Research

-

Core Technology for Lithium Air Secondary Battery Developed

KAIST-Kyonggi University joint research team developed composite catalyst out of nano fiber and graphene

Five times improvement in capacity compared to lithium-ion secondary battery, driving 800 km at maximum

The core technology for lithium air secondary battery, the next generation high capacity battery, has been developed.

A research team formed by KAIST Department of Materials Science’s Professors Il-Doo Kim and Seokwoo Jeon, and Kyonggi University Department of Materials Science’s Professor Yong-Joon Park has created a lithium air secondary battery, with five times greater storage than the lithium-ion secondary battery, by developing a nano fiber-graphene composite catalyst. The research results are published in the August 8th online edition of Nano Letters.

A cathode of a lithium-ion battery consists of graphite and an anode of the battery consists of a lithium transition metal oxide. Lithium-ion batteries are widely used in mobile phones and laptops. However, lithium-ion batteries cannot support electric vehicles, providing energy for only 160 kilometers on one full charge. The lithium air secondary battery just developed by the research team uses lithium on the cathode and oxygen on the anode. It is earning a popular acknowledgement among the next generation secondary battery research community for having lightweight mass and high energy density.

However, lithium-ion batteries remain difficult to commercialize because of their short lifespan. Lithium and oxygen meet up to form lithium oxide (Li2O2) at discharge, and decompose again at charge. In a traditional lithium air battery, this cycle does not occur smoothly and results in high resistance, thereby reducing the lifespan of the battery. It is thus essential to develop high efficiency catalyst that facilitates the formation and decomposition of lithium oxides.

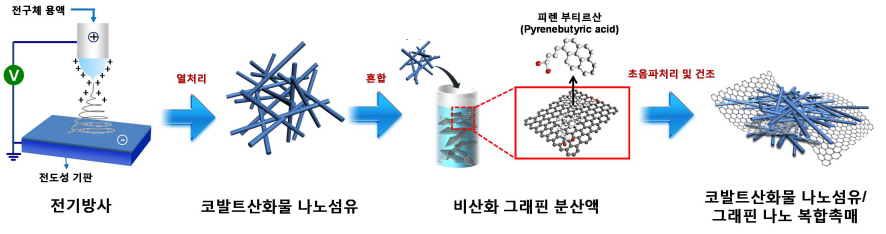

The research team used electric radiation to develop a nano composite catalyst by mixing cobalt oxide nano fiber and graphene. The performance of the battery has been maximized by settling nonoxidative graphene, which has high specific surface area and electrical conductivity, on catalyst active cobalt oxide nano fiber. Applying the nano composite catalyst on both poles of the lithium air battery resulted in an improved lifespan of over 80 recharge cycles with capacity greater than 100mAh/g, five times greater than a lithium ion battery. The newly discovered charge-discharge property is the highest among the reported performances of the lithium air battery so far.

The lithium air battery is cheap to make, as the main materials are metal oxide and graphene. “There are yet more issues to resolve such as stability, but we will collaborate with other organizations to open up the era of electronic vehicles,” said Professor Il-Doo Kim. “We hope to contribute to vitalizing the fields of next generation lithium air battery by leading nanocatalyst synthesis technology, one of the core materials in the fields of secondary battery,” Professor Kim spoke of his aspiration.

The graduate students participated in the research are Won-Hee Ryu, a postdoctorate at KAIST Department of Materials Science, Sungho Song, a PhD candidate at KAIST Department of Materials Science, and Taek-Han Yoon, a graduate student at Kyonggi University.

Picture I: Schematic Diagram of Lithium Air Battery Made of Nano Composite Catalysts

Picture II: Images of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts

Picture III: Images of Manufacturing Process of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts for Lithium Air Battery

2013.10.18 View 12146

Core Technology for Lithium Air Secondary Battery Developed

KAIST-Kyonggi University joint research team developed composite catalyst out of nano fiber and graphene

Five times improvement in capacity compared to lithium-ion secondary battery, driving 800 km at maximum

The core technology for lithium air secondary battery, the next generation high capacity battery, has been developed.

A research team formed by KAIST Department of Materials Science’s Professors Il-Doo Kim and Seokwoo Jeon, and Kyonggi University Department of Materials Science’s Professor Yong-Joon Park has created a lithium air secondary battery, with five times greater storage than the lithium-ion secondary battery, by developing a nano fiber-graphene composite catalyst. The research results are published in the August 8th online edition of Nano Letters.

A cathode of a lithium-ion battery consists of graphite and an anode of the battery consists of a lithium transition metal oxide. Lithium-ion batteries are widely used in mobile phones and laptops. However, lithium-ion batteries cannot support electric vehicles, providing energy for only 160 kilometers on one full charge. The lithium air secondary battery just developed by the research team uses lithium on the cathode and oxygen on the anode. It is earning a popular acknowledgement among the next generation secondary battery research community for having lightweight mass and high energy density.

However, lithium-ion batteries remain difficult to commercialize because of their short lifespan. Lithium and oxygen meet up to form lithium oxide (Li2O2) at discharge, and decompose again at charge. In a traditional lithium air battery, this cycle does not occur smoothly and results in high resistance, thereby reducing the lifespan of the battery. It is thus essential to develop high efficiency catalyst that facilitates the formation and decomposition of lithium oxides.

The research team used electric radiation to develop a nano composite catalyst by mixing cobalt oxide nano fiber and graphene. The performance of the battery has been maximized by settling nonoxidative graphene, which has high specific surface area and electrical conductivity, on catalyst active cobalt oxide nano fiber. Applying the nano composite catalyst on both poles of the lithium air battery resulted in an improved lifespan of over 80 recharge cycles with capacity greater than 100mAh/g, five times greater than a lithium ion battery. The newly discovered charge-discharge property is the highest among the reported performances of the lithium air battery so far.

The lithium air battery is cheap to make, as the main materials are metal oxide and graphene. “There are yet more issues to resolve such as stability, but we will collaborate with other organizations to open up the era of electronic vehicles,” said Professor Il-Doo Kim. “We hope to contribute to vitalizing the fields of next generation lithium air battery by leading nanocatalyst synthesis technology, one of the core materials in the fields of secondary battery,” Professor Kim spoke of his aspiration.

The graduate students participated in the research are Won-Hee Ryu, a postdoctorate at KAIST Department of Materials Science, Sungho Song, a PhD candidate at KAIST Department of Materials Science, and Taek-Han Yoon, a graduate student at Kyonggi University.

Picture I: Schematic Diagram of Lithium Air Battery Made of Nano Composite Catalysts

Picture II: Images of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts

Picture III: Images of Manufacturing Process of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts for Lithium Air Battery

2013.10.18 View 12146 -

Nanowire Made of Diverse Materials May Become Marketable

- Technology to commercialize nanowire developed after 2 years of industrial-academic joint research -

- 2 million strands of 50nm-width, 20 cm-length nanowire mass producible in 2 hours –

A South Korean joint industrial-academic research team has developed the technology to put forward the commercialization of nanowire that is only a few nanometers wide. It is expected to be applied in various fields such as semiconductors, high performance sensors, and biodevices.

In cooperation with LG Innotek and the National Nanofab center, Professor Jun-Bo Yoon, from KAIST Department of Electrical Engineering, developed the technology to mass produce nanowire at any length with various materials. The research results are published on the online edition of Nano Letters on July 30th.

Nanowire has a long linear structure with its width at 100 nanometers at maximum. It is a multifunctional material that has yet undiscovered thermal, electric, and mechanical properties. Nanowire is highly acclaimed as a cutting-edge material with unique nano-level properties that can be applied in semiconductors, energy, biodevices, and optic devices.

Previously, nanowires had an extremely low synthesis rate that required three or four days to grow few millimeters. It was therefore difficult to produce the desired products using nanowires. Moreover, nanowires needed to be evenly arranged for practical application, but the traditional technology required complex post-treatment, not to mention the arrangement was not immaculate.

The research team applied semiconductor process instead of chemical synthesis to resolve these issues. The team first formed a pattern greater that of the target frequency by using a photo-engraving process on a silicon wafer board whose diameter was 20 centimeters, then repeatedly reduced the frequency to produce 100 nm ultrafine linear grid pattern. Based on this pattern, the research team applied the sputtering process to mass-produce nanowires in perfect shapes of 50 nm width and 20 cm maximum length.

The new technology requires neither a lengthy synthesis process nor post-cleaning to attain a perfectly aligned state. Thus, academic and industrial circles consider the technology has high possibilities for commercialization.

“The significance is in resolving the issues in traditional technology, such as low productivity, long manufacturing time, restrictions in material synthesis, and nanowire alignment,” commented Professor Yoon on this research. “Nanowires have not been widely applied in the industry, but this technology will bring forward the commercialization of high performance semiconductors, optic devices, and biodevices that make use of nanowires.”

2013.10.18 View 9608

Nanowire Made of Diverse Materials May Become Marketable

- Technology to commercialize nanowire developed after 2 years of industrial-academic joint research -

- 2 million strands of 50nm-width, 20 cm-length nanowire mass producible in 2 hours –

A South Korean joint industrial-academic research team has developed the technology to put forward the commercialization of nanowire that is only a few nanometers wide. It is expected to be applied in various fields such as semiconductors, high performance sensors, and biodevices.

In cooperation with LG Innotek and the National Nanofab center, Professor Jun-Bo Yoon, from KAIST Department of Electrical Engineering, developed the technology to mass produce nanowire at any length with various materials. The research results are published on the online edition of Nano Letters on July 30th.

Nanowire has a long linear structure with its width at 100 nanometers at maximum. It is a multifunctional material that has yet undiscovered thermal, electric, and mechanical properties. Nanowire is highly acclaimed as a cutting-edge material with unique nano-level properties that can be applied in semiconductors, energy, biodevices, and optic devices.

Previously, nanowires had an extremely low synthesis rate that required three or four days to grow few millimeters. It was therefore difficult to produce the desired products using nanowires. Moreover, nanowires needed to be evenly arranged for practical application, but the traditional technology required complex post-treatment, not to mention the arrangement was not immaculate.

The research team applied semiconductor process instead of chemical synthesis to resolve these issues. The team first formed a pattern greater that of the target frequency by using a photo-engraving process on a silicon wafer board whose diameter was 20 centimeters, then repeatedly reduced the frequency to produce 100 nm ultrafine linear grid pattern. Based on this pattern, the research team applied the sputtering process to mass-produce nanowires in perfect shapes of 50 nm width and 20 cm maximum length.

The new technology requires neither a lengthy synthesis process nor post-cleaning to attain a perfectly aligned state. Thus, academic and industrial circles consider the technology has high possibilities for commercialization.

“The significance is in resolving the issues in traditional technology, such as low productivity, long manufacturing time, restrictions in material synthesis, and nanowire alignment,” commented Professor Yoon on this research. “Nanowires have not been widely applied in the industry, but this technology will bring forward the commercialization of high performance semiconductors, optic devices, and biodevices that make use of nanowires.”

2013.10.18 View 9608 -

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

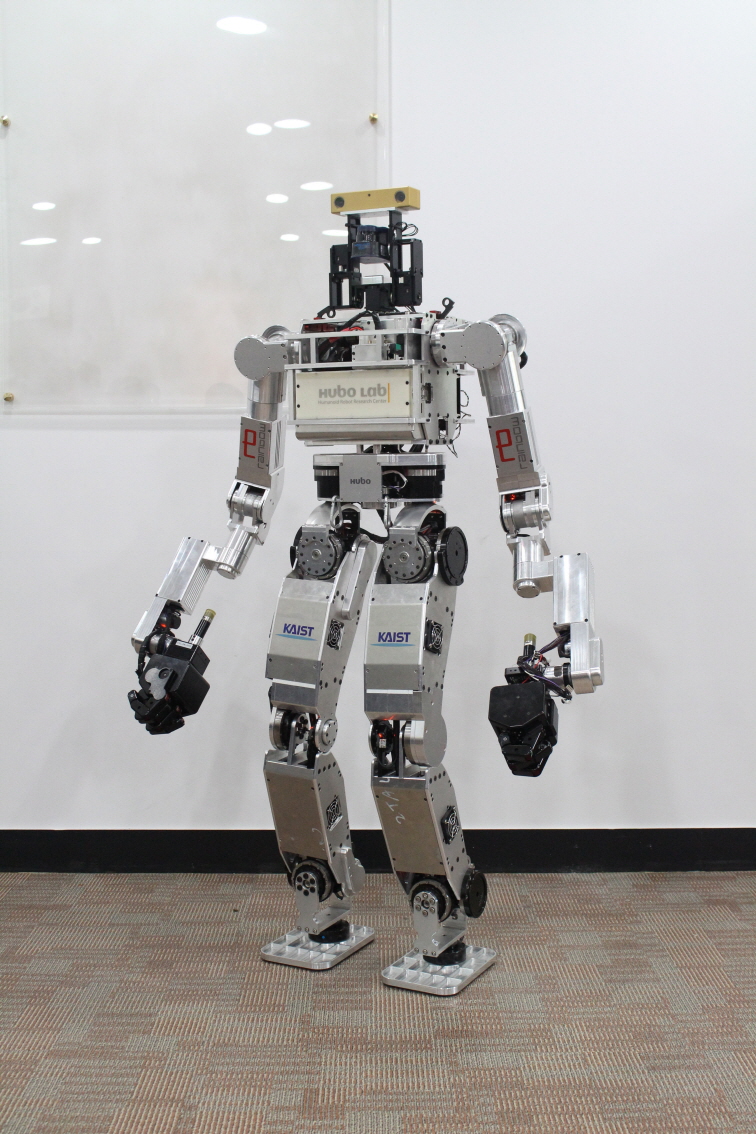

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 14535

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 14535 -

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 8908

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 8908 -

KAIST Holds Robot Taekwondo Competition Recognized by the World Taekwondo Federation

KAIST will host the 12th Intelligent System-on-Chip (SoC) Robot War in October 2013, a robot competition. The event will have two entries: robot Taekwondo contest and HURO competition.

The World Taekwondo Federation has decided to offer an honorary Taekwondo degree to the winner of SoC Taekwondo Robot competition.

The Intelligent SoC Robot War was created in 2002 by KAIST’s Professor Hoi-Jun Yoo in the Department of Electrical Engineering.

For SoC Taekwondo Robot event, two robots compete in the form of Taekwondo, traditional Korean martial arts. The robots competing in this event have a camera and semiconductor chips on board, and therefore they have the brain-like functions to identify an object and control movements on their own. The robots have 21 joints with humanoid robot technology on their body for the techniques needed to compete in a typical Taekwondo match. They employ moves such as front kicks, side kicks, and upper punches.

In particular, KAIST’s System Design Innovation & Application Research Center, the organizer of this competition, has operated a team to demonstrate robot Taekwondo since last year with the purpose of displaying the basic movements of Taekwondo.

“Robots received attention as the source of growth in the near future. We have been developing robotics technology, and as part of our endeavor, preparing the Taekwondo demonstration team since 2012 to exhibit Korea’s robot technology and introduce our traditional martial arts,” said Professor Hoi-Jun Yoo. “We will continue to develop various capabilities for Taekwondo robots in cooperation with the World Taekwondo Federation.”

In HURO-Competition, robots compete for crossing the finishing line first by completing various missions, such as putting in a golf ball or overcoming obstacles while avoiding unexpected accidents. The winning team is awarded with a Presidential Award of Korea.

The 12th Intelligent SoC Robot War Competition is open to all graduate or undergraduate students. For details, visit the homepage at http://www.socrobotwar.org/.

2013.05.06 View 10918

KAIST Holds Robot Taekwondo Competition Recognized by the World Taekwondo Federation

KAIST will host the 12th Intelligent System-on-Chip (SoC) Robot War in October 2013, a robot competition. The event will have two entries: robot Taekwondo contest and HURO competition.

The World Taekwondo Federation has decided to offer an honorary Taekwondo degree to the winner of SoC Taekwondo Robot competition.

The Intelligent SoC Robot War was created in 2002 by KAIST’s Professor Hoi-Jun Yoo in the Department of Electrical Engineering.

For SoC Taekwondo Robot event, two robots compete in the form of Taekwondo, traditional Korean martial arts. The robots competing in this event have a camera and semiconductor chips on board, and therefore they have the brain-like functions to identify an object and control movements on their own. The robots have 21 joints with humanoid robot technology on their body for the techniques needed to compete in a typical Taekwondo match. They employ moves such as front kicks, side kicks, and upper punches.

In particular, KAIST’s System Design Innovation & Application Research Center, the organizer of this competition, has operated a team to demonstrate robot Taekwondo since last year with the purpose of displaying the basic movements of Taekwondo.

“Robots received attention as the source of growth in the near future. We have been developing robotics technology, and as part of our endeavor, preparing the Taekwondo demonstration team since 2012 to exhibit Korea’s robot technology and introduce our traditional martial arts,” said Professor Hoi-Jun Yoo. “We will continue to develop various capabilities for Taekwondo robots in cooperation with the World Taekwondo Federation.”

In HURO-Competition, robots compete for crossing the finishing line first by completing various missions, such as putting in a golf ball or overcoming obstacles while avoiding unexpected accidents. The winning team is awarded with a Presidential Award of Korea.

The 12th Intelligent SoC Robot War Competition is open to all graduate or undergraduate students. For details, visit the homepage at http://www.socrobotwar.org/.

2013.05.06 View 10918 -

KAIST and Saudi Aramco agreed to establish a joint CO2 research center in Korea

The Korea Advanced Institute of Science and Technology (KAIST) and Saudi Aramco, a global energy and petrochemicals enterprise, signed a memorandum of understanding (MOU) on January 6, 2013 in Dhahran, Saudi Arabia and pledged to jointly collaborate in research and development of innovative technologies and solutions to address the world"s energy challenges.

Under the MOU, the two entities agreed to establish a research center, Saudi Aramco-KAIST CO2 Research Center, near KAIST"s main campus in Daejeon, Korea. The research center, to be jointly managed by KAIST and Saudi Aramco, will foster and facilitate research collaborations in areas such as tackling carbon dioxide (CO2) emissions by removal or capture of CO2, conversing CO2 into useful products, developing efficiency improvements in energy production, sharing carbon management technologies, establishing exchange programs, and conducting joint projects.

According to Saudi Aramco, the company"s collaboration with KAIST is the first partnership established in Asia. Khalid A. Al-Falih, President and CEO of Saudi Aramco, said,

"The CO2 Research Center represents a major step in Saudi Aramco"s research and technology strategy to partner with top global institutions to help address and find sustainable solutions to the world’s energy challenge both domestically and internationally."

2013.03.19 View 10236

KAIST and Saudi Aramco agreed to establish a joint CO2 research center in Korea

The Korea Advanced Institute of Science and Technology (KAIST) and Saudi Aramco, a global energy and petrochemicals enterprise, signed a memorandum of understanding (MOU) on January 6, 2013 in Dhahran, Saudi Arabia and pledged to jointly collaborate in research and development of innovative technologies and solutions to address the world"s energy challenges.

Under the MOU, the two entities agreed to establish a research center, Saudi Aramco-KAIST CO2 Research Center, near KAIST"s main campus in Daejeon, Korea. The research center, to be jointly managed by KAIST and Saudi Aramco, will foster and facilitate research collaborations in areas such as tackling carbon dioxide (CO2) emissions by removal or capture of CO2, conversing CO2 into useful products, developing efficiency improvements in energy production, sharing carbon management technologies, establishing exchange programs, and conducting joint projects.

According to Saudi Aramco, the company"s collaboration with KAIST is the first partnership established in Asia. Khalid A. Al-Falih, President and CEO of Saudi Aramco, said,

"The CO2 Research Center represents a major step in Saudi Aramco"s research and technology strategy to partner with top global institutions to help address and find sustainable solutions to the world’s energy challenge both domestically and internationally."

2013.03.19 View 10236 -

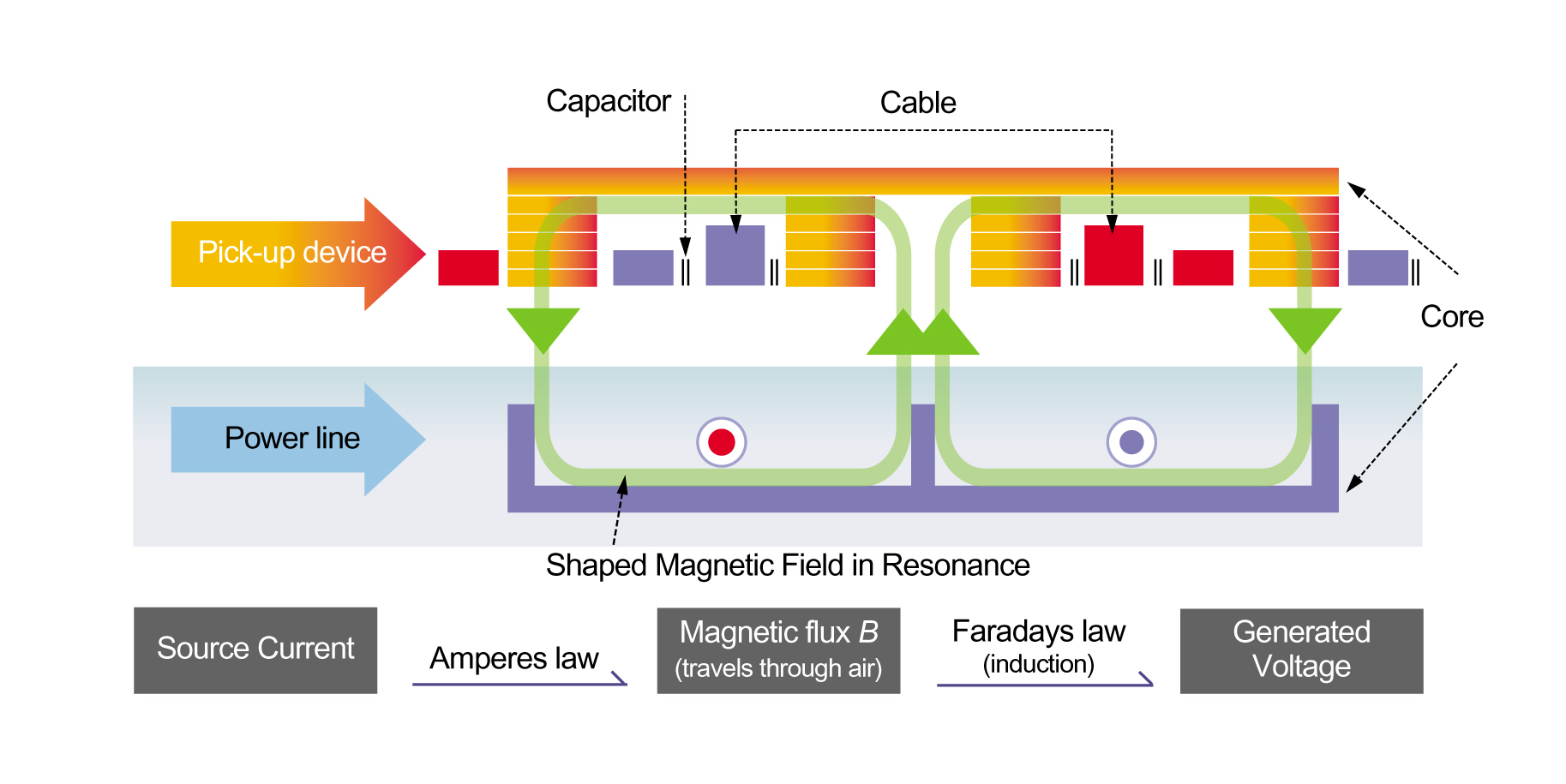

KAIST Develops Wireless Power Transfer Technology for High Capacity Transit

KAIST and the Korea Railroad Research Institute (KRRI) have developed a wireless power transfer technology that can be applied to high capacity transportation systems such as railways, harbor freight, and airport transportation and logistics. The technology supplies 60 kHz and 180 kW of power remotely to transport vehicles at a stable, constant rate.

KAIST and KRRI successfully showcased the wireless power transfer technology to the public on February 13, 2013 by testing it on the railroad tracks at Osong Station in Korea. Originally, this technology was developed as part of an electric vehicle system introduced by KAIST in 2011 known as the On-line Electric Vehicle (OLEV).

OLEV does not need to be parked at a charging station to have a fully powered battery. It gets charged while running, idling, and parking, enabling a reduction in size of the reserve battery down to one-fifth of the battery on board a regular electric car. The initial models of OLEV, a bus and a tram, receive 20 kHz and 100 kW power at an 85% transmission efficiency rate while maintaining a 20cm air gap between the underbody of vehicle and the road surface. OLEV complies with the national and international standards of 62.5 mG, a safety net for electromagnetic fields. In July 2013, for the first time since its development, OLEV will run on a regular road, an inner city route in the city of Gumi, requiring 40 minutes of driving each way.

Today’s technology demonstration offers further support that OLEV can be utilized for large-scale systems. Professor Dong-Ho Cho, Director of Center for Wireless Power Transfer Technology Business Development at KAIST, explained the recent improvements to OLEV:

“We have greatly improved the OLEV technology from the early development stage by increasing its power transmission density by more than three times. The size and weight of the power pickup modules have been reduced as well. We were able to cut down the production costs for major OLEV components, the power supply, and the pickup system, and in turn, OLEV is one step closer to being commercialized.”

If trains receive power wirelessly, the costs of railway wear and tear will be dramatically reduced. There will be no power rails, including electrical poles, required for the establishment of a railway system, and accordingly, lesser space will be needed. Tunnels will be built on a smaller scale, lowering construction costs. In addition, it will be helpful to overcome major obstacles that discourage the construction of high speed railway systems such as noise levels and problems in connecting pantograph and power rails.

KAIST and KRRI plan to apply the wireless power transfer technology to trams in May and high speed trains in September.

2013.03.19 View 12897

KAIST Develops Wireless Power Transfer Technology for High Capacity Transit

KAIST and the Korea Railroad Research Institute (KRRI) have developed a wireless power transfer technology that can be applied to high capacity transportation systems such as railways, harbor freight, and airport transportation and logistics. The technology supplies 60 kHz and 180 kW of power remotely to transport vehicles at a stable, constant rate.

KAIST and KRRI successfully showcased the wireless power transfer technology to the public on February 13, 2013 by testing it on the railroad tracks at Osong Station in Korea. Originally, this technology was developed as part of an electric vehicle system introduced by KAIST in 2011 known as the On-line Electric Vehicle (OLEV).

OLEV does not need to be parked at a charging station to have a fully powered battery. It gets charged while running, idling, and parking, enabling a reduction in size of the reserve battery down to one-fifth of the battery on board a regular electric car. The initial models of OLEV, a bus and a tram, receive 20 kHz and 100 kW power at an 85% transmission efficiency rate while maintaining a 20cm air gap between the underbody of vehicle and the road surface. OLEV complies with the national and international standards of 62.5 mG, a safety net for electromagnetic fields. In July 2013, for the first time since its development, OLEV will run on a regular road, an inner city route in the city of Gumi, requiring 40 minutes of driving each way.

Today’s technology demonstration offers further support that OLEV can be utilized for large-scale systems. Professor Dong-Ho Cho, Director of Center for Wireless Power Transfer Technology Business Development at KAIST, explained the recent improvements to OLEV:

“We have greatly improved the OLEV technology from the early development stage by increasing its power transmission density by more than three times. The size and weight of the power pickup modules have been reduced as well. We were able to cut down the production costs for major OLEV components, the power supply, and the pickup system, and in turn, OLEV is one step closer to being commercialized.”

If trains receive power wirelessly, the costs of railway wear and tear will be dramatically reduced. There will be no power rails, including electrical poles, required for the establishment of a railway system, and accordingly, lesser space will be needed. Tunnels will be built on a smaller scale, lowering construction costs. In addition, it will be helpful to overcome major obstacles that discourage the construction of high speed railway systems such as noise levels and problems in connecting pantograph and power rails.

KAIST and KRRI plan to apply the wireless power transfer technology to trams in May and high speed trains in September.

2013.03.19 View 12897 -

Launched the Saudi Aramco-KAIST CO2 Management Center in Korea

KAIST and Saudi Aramco, a global energy and petrochemicals enterprise, signed on February 20, 2013 the Master Research and Collaboration Agreement (the Agreement) on joint collaborations in research and development of carbon management between the two entities.

The Agreement was subsequently concluded upon the signing of the Memorandum of Understanding (MOU) between KAIST and Saudi Aramco, dated January 7th, 2013. In the Agreement, the two organizations specified terms and conditions necessary to conduct joint research projects and stipulated governing body for the operation of the Saudi Aramco-KAIST CO2 Management Center.

KAIST and Saudi Aramco, a national oil company for Saudi Arabia, entered into the MOU, in which the two parties shared a common interest in addressing the issue of CO2 capture, CO2storage, CO2 avoidance using efficiency improvements, and converting CO2 into useful chemicals and other materials, and agreed to “create a major research center for CO2” in Korea.

As envisioned by the MOU and its subsequent agreement, KAIST and Saudi Aramco decided to operate an interim office of the Saudi Aramco-KAIST CO2 Management Center at KAIST campus in Daejeon, Korea, pending the establishment of the research center. The full-fledged, independent research facility will be built at a location and during a period to be agreed between the two parties.

Following the signing of the Agreement, there was a celebration event taken place, including a signboard hanging ceremony for the interim research office. A 10-member delegation from Saudi Aramco, which was headed by Vice President of Engineering Services Samir Al-Tubayyeb, Dr. Nam-Pyo Suh, former president of KAIST, Vice President of Research at KAIST Kyung-Wook Paik, and senior representatives from Korean oil and petrochemical companies such as S-Oil, Lotte Chemicals, SK Innovation, and STX attended the event.

Kyung-Wook Paik, Vice President of Research at KAIST, said,

“In order to help find solutions to carbon management, KAIST and Saudi Aramco will facilitate to exchange each party’s complementary technical expertise, gain insight into new research fields, and have access to key sources of talent, while promoting innovation for technology solutions and contributing to the lifelong learning agenda of both organizations.”

Samir Al-Tubayyeb, Vice President of Engineering Services at Saudi Aramco, added that “As a world-leading oil and gas company, Saudi Aramco’s mission is to promote the continued use of safe, environmentally-friendly petroleum products with a vision to becoming a global leader in research and technology. Building a strong and cooperative relationship with KAIST in our endeavor to search for alternative ways to better utilization of fossil fuels will expedite the creation of opportunities to make the world environmentally safer and sustainable.”

KAIST and Saudi Aramco will each chip in a maximum of USD 5 million annually for the establishment and operation of the Saudi Aramco-KAIST CO2 Management Center during the initial term of the Master Research and Collaboration Agreement, which starts in 2013 and continues through 2018.

2013.03.19 View 14247

Launched the Saudi Aramco-KAIST CO2 Management Center in Korea

KAIST and Saudi Aramco, a global energy and petrochemicals enterprise, signed on February 20, 2013 the Master Research and Collaboration Agreement (the Agreement) on joint collaborations in research and development of carbon management between the two entities.

The Agreement was subsequently concluded upon the signing of the Memorandum of Understanding (MOU) between KAIST and Saudi Aramco, dated January 7th, 2013. In the Agreement, the two organizations specified terms and conditions necessary to conduct joint research projects and stipulated governing body for the operation of the Saudi Aramco-KAIST CO2 Management Center.

KAIST and Saudi Aramco, a national oil company for Saudi Arabia, entered into the MOU, in which the two parties shared a common interest in addressing the issue of CO2 capture, CO2storage, CO2 avoidance using efficiency improvements, and converting CO2 into useful chemicals and other materials, and agreed to “create a major research center for CO2” in Korea.

As envisioned by the MOU and its subsequent agreement, KAIST and Saudi Aramco decided to operate an interim office of the Saudi Aramco-KAIST CO2 Management Center at KAIST campus in Daejeon, Korea, pending the establishment of the research center. The full-fledged, independent research facility will be built at a location and during a period to be agreed between the two parties.

Following the signing of the Agreement, there was a celebration event taken place, including a signboard hanging ceremony for the interim research office. A 10-member delegation from Saudi Aramco, which was headed by Vice President of Engineering Services Samir Al-Tubayyeb, Dr. Nam-Pyo Suh, former president of KAIST, Vice President of Research at KAIST Kyung-Wook Paik, and senior representatives from Korean oil and petrochemical companies such as S-Oil, Lotte Chemicals, SK Innovation, and STX attended the event.

Kyung-Wook Paik, Vice President of Research at KAIST, said,

“In order to help find solutions to carbon management, KAIST and Saudi Aramco will facilitate to exchange each party’s complementary technical expertise, gain insight into new research fields, and have access to key sources of talent, while promoting innovation for technology solutions and contributing to the lifelong learning agenda of both organizations.”

Samir Al-Tubayyeb, Vice President of Engineering Services at Saudi Aramco, added that “As a world-leading oil and gas company, Saudi Aramco’s mission is to promote the continued use of safe, environmentally-friendly petroleum products with a vision to becoming a global leader in research and technology. Building a strong and cooperative relationship with KAIST in our endeavor to search for alternative ways to better utilization of fossil fuels will expedite the creation of opportunities to make the world environmentally safer and sustainable.”

KAIST and Saudi Aramco will each chip in a maximum of USD 5 million annually for the establishment and operation of the Saudi Aramco-KAIST CO2 Management Center during the initial term of the Master Research and Collaboration Agreement, which starts in 2013 and continues through 2018.

2013.03.19 View 14247 -

KAIST Alumni Association Selects 'Proud Alums'

KAIST Alumni Association selected ‘Proud Alums’ who have contributed to the development of Korea and society and brought honor to KAIST.

The Alums selected were: CEO of Hyundai Heavy Industry Lee Jae Seong, Vice President of SK Hynix Park Sang Hoon, President of Samsung Display Kim Ki Nam, Director of Korea Research Institute of Standards and Science Kang Dae Lim, and President of Dawonsys Park Sun Soon.

Lee Jae Song (Department of Industrial and Systems Engineering, M.S. 3rd) has led Hyundai Heavy Industries through innovation and had contributed in the development of Korea and oversaw the growth of Hyundai Heavy Industries to number 1 in Shipbuilding.

Park Sang Hoon (Biological and Chemical Engineering, M.S. 5th) has led SK Hynix in the fields of energy, chemical and biological medicine and oversaw the development of world class R&D and production technologies to aid the development of Korea.

Kim Ki Nam (Electrical and Electronic Engineering, M.S. 9th) has led the development of innovative semiconductor technologies thereby helping strengthening the competitiveness of Korean semiconductor industry.

Kang Dae Lim (Mechanical Engineering, Ph.D. 1994 graduate) has helped in the development of Korean science and technology by leading the field of measurement standardization as Chairman of International Measurement Confederation and Chairman of Korea Association of Standards & Testing Organizations.

Park Sun Soon (Electrical and Electronic Engineering, M.S. 12th) has succeeded in advancing the field of electronics by pioneering the field of creative technology.

2013.01.22 View 10082

KAIST Alumni Association Selects 'Proud Alums'

KAIST Alumni Association selected ‘Proud Alums’ who have contributed to the development of Korea and society and brought honor to KAIST.

The Alums selected were: CEO of Hyundai Heavy Industry Lee Jae Seong, Vice President of SK Hynix Park Sang Hoon, President of Samsung Display Kim Ki Nam, Director of Korea Research Institute of Standards and Science Kang Dae Lim, and President of Dawonsys Park Sun Soon.

Lee Jae Song (Department of Industrial and Systems Engineering, M.S. 3rd) has led Hyundai Heavy Industries through innovation and had contributed in the development of Korea and oversaw the growth of Hyundai Heavy Industries to number 1 in Shipbuilding.

Park Sang Hoon (Biological and Chemical Engineering, M.S. 5th) has led SK Hynix in the fields of energy, chemical and biological medicine and oversaw the development of world class R&D and production technologies to aid the development of Korea.

Kim Ki Nam (Electrical and Electronic Engineering, M.S. 9th) has led the development of innovative semiconductor technologies thereby helping strengthening the competitiveness of Korean semiconductor industry.

Kang Dae Lim (Mechanical Engineering, Ph.D. 1994 graduate) has helped in the development of Korean science and technology by leading the field of measurement standardization as Chairman of International Measurement Confederation and Chairman of Korea Association of Standards & Testing Organizations.

Park Sun Soon (Electrical and Electronic Engineering, M.S. 12th) has succeeded in advancing the field of electronics by pioneering the field of creative technology.

2013.01.22 View 10082 -

KAIST Professors win 2012 Korea Engineering Award

Distinguished Professor Hwang Gyu Young (Department of Computer Science) and Professor Yang Dong Yol (Department of Mechanical Engineering) from KAIST received the 2012 ‘Korea Engineering Award’ hosted by the Ministry of Education, Science and Technology and the Korea Research Foundation.

The ‘Korea Engineering Award’ is given biennially to researchers who have accomplished world class research and have contributed greatly to Korea’s development in the field of Science and Technology. The award started in 1994 and a total of 24 recipients were recognized in various fields such as electronics, mechanics, chemistry, construction, etc. The recipients of the award areawarded the Presidential award as well as 50million won as prize money.

Professor Hwang was recognized for his research on DBMS close-coupling architecture as well as other new data base system theories, contributing to the development of the IT software industry in Korea. Professor Yang was praised for his work in precision shape creation and manufacturing, especially for his work in the nano-stereolithography process.

In addition, Professor Oum Sang-il from the Deparment of Mathematical Science received the 2012 ‘Young Scientist Award’ hosted by the Ministry of Education, Science and Technology and the Korean Academy of Science and Technology.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 21st of December.

2012.12.26 View 13409

KAIST Professors win 2012 Korea Engineering Award

Distinguished Professor Hwang Gyu Young (Department of Computer Science) and Professor Yang Dong Yol (Department of Mechanical Engineering) from KAIST received the 2012 ‘Korea Engineering Award’ hosted by the Ministry of Education, Science and Technology and the Korea Research Foundation.

The ‘Korea Engineering Award’ is given biennially to researchers who have accomplished world class research and have contributed greatly to Korea’s development in the field of Science and Technology. The award started in 1994 and a total of 24 recipients were recognized in various fields such as electronics, mechanics, chemistry, construction, etc. The recipients of the award areawarded the Presidential award as well as 50million won as prize money.

Professor Hwang was recognized for his research on DBMS close-coupling architecture as well as other new data base system theories, contributing to the development of the IT software industry in Korea. Professor Yang was praised for his work in precision shape creation and manufacturing, especially for his work in the nano-stereolithography process.

In addition, Professor Oum Sang-il from the Deparment of Mathematical Science received the 2012 ‘Young Scientist Award’ hosted by the Ministry of Education, Science and Technology and the Korean Academy of Science and Technology.

The ceremony for ‘Korea Engineering Award’ and the ‘Young Scientist Award’ was held in Seoul Press Center Press Club on the 21st of December.

2012.12.26 View 13409 -

Education 3.0: a change from teaching to learning

On October 16th, educationalists and Presidents from research-oriented universities around the world gathered in Seoul to attend the 2012 International Presidential Forum on Global Research Universities, where KAIST introduced its new smart learning model ‘Education 3.0’.

Smart learning ‘Education 3.0’ allows students to learn from lectures given by renowned scholars through the internet and encouraged student to professor discussion. This technology was created to deal with the ever-changing classroom dynamics due to the advancement of IT technology.‘Education 3.0’ differs from the traditional teaching-based lectures in that it offers a platform for self-directed learning. KAIST is working to spread ‘Education 3.0’ by providing specialized classrooms and running an online learning platform that complements it.

This spring, KAIST adopted ‘Education 3.0’ in 3 courses and received high praise from students (a rating of 4.4 out of 5.0). Hence, the number of courses was extended to 10 this fall.

Through this gathering, KAIST hopes to develop cooperative connections between foreign universities to share learning platforms and contents. On October 16th, KAIST signed a MOU with Denmark’s Danmarks Tekniske Universitet (DTU) to provide a cyber-dual degree program using ‘Education 3.0’. Hence, students studying Web science and Digital Media in either KAIST or DTU can receive degrees from both schools without physically visiting them.

President Suh said that “‘Education 3.0’ provides a new paradigm of learning which moves from the tradition cramming method of teaching to self-directed learning” and that this model will help the globalization of KAIST by initiating global cooperation with foreign universities.

Over 60 Universities from 27 different countries attended the forum, including ULCA and Caltech from the United States, DTU from Denmark, University of Southampton and University of York from England, University of Queensland from Australia, Nanyang Technological University from Singapore and Tokyo Institute of Technology from Japan. Members from Korean Universities such as Hanyang University, Handong Global University, Sogang University and Sookmyung Women"s University also attended.

2012.10.25 View 10850

Education 3.0: a change from teaching to learning

On October 16th, educationalists and Presidents from research-oriented universities around the world gathered in Seoul to attend the 2012 International Presidential Forum on Global Research Universities, where KAIST introduced its new smart learning model ‘Education 3.0’.

Smart learning ‘Education 3.0’ allows students to learn from lectures given by renowned scholars through the internet and encouraged student to professor discussion. This technology was created to deal with the ever-changing classroom dynamics due to the advancement of IT technology.‘Education 3.0’ differs from the traditional teaching-based lectures in that it offers a platform for self-directed learning. KAIST is working to spread ‘Education 3.0’ by providing specialized classrooms and running an online learning platform that complements it.

This spring, KAIST adopted ‘Education 3.0’ in 3 courses and received high praise from students (a rating of 4.4 out of 5.0). Hence, the number of courses was extended to 10 this fall.

Through this gathering, KAIST hopes to develop cooperative connections between foreign universities to share learning platforms and contents. On October 16th, KAIST signed a MOU with Denmark’s Danmarks Tekniske Universitet (DTU) to provide a cyber-dual degree program using ‘Education 3.0’. Hence, students studying Web science and Digital Media in either KAIST or DTU can receive degrees from both schools without physically visiting them.

President Suh said that “‘Education 3.0’ provides a new paradigm of learning which moves from the tradition cramming method of teaching to self-directed learning” and that this model will help the globalization of KAIST by initiating global cooperation with foreign universities.

Over 60 Universities from 27 different countries attended the forum, including ULCA and Caltech from the United States, DTU from Denmark, University of Southampton and University of York from England, University of Queensland from Australia, Nanyang Technological University from Singapore and Tokyo Institute of Technology from Japan. Members from Korean Universities such as Hanyang University, Handong Global University, Sogang University and Sookmyung Women"s University also attended.

2012.10.25 View 10850 -

2012 Intellectual Property Rights Award Ceremony Held

The 2012 Intellectual Property Rights Award Ceremony was held at Seoul KAIST Campus.

Recipients of the award included former congressmen Kim Young Sun and Lee Jeong Hyuk, and Kim Boo Kyung researcher at Electronics and Telecommunications Research Institute also representing Vooz Ltd. that created the character POOCA.

The Intellectual Property Rights Award is given to an individual or a group that succeeded in utilizing, protecting, creating, and establishment of its foundation including patent, copyright, and brand. Intellectual Property Rights is viewed as of importance for future national competitiveness.

The Award is organized by the Korea Patent Attorneys Association, the Korea Association of Intellectual Property Services, and KAIST and are respectively core institutions in the training of Intellectual Property Rights Experts and the creation, utilization, and the protection of intellectual property.

In addition the Award is also co-organized by the KAIST Graduate School of Intellectual Property Rights (established in cooperation with KAIST and the Korean Intellectual Property Office) and the total 20 million Won of prize money is funded by Korea Institute of Intellectual Strategy and Kim Ok Lan Foundation.

The Award Ceremony was held with a special lecture by the recipients.

It was stressed that the evaluation process was carried out with that the decision is a silent message to the society and is also a type of market signal.

Director Ko Gi Seok (Presidential Council on Intellectual Property) revealed that the candidates’ impact on the strength of national intellectual property rights was thoroughly scrutinized.

In the criteria of Creation of Intellectual Property, ETRI received the award in recognition of the institution’s successful patenting and commercializing of products of Korean R&D.

ETRI created a total of 251 International Patents in cooperation with ITU, ISO, IEE, etc. and also participated in a total of 9 International Standard Patent Pool, showing its active Intellectual Property management.

Such efforts ranked ETRI 1st in the United States Patent Evaluation performed by the US Patent Board in 2011 out of 237 institutions.

In addition Recipient of the Intellectual Property Utilization criteria, VOOZ ltd.’s Kim Boo Kyung promised the free use of their character POOCA in ETRI’s automated Korean-English translator. Researcher Kim Boo Kyung was rewarded with the award in recognition of his contribution to the domestic economy and realization of the commercialization of a copy right through licensing.

Former congressman Kim Young Son received an Award in the Foundation criteria in recognition of his efforts in the establishment of the Presidential Council on Intellectual Property and the Basic Blueprints for the Intellectual Property Law.

Former congressman Lee Jeong Hyuk received the same award in recognition of standardization and streamlining Intellectual Property Rights Policies. His realization and pursuit of the establishment of a balanced growth based on law for the competitiveness of businesses was the driving force behind his accomplishments.

2012.10.16 View 11524

2012 Intellectual Property Rights Award Ceremony Held

The 2012 Intellectual Property Rights Award Ceremony was held at Seoul KAIST Campus.

Recipients of the award included former congressmen Kim Young Sun and Lee Jeong Hyuk, and Kim Boo Kyung researcher at Electronics and Telecommunications Research Institute also representing Vooz Ltd. that created the character POOCA.

The Intellectual Property Rights Award is given to an individual or a group that succeeded in utilizing, protecting, creating, and establishment of its foundation including patent, copyright, and brand. Intellectual Property Rights is viewed as of importance for future national competitiveness.

The Award is organized by the Korea Patent Attorneys Association, the Korea Association of Intellectual Property Services, and KAIST and are respectively core institutions in the training of Intellectual Property Rights Experts and the creation, utilization, and the protection of intellectual property.

In addition the Award is also co-organized by the KAIST Graduate School of Intellectual Property Rights (established in cooperation with KAIST and the Korean Intellectual Property Office) and the total 20 million Won of prize money is funded by Korea Institute of Intellectual Strategy and Kim Ok Lan Foundation.

The Award Ceremony was held with a special lecture by the recipients.

It was stressed that the evaluation process was carried out with that the decision is a silent message to the society and is also a type of market signal.

Director Ko Gi Seok (Presidential Council on Intellectual Property) revealed that the candidates’ impact on the strength of national intellectual property rights was thoroughly scrutinized.

In the criteria of Creation of Intellectual Property, ETRI received the award in recognition of the institution’s successful patenting and commercializing of products of Korean R&D.

ETRI created a total of 251 International Patents in cooperation with ITU, ISO, IEE, etc. and also participated in a total of 9 International Standard Patent Pool, showing its active Intellectual Property management.

Such efforts ranked ETRI 1st in the United States Patent Evaluation performed by the US Patent Board in 2011 out of 237 institutions.

In addition Recipient of the Intellectual Property Utilization criteria, VOOZ ltd.’s Kim Boo Kyung promised the free use of their character POOCA in ETRI’s automated Korean-English translator. Researcher Kim Boo Kyung was rewarded with the award in recognition of his contribution to the domestic economy and realization of the commercialization of a copy right through licensing.

Former congressman Kim Young Son received an Award in the Foundation criteria in recognition of his efforts in the establishment of the Presidential Council on Intellectual Property and the Basic Blueprints for the Intellectual Property Law.

Former congressman Lee Jeong Hyuk received the same award in recognition of standardization and streamlining Intellectual Property Rights Policies. His realization and pursuit of the establishment of a balanced growth based on law for the competitiveness of businesses was the driving force behind his accomplishments.

2012.10.16 View 11524