials to chemical solvents, heat, and photo-radiation used in conventional “via-hole” methods, alternative printing methods or laser drilling methods have been developed. However, finding a reliable and practical metal interconnection for organic ICs is still challenging.

The research team of KAIST Professor Sung Gap Im and Postech Professor Kim Jae-Joon reported a new interconnection method that does not require via-hole formation, “via-hole-less metal interconnection,” in Nature Communications on June 3.

Metal electrodes in different layers can be isolated from each other by patterned dielectric layers, where they then can be interconnected to others in the open area where the dielectric layer is not present. See the images below. Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Vapor phase deposition and in-situ patterning of dielectric layer using iCVD (initiated chemical vapor deposition), used in the “via-hole-less” method, ensure a damage-free process for organic semiconductor materials and result in outstanding performance of the organic devices as multilevel metal interconnects are reliably formed. The team successfully demonstrated three-dimensional (3D) stacking of five organic transistors and integrated circuits using the proposed via-hole-less interconnect method. See the image below.

Professor Kim explained, “Our proposed via-hole-less interconnect method using a selectively patterned dielectric overcomes the limitations of the previous time-consuming, one-by-one via-hole formation process and provides reliable methods for creating metal interconnects in organic ICs. We expect the via-hole-less scheme to bring advances to organic IC technology.”

2019.06.18 View 45965 -

Research Day Highlights Most Outstanding Research Achievements

Professor Byung Jin Cho from the School of Electrical Engineering was selected as the Grand Research Prize Winner in recognition of his innovative research achievement in the fields of nano electric and flexible energy devices during the 2019 KAIST Research Day ceremony held on April 23 at the Chung Kunmo Conference Hall.

The ten most outstanding research achievements from the past year were also awarded in the three areas of Research, Innovation, Convergence Researches.

Professor Cho is an internationally recognized researcher in the field of future nano and energy device technology. Professor Cho’s team has continued to research on advanced CMOS (complementary metal-oxide semiconductors). CMOS has become his key research topic over the past three decades.

In 2014, he developed a glass fabric-based thermoelectric generator, which is extremely light and flexible and produces electricity from the heat of the human body. It is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles. His wearable thermoelectric generator was selected as one of the top ten most promising digital technologies by the Netexplo Forum in 2015.

He now is working on high-performance and ultra-flexible CMOS IC for biomedical applications, expanding his scope to thermal haptic technology in VR using graphene-CMOS hybrid integrated circuits; to self-powered wireless sensor nodes and self-powered ECG system using wearable thermoelectric generators .

In his special lecture at the ceremony, Professor Cho stressed the importance of collaboration in making scientific research and presented how he moved to future devices after focusing on scaling the devices.

“When I started the research on semiconductors, I focused on how to scale the device down as much as possible. For decades, we have conducted a number of procedures to produce tiny but efficient materials. Now we have shifted to develop flexible thermoelements and wearable devices,” said Professor Cho.

“We all thought the scaling down is the only way to create value-added technological breakthroughs. Now, the devices have been scaled down to 7nm and will go down to 5 nm soon. Over the past few years, I think we have gone through all the possible technological breakthroughs for reducing the size to 5nm. The semiconductor devices are made of more 1 billion transistors and go through 1,000 technological processes. So, there won’t be any possible way for a single genius to make a huge breakthrough. Without collaboration with others, it is nearly impossible to make any new technological breakthroughs.”

Professor Cho has published more than 240 papers in renowned academic journals and presented more than 300 papers at academic conferences. He has also registered approximately 50 patents in the field of semiconductor device technology.

The top ten research highlights of 2018 as follows:

- Rydberg-Atom Quantum Simulator Development by Professor Jaewook Ahn and Heung-Sun Sim from the Department of Physics

- From C-H to C-C Bonds at Room Temperature by Professor Mu-Hyun Baik from the Department of Chemistry

- The Role of Rodlike Counterions on the Interactions of DNAs by Professor Yong Woon Kim of the Graduate School of Nanoscience and Technology

- The Medal Preoptic Area Induces Hunting-Like Behaviors to Target Objects and Prey by Professor Daesoo Kim from the Department of Biological Sciences

- Identification of the Origin of Brain Tumors and New Therapeutic Strategy by Professor Jeong Ho Lee from the Graduate School of Medical Science and Engineering

- The Linear Frequency Conversion of Light at a Spatiotemporal Boundary by Professor Bumki Min from the Department of Mechanical Engineering

- An Industrial Grade Flexible Transparent Force Touch Sensor by Professor Jun-Bo Yoon from the School of Electrical Engineering

- The Detection and Clustering of Mixed-Type Defect Patterns in Wafer Bin Maps by Professor Heeyoung Kim from the Department of Industrial and Systems Engineering

- The Development of a Reconfigurable Spin-Based Logic Device by Professor Byong-Guk Park from the Department of Materials Science and Engineering

- The Development of a Miniaturized X-Ray Tube Based on Carbon Nanotube and Electronic Brachytherapy Device by Professor Sung Oh Cho from the Department of Nuclear and Quantum Engineering

Professor YongKeun Park from the Department of Physics and Professor In-Chel Park from the School of Electrical Engineering received the Research Award. For the Innovation Award, Professor Munchurl Kim from the School of Electrical Engineering was the recipient and the Convergence Research Awards was conferred to Professor Sung-Yool Choi from the School of Electrical Engineering, Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering, and Professor SangHee Park from the Department of Materials Science and Engineering during the ceremony.

For more on KAIST’s Top Research Achievements and Highlight of 2018, please refer to the attached below. click.

2019.04.25 View 18621

Research Day Highlights Most Outstanding Research Achievements

Professor Byung Jin Cho from the School of Electrical Engineering was selected as the Grand Research Prize Winner in recognition of his innovative research achievement in the fields of nano electric and flexible energy devices during the 2019 KAIST Research Day ceremony held on April 23 at the Chung Kunmo Conference Hall.

The ten most outstanding research achievements from the past year were also awarded in the three areas of Research, Innovation, Convergence Researches.

Professor Cho is an internationally recognized researcher in the field of future nano and energy device technology. Professor Cho’s team has continued to research on advanced CMOS (complementary metal-oxide semiconductors). CMOS has become his key research topic over the past three decades.

In 2014, he developed a glass fabric-based thermoelectric generator, which is extremely light and flexible and produces electricity from the heat of the human body. It is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles. His wearable thermoelectric generator was selected as one of the top ten most promising digital technologies by the Netexplo Forum in 2015.

He now is working on high-performance and ultra-flexible CMOS IC for biomedical applications, expanding his scope to thermal haptic technology in VR using graphene-CMOS hybrid integrated circuits; to self-powered wireless sensor nodes and self-powered ECG system using wearable thermoelectric generators .

In his special lecture at the ceremony, Professor Cho stressed the importance of collaboration in making scientific research and presented how he moved to future devices after focusing on scaling the devices.

“When I started the research on semiconductors, I focused on how to scale the device down as much as possible. For decades, we have conducted a number of procedures to produce tiny but efficient materials. Now we have shifted to develop flexible thermoelements and wearable devices,” said Professor Cho.

“We all thought the scaling down is the only way to create value-added technological breakthroughs. Now, the devices have been scaled down to 7nm and will go down to 5 nm soon. Over the past few years, I think we have gone through all the possible technological breakthroughs for reducing the size to 5nm. The semiconductor devices are made of more 1 billion transistors and go through 1,000 technological processes. So, there won’t be any possible way for a single genius to make a huge breakthrough. Without collaboration with others, it is nearly impossible to make any new technological breakthroughs.”

Professor Cho has published more than 240 papers in renowned academic journals and presented more than 300 papers at academic conferences. He has also registered approximately 50 patents in the field of semiconductor device technology.

The top ten research highlights of 2018 as follows:

- Rydberg-Atom Quantum Simulator Development by Professor Jaewook Ahn and Heung-Sun Sim from the Department of Physics

- From C-H to C-C Bonds at Room Temperature by Professor Mu-Hyun Baik from the Department of Chemistry

- The Role of Rodlike Counterions on the Interactions of DNAs by Professor Yong Woon Kim of the Graduate School of Nanoscience and Technology

- The Medal Preoptic Area Induces Hunting-Like Behaviors to Target Objects and Prey by Professor Daesoo Kim from the Department of Biological Sciences

- Identification of the Origin of Brain Tumors and New Therapeutic Strategy by Professor Jeong Ho Lee from the Graduate School of Medical Science and Engineering

- The Linear Frequency Conversion of Light at a Spatiotemporal Boundary by Professor Bumki Min from the Department of Mechanical Engineering

- An Industrial Grade Flexible Transparent Force Touch Sensor by Professor Jun-Bo Yoon from the School of Electrical Engineering

- The Detection and Clustering of Mixed-Type Defect Patterns in Wafer Bin Maps by Professor Heeyoung Kim from the Department of Industrial and Systems Engineering

- The Development of a Reconfigurable Spin-Based Logic Device by Professor Byong-Guk Park from the Department of Materials Science and Engineering

- The Development of a Miniaturized X-Ray Tube Based on Carbon Nanotube and Electronic Brachytherapy Device by Professor Sung Oh Cho from the Department of Nuclear and Quantum Engineering

Professor YongKeun Park from the Department of Physics and Professor In-Chel Park from the School of Electrical Engineering received the Research Award. For the Innovation Award, Professor Munchurl Kim from the School of Electrical Engineering was the recipient and the Convergence Research Awards was conferred to Professor Sung-Yool Choi from the School of Electrical Engineering, Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering, and Professor SangHee Park from the Department of Materials Science and Engineering during the ceremony.

For more on KAIST’s Top Research Achievements and Highlight of 2018, please refer to the attached below. click.

2019.04.25 View 18621 -

Yoon Ki Hong Named 2018 Jeong Hun Cho Awardee

(From left: PhD candidate Seungkwan Baek from the Department of Aerospace Engineering, Dr. Yoon Ki Hong from ADD, PhD candidate Wonhee Choi from the School of Mechanical Engineering at Korea University, and Jaehun Lee from Kongju National University High School)

Dr. Yoon Ki Hong from the Agency of Defense Development (ADD) was named the 2018 recipient of the Jong-Hoon Cho Award. The award recognizes outstanding young scientists in the field of aerospace engineering annually. The recipient of this award receives a 25 million KRW prize.

The Award Committee said that Dr. Hong has achieved outstanding work in the field of aerospace engineering. In particular, he conducted research on designing an air heating device which is the crucial component for ground experimental equipment. It is required for testing and evaluating supersonic vehicles’ structural strength tests using technology cannot be imported. In cooperation with his colleagues, he succeeded in developing an air heating device, a feat that has only been accomplished by developed countries. He also verified its operational performance.

Moreover, he received the best paper award from Korean Federation of Science and Minister of Defense Acquisition Program Administration’s Prize.

The award was endowed by the family of the late PhD candidate Jeong Hun Cho, who died in a rocket lab accident in the Department of Aerospace Engineering in 2003. Cho was posthumously conferred an honorary doctorate degree.

In Cho’s memory, his father established the ‘Jeong Hun Cho Award and Scholarship’. Since 2005, the scholarship annually selects three young scholars specializing in aerospace engineering from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

In addition to Dr. Hong, the Award Committee chose three students for scholarships: PhD candidate Seungkwan Baek from the Department of Aerospace Engineering, PhD candidate Wonhee Choi from the School of Mechanical Engineering at Korea University, and Jaehun Lee from Kongju National University High School.

2018.05.11 View 11931

Yoon Ki Hong Named 2018 Jeong Hun Cho Awardee

(From left: PhD candidate Seungkwan Baek from the Department of Aerospace Engineering, Dr. Yoon Ki Hong from ADD, PhD candidate Wonhee Choi from the School of Mechanical Engineering at Korea University, and Jaehun Lee from Kongju National University High School)

Dr. Yoon Ki Hong from the Agency of Defense Development (ADD) was named the 2018 recipient of the Jong-Hoon Cho Award. The award recognizes outstanding young scientists in the field of aerospace engineering annually. The recipient of this award receives a 25 million KRW prize.

The Award Committee said that Dr. Hong has achieved outstanding work in the field of aerospace engineering. In particular, he conducted research on designing an air heating device which is the crucial component for ground experimental equipment. It is required for testing and evaluating supersonic vehicles’ structural strength tests using technology cannot be imported. In cooperation with his colleagues, he succeeded in developing an air heating device, a feat that has only been accomplished by developed countries. He also verified its operational performance.

Moreover, he received the best paper award from Korean Federation of Science and Minister of Defense Acquisition Program Administration’s Prize.

The award was endowed by the family of the late PhD candidate Jeong Hun Cho, who died in a rocket lab accident in the Department of Aerospace Engineering in 2003. Cho was posthumously conferred an honorary doctorate degree.

In Cho’s memory, his father established the ‘Jeong Hun Cho Award and Scholarship’. Since 2005, the scholarship annually selects three young scholars specializing in aerospace engineering from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School.

In addition to Dr. Hong, the Award Committee chose three students for scholarships: PhD candidate Seungkwan Baek from the Department of Aerospace Engineering, PhD candidate Wonhee Choi from the School of Mechanical Engineering at Korea University, and Jaehun Lee from Kongju National University High School.

2018.05.11 View 11931 -

Multi-Device Mobile Platform for App Functionality Sharing

Case 1. Mr. Kim, an employee, logged on to his SNS account using a tablet PC at the airport while traveling overseas. However, a malicious virus was installed on the tablet PC and some photos posted on his SNS were deleted by someone else.

Case 2. Mr. and Mrs. Brown are busy contacting credit card and game companies, because his son, who likes games, purchased a million dollars worth of game items using his smartphone.

Case 3. Mr. Park, who enjoys games, bought a sensor-based racing game through his tablet PC. However, he could not enjoy the racing game on his tablet because it was not comfortable to tilt the device for game control.

The above cases are some of the various problems that can arise in modern society where diverse smart devices, including smartphones, exist. Recently, new technology has been developed to easily solve these problems. Professor Insik Shin from the School of Computing has developed ‘Mobile Plus,’ which is a mobile platform that can share the functionalities of applications between smart devices.

This is a novel technology that allows applications to easily share their functionalities without needing any modifications. Smartphone users often use Facebook to log in to another SNS account like Instagram, or use a gallery app to post some photos on their SNS. These examples are possible, because the applications share their login and photo management functionalities.

The functionality sharing enables users to utilize smartphones in various and convenient ways and allows app developers to easily create applications. However, current mobile platforms such as Android or iOS only support functionality sharing within a single mobile device. It is burdensome for both developers and users to share functionalities across devices because developers would need to create more complex applications and users would need to install the applications on each device.

To address this problem, Professor Shin’s research team developed platform technology to support functionality sharing between devices. The main concept is using virtualization to give the illusion that the applications running on separate devices are on a single device. They succeeded in this virtualization by extending a RPC (Remote Procedure Call) scheme to multi-device environments.

This virtualization technology enables the existing applications to share their functionalities without needing any modifications, regardless of the type of applications. So users can now use them without additional purchases or updates. Mobile Plus can support hardware functionalities like cameras, microphones, and GPS as well as application functionalities such as logins, payments, and photo sharing. Its greatest advantage is its wide range of possible applications.

Professor Shin said, "Mobile Plus is expected to have great synergy with smart home and smart car technologies. It can provide novel user experiences (UXs) so that users can easily utilize various applications of smart home/vehicle infotainment systems by using a smartphone as their hub."

This research was published at ACM MobiSys, an international conference on mobile computing that was hosted in the United States on June 21.

Figure1. Users can securely log on to SNS accounts by using their personal devices

Figure 2. Parents can control impulse shopping of their children.

Figure 3. Users can enjoy games more and more by using the smartphone as a controller.

2017.08.09 View 11212

Multi-Device Mobile Platform for App Functionality Sharing

Case 1. Mr. Kim, an employee, logged on to his SNS account using a tablet PC at the airport while traveling overseas. However, a malicious virus was installed on the tablet PC and some photos posted on his SNS were deleted by someone else.

Case 2. Mr. and Mrs. Brown are busy contacting credit card and game companies, because his son, who likes games, purchased a million dollars worth of game items using his smartphone.

Case 3. Mr. Park, who enjoys games, bought a sensor-based racing game through his tablet PC. However, he could not enjoy the racing game on his tablet because it was not comfortable to tilt the device for game control.

The above cases are some of the various problems that can arise in modern society where diverse smart devices, including smartphones, exist. Recently, new technology has been developed to easily solve these problems. Professor Insik Shin from the School of Computing has developed ‘Mobile Plus,’ which is a mobile platform that can share the functionalities of applications between smart devices.

This is a novel technology that allows applications to easily share their functionalities without needing any modifications. Smartphone users often use Facebook to log in to another SNS account like Instagram, or use a gallery app to post some photos on their SNS. These examples are possible, because the applications share their login and photo management functionalities.

The functionality sharing enables users to utilize smartphones in various and convenient ways and allows app developers to easily create applications. However, current mobile platforms such as Android or iOS only support functionality sharing within a single mobile device. It is burdensome for both developers and users to share functionalities across devices because developers would need to create more complex applications and users would need to install the applications on each device.

To address this problem, Professor Shin’s research team developed platform technology to support functionality sharing between devices. The main concept is using virtualization to give the illusion that the applications running on separate devices are on a single device. They succeeded in this virtualization by extending a RPC (Remote Procedure Call) scheme to multi-device environments.

This virtualization technology enables the existing applications to share their functionalities without needing any modifications, regardless of the type of applications. So users can now use them without additional purchases or updates. Mobile Plus can support hardware functionalities like cameras, microphones, and GPS as well as application functionalities such as logins, payments, and photo sharing. Its greatest advantage is its wide range of possible applications.

Professor Shin said, "Mobile Plus is expected to have great synergy with smart home and smart car technologies. It can provide novel user experiences (UXs) so that users can easily utilize various applications of smart home/vehicle infotainment systems by using a smartphone as their hub."

This research was published at ACM MobiSys, an international conference on mobile computing that was hosted in the United States on June 21.

Figure1. Users can securely log on to SNS accounts by using their personal devices

Figure 2. Parents can control impulse shopping of their children.

Figure 3. Users can enjoy games more and more by using the smartphone as a controller.

2017.08.09 View 11212 -

KAIST's Doctoral Student Receives a Hoffman Scholarship Award

Hyo-Sun Lee, a doctoral student at the Graduate School of EEWS (Environment, Energy, Water and Sustainability), KAIST, is a recipient of the 2016 Dorothy M. and Earl S. Hoffman Scholarships presented by the American Vacuum Society (AVS). The award ceremony took place during the Society’s 63rd International Symposium and Exhibition on November 6-11, 2016 in Nashville, Tennessee.

Lee is the first Korean and foreign student to receive this scholarship.

The Hoffman Scholarships were established in 2002 to recognize and encourage excellence in graduate studies in the sciences and technologies of interest to AVS. The scholarships are funded by a bequest from Dorothy M. Hoffman, who was a pioneering member of the Society of Women Engineers and served as the president of AVS in 1974.

Lee received the scholarship for her research that detects hot electrons from chemical reactions on catalytic surface using nanodevices. Nano Letters, an academic journal published by the American Chemical Society, described her work in its February 2016 issue as a technology that allows quantitative analysis of hot electrons by employing a new nanodevice and therefore helps researchers understand better the mechanism of chemical reactions on nanocatalytic surface. She also published her work to detect the flow of hot electrons that occur on metal nanocatalytic surface during hydrogen oxidation reactions in Angewandte Chemie.

Lee said, “I am pleased to receive this honor from such a world-renowned academic society. Certainly, this will be a great support for my future study and research.”

Founded in 1953, AVS is an interdisciplinary, professional society composed of approximately 4,500 members worldwide. It supports networking among academic, industrial, government, and consulting professionals involved in a range of established and emerging science and technology areas such as chemistry, physics, engineering, business, and technology development.

2016.11.17 View 11881

KAIST's Doctoral Student Receives a Hoffman Scholarship Award

Hyo-Sun Lee, a doctoral student at the Graduate School of EEWS (Environment, Energy, Water and Sustainability), KAIST, is a recipient of the 2016 Dorothy M. and Earl S. Hoffman Scholarships presented by the American Vacuum Society (AVS). The award ceremony took place during the Society’s 63rd International Symposium and Exhibition on November 6-11, 2016 in Nashville, Tennessee.

Lee is the first Korean and foreign student to receive this scholarship.

The Hoffman Scholarships were established in 2002 to recognize and encourage excellence in graduate studies in the sciences and technologies of interest to AVS. The scholarships are funded by a bequest from Dorothy M. Hoffman, who was a pioneering member of the Society of Women Engineers and served as the president of AVS in 1974.

Lee received the scholarship for her research that detects hot electrons from chemical reactions on catalytic surface using nanodevices. Nano Letters, an academic journal published by the American Chemical Society, described her work in its February 2016 issue as a technology that allows quantitative analysis of hot electrons by employing a new nanodevice and therefore helps researchers understand better the mechanism of chemical reactions on nanocatalytic surface. She also published her work to detect the flow of hot electrons that occur on metal nanocatalytic surface during hydrogen oxidation reactions in Angewandte Chemie.

Lee said, “I am pleased to receive this honor from such a world-renowned academic society. Certainly, this will be a great support for my future study and research.”

Founded in 1953, AVS is an interdisciplinary, professional society composed of approximately 4,500 members worldwide. It supports networking among academic, industrial, government, and consulting professionals involved in a range of established and emerging science and technology areas such as chemistry, physics, engineering, business, and technology development.

2016.11.17 View 11881 -

Extremely Thin and Highly Flexible Graphene-Based Thermoacoustic Speakers

A joint research team led by Professors Jung-Woo Choi and Byung Jin Cho of the School of Electrical Engineering and Professor Sang Ouk Kim of the Material Science and Engineering Department, all on the faculty of the Korea Advanced Institute of Science and Technology (KAIST), has developed a simpler way to mass-produce ultra-thin graphene thermosacoustic speakers.

Their research results were published online on August 17, 2016 in a journal called Applied Materials & Interfaces. The IEEE Spectrum, a monthly magazine published by the Institute of Electrical and Electronics Engineers, reported on the research on September 9, 2016, in an article titled, “Graphene Enables Flat Speakers for Mobile Audio Systems.” The American Chemical Society also drew attention to the team’s work in its article dated September 7, 2016, “Bringing Graphene Speakers to the Mobile Market.”

Thermoacoustic speakers generate sound waves from temperature fluctuations by rapidly heating and cooling conducting materials. Unlike conventional voice-coil speakers, thermoacoustic speakers do not rely on vibrations to produce sound, and thus do not need bulky acoustic boxes to keep complicated mechanical parts for sound production. They also generate good quality sound in all directions, enabling them to be placed on any surface including curved ones without canceling out sounds generated from opposite sides.

Based on a two-step, template-free fabrication method that involved freeze-drying a solution of graphene oxide flakes and the reduction/doping of oxidized graphene to improve electrical properties, the research team produced a N-doped, three-dimensional (3D), reduced graphene oxide aerogel (N-rGOA) with a porous macroscopic structure that permitted easy modulation for many potential applications.

Using 3D graphene aerogels, the team succeeded in fabricating an array of loudspeakers that were able to withstand over 40 W input power and that showed excellent sound pressure level (SPL), comparable to those of previously reported 2D and 3D graphene loudspeakers.

Choong Sun Kim, the lead author of the research paper and a doctoral student in the School of Electrical Engineering at KAIST, said:

“Thermoacoustic speakers have a higher efficiency when conducting materials have a smaller heat capacity. Nanomaterials such as graphene are an ideal candidate for conductors, but they require a substrate to support their extremely thinness. The substrate’s tendency to lose heat lowers the speakers’ efficiency. Here, we developed 3D graphene aerogels without a substrate by using a simple two-step process. With graphene aerogels, we have fabricated an array of loudspeakers that demonstrated stable performance. This is a practical technology that will enable mass-production of thermosacoustic speakers including on mobile platforms.”

The research paper is entitled “Application of N-Doped Three-Dimensional Reduced Graphene Oxide Aerogel to Thin Film Loudspeaker.” (DOI: 10.1021/acsami.6b03618)

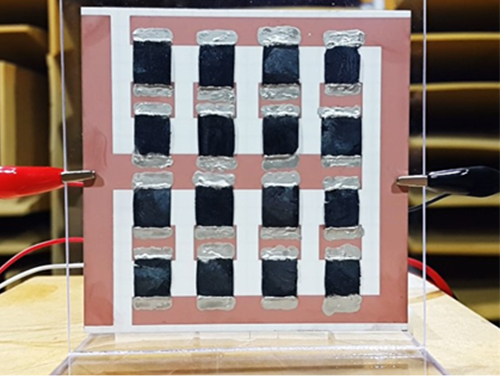

Figure 1: A Thermoacoustic Loudspeaker Consisted of an Array of 16 3D Graphene Aerogels

Figure 2: Two-step Fabrication Process of 3D Reduced Graphene Oxide Aerogel Using Freeze-Drying and Reduction/Doping

Figure 3: X-ray Photoelectron Spectroscopy Graph of the 3D Reduced Graphene Oxide Aerogel and Its Scanning Electron Microscope Image

2016.10.05 View 16102

Extremely Thin and Highly Flexible Graphene-Based Thermoacoustic Speakers

A joint research team led by Professors Jung-Woo Choi and Byung Jin Cho of the School of Electrical Engineering and Professor Sang Ouk Kim of the Material Science and Engineering Department, all on the faculty of the Korea Advanced Institute of Science and Technology (KAIST), has developed a simpler way to mass-produce ultra-thin graphene thermosacoustic speakers.

Their research results were published online on August 17, 2016 in a journal called Applied Materials & Interfaces. The IEEE Spectrum, a monthly magazine published by the Institute of Electrical and Electronics Engineers, reported on the research on September 9, 2016, in an article titled, “Graphene Enables Flat Speakers for Mobile Audio Systems.” The American Chemical Society also drew attention to the team’s work in its article dated September 7, 2016, “Bringing Graphene Speakers to the Mobile Market.”

Thermoacoustic speakers generate sound waves from temperature fluctuations by rapidly heating and cooling conducting materials. Unlike conventional voice-coil speakers, thermoacoustic speakers do not rely on vibrations to produce sound, and thus do not need bulky acoustic boxes to keep complicated mechanical parts for sound production. They also generate good quality sound in all directions, enabling them to be placed on any surface including curved ones without canceling out sounds generated from opposite sides.

Based on a two-step, template-free fabrication method that involved freeze-drying a solution of graphene oxide flakes and the reduction/doping of oxidized graphene to improve electrical properties, the research team produced a N-doped, three-dimensional (3D), reduced graphene oxide aerogel (N-rGOA) with a porous macroscopic structure that permitted easy modulation for many potential applications.

Using 3D graphene aerogels, the team succeeded in fabricating an array of loudspeakers that were able to withstand over 40 W input power and that showed excellent sound pressure level (SPL), comparable to those of previously reported 2D and 3D graphene loudspeakers.

Choong Sun Kim, the lead author of the research paper and a doctoral student in the School of Electrical Engineering at KAIST, said:

“Thermoacoustic speakers have a higher efficiency when conducting materials have a smaller heat capacity. Nanomaterials such as graphene are an ideal candidate for conductors, but they require a substrate to support their extremely thinness. The substrate’s tendency to lose heat lowers the speakers’ efficiency. Here, we developed 3D graphene aerogels without a substrate by using a simple two-step process. With graphene aerogels, we have fabricated an array of loudspeakers that demonstrated stable performance. This is a practical technology that will enable mass-production of thermosacoustic speakers including on mobile platforms.”

The research paper is entitled “Application of N-Doped Three-Dimensional Reduced Graphene Oxide Aerogel to Thin Film Loudspeaker.” (DOI: 10.1021/acsami.6b03618)

Figure 1: A Thermoacoustic Loudspeaker Consisted of an Array of 16 3D Graphene Aerogels

Figure 2: Two-step Fabrication Process of 3D Reduced Graphene Oxide Aerogel Using Freeze-Drying and Reduction/Doping

Figure 3: X-ray Photoelectron Spectroscopy Graph of the 3D Reduced Graphene Oxide Aerogel and Its Scanning Electron Microscope Image

2016.10.05 View 16102 -

Professor Tae-Eog Lee Receives December's Scientist of the Month Award by the Korean Government

Professor Tae-Eog Lee of the Industrial and Systems Engineering at KAIST received the Scientist of the Month Award for December 2015. The award is sponsored by the Ministry of Science, ICT and Future Planning of Korea, which was hosted by the National Research Foundation of Korea.

The award recognizes Professor Lee’s efforts to advance the field of semiconductor device fabrication processing. This includes the development of the most efficient scheduling and controlling of cluster tools. He also created mathematical solutions to optimize the complicated cycle time of cluster tools in semiconductor manufacturing and the process of robot task workload.

Professor Lee contributed to the formation of various discrete event systems and automation systems based on his mathematical theories and solutions and advanced a scheduling technology for the automation of semiconductor production.

He has published 18 research papers in the past three years and has pioneered to develop Korean tool schedulers through the private sector-university cooperation.

2015.12.10 View 9507

Professor Tae-Eog Lee Receives December's Scientist of the Month Award by the Korean Government

Professor Tae-Eog Lee of the Industrial and Systems Engineering at KAIST received the Scientist of the Month Award for December 2015. The award is sponsored by the Ministry of Science, ICT and Future Planning of Korea, which was hosted by the National Research Foundation of Korea.

The award recognizes Professor Lee’s efforts to advance the field of semiconductor device fabrication processing. This includes the development of the most efficient scheduling and controlling of cluster tools. He also created mathematical solutions to optimize the complicated cycle time of cluster tools in semiconductor manufacturing and the process of robot task workload.

Professor Lee contributed to the formation of various discrete event systems and automation systems based on his mathematical theories and solutions and advanced a scheduling technology for the automation of semiconductor production.

He has published 18 research papers in the past three years and has pioneered to develop Korean tool schedulers through the private sector-university cooperation.

2015.12.10 View 9507 -

KAIST and Four Science and Technology Universities Host a Start-up Competition

KAIST and four other science and technology universities, such as Gwangju Institute of Science and Technology (GIST), Ulsan National Institute of Science and Technology (UNIST), Daegu Gyeongbuk Institute of Science and Technology (DGIST), and Pohang University of Science and Technology (POSTECH), hosted a startup competition on November 27, 2015 at the Dongdaemun Design Plaza in Seoul.

Approximately 150 participants including students from the five universities, "angel" investors, and entrepreneurs attended the competition.

The competition was held to promote startups that are based on research achievements in science and technology and to foster entrepreneurs with great potential.

Two hundred and sixty applicants from 81 teams competed this year. Only ten teams made it to the finals.

KAIST students presented two business plans: an experience-centered education platform and mobile taxi-pooling service. Students from other universities presented a brain-stimulating simulation software (GIST), handy smart health trainer (GIST), real-time reporting system for luggage (DGIST), a flower delivery system (UNIST), surveillance and alarm system for stock-related events via machinery studies (UNIST), augmented emotion toys using augmented reality (POSTECH), and a nasal spray for fine dust prevention (POSTECH).

KAIST also displayed an exhibition of “wearable haptic device for multimedia contents” and “next generation recommendation service platform based on one-on-one matching system with high expandability and improved user experience system.”

The winning team received an award from the Minister of Science, ICT and Future Planning of Korea, as well as an opportunity to participate in overseas startup programs over the course of ten days.

Joongmyeon Bae, Director of the KAIST Industry and University Cooperation, who organized the contest, said, “The alumni of Stanford University (USA) has annually created over 5.4 million jobs through startup activities. Likewise, we hope that our event will contribute to job creation by fostering innovative entrepreneurs.”

2015.11.26 View 13551

KAIST and Four Science and Technology Universities Host a Start-up Competition

KAIST and four other science and technology universities, such as Gwangju Institute of Science and Technology (GIST), Ulsan National Institute of Science and Technology (UNIST), Daegu Gyeongbuk Institute of Science and Technology (DGIST), and Pohang University of Science and Technology (POSTECH), hosted a startup competition on November 27, 2015 at the Dongdaemun Design Plaza in Seoul.

Approximately 150 participants including students from the five universities, "angel" investors, and entrepreneurs attended the competition.

The competition was held to promote startups that are based on research achievements in science and technology and to foster entrepreneurs with great potential.

Two hundred and sixty applicants from 81 teams competed this year. Only ten teams made it to the finals.

KAIST students presented two business plans: an experience-centered education platform and mobile taxi-pooling service. Students from other universities presented a brain-stimulating simulation software (GIST), handy smart health trainer (GIST), real-time reporting system for luggage (DGIST), a flower delivery system (UNIST), surveillance and alarm system for stock-related events via machinery studies (UNIST), augmented emotion toys using augmented reality (POSTECH), and a nasal spray for fine dust prevention (POSTECH).

KAIST also displayed an exhibition of “wearable haptic device for multimedia contents” and “next generation recommendation service platform based on one-on-one matching system with high expandability and improved user experience system.”

The winning team received an award from the Minister of Science, ICT and Future Planning of Korea, as well as an opportunity to participate in overseas startup programs over the course of ten days.

Joongmyeon Bae, Director of the KAIST Industry and University Cooperation, who organized the contest, said, “The alumni of Stanford University (USA) has annually created over 5.4 million jobs through startup activities. Likewise, we hope that our event will contribute to job creation by fostering innovative entrepreneurs.”

2015.11.26 View 13551 -

Professor Keon-Jae Lee Lectures at IEDM and ISSCC Forums

Professor Keon-Jae Lee of KAIST’s Materials Science and Engineering Department delivered a speech at the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Electron Devices Meeting (IEDM) held on December 7-9, 2015 in Washington, D.C.

He will also present a speech at the 2016 International Solid-State Circuits Conference scheduled on January 31-February 4, 2016 in San Francisco, California.

Both professional gatherings are considered the world’s most renowned forums in electronic devices and semiconductor technology. It is rare for a Korean researcher to be invited to speak at these global conferences.

Professor Lee was recognized for his research on flexible NAND chips. The Korea Times, an English language daily newspaper in Korea, reported on his participation in the forums and his recent work. An excerpt of the article follows below:

“KAIST Professor to Lecture at Renowned Tech Forums”

By Lee Min-hyung, The Korea Times, November 26, 2015

Recently he has focused on delivering technologies for producing flexible materials that can be applied to everyday life. The flexible NAND flash memory chips are expected to be widely used for developing flexible handsets. His latest research also includes flexible light-emitting diodes (LED) for implantable biomedical applications.

Lee is currently running a special laboratory focused on developing new flexible nano-materials. The research group is working to develop what it calls “self-powered flexible electronic systems” using nanomaterials and electronic technology.

Lee’s achievement with flexible NAND chips was published in the October edition of Nano Letters, the renowned U.S.-based scientific journal.

He said that flexible memory chips will be used to develop wearable computers that can be installed anywhere.

2015.11.26 View 14485

Professor Keon-Jae Lee Lectures at IEDM and ISSCC Forums

Professor Keon-Jae Lee of KAIST’s Materials Science and Engineering Department delivered a speech at the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Electron Devices Meeting (IEDM) held on December 7-9, 2015 in Washington, D.C.

He will also present a speech at the 2016 International Solid-State Circuits Conference scheduled on January 31-February 4, 2016 in San Francisco, California.

Both professional gatherings are considered the world’s most renowned forums in electronic devices and semiconductor technology. It is rare for a Korean researcher to be invited to speak at these global conferences.

Professor Lee was recognized for his research on flexible NAND chips. The Korea Times, an English language daily newspaper in Korea, reported on his participation in the forums and his recent work. An excerpt of the article follows below:

“KAIST Professor to Lecture at Renowned Tech Forums”

By Lee Min-hyung, The Korea Times, November 26, 2015

Recently he has focused on delivering technologies for producing flexible materials that can be applied to everyday life. The flexible NAND flash memory chips are expected to be widely used for developing flexible handsets. His latest research also includes flexible light-emitting diodes (LED) for implantable biomedical applications.

Lee is currently running a special laboratory focused on developing new flexible nano-materials. The research group is working to develop what it calls “self-powered flexible electronic systems” using nanomaterials and electronic technology.

Lee’s achievement with flexible NAND chips was published in the October edition of Nano Letters, the renowned U.S.-based scientific journal.

He said that flexible memory chips will be used to develop wearable computers that can be installed anywhere.

2015.11.26 View 14485 -

KAIST's Patina Engraving System Awarded at ACM CHI

Professor Tek-Jin Nam’s research team of the Industrial Design Department of KAIST received the Best Paper Award in the 2015 Association for Computing Machinery’s (ACM) Conference on Human Factors in Computing Systems (CHI) which was held from April 18 to 23, 2015. The team consisted of two KAIST students: Moon-Hwan Lee, a Ph.D. candidate, and Sejin Cha, a master's student. The team was the first in Asia to receive the award.

The ACM CHI represents the premier conference in the field of Human-Computer Interaction (HCI). This year’s event, held in Seoul, South Korea, was the first conference that the ACM had held in Asia in its thirty-three year history. The KAIST team’s paper, entitled “Patina Engraver: Visualizing Activity Logs as Patina in Fashionable Trackers,” ranked in the top 1% of 2,000 submitted papers.

The team developed Patina Engraver, an activity tracker, which monitors and tracks fitness-related metrics such as distances walked or run, calorie consumption, heartbeat, sleep quality, and blood pressure. The device wirelessly connects to a computer or smartphone so that it can store and utilize long-term tracking data.

However, what makes Patina Engraver, a smart wristband, different from other health trackers is its ability to display different design patterns based on users’ activity on the surface of the wristband. The research team was inspired to build this system from the fact that wearable electronics including activity trackers can be used not only as health care devices, but also as fashion items to express emotions and personalities.

Equipped with an engraving feature, the charging pad or holder for Patina Engraver draws individualized patterns to reflect the user’s activities, such as walking or running, while the device is being charged. The pattern display syncs with the frequency of usage, therefore, the more the tracker is used, the greater the number of patterns will show up.

According to the team, since Patina Engraver provides users with a personalized illustration of their activity on the tracker, users are more motivated to put on the tracker and exercise.

Professor Nam said, “This research can be applied in producing other wearable devices to enhance users’ emotional satisfaction. When wearable technology is combined with design and emotion, the industry market will quickly expand.”

Figure 1: Patina engraving system developed by KAIST research team

Figure 2: The process of engraving illustrations of the activity records onto the tracker

Figure 3: Personalized activity trackers based on activity records

2015.05.15 View 16209

KAIST's Patina Engraving System Awarded at ACM CHI

Professor Tek-Jin Nam’s research team of the Industrial Design Department of KAIST received the Best Paper Award in the 2015 Association for Computing Machinery’s (ACM) Conference on Human Factors in Computing Systems (CHI) which was held from April 18 to 23, 2015. The team consisted of two KAIST students: Moon-Hwan Lee, a Ph.D. candidate, and Sejin Cha, a master's student. The team was the first in Asia to receive the award.

The ACM CHI represents the premier conference in the field of Human-Computer Interaction (HCI). This year’s event, held in Seoul, South Korea, was the first conference that the ACM had held in Asia in its thirty-three year history. The KAIST team’s paper, entitled “Patina Engraver: Visualizing Activity Logs as Patina in Fashionable Trackers,” ranked in the top 1% of 2,000 submitted papers.

The team developed Patina Engraver, an activity tracker, which monitors and tracks fitness-related metrics such as distances walked or run, calorie consumption, heartbeat, sleep quality, and blood pressure. The device wirelessly connects to a computer or smartphone so that it can store and utilize long-term tracking data.

However, what makes Patina Engraver, a smart wristband, different from other health trackers is its ability to display different design patterns based on users’ activity on the surface of the wristband. The research team was inspired to build this system from the fact that wearable electronics including activity trackers can be used not only as health care devices, but also as fashion items to express emotions and personalities.

Equipped with an engraving feature, the charging pad or holder for Patina Engraver draws individualized patterns to reflect the user’s activities, such as walking or running, while the device is being charged. The pattern display syncs with the frequency of usage, therefore, the more the tracker is used, the greater the number of patterns will show up.

According to the team, since Patina Engraver provides users with a personalized illustration of their activity on the tracker, users are more motivated to put on the tracker and exercise.

Professor Nam said, “This research can be applied in producing other wearable devices to enhance users’ emotional satisfaction. When wearable technology is combined with design and emotion, the industry market will quickly expand.”

Figure 1: Patina engraving system developed by KAIST research team

Figure 2: The process of engraving illustrations of the activity records onto the tracker

Figure 3: Personalized activity trackers based on activity records

2015.05.15 View 16209