American+Chemical+Society

-

Capillary Forces at Work for Lithium-Sulfur Batteries

Professor Do Kyung Kim from the KAIST Department of Materials Science and Engineering and his team succeeded in developing high-areal-capacity lithium sulfur batteries (Li-S batteries) by capturing polysulfide with carbon nanofibers. This research will provide new batteries to replace existing lithium rechargeable batteries, shifting the commercialization of related technologies ahead.

Electrical vehicles and large-scale energy storage systems necessitate the development of batteries with high energy density and cost effectiveness, and Li-S batteries are known to be one of the promising alternatives to the predominant lithium ion batteries.

With six times as much energy density, Li-S batteries theoretically thrust electric vehicle to twice the distance of lithium ion batteries. Therefore, they have been spotlighted as next-generation lithium rechargeable batteries because they can go up to 400km once charged.

However, several issues make it challenging to readily commercialize Li-S batteries. The low electrical conductivity of sulfur, volumetric expansion and contraction of the battery during charge and discharge, and permanent damage of the electrode caused by the dissolution of the lithium polysulfide into the electrolyte – known as the “shuttle effect” – are three of the biggest obstacles to commercial-grade Li-S batteries.

While there have been numerous attempts to curb, avoid, or alleviate these issues — such as the physical encapsulation of sulfur using various metal oxides or carbonaceous matrices — most of them entail utilizing zero-dimensional (0D) carbon materials. This encapsulation method has been somewhat effective in enhancing the electrical conductivity of sulfur while simultaneously tolerating some volumetric alterations and suppressing the shuttle effect. The downside of 0D carbon material-based encapsulation methods is their complicated synthetic processing and the limited mass loading of sulfur.

With this in mind, the team set out to employ one-dimensional (1D) carbon materials instead. Unlike the 0D case, 1D carbon materials render a large surface area and a long-range conduction path for electrons and lithium ions. Being 1D also solves the undesirable high-contact resistance problem frequently encountered by 0D carbon material-based encapsulation.

The key to developing the proposed material was to exploit the capillary force to decrease the energy associated with the dissolution of polysulfides. As such, carbon nanofibers (CNFs) were found to be suitable for high-areal-capacity lithium-sulfur batteries since capillary force acting between CNFs can take advantage of the high electrical conductivity with the suppressed dissolution of sulfides.

The research findings show that sulfur was successfully contained in between the CNFs by wetting due to the capillary force without the need for complicated synthetic processing, as in the 0D case. The research results indicate that the sulfur contained per unit area (mg/cm2) is five times greater for the newly implemented method, which then enabled the lithium-sulfur battery to achieve an areal capacity of 7 mAh/cm2, which amounts to as much as at most seven times that of conventional lithium ion batteries.

First author Jong Hyuk Yun stated that the unprecedented methods utilized in this study will help further and widen the progress of lithium batteries in general. Meanwhile, Professor Kim said, “This study brought us closer to commercial-grade high-capacity Li-S batteries, which are applicable for a wide variety of products, including electric vehicles, unmanned aerial vehicles (UAVs), and drones.”

This research, led by PhD candidate Yun, was published in the 18th issue of this year’s Nano Letters.

Figure 1. Electrochemical reaction leading to the containment of the sulfur within the carbon nanofiber and the corresponding specific capacity of the battery over a number of charge-discharge cycles

Figure 2. SEM images of the first discharged electrode containing lithium sulfide at the junction between the nanofibers, and the first charged electrode

Figure 3. carbon nanofiber effectively absorbing liquid based lithium polysulfide

2018.05.14 View 8466

Capillary Forces at Work for Lithium-Sulfur Batteries

Professor Do Kyung Kim from the KAIST Department of Materials Science and Engineering and his team succeeded in developing high-areal-capacity lithium sulfur batteries (Li-S batteries) by capturing polysulfide with carbon nanofibers. This research will provide new batteries to replace existing lithium rechargeable batteries, shifting the commercialization of related technologies ahead.

Electrical vehicles and large-scale energy storage systems necessitate the development of batteries with high energy density and cost effectiveness, and Li-S batteries are known to be one of the promising alternatives to the predominant lithium ion batteries.

With six times as much energy density, Li-S batteries theoretically thrust electric vehicle to twice the distance of lithium ion batteries. Therefore, they have been spotlighted as next-generation lithium rechargeable batteries because they can go up to 400km once charged.

However, several issues make it challenging to readily commercialize Li-S batteries. The low electrical conductivity of sulfur, volumetric expansion and contraction of the battery during charge and discharge, and permanent damage of the electrode caused by the dissolution of the lithium polysulfide into the electrolyte – known as the “shuttle effect” – are three of the biggest obstacles to commercial-grade Li-S batteries.

While there have been numerous attempts to curb, avoid, or alleviate these issues — such as the physical encapsulation of sulfur using various metal oxides or carbonaceous matrices — most of them entail utilizing zero-dimensional (0D) carbon materials. This encapsulation method has been somewhat effective in enhancing the electrical conductivity of sulfur while simultaneously tolerating some volumetric alterations and suppressing the shuttle effect. The downside of 0D carbon material-based encapsulation methods is their complicated synthetic processing and the limited mass loading of sulfur.

With this in mind, the team set out to employ one-dimensional (1D) carbon materials instead. Unlike the 0D case, 1D carbon materials render a large surface area and a long-range conduction path for electrons and lithium ions. Being 1D also solves the undesirable high-contact resistance problem frequently encountered by 0D carbon material-based encapsulation.

The key to developing the proposed material was to exploit the capillary force to decrease the energy associated with the dissolution of polysulfides. As such, carbon nanofibers (CNFs) were found to be suitable for high-areal-capacity lithium-sulfur batteries since capillary force acting between CNFs can take advantage of the high electrical conductivity with the suppressed dissolution of sulfides.

The research findings show that sulfur was successfully contained in between the CNFs by wetting due to the capillary force without the need for complicated synthetic processing, as in the 0D case. The research results indicate that the sulfur contained per unit area (mg/cm2) is five times greater for the newly implemented method, which then enabled the lithium-sulfur battery to achieve an areal capacity of 7 mAh/cm2, which amounts to as much as at most seven times that of conventional lithium ion batteries.

First author Jong Hyuk Yun stated that the unprecedented methods utilized in this study will help further and widen the progress of lithium batteries in general. Meanwhile, Professor Kim said, “This study brought us closer to commercial-grade high-capacity Li-S batteries, which are applicable for a wide variety of products, including electric vehicles, unmanned aerial vehicles (UAVs), and drones.”

This research, led by PhD candidate Yun, was published in the 18th issue of this year’s Nano Letters.

Figure 1. Electrochemical reaction leading to the containment of the sulfur within the carbon nanofiber and the corresponding specific capacity of the battery over a number of charge-discharge cycles

Figure 2. SEM images of the first discharged electrode containing lithium sulfide at the junction between the nanofibers, and the first charged electrode

Figure 3. carbon nanofiber effectively absorbing liquid based lithium polysulfide

2018.05.14 View 8466 -

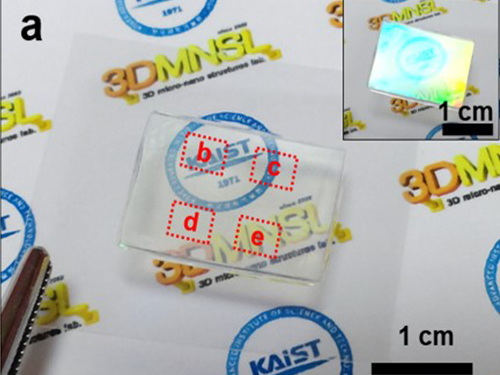

Printed Thermo-Plasmonic Heat Patterns for Neurological Disorder Treatment

(Professor Nam and Dr. Kang, right)

A KAIST team presented a highly customizable neural stimulation method. The research team developed a technology that can print the heat pattern on a micron scale to enable the control of biological activities remotely.

The researchers integrated a precision inkjet printing technology with bio-functional thermo-plasmonic nanoparticles to achieve a ‘selective nano-photothermal neural stimulation method.’

The research team of Professor Yoonkey Nam at the Department of Bio and Brain Engineering expects this will serve as an enabling technology for personalized precision neuromodulation therapy for patients with neurological disorders.

The nano-photothermal neural stimulation method uses the thermo-plasmonic effect of metal nanoparticles to modulate the activities of neuronal networks. With the thermo-plasmonic effect, metal nanoparticles can absorb specific wavelength of illuminated light to efficiently generate localized heat. The research team discovered the inhibitory behavior of spontaneous activities of neurons upon photothermal stimulation four years ago. Since then, they have developed this technology to control hyperactive behaviors of neurons and neural circuits, which is often found in neurological disorders such as epilepsy.

In order to overcome the limitation on the spatial selectivity and resolution of the previously developed nano-photothermal method, the team adopted an inkjet printing technology to micro pattern the plasmonic nanoparticles (a few tens of microns), and successfully demonstrated that the nano-photothermal stimulation can be selectively applied according to the printed patterns.

The researchers applied a polyelectrolyte layer-by-layer coating method to printing substrates in a way to improve the pattern fidelity and achieve the uniform assembly of nanoparticles. The electrostatic attraction between the printed nanoparticles and the coated printing substrate also helped the stability of the attached nanoparticles. Because the polyelectrolyte coating is biocompatible, biological experiments including cell culture are possible with the technology developed in this work.

Using printed gold nanorod particles in a few tens of microns resolution over a several centimeters area, the researchers showed that highly complex heat patterns can be precisely formed upon light illumination according to the printing image.

Lastly, the team confirmed that the printed heat patterns can selectively and instantaneously inhibit the activities of cultured hippocampal neurons upon near-infrared light illumination. Because the printing process is applicable to thin and flexible substrates, the technology can be easily applied to implantable neurological disorder treatment devices and wearable devices. By selectively applying the heat patterns to only the desired cellular areas, customized and personalized photothermal neuromodulation therapy can be applied to patients.

“The fact that any desired heat patterns can be simply ‘printed’ anywhere broadens the applicability of this technology in many engineering fields. In bioengineering, it can be applied to neural interfaces using light and heat to modulate physiological functions. As another engineering application, for example, printed heat patterns can be used as a new concept of anti-counterfeit applications,” said the principal investigator, Yoonkey Nam at KAIST. This work, led mainly by Dr. Hongki Kang, was published in ACS Nano on February 5th 2018.

2018.04.06 View 7493

Printed Thermo-Plasmonic Heat Patterns for Neurological Disorder Treatment

(Professor Nam and Dr. Kang, right)

A KAIST team presented a highly customizable neural stimulation method. The research team developed a technology that can print the heat pattern on a micron scale to enable the control of biological activities remotely.

The researchers integrated a precision inkjet printing technology with bio-functional thermo-plasmonic nanoparticles to achieve a ‘selective nano-photothermal neural stimulation method.’

The research team of Professor Yoonkey Nam at the Department of Bio and Brain Engineering expects this will serve as an enabling technology for personalized precision neuromodulation therapy for patients with neurological disorders.

The nano-photothermal neural stimulation method uses the thermo-plasmonic effect of metal nanoparticles to modulate the activities of neuronal networks. With the thermo-plasmonic effect, metal nanoparticles can absorb specific wavelength of illuminated light to efficiently generate localized heat. The research team discovered the inhibitory behavior of spontaneous activities of neurons upon photothermal stimulation four years ago. Since then, they have developed this technology to control hyperactive behaviors of neurons and neural circuits, which is often found in neurological disorders such as epilepsy.

In order to overcome the limitation on the spatial selectivity and resolution of the previously developed nano-photothermal method, the team adopted an inkjet printing technology to micro pattern the plasmonic nanoparticles (a few tens of microns), and successfully demonstrated that the nano-photothermal stimulation can be selectively applied according to the printed patterns.

The researchers applied a polyelectrolyte layer-by-layer coating method to printing substrates in a way to improve the pattern fidelity and achieve the uniform assembly of nanoparticles. The electrostatic attraction between the printed nanoparticles and the coated printing substrate also helped the stability of the attached nanoparticles. Because the polyelectrolyte coating is biocompatible, biological experiments including cell culture are possible with the technology developed in this work.

Using printed gold nanorod particles in a few tens of microns resolution over a several centimeters area, the researchers showed that highly complex heat patterns can be precisely formed upon light illumination according to the printing image.

Lastly, the team confirmed that the printed heat patterns can selectively and instantaneously inhibit the activities of cultured hippocampal neurons upon near-infrared light illumination. Because the printing process is applicable to thin and flexible substrates, the technology can be easily applied to implantable neurological disorder treatment devices and wearable devices. By selectively applying the heat patterns to only the desired cellular areas, customized and personalized photothermal neuromodulation therapy can be applied to patients.

“The fact that any desired heat patterns can be simply ‘printed’ anywhere broadens the applicability of this technology in many engineering fields. In bioengineering, it can be applied to neural interfaces using light and heat to modulate physiological functions. As another engineering application, for example, printed heat patterns can be used as a new concept of anti-counterfeit applications,” said the principal investigator, Yoonkey Nam at KAIST. This work, led mainly by Dr. Hongki Kang, was published in ACS Nano on February 5th 2018.

2018.04.06 View 7493 -

Developing Flexible Vertical Micro LED

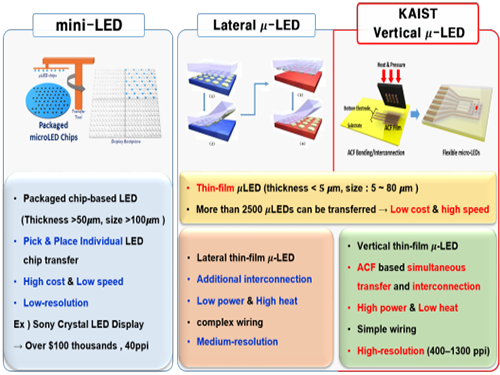

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering and Professor Daesoo Kim from the Department of Biological Sciences has developed flexible vertical micro LEDs (f-VLEDs) using anisotropic conductive film (ACF)-based transfer and interconnection technology. The team also succeeded in controlling animal behavior via optogenetic stimulation of the f-VLEDs.

Flexible micro LEDs have become a strong candidate for the next-generation display due to their ultra-low power consumption, fast response speed, and excellent flexibility. However, the previous micro LED technology had critical issues such as poor device efficiency, low thermal reliability, and the lack of interconnection technology for high-resolution micro LED displays.

The research team has designed new transfer equipment and fabricated a f-VLED array (50ⅹ50) using simultaneous transfer and interconnection through the precise alignment of ACF bonding process. These f-VLEDs (thickness: 5 ㎛, size: below 80 ㎛) achieved optical power density (30 mW/mm2) three times higher than that of lateral micro LEDs, improving thermal reliability and lifetime by reducing heat generation within the thin film LEDs.

These f-VLEDs can be applied to optogenetics for controlling the behavior of neuron cells and brains. In contrast to the electrical stimulation that activates all of the neurons in brain, optogenetics can stimulate specific excitatory or inhibitory neurons within the localized cortical areas of the brain, which facilitates precise analysis, high-resolution mapping, and neuron modulation of animal brains. (Refer to the author’s previous ACS Nano paper of “Optogenetic Mapping of Functional Connectivity in Freely Moving Mice via Insertable Wrapping Electrode Array Beneath the Skull.” )

In this work, they inserted the innovative f-VLEDs into the narrow space between the skull and the brain surface and succeeded in controlling mouse behavior by illuminating motor neurons on two-dimensional cortical areas located deep below the brain surface.

Professor Lee said, “The flexible vertical micro LED can be used in low-power smart watches, mobile displays, and wearable lighting. In addition, these flexible optoelectronic devices are suitable for biomedical applications such as brain science, phototherapeutic treatment, and contact lens biosensors.”

He recently established a startup company ( FRONICS Inc. ) based on micro LED technology and is looking for global partnerships for commercialization. This result entitled “ Optogenetic Control of Body Movements via Flexible Vertical Light-Emitting Diodes on Brain Surface ” was published in the February 2018 issue of Nano Energy.

Figure 1. Comparison of μ-LEDs Technology

2018.01.29 View 14215

Developing Flexible Vertical Micro LED

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering and Professor Daesoo Kim from the Department of Biological Sciences has developed flexible vertical micro LEDs (f-VLEDs) using anisotropic conductive film (ACF)-based transfer and interconnection technology. The team also succeeded in controlling animal behavior via optogenetic stimulation of the f-VLEDs.

Flexible micro LEDs have become a strong candidate for the next-generation display due to their ultra-low power consumption, fast response speed, and excellent flexibility. However, the previous micro LED technology had critical issues such as poor device efficiency, low thermal reliability, and the lack of interconnection technology for high-resolution micro LED displays.

The research team has designed new transfer equipment and fabricated a f-VLED array (50ⅹ50) using simultaneous transfer and interconnection through the precise alignment of ACF bonding process. These f-VLEDs (thickness: 5 ㎛, size: below 80 ㎛) achieved optical power density (30 mW/mm2) three times higher than that of lateral micro LEDs, improving thermal reliability and lifetime by reducing heat generation within the thin film LEDs.

These f-VLEDs can be applied to optogenetics for controlling the behavior of neuron cells and brains. In contrast to the electrical stimulation that activates all of the neurons in brain, optogenetics can stimulate specific excitatory or inhibitory neurons within the localized cortical areas of the brain, which facilitates precise analysis, high-resolution mapping, and neuron modulation of animal brains. (Refer to the author’s previous ACS Nano paper of “Optogenetic Mapping of Functional Connectivity in Freely Moving Mice via Insertable Wrapping Electrode Array Beneath the Skull.” )

In this work, they inserted the innovative f-VLEDs into the narrow space between the skull and the brain surface and succeeded in controlling mouse behavior by illuminating motor neurons on two-dimensional cortical areas located deep below the brain surface.

Professor Lee said, “The flexible vertical micro LED can be used in low-power smart watches, mobile displays, and wearable lighting. In addition, these flexible optoelectronic devices are suitable for biomedical applications such as brain science, phototherapeutic treatment, and contact lens biosensors.”

He recently established a startup company ( FRONICS Inc. ) based on micro LED technology and is looking for global partnerships for commercialization. This result entitled “ Optogenetic Control of Body Movements via Flexible Vertical Light-Emitting Diodes on Brain Surface ” was published in the February 2018 issue of Nano Energy.

Figure 1. Comparison of μ-LEDs Technology

2018.01.29 View 14215 -

Plasma, an Excellent Sterilizer to Remove Harmful Bacteria

(PhD candidate Joo Young Park, Professor Wonho Choe and PhD researcher Sanghoo Park)

KAIST researchers are using plasma to remove bacteria that are stuck to surfaces of plastic bottles and food. This novel technology will contribute to disinfection in medical settings as well as food and agricultural industries.

Professor Wonho Choe and his team from the Department of Physics developed a technology that removes biofilm, which is comprised of microorganisms, by using plasma as a non-thermal sterilization method.

Plasma contains multiple bactericidal agents, including reactive species. In particular, the chemicals formed in aqueous solution during plasma exposure have the potential for high antibacterial activity against various bacterial infections.

The team treated water with plasma to see how effectively bactericidal agents in the plasma water can remove biofilm comprised of harmful microorganism such as Escherichia coli, Salmonella, and Listeria.

The team identified that reactive species, including hydroxyl radical, hydrogen peroxide, ozone, nitrite, and superoxide produced during plasma treatment, showed considerable ability to remove the biofilm. Hydrogen peroxide showed the strongest effect removing the biofilm; however, the hydroxyl radical also played a significant role in removing biofilm. Despite having a concentration 100 to 10,000 times lower than other reactive species, the hydroxyl radical showed a high biofilm removal efficacy owing to its strong oxidative power.

These findings reveal that plasma can be used as a no-residual and safe sterilization process alternative to conventional methods. With these outcomes, the team is planning to develop and commercialize a technology that can produce hydroxyl radicals with plasma.

Professor Choe has registered a patent for flexible packaging materials that facilitate plasma and completed the technology transfer to the startup company, named ‘Plasmapp’, which focuses on commercializing bactericidal technology.

“This research outcome will be the foundation for understanding plasma control technology and physicochemical interactions between plasma and microorganisms. It will also become an accelerator for utilizing plasma technology in the medical, food, and agricultural fields,” said Professor Choe.

This research, led by PhD candidate Joo Young Park and PhD researcher Sanghoo Park in collaboration with Professor Cheorun Jo’s team from Seoul National University, was published in ACS Applied Materials and Interfaces on December 20, 2017.

Figure 1. Flexible packaging materials that facilitate plasma

Figure 2. Schematic diagram of biofilm treatment with plasma

Figure 3. Concept of plasma application and evaluation result of reactive species' efficacy

Figure 4. STERPACK, the product launched by Plasmapp

2018.01.25 View 10549

Plasma, an Excellent Sterilizer to Remove Harmful Bacteria

(PhD candidate Joo Young Park, Professor Wonho Choe and PhD researcher Sanghoo Park)

KAIST researchers are using plasma to remove bacteria that are stuck to surfaces of plastic bottles and food. This novel technology will contribute to disinfection in medical settings as well as food and agricultural industries.

Professor Wonho Choe and his team from the Department of Physics developed a technology that removes biofilm, which is comprised of microorganisms, by using plasma as a non-thermal sterilization method.

Plasma contains multiple bactericidal agents, including reactive species. In particular, the chemicals formed in aqueous solution during plasma exposure have the potential for high antibacterial activity against various bacterial infections.

The team treated water with plasma to see how effectively bactericidal agents in the plasma water can remove biofilm comprised of harmful microorganism such as Escherichia coli, Salmonella, and Listeria.

The team identified that reactive species, including hydroxyl radical, hydrogen peroxide, ozone, nitrite, and superoxide produced during plasma treatment, showed considerable ability to remove the biofilm. Hydrogen peroxide showed the strongest effect removing the biofilm; however, the hydroxyl radical also played a significant role in removing biofilm. Despite having a concentration 100 to 10,000 times lower than other reactive species, the hydroxyl radical showed a high biofilm removal efficacy owing to its strong oxidative power.

These findings reveal that plasma can be used as a no-residual and safe sterilization process alternative to conventional methods. With these outcomes, the team is planning to develop and commercialize a technology that can produce hydroxyl radicals with plasma.

Professor Choe has registered a patent for flexible packaging materials that facilitate plasma and completed the technology transfer to the startup company, named ‘Plasmapp’, which focuses on commercializing bactericidal technology.

“This research outcome will be the foundation for understanding plasma control technology and physicochemical interactions between plasma and microorganisms. It will also become an accelerator for utilizing plasma technology in the medical, food, and agricultural fields,” said Professor Choe.

This research, led by PhD candidate Joo Young Park and PhD researcher Sanghoo Park in collaboration with Professor Cheorun Jo’s team from Seoul National University, was published in ACS Applied Materials and Interfaces on December 20, 2017.

Figure 1. Flexible packaging materials that facilitate plasma

Figure 2. Schematic diagram of biofilm treatment with plasma

Figure 3. Concept of plasma application and evaluation result of reactive species' efficacy

Figure 4. STERPACK, the product launched by Plasmapp

2018.01.25 View 10549 -

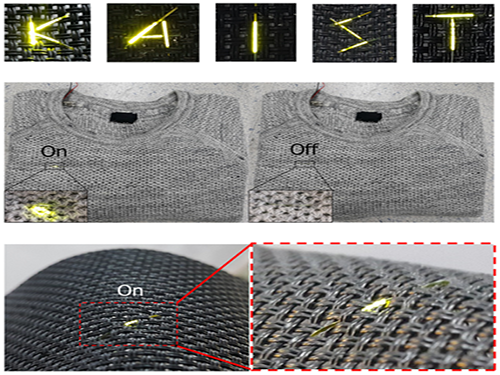

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14475

Fiber OLEDs, Thinner Than a Hair

(Seonil Kwon, PhD Candidate)

Professor Kyung Cheol Choi from the School of Electrical Engineering and his team succeeded in fabricating highly efficient Organic Light-Emitting Diodes (OLEDs) on an ultra-thin fiber.

The team expects the technology, which produces high-efficiency, long-lasting OLEDs, can be widely utilized in wearable displays.

Existing fiber-based wearable displays’ OLEDs show much lower performance compared to those fabricated on planar substrates. This low performance caused a limitation for applying it to actual wearable displays.

In order to solve this problem, the team designed a structure of OLEDs compatible to fiber and used a dip-coating method in a three-dimensional structure of fibers. Through this method, the team successfully developed efficient OLEDs that are designed to last a lifetime and are still equivalent to those on planar substrates.

The team identified that solution process planar OLEDs can be applied to fibers without any reduction in performance through the technology. This fiber OLEDs exhibited luminance and current efficiency values of over 10,000 cd/m^2(candela/square meter) and 11 cd/A (candela/ampere).

The team also verified that the fiber OLEDs withstood tensile strains of up to 4.3% while retaining more than 90% of their current efficiency. In addition, they could be woven into textiles and knitted clothes without causing any problems.

Moreover, the technology allows for fabricating OLEDs on fibers with diameters ranging from 300㎛ down to 90㎛, thinner than a human hair, which attests to the scalability of the proposed fabrication scheme.

Noting that every process is carried out at a low temperature (~105℃), fibers vulnerable to high temperatures can also employ this fabrication scheme.

Professor Choi said, “Existing fiber-based wearable displays had limitations for applicability due to their low performance. However, this technology can fabricate OLEDs with high performance on fibers. This simple, low-cost process opens a way to commercialize fiber-based wearable displays.”

This research led by a PhD candidate Seonil Kwon was published online in the international journal for nanoscience, Nano Letters, on December 6.

(Fiber-based OLEDs woven into knitted clothes)

This work was funded by the Engineering Research Center of Excellence Program (Grant No. NRF-2017R1A5A1014708) and Nano-Material Technology Development Program (Grant No. NRF-2016M3A7B4910635) by the National Research Foundation of Korea, the Ministry of Science and ICT of Korea.

2018.01.09 View 14475 -

Non-Adiabatic Reaction Mechanism Identified at Conical Intersection

(Professor Kim(center) and Ph.D. candidates Kyung Chul Woo (left) and Kang Do Hyung)

Research team led by Professor Sang Kyu Kim at KAIST Department of Chemistry observed two distinct reaction pathways that occur at conical intersection where two different adiabatic potential energy surfaces cross at the same nuclear configuration.

Professor Kim previously identified the existence and molecular structure of conical intersection in 2010. In this following study, the team accurately measured reaction rates of two totally different reaction pathways activated only at conical intersection where the seminal Born-Oppenheimer approximation breaks down.

This study led by Kyung Chul Woo (1st author) and Do Hyung Kang, both Ph.D. candidates at KAIST, was published in Journal of the American Chemical Society in November 7th, 2017.

Chemical reaction induced by light occurs in excited electronic states where the reaction outcome is often destined by coupling among different electronic states mediated by nuclear motions during chemical reaction. Such a coupling is most critical and important at the conical intersection as nonadiabtic surface-hopping is most probable at situation where the Born-Oppenheimer approximation fails.

Professor Kim used spectroscopic methods in 2010 to experimentally observe conical intersection of polyatomic molecule. And yet, it was not possible to disentangle complex dynamic processes with frequency-domain study only.

The research team used pico-second time-resolution kinetic energy resolved mass spectrometry to identify two possible distinct reaction pathways in both energy and time domains.,.

The research team demonstrated that the reactive flux prepared at the conical intersection is bifurcated into adiabatic or non-adiabatic reaction pathways. These two pathways are quite distinct in terms of reaction rates, energy releases, and product branching ratios.

This is the first study to capture the moment of bifurcation dynamics at the conical intersection for complex polyatomic molecular system. The study could contribute to conceptual improvement in understanding complicated nonadiabatic dynamics in general.

Professor Kim said, “Basic science research is essential in understanding and wisely using the nature. New technological advances cannot be made without the advancement in basic science.” He continued, “I hope this study could lead to growth in many young academic talents in basic sciences.”

(Figure 1. Reaction graph starting from reaction intersection that divides into adiabatic reaction pathway (red) and non-adiabatic pathway (blue))

2017.12.19 View 6837

Non-Adiabatic Reaction Mechanism Identified at Conical Intersection

(Professor Kim(center) and Ph.D. candidates Kyung Chul Woo (left) and Kang Do Hyung)

Research team led by Professor Sang Kyu Kim at KAIST Department of Chemistry observed two distinct reaction pathways that occur at conical intersection where two different adiabatic potential energy surfaces cross at the same nuclear configuration.

Professor Kim previously identified the existence and molecular structure of conical intersection in 2010. In this following study, the team accurately measured reaction rates of two totally different reaction pathways activated only at conical intersection where the seminal Born-Oppenheimer approximation breaks down.

This study led by Kyung Chul Woo (1st author) and Do Hyung Kang, both Ph.D. candidates at KAIST, was published in Journal of the American Chemical Society in November 7th, 2017.

Chemical reaction induced by light occurs in excited electronic states where the reaction outcome is often destined by coupling among different electronic states mediated by nuclear motions during chemical reaction. Such a coupling is most critical and important at the conical intersection as nonadiabtic surface-hopping is most probable at situation where the Born-Oppenheimer approximation fails.

Professor Kim used spectroscopic methods in 2010 to experimentally observe conical intersection of polyatomic molecule. And yet, it was not possible to disentangle complex dynamic processes with frequency-domain study only.

The research team used pico-second time-resolution kinetic energy resolved mass spectrometry to identify two possible distinct reaction pathways in both energy and time domains.,.

The research team demonstrated that the reactive flux prepared at the conical intersection is bifurcated into adiabatic or non-adiabatic reaction pathways. These two pathways are quite distinct in terms of reaction rates, energy releases, and product branching ratios.

This is the first study to capture the moment of bifurcation dynamics at the conical intersection for complex polyatomic molecular system. The study could contribute to conceptual improvement in understanding complicated nonadiabatic dynamics in general.

Professor Kim said, “Basic science research is essential in understanding and wisely using the nature. New technological advances cannot be made without the advancement in basic science.” He continued, “I hope this study could lead to growth in many young academic talents in basic sciences.”

(Figure 1. Reaction graph starting from reaction intersection that divides into adiabatic reaction pathway (red) and non-adiabatic pathway (blue))

2017.12.19 View 6837 -

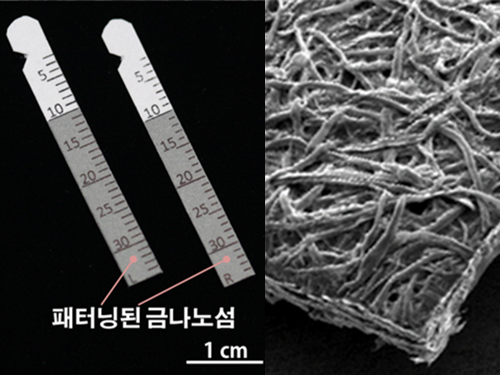

Ultra-Fast and Ultra-Sensitive Hydrogen Sensor

(From left: Professor Kim, Ph.D. candidate Koo, and Professor Penner)

A KAIST team made an ultra-fast hydrogen sensor that can detect hydrogen gas levels under 1% in less than seven seconds. The sensor also can detect hundreds of parts per million levels of hydrogen gas within 60 seconds at room temperature.

A research group under Professor Il-Doo Kim in the Department of Materials Science and Engineering at KAIST, in collaboration with Professor Reginald M. Penner of the University of California-Irvine, has developed an ultra-fast hydrogen gas detection system based on a palladium (Pd) nanowire array coated with a metal-organic framework (MOF).

Hydrogen has been regarded as an eco-friendly next-generation energy source. However, it is a flammable gas that can explode even with a small spark. For safety, the lower explosion limit for hydrogen gas is 4 vol% so sensors should be able to detect the colorless and odorless hydrogen molecule quickly. The importance of sensors capable of rapidly detecting colorless and odorless hydrogen gas has been emphasized in recent guidelines issued by the U.S. Department of Energy. According to the guidelines, hydrogen sensors should detect 1 vol% of hydrogen in air in less than 60 seconds for adequate response and recovery times.

To overcome the limitations of Pd-based hydrogen sensors, the research team introduced a MOF layer on top of a Pd nanowire array. Lithographically patterned Pd nanowires were simply overcoated with a Zn-based zeolite imidazole framework (ZIF-8) layer composed of Zn ions and organic ligands. ZIF-8 film is easily coated on Pd nanowires by simple dipping (for 2–6 hours) in a methanol solution including Zn (NO3)2·6H2O and 2-methylimidazole.

(This cover image depicts lithographically-patterned Pd nanowires overcoated with a Zn-based zeolite imidazole framework (ZIF-8) layer.)

As synthesized ZIF-8 is a highly porous material composed of a number of micro-pores of 0.34 nm and 1.16 nm, hydrogen gas with a kinetic diameter of 0.289 nm can easily penetrate inside the ZIF-8 membrane, while large molecules (> 0.34 nm) are effectively screened by the MOF filter. Thus, the ZIF-8 filter on the Pd nanowires allows the predominant penetration of hydrogen molecules, leading to the acceleration of Pd-based H2 sensors with a 20-fold faster recovery and response speed compared to pristine Pd nanowires at room temperature.

Professor Kim expects that the ultra-fast hydrogen sensor can be useful for the prevention of explosion accidents caused by the leakage of hydrogen gas. In addition, he expects that other harmful gases in the air can be accurately detected through effective nano-filtration by using of a variety of MOF layers.

This study was carried out by Ph.D. candidate Won-Tae Koo (first author), Professor Kim (co-corresponding author), and Professor Penner (co-corresponding author). The study has been published in the online edition of ACS Nano, as the cover-featured image for the September issue.

Figure 1. Representative image for this paper published in ACS Nano, August, 18.

Figure 2. Images of Pd nanowire array-based hydrogen sensors, scanning electron microscopy image of a Pd nanowire covered by a metal-organic framework layer, and the hydrogen sensing properties of the sensors.

Figure 3. Schematic illustration of a metal-organic framework (MOF). The MOF, consisting of metal ions and organic ligands, is a highly porous material with an ultrahigh surface area. The various structures of MOFs can be synthesized depending on the kinds of metal ions and organic ligands.

2017.09.28 View 11588

Ultra-Fast and Ultra-Sensitive Hydrogen Sensor

(From left: Professor Kim, Ph.D. candidate Koo, and Professor Penner)

A KAIST team made an ultra-fast hydrogen sensor that can detect hydrogen gas levels under 1% in less than seven seconds. The sensor also can detect hundreds of parts per million levels of hydrogen gas within 60 seconds at room temperature.

A research group under Professor Il-Doo Kim in the Department of Materials Science and Engineering at KAIST, in collaboration with Professor Reginald M. Penner of the University of California-Irvine, has developed an ultra-fast hydrogen gas detection system based on a palladium (Pd) nanowire array coated with a metal-organic framework (MOF).

Hydrogen has been regarded as an eco-friendly next-generation energy source. However, it is a flammable gas that can explode even with a small spark. For safety, the lower explosion limit for hydrogen gas is 4 vol% so sensors should be able to detect the colorless and odorless hydrogen molecule quickly. The importance of sensors capable of rapidly detecting colorless and odorless hydrogen gas has been emphasized in recent guidelines issued by the U.S. Department of Energy. According to the guidelines, hydrogen sensors should detect 1 vol% of hydrogen in air in less than 60 seconds for adequate response and recovery times.

To overcome the limitations of Pd-based hydrogen sensors, the research team introduced a MOF layer on top of a Pd nanowire array. Lithographically patterned Pd nanowires were simply overcoated with a Zn-based zeolite imidazole framework (ZIF-8) layer composed of Zn ions and organic ligands. ZIF-8 film is easily coated on Pd nanowires by simple dipping (for 2–6 hours) in a methanol solution including Zn (NO3)2·6H2O and 2-methylimidazole.

(This cover image depicts lithographically-patterned Pd nanowires overcoated with a Zn-based zeolite imidazole framework (ZIF-8) layer.)

As synthesized ZIF-8 is a highly porous material composed of a number of micro-pores of 0.34 nm and 1.16 nm, hydrogen gas with a kinetic diameter of 0.289 nm can easily penetrate inside the ZIF-8 membrane, while large molecules (> 0.34 nm) are effectively screened by the MOF filter. Thus, the ZIF-8 filter on the Pd nanowires allows the predominant penetration of hydrogen molecules, leading to the acceleration of Pd-based H2 sensors with a 20-fold faster recovery and response speed compared to pristine Pd nanowires at room temperature.

Professor Kim expects that the ultra-fast hydrogen sensor can be useful for the prevention of explosion accidents caused by the leakage of hydrogen gas. In addition, he expects that other harmful gases in the air can be accurately detected through effective nano-filtration by using of a variety of MOF layers.

This study was carried out by Ph.D. candidate Won-Tae Koo (first author), Professor Kim (co-corresponding author), and Professor Penner (co-corresponding author). The study has been published in the online edition of ACS Nano, as the cover-featured image for the September issue.

Figure 1. Representative image for this paper published in ACS Nano, August, 18.

Figure 2. Images of Pd nanowire array-based hydrogen sensors, scanning electron microscopy image of a Pd nanowire covered by a metal-organic framework layer, and the hydrogen sensing properties of the sensors.

Figure 3. Schematic illustration of a metal-organic framework (MOF). The MOF, consisting of metal ions and organic ligands, is a highly porous material with an ultrahigh surface area. The various structures of MOFs can be synthesized depending on the kinds of metal ions and organic ligands.

2017.09.28 View 11588 -

A Novel and Practical Fab-route for Superomniphobic Liquid-free Surfaces

(clockwise from left: Jaeho Choi, Hee Tak Kim, Shin-Hyun Kim)

A joint research team led by Professor Hee Tak Kim and Shin-Hyun Kim in the Department of Chemical and Biomolecular Engineering at KAIST developed a fabrication technology that can inexpensively produce surfaces capable of repelling liquids, including water and oil.

The team used the photofluidization of azobenzene molecule-containing polymers to generate a superomniphobic surface which can be applied for developing stain-free fabrics, non-biofouling medical tubing, and corrosion-free surfaces.

Mushroom-shaped surface textures, also called doubly re-entrant structures, are known to be the most effective surface structure that enhances resistance against liquid invasion, thereby exhibiting superior superomniphobic property.

However, the existing procedures for their fabrication are highly delicate, time-consuming, and costly. Moreover, the materials required for the fabrication are restricted to an inflexible and expensive silicon wafer, which limits the practical use of the surface.

To overcome such limitations, the research team used a different approach to fabricate the re-entrant structures called localized photofludization by using the peculiar optical phenomenon of azobenzene molecule-containing polymers (referred to as azopolymers). It is a phenomenon where an azopolymer becomes fluidized under irradiation, and the fluidization takes place locally within the thin surface layer of the azopolymer.

With this novel approach, the team facilitated the localized photofluidization in the top surface layer of azopolymer cylindrical posts, successfully reconfiguring the cylindrical posts to doubly re-entrant geometry while the fluidized thin top surface of an azopolymer is flowing down.

The structure developed by the team exhibits a superior superomniphobic property even for liquids infiltrating the surface immediately.

Moreover, the superomniphobic property can be maintained on a curved target surface because its surficial materials are based on high molecules.

Furthermore, the fabrication procedure of the structure is highly reproducible and scalable, providing a practical route to creating robust omniphobic surfaces.

Professor Hee Tak Kim said, “Not only does the novel photo-fluidization technology in this study produce superior superomniphobic surfaces, but it also possesses many practical advantages in terms of fab-procedures and material flexibility; therefore, it could greatly contribute to real uses in diverse applications.”

Professor Shin-Hyun Kim added, “The designed doubly re-entrant geometry in this study was inspired by the skin structure of springtails, insects dwelling in soil that breathe through their skin. As I carried out this research, I once again realized that humans can learn from nature to create new engineering designs.”

The paper (Jaeho Choi as a first author) was published in ACS Nano, an international journal for Nano-technology, in August.

(Schematic diagram of mushroom-shaped structure fabrication)

(SEM image of mushroom-shaped structure)

(Image of superomniphobic property of different types of liquid)

2017.09.08 View 8224

A Novel and Practical Fab-route for Superomniphobic Liquid-free Surfaces

(clockwise from left: Jaeho Choi, Hee Tak Kim, Shin-Hyun Kim)

A joint research team led by Professor Hee Tak Kim and Shin-Hyun Kim in the Department of Chemical and Biomolecular Engineering at KAIST developed a fabrication technology that can inexpensively produce surfaces capable of repelling liquids, including water and oil.

The team used the photofluidization of azobenzene molecule-containing polymers to generate a superomniphobic surface which can be applied for developing stain-free fabrics, non-biofouling medical tubing, and corrosion-free surfaces.

Mushroom-shaped surface textures, also called doubly re-entrant structures, are known to be the most effective surface structure that enhances resistance against liquid invasion, thereby exhibiting superior superomniphobic property.

However, the existing procedures for their fabrication are highly delicate, time-consuming, and costly. Moreover, the materials required for the fabrication are restricted to an inflexible and expensive silicon wafer, which limits the practical use of the surface.

To overcome such limitations, the research team used a different approach to fabricate the re-entrant structures called localized photofludization by using the peculiar optical phenomenon of azobenzene molecule-containing polymers (referred to as azopolymers). It is a phenomenon where an azopolymer becomes fluidized under irradiation, and the fluidization takes place locally within the thin surface layer of the azopolymer.

With this novel approach, the team facilitated the localized photofluidization in the top surface layer of azopolymer cylindrical posts, successfully reconfiguring the cylindrical posts to doubly re-entrant geometry while the fluidized thin top surface of an azopolymer is flowing down.

The structure developed by the team exhibits a superior superomniphobic property even for liquids infiltrating the surface immediately.

Moreover, the superomniphobic property can be maintained on a curved target surface because its surficial materials are based on high molecules.

Furthermore, the fabrication procedure of the structure is highly reproducible and scalable, providing a practical route to creating robust omniphobic surfaces.

Professor Hee Tak Kim said, “Not only does the novel photo-fluidization technology in this study produce superior superomniphobic surfaces, but it also possesses many practical advantages in terms of fab-procedures and material flexibility; therefore, it could greatly contribute to real uses in diverse applications.”

Professor Shin-Hyun Kim added, “The designed doubly re-entrant geometry in this study was inspired by the skin structure of springtails, insects dwelling in soil that breathe through their skin. As I carried out this research, I once again realized that humans can learn from nature to create new engineering designs.”

The paper (Jaeho Choi as a first author) was published in ACS Nano, an international journal for Nano-technology, in August.

(Schematic diagram of mushroom-shaped structure fabrication)

(SEM image of mushroom-shaped structure)

(Image of superomniphobic property of different types of liquid)

2017.09.08 View 8224 -

Innovative Nanosensor for Disease Diagnosis

(Figure 1. Sensing Device)

(Figure 2. Protein templating route)

Breath pattern recognition is a futuristic diagnostic platform. Simple characterizing target gas concentrations of human exhaled breath will lead to diagnose of the disease as well as physical condition.

A research group under Prof. Il-Doo Kim in the Department of Materials Science has developed diagnostic sensors using protein-encapsulated nanocatalysts, which can diagnose certain diseases by analyzing human exhaled breath. This technology enables early monitoring of various diseases through pattern recognition of biomarker gases related to diseases in human exhalation.

The protein-templated catalyst synthesis route is very simple and versatile for producing not only a single component of catalytic nanoparticles, but also diverse heterogeneous intermetallic catalysts with sizes less than 3 nm. The research team has developed ever more sensitive and selective chemiresistive sensors that can potentially diagnose specific diseases by analyzing exhaled breath gases.

The results of this study, which were contributed by Dr. Sang-Joon Kim and Dr. Seon-Jin Choi as first authors were selected as the cover-featured article in the July issue of 'Accounts of Chemical Research,' an international journal of the American Chemical Society.

In human breath, diverse components are found including water vapor, hydrogen, acetone, toluene, ammonia, hydrogen sulfide, and carbon monoxide, which are more excessively exhaled from patients. Some of these components are closely related to diseases such as asthma, lung cancer, type 1 diabetes mellitus, and halitosis.

Breath analysis for disease diagnosis started from capturing exhaled breaths in a Tedlar bag and subsequently the captured breath gases were injected into a miniaturized sensor system, similar to an alcohol detector. It is possible to analyze exhaled breath very rapidly with a simple analyzing process. The breath analysis can detect trace changes in exhaled breath components, which contribute to early diagnosis of diseases.

However, technological advances are needed to accurately analyze gases in the breath, which occur at very low levels, from 1 ppb to 1 ppm. In particular, it has been a critical challenge for chemiresistive type chemical sensors to selectively detect specific biomarkers in thousands of interfering gases including humid vapor.

Conventionally, noble metallic catalysts such as platinum and palladium have been functionalized onto metal oxide sensing layers. However, the gas sensitivity was not enough to detect ppb-levels of biomarker species in exhaled breath.

To overcome the current limitations, the research team utilized nanoscale protein (apoferritin) in animals as sacrificial templates. The protein templates possess hollow nanocages at the core site and various alloy catalytic nanoparticles can be encapsulated inside the protein nanocages.

The protein nanocages are advantageous because a nearly unlimited number of material compositions in the periodic table can be assembled for the synthesis of heterogeneous catalytic nanoparticles. In addition, intermetallic nanocatalysts with a controlled atomic ratio of two different elements can be achieved using the protein nanocages, which is an innovative strategy for finding new types of catalysts. For example, highly efficient platinum-based catalysts can be synthesized, such as platinum-palladium (PtPd), platinum-nickel (PtNi), platinum-ruthenium (PtRu), and platinum-yttrium (PtY).

The research team developed outstanding sensing layers consisting of metal oxide nanofibers functionalized by the heterogeneous catalysts with large and highly-porous surface areas, which are especially optimized for selective detection of specific biomarkers. The biomarker sensing performance was improved approximately 3~4-fold as compared to the conventional single component of platinum and palladium catalysts-loaded nanofiber sensors. In particular, 100-fold resistance transitions toward acetone (1 ppm) and hydrogen sulfide (1 ppm) were observed in exhaled breath sensors using the heterogeneous nanocatalysts, which is the best performance ever reported in literature.

The research team developed a disease diagnosis platform that recognizes individual breathing patterns by using a multiple sensor array system with diverse sensing layers and heterogeneous catalysts, so that the people can easily identify health abnormalities. Using a 16-sensor array system, physical conditions can be continuously monitored by analyzing concentration changes of biomarkers in exhaled breath gases.

Prof. Kim said, “New types of heterogeneous nanocatalysts were synthesized using protein templates with sizes around 2 nm and functionalized on various metal oxide nanofiber sensing layers. The established sensing libraries can detect biomarker species with high sensitivity and selectivity.” He added, “the new and innovative breath gas analysis platform will be very helpful for reducing medical expenditures and continuous monitoring of physical conditions”

Patents related to this technology were licensed to two companies in March and June this year.

2017.07.19 View 11458

Innovative Nanosensor for Disease Diagnosis

(Figure 1. Sensing Device)

(Figure 2. Protein templating route)

Breath pattern recognition is a futuristic diagnostic platform. Simple characterizing target gas concentrations of human exhaled breath will lead to diagnose of the disease as well as physical condition.

A research group under Prof. Il-Doo Kim in the Department of Materials Science has developed diagnostic sensors using protein-encapsulated nanocatalysts, which can diagnose certain diseases by analyzing human exhaled breath. This technology enables early monitoring of various diseases through pattern recognition of biomarker gases related to diseases in human exhalation.

The protein-templated catalyst synthesis route is very simple and versatile for producing not only a single component of catalytic nanoparticles, but also diverse heterogeneous intermetallic catalysts with sizes less than 3 nm. The research team has developed ever more sensitive and selective chemiresistive sensors that can potentially diagnose specific diseases by analyzing exhaled breath gases.

The results of this study, which were contributed by Dr. Sang-Joon Kim and Dr. Seon-Jin Choi as first authors were selected as the cover-featured article in the July issue of 'Accounts of Chemical Research,' an international journal of the American Chemical Society.

In human breath, diverse components are found including water vapor, hydrogen, acetone, toluene, ammonia, hydrogen sulfide, and carbon monoxide, which are more excessively exhaled from patients. Some of these components are closely related to diseases such as asthma, lung cancer, type 1 diabetes mellitus, and halitosis.

Breath analysis for disease diagnosis started from capturing exhaled breaths in a Tedlar bag and subsequently the captured breath gases were injected into a miniaturized sensor system, similar to an alcohol detector. It is possible to analyze exhaled breath very rapidly with a simple analyzing process. The breath analysis can detect trace changes in exhaled breath components, which contribute to early diagnosis of diseases.

However, technological advances are needed to accurately analyze gases in the breath, which occur at very low levels, from 1 ppb to 1 ppm. In particular, it has been a critical challenge for chemiresistive type chemical sensors to selectively detect specific biomarkers in thousands of interfering gases including humid vapor.

Conventionally, noble metallic catalysts such as platinum and palladium have been functionalized onto metal oxide sensing layers. However, the gas sensitivity was not enough to detect ppb-levels of biomarker species in exhaled breath.

To overcome the current limitations, the research team utilized nanoscale protein (apoferritin) in animals as sacrificial templates. The protein templates possess hollow nanocages at the core site and various alloy catalytic nanoparticles can be encapsulated inside the protein nanocages.

The protein nanocages are advantageous because a nearly unlimited number of material compositions in the periodic table can be assembled for the synthesis of heterogeneous catalytic nanoparticles. In addition, intermetallic nanocatalysts with a controlled atomic ratio of two different elements can be achieved using the protein nanocages, which is an innovative strategy for finding new types of catalysts. For example, highly efficient platinum-based catalysts can be synthesized, such as platinum-palladium (PtPd), platinum-nickel (PtNi), platinum-ruthenium (PtRu), and platinum-yttrium (PtY).

The research team developed outstanding sensing layers consisting of metal oxide nanofibers functionalized by the heterogeneous catalysts with large and highly-porous surface areas, which are especially optimized for selective detection of specific biomarkers. The biomarker sensing performance was improved approximately 3~4-fold as compared to the conventional single component of platinum and palladium catalysts-loaded nanofiber sensors. In particular, 100-fold resistance transitions toward acetone (1 ppm) and hydrogen sulfide (1 ppm) were observed in exhaled breath sensors using the heterogeneous nanocatalysts, which is the best performance ever reported in literature.

The research team developed a disease diagnosis platform that recognizes individual breathing patterns by using a multiple sensor array system with diverse sensing layers and heterogeneous catalysts, so that the people can easily identify health abnormalities. Using a 16-sensor array system, physical conditions can be continuously monitored by analyzing concentration changes of biomarkers in exhaled breath gases.

Prof. Kim said, “New types of heterogeneous nanocatalysts were synthesized using protein templates with sizes around 2 nm and functionalized on various metal oxide nanofiber sensing layers. The established sensing libraries can detect biomarker species with high sensitivity and selectivity.” He added, “the new and innovative breath gas analysis platform will be very helpful for reducing medical expenditures and continuous monitoring of physical conditions”

Patents related to this technology were licensed to two companies in March and June this year.

2017.07.19 View 11458 -

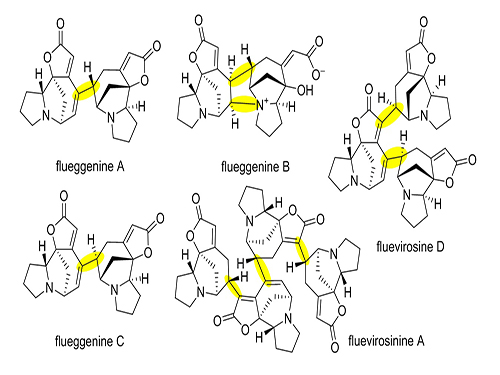

Total Synthesis of Flueggenine C via an Accelerated Intermolecular Rauhut-Currier Reaction

The first total synthesis of dimeric securinega alkaloid (-)-flueggenine C was completed via an accelerated intermolecular Rauhut–Currier (RC) reaction. The research team led by Professor Sunkyu Han in the Department of Chemistry succeeded in synthesizing the natural product by reinventing the conventional RC reaction.

The total synthesis of natural products refers to the process of synthesizing secondary metabolites isolated from living organisms in the laboratory through a series of chemical reactions. Each stage of chemical reaction needs to be successful to produce the final target molecule, and thus the process requires high levels of patience and creativity. For that reason, the researchers working on natural products total synthesis are often called “molecular artists”.

Despite numerous reports on the total synthesis of monomeric securinegas, the synthesis of dimeric securinegas, whose monomeric units are connected by a putative enzymatic RC reaction, has not been reported to date.

The team used a Rauhut-Currier (RC) reaction, a carboncarbon bond forming a reaction between two Michael acceptors first reported by Rauhut and Currier in 1963, to successfully synthesize a dimeric natural product, flueggenine C. This new work featured the first application of an intermolecular RC reaction in total synthesis.

The conventional intermolecular RC reaction was driven non-selectively by a toxic nucleophilic catalyst at a high temperature of over 150°C and a highly concentrated reaction mixture, and thus has never been applied to natural products total synthesis. To overcome this long-standing problem, the research team placed a nucleophilic moiety at the γ-position of the enone derivative. As a result, the RC reaction could be induced by the simple addition of a base at ambient temperature and dilute solution, without the need of a nucleophilic catalyst. Using this newly discovered reactivity, the team successfully synthesized the natural product (-)-flueggenine C from commercially available amino acid derivative in 12 steps.

Professor Han said, “Our key finding regarding the remarkably improved reactivity and selectivity of the intermolecular RC reaction will serve as a significant stepping stone in allowing this reaction to be considered a practical and reliable chemical tool with broad applicability in natural products, pharmaceuticals, and materials syntheses. ”

This research was led by Ph.D. candidate Sangbin Jeon and was published in The Journal of the American Chemical Society (JACS) on May 10. This research was funded by KAIST start-up funds, HRHR (High-Risk High-Return), RED&B (Research, Education, Development & Business) projects, the National Research Foundation of Korea, and the Institute for Basic Science.

(Figure 1: Representative dimeric/oligomeric securinega alkaloids)

(Figure 2: Our reinvented Rauhut-Currier reaction)

(Figure 3: Total Synthesis of (-)-flueggenine C)

2017.05.23 View 10413

Total Synthesis of Flueggenine C via an Accelerated Intermolecular Rauhut-Currier Reaction

The first total synthesis of dimeric securinega alkaloid (-)-flueggenine C was completed via an accelerated intermolecular Rauhut–Currier (RC) reaction. The research team led by Professor Sunkyu Han in the Department of Chemistry succeeded in synthesizing the natural product by reinventing the conventional RC reaction.

The total synthesis of natural products refers to the process of synthesizing secondary metabolites isolated from living organisms in the laboratory through a series of chemical reactions. Each stage of chemical reaction needs to be successful to produce the final target molecule, and thus the process requires high levels of patience and creativity. For that reason, the researchers working on natural products total synthesis are often called “molecular artists”.

Despite numerous reports on the total synthesis of monomeric securinegas, the synthesis of dimeric securinegas, whose monomeric units are connected by a putative enzymatic RC reaction, has not been reported to date.

The team used a Rauhut-Currier (RC) reaction, a carboncarbon bond forming a reaction between two Michael acceptors first reported by Rauhut and Currier in 1963, to successfully synthesize a dimeric natural product, flueggenine C. This new work featured the first application of an intermolecular RC reaction in total synthesis.

The conventional intermolecular RC reaction was driven non-selectively by a toxic nucleophilic catalyst at a high temperature of over 150°C and a highly concentrated reaction mixture, and thus has never been applied to natural products total synthesis. To overcome this long-standing problem, the research team placed a nucleophilic moiety at the γ-position of the enone derivative. As a result, the RC reaction could be induced by the simple addition of a base at ambient temperature and dilute solution, without the need of a nucleophilic catalyst. Using this newly discovered reactivity, the team successfully synthesized the natural product (-)-flueggenine C from commercially available amino acid derivative in 12 steps.

Professor Han said, “Our key finding regarding the remarkably improved reactivity and selectivity of the intermolecular RC reaction will serve as a significant stepping stone in allowing this reaction to be considered a practical and reliable chemical tool with broad applicability in natural products, pharmaceuticals, and materials syntheses. ”

This research was led by Ph.D. candidate Sangbin Jeon and was published in The Journal of the American Chemical Society (JACS) on May 10. This research was funded by KAIST start-up funds, HRHR (High-Risk High-Return), RED&B (Research, Education, Development & Business) projects, the National Research Foundation of Korea, and the Institute for Basic Science.

(Figure 1: Representative dimeric/oligomeric securinega alkaloids)

(Figure 2: Our reinvented Rauhut-Currier reaction)

(Figure 3: Total Synthesis of (-)-flueggenine C)

2017.05.23 View 10413 -

Gout Diagnostic Strip Using a Single Teardrop

A novel diagnostic strip for gout patients using a single teardrop has been announced by KAIST research team. This technology analyzes biological molecules in tears for a non-invasive diagnosis, significantly reducing the time and expense previously required for a diagnosis.

The research team under Professor Ki-Hun Jeong of the Department of Bio and Brain Engineering succeeded in developing an affordable and elaborate gout diagnostic strip by depositing metal nanoparticles on paper. This technology can not only be used in diagnostic medicine and drug testing, but also in various other areas such as field diagnoses that require prompt and accurate detection of a certain substance.

Gout induces pain in joints due to needle-shaped uric acid crystal build up. In general, therapeutic treatments exist to administer pain relief, stimulate uric acid discharge, and uric acid depressant. Such treatments work for temporary relief, but there have significant limitations. Thus, patients are required to regularly check uric acid concentrations, as well as control their diets. Therefore, simpler ways to measure uric acid would greatly benefit gout control and its prevention in a more affordable and convenient manner.

Existing gout diagnostic techniques include measuring uric acid concentrations from blood samples or observing uric acid crystals from joint synovial fluid under a microscope. These existing methods are invasive and time consuming. To overcome their limitations, the research team uniformly deposited gold nanoislands with nanoplasnomics properties on the surface of paper that can easily collect tears.

Nanoplasnomics techniques collect light on the surface of a metal nanostructure, and can be applied to disease and health diagnostic indicators as well as for genetic material detection. Further, metals such as gold absorb stronger light when it is irradiated, and thus can maximize light concentration on board surfaces while maintaining the properties of paper. The developed metal nanostructure production technology allows the flexible manufacturing of nanostructures on a large surface, which in turn allows flexible control of light concentrations.

The research team grafted surface-enhanced Raman spectroscopy on paper diagnostic strips to allow uric acid concentration measurements in teardrops without additional indicators. The measured concentration in teardrops can be compared to blood uric acid concentrations for diagnosing gout.

Professor Jeong explained, “Based on these research results, our strip will make it possible to conduct low-cost, no indicator, supersensitive biological molecule analysis and fast field diagnosis using tears.” He continued, “Tears, as well as various other bodily fluids, can be used to contribute to disease diagnosis and physiological functional research.”

Ph.D. candidate Moonseong Park participated in the research as the first author of the paper that was published in the online edition of ACS Nano on December 14, 2016. Park said, “The strip will allow fast and simple field diagnosis, and can be produced on a large scale using the existing semiconductor process.”

(Figure 1. Optical image of paper gout diagnostic strip covered with gold)

(Figure 2. Scanning delectron microscopic image of paper gout diagnostic strip)

(Figure 3. Scanning electron microscope image of cellulos fiber coated with gold nanoislands)

(Figure 4. Gout diagnosis using tears)

2017.04.27 View 9592

Gout Diagnostic Strip Using a Single Teardrop

A novel diagnostic strip for gout patients using a single teardrop has been announced by KAIST research team. This technology analyzes biological molecules in tears for a non-invasive diagnosis, significantly reducing the time and expense previously required for a diagnosis.

The research team under Professor Ki-Hun Jeong of the Department of Bio and Brain Engineering succeeded in developing an affordable and elaborate gout diagnostic strip by depositing metal nanoparticles on paper. This technology can not only be used in diagnostic medicine and drug testing, but also in various other areas such as field diagnoses that require prompt and accurate detection of a certain substance.

Gout induces pain in joints due to needle-shaped uric acid crystal build up. In general, therapeutic treatments exist to administer pain relief, stimulate uric acid discharge, and uric acid depressant. Such treatments work for temporary relief, but there have significant limitations. Thus, patients are required to regularly check uric acid concentrations, as well as control their diets. Therefore, simpler ways to measure uric acid would greatly benefit gout control and its prevention in a more affordable and convenient manner.

Existing gout diagnostic techniques include measuring uric acid concentrations from blood samples or observing uric acid crystals from joint synovial fluid under a microscope. These existing methods are invasive and time consuming. To overcome their limitations, the research team uniformly deposited gold nanoislands with nanoplasnomics properties on the surface of paper that can easily collect tears.

Nanoplasnomics techniques collect light on the surface of a metal nanostructure, and can be applied to disease and health diagnostic indicators as well as for genetic material detection. Further, metals such as gold absorb stronger light when it is irradiated, and thus can maximize light concentration on board surfaces while maintaining the properties of paper. The developed metal nanostructure production technology allows the flexible manufacturing of nanostructures on a large surface, which in turn allows flexible control of light concentrations.

The research team grafted surface-enhanced Raman spectroscopy on paper diagnostic strips to allow uric acid concentration measurements in teardrops without additional indicators. The measured concentration in teardrops can be compared to blood uric acid concentrations for diagnosing gout.

Professor Jeong explained, “Based on these research results, our strip will make it possible to conduct low-cost, no indicator, supersensitive biological molecule analysis and fast field diagnosis using tears.” He continued, “Tears, as well as various other bodily fluids, can be used to contribute to disease diagnosis and physiological functional research.”

Ph.D. candidate Moonseong Park participated in the research as the first author of the paper that was published in the online edition of ACS Nano on December 14, 2016. Park said, “The strip will allow fast and simple field diagnosis, and can be produced on a large scale using the existing semiconductor process.”

(Figure 1. Optical image of paper gout diagnostic strip covered with gold)

(Figure 2. Scanning delectron microscopic image of paper gout diagnostic strip)

(Figure 3. Scanning electron microscope image of cellulos fiber coated with gold nanoislands)

(Figure 4. Gout diagnosis using tears)

2017.04.27 View 9592 -

A Transport Technology for Nanowires Thermally Treated at 700 Celsius Degrees

Professor Jun-Bo Yoon and his research team of the Department of Electrical Engineering at KAIST developed a technology for transporting thermally treated nanowires to a flexible substrate and created a high performance device for collecting flexible energy by using the new technology.

Mr. Min-Ho Seo, a Ph.D. candidate, participated in this study as the first author. The results were published online on January 30th in ACS Nano, an international journal in the field of nanoscience and engineering. (“Versatile Transfer of an Ultralong and Seamless Nanowire Array Crystallized at High Temperature for Use in High-performance Flexible Devices,” DOI: 10.1021/acsnano.6b06842)

Nanowires are one of the most representative nanomaterials. They have wire structures with dimensions in nanometers. The nanowires are widely used in the scientific and engineering fields due to their prominent physical and chemical properties that depend on a one-dimensional structure, and their high applicability.

Nanowires have much higher performance if their structure has unique features such as an excellent arrangement and a longer-than-average length. Many researchers are thus actively participating in the research for making nanowires without much difficulty, analyzing them, and developing them for high performance application devices.

Scientists have recently favored a research topic on making nanowires chemically and physically on a flexible substrate and applies the nanowires to a flexible electric device such as a high performance wearable sensor.

The existing technology, however, mixed nanowires from a chemical synthesis with a solution and spread the mixture on a flexible substrate. The resultant distribution was random, and it was difficult to produce a high performance device based on the structural advantages of nanowires. In addition, the technology used a cutting edge nano-process and flexible materials, but this was not economically beneficial. The production of stable materials at a temperature of 700 Celsius degrees or higher is unattainable, a great challenge for the application.

To solve this problem, the research team developed a new nano-transfer technology that combines a silicon nano-grating board with a large surface area and a nano-sacrificial layer process. A nano-sacrificial layer exists between nanowires and a nano-grating board, which acts as the mold for the nano-transfer. The new technology allows the device undergo thermal treatment. After this, the layer disappears when the nanowires are transported to a flexible substrate.