Engineering

-

News Article on the Development of Synthesis Process for Graphene Quantum Dots

Before It's News, an international online news agency, highlighted the recent research conducted by KAIST professors (Seokwoo Jeon of the Department of Materials Science and Engineering, Yong-Hoon Cho of the Department of Physics, and Seunghyup Yoo of the Department of Electrical Engineering) on the development of synthesis process for graphene quantum dots, nanometer-sized round semiconductor nanoparticles that are very efficient at emitting photons. If commercialized, this synthetic technology will lead the way to the development of paper-thin displays in the future.

For the article, please go to the link below:

Before It’s News, September 3, 2014“Graphene quantum dots prove highly efficient in emitting light”

http://beforeitsnews.com/science-and-technology/2014/09/graphene-quantum-dots-prove-highly-efficient-in-emitting-light-2718190.html

2014.09.07 View 13998

News Article on the Development of Synthesis Process for Graphene Quantum Dots

Before It's News, an international online news agency, highlighted the recent research conducted by KAIST professors (Seokwoo Jeon of the Department of Materials Science and Engineering, Yong-Hoon Cho of the Department of Physics, and Seunghyup Yoo of the Department of Electrical Engineering) on the development of synthesis process for graphene quantum dots, nanometer-sized round semiconductor nanoparticles that are very efficient at emitting photons. If commercialized, this synthetic technology will lead the way to the development of paper-thin displays in the future.

For the article, please go to the link below:

Before It’s News, September 3, 2014“Graphene quantum dots prove highly efficient in emitting light”

http://beforeitsnews.com/science-and-technology/2014/09/graphene-quantum-dots-prove-highly-efficient-in-emitting-light-2718190.html

2014.09.07 View 13998 -

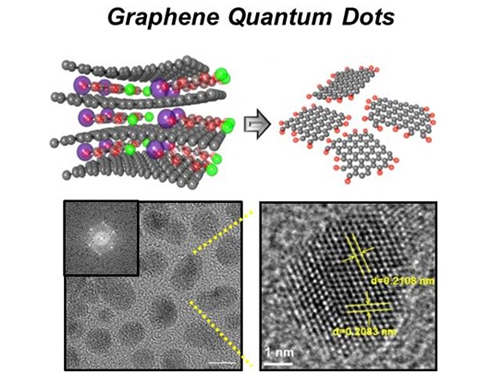

Extracting Light from Graphite: Core Technology of Graphene Quantum Dots Display Developed

Professor Seokwoo Jeon of the Department of Materials Science and Engineering, Professor Yong-Hoon Cho of the Department of Physics, and Professor Seunghyup Yoo of the Department of Electrical Engineering announced that they were able to develop topnotch graphene quantum dots from graphite.

Using the method of synthesizing graphite intercalation compound from graphite with salt and water, the research team developed graphene quantum dots in an ecofriendly way.

The quantum dots have a diameter of 5 nanometers with their sizes equal and yield high quantum efficiency. Unlike conventional quantum dots, they are not comprised of toxic materials such as lead or cadmium. As the quantum dots can be developed from materials which can be easily found in the nature, researchers look forward to putting these into mass production at low cost.

The research team also discovered a luminescence mechanism of graphene quantum dots and confirmed the possibility of commercial use by developing quantum dot light-emitting diodes with brightness of 1,000 cd/m2, which is greater than that of cellphone displays.

Professor Seokwoo Jeon said, “Although quantum dot LEDs have a lower luminous efficiency than existing ones, their luminescent property can be further improved” and emphasized that “using quantum dot displays will allow us to develop not only paper-thin displays but also flexible ones.”

Sponsored by Graphene Research Center in KAIST Institute for NanoCentury, the research finding was published online in the April 20th issue of Advanced Optical Materials.

Picture 1: Graphene quantum dots and their synthesis

Picture 2: Luminescence mechanism of graphene quantum dots

Picture 3: Structure of graphene quantum dots LED and its emission

2014.09.06 View 18433

Extracting Light from Graphite: Core Technology of Graphene Quantum Dots Display Developed

Professor Seokwoo Jeon of the Department of Materials Science and Engineering, Professor Yong-Hoon Cho of the Department of Physics, and Professor Seunghyup Yoo of the Department of Electrical Engineering announced that they were able to develop topnotch graphene quantum dots from graphite.

Using the method of synthesizing graphite intercalation compound from graphite with salt and water, the research team developed graphene quantum dots in an ecofriendly way.

The quantum dots have a diameter of 5 nanometers with their sizes equal and yield high quantum efficiency. Unlike conventional quantum dots, they are not comprised of toxic materials such as lead or cadmium. As the quantum dots can be developed from materials which can be easily found in the nature, researchers look forward to putting these into mass production at low cost.

The research team also discovered a luminescence mechanism of graphene quantum dots and confirmed the possibility of commercial use by developing quantum dot light-emitting diodes with brightness of 1,000 cd/m2, which is greater than that of cellphone displays.

Professor Seokwoo Jeon said, “Although quantum dot LEDs have a lower luminous efficiency than existing ones, their luminescent property can be further improved” and emphasized that “using quantum dot displays will allow us to develop not only paper-thin displays but also flexible ones.”

Sponsored by Graphene Research Center in KAIST Institute for NanoCentury, the research finding was published online in the April 20th issue of Advanced Optical Materials.

Picture 1: Graphene quantum dots and their synthesis

Picture 2: Luminescence mechanism of graphene quantum dots

Picture 3: Structure of graphene quantum dots LED and its emission

2014.09.06 View 18433 -

KAIST's Advanced Biomass R&D Center and ToolGen will cooperate

The Advanced Biomass R&D Center (ABC) at KAIST and ToolGen, Inc., a Korean biotechnology company focused on the development of engineered nucleases that can be used as essential tools for editing genetic information in microbial, plant, animal, and human cells, signed a memorandum of understanding (MOU) on August 18, 2014 for technology exchange and research collaboration.

ABC is headed by Executive Director Ji-Won Yang, a professor emeritus at the Department of Chemical and Biomolecular Engineering, and Chief Executive Officer Jong-Moon Kim for ToolGen.

The newly signed MOU encourages collaborations in the following areas:

- Development of genome editing technology for microalgae modification

- Development of microalgae that increases biofuel production through the

application of genome editing technology

- Creation of education and training programs for researchers

- Collaboration in other areas

In addition, the two organizations decided to cooperate in the improvement of biofuel yields using ToolGen’s genome editing technology, the commercialization of research outcomes, and the development of eco-friendly biofuels from biomass.

Executive Director Yang commented that “improving biofuel production is crucial to accelerate the commercialization of biofuels, and collaborating with ToolGen will help us realize that goal.” He further said that “The importance of this MOU lies in the fact that the global chemical industry including Korea has been making substantial efforts to shift its attention from a fossil fuel-based development to a more bio-based technology.”

Jin-Soo Kim, the director of the Genome Editing Research Center at the Institute of Basic Sciences in Korea and the cofounder of ToolGen, added that “ToolGen has successfully commercialized its third generation genetic scissors, which shows a lot of promise for commercialization. Our collaboration with KAIST will serve as the driving force to create new industries and accordingly, new jobs.”

2014.09.03 View 11152

KAIST's Advanced Biomass R&D Center and ToolGen will cooperate

The Advanced Biomass R&D Center (ABC) at KAIST and ToolGen, Inc., a Korean biotechnology company focused on the development of engineered nucleases that can be used as essential tools for editing genetic information in microbial, plant, animal, and human cells, signed a memorandum of understanding (MOU) on August 18, 2014 for technology exchange and research collaboration.

ABC is headed by Executive Director Ji-Won Yang, a professor emeritus at the Department of Chemical and Biomolecular Engineering, and Chief Executive Officer Jong-Moon Kim for ToolGen.

The newly signed MOU encourages collaborations in the following areas:

- Development of genome editing technology for microalgae modification

- Development of microalgae that increases biofuel production through the

application of genome editing technology

- Creation of education and training programs for researchers

- Collaboration in other areas

In addition, the two organizations decided to cooperate in the improvement of biofuel yields using ToolGen’s genome editing technology, the commercialization of research outcomes, and the development of eco-friendly biofuels from biomass.

Executive Director Yang commented that “improving biofuel production is crucial to accelerate the commercialization of biofuels, and collaborating with ToolGen will help us realize that goal.” He further said that “The importance of this MOU lies in the fact that the global chemical industry including Korea has been making substantial efforts to shift its attention from a fossil fuel-based development to a more bio-based technology.”

Jin-Soo Kim, the director of the Genome Editing Research Center at the Institute of Basic Sciences in Korea and the cofounder of ToolGen, added that “ToolGen has successfully commercialized its third generation genetic scissors, which shows a lot of promise for commercialization. Our collaboration with KAIST will serve as the driving force to create new industries and accordingly, new jobs.”

2014.09.03 View 11152 -

2014 NEREC Conference on Nuclear Nonproliferation: July 31-August 1, 2014, Seoul

The Nonproliferation Education and Research Center (NEREC) at KAIST hosted an international conference on nuclear nonproliferation on July 31-August 1, 2014 in Seoul. The Ministry of Science, ICT and Future Planning, the Korean Nuclear Safety and Security Commission, and the Korea Nuclear Policy Society (KNPS) sponsored the event.

Over one hundred experts and "thought leaders" in nuclear security and nonproliferation attended the conference and discussed issues related to the nonproliferation of nuclear weapons, the role of scientific community in mitigating nuclear threat and promoting the peaceful use of nuclear power, and nuclear disarmament policy.

Keynote speakers were: Steven E. Miller, Director of International Security Program at Belfer Center for Science and International Affairs, Harvard University; Scott D. Sagan, Senior Fellow of the Center for International Security and Cooperation, Freeman Spogli Institute for International Studies, Stanford University; Mark Fitzpatrick, Director of the Nonproliferation and Disarmament Programme, International Institute for Strategic Studies; Sang-Hyun Lee, Director of Security Strategy, Sejong Institute; and Man-Sung Yim, Professor of Nuclear and Quantum Engineering, KAIST.

At the conference, Professor Yim, Director of KAIST NEREC said, “Korea has grown to become a key player in the development of commercial nuclear energy over the past decades. We hope that our conference encourages Korea to be more involved in the efforts of the international community to enhance the global nonproliferation regime.”

2014.08.05 View 14703

2014 NEREC Conference on Nuclear Nonproliferation: July 31-August 1, 2014, Seoul

The Nonproliferation Education and Research Center (NEREC) at KAIST hosted an international conference on nuclear nonproliferation on July 31-August 1, 2014 in Seoul. The Ministry of Science, ICT and Future Planning, the Korean Nuclear Safety and Security Commission, and the Korea Nuclear Policy Society (KNPS) sponsored the event.

Over one hundred experts and "thought leaders" in nuclear security and nonproliferation attended the conference and discussed issues related to the nonproliferation of nuclear weapons, the role of scientific community in mitigating nuclear threat and promoting the peaceful use of nuclear power, and nuclear disarmament policy.

Keynote speakers were: Steven E. Miller, Director of International Security Program at Belfer Center for Science and International Affairs, Harvard University; Scott D. Sagan, Senior Fellow of the Center for International Security and Cooperation, Freeman Spogli Institute for International Studies, Stanford University; Mark Fitzpatrick, Director of the Nonproliferation and Disarmament Programme, International Institute for Strategic Studies; Sang-Hyun Lee, Director of Security Strategy, Sejong Institute; and Man-Sung Yim, Professor of Nuclear and Quantum Engineering, KAIST.

At the conference, Professor Yim, Director of KAIST NEREC said, “Korea has grown to become a key player in the development of commercial nuclear energy over the past decades. We hope that our conference encourages Korea to be more involved in the efforts of the international community to enhance the global nonproliferation regime.”

2014.08.05 View 14703 -

A KAIST startup, YBrain, builds a wearable device to cure Alzheimer's

A group of KAIST graduates from the Departments of Bio and Brain Engineering, Computer Science, Materials Science Engineering, and Industrial Design created a startup called YBrain (http://ybrain.com/). YBrain develops a wearable neuroscience technology to treat or reduce the symptoms of degenerative brain diseases such as dementia and Alzheimer’s. Their recent technological developments were covered in e27, one of the leading blogs based in Singapore. The blog covers topics like the latest technology innovation, startups, and entrepreneurship in Asia. A news article follows below:

e27, June 24, 2014

“This wearable tech may be able to combat effects of Alzheimer’s”

http://e27.co/this-wearable-tech-may-be-able-combat-effects-of-alzheimers-20140624/

2014.06.25 View 12727

A KAIST startup, YBrain, builds a wearable device to cure Alzheimer's

A group of KAIST graduates from the Departments of Bio and Brain Engineering, Computer Science, Materials Science Engineering, and Industrial Design created a startup called YBrain (http://ybrain.com/). YBrain develops a wearable neuroscience technology to treat or reduce the symptoms of degenerative brain diseases such as dementia and Alzheimer’s. Their recent technological developments were covered in e27, one of the leading blogs based in Singapore. The blog covers topics like the latest technology innovation, startups, and entrepreneurship in Asia. A news article follows below:

e27, June 24, 2014

“This wearable tech may be able to combat effects of Alzheimer’s”

http://e27.co/this-wearable-tech-may-be-able-combat-effects-of-alzheimers-20140624/

2014.06.25 View 12727 -

Professor Sung Yong Kim Appointed as Committee Member to Serve PICES

The Pacific International Council for the Exploration of the Sea: North Pacific Marine Science Organization (PICES) is an intergovernmental organization, which was established in 1992 to promote and coordinate marine research in the North Pacific and adjacent areas. Currently, the United States, Canada, Japan, China, Russia, and Korea are members of the organization.

Professor Sung Yong Kim of Ocean Systems Engineering, KAIST, has been appointed to serve the Scientific and Technical Committees of PICES. He will begin his stint from July 1, 2014. During his assignment, Professor Kim will identify the need for observation of the North Pacific marine environment, develop observation methodology, and publish an annual report on the observation.

Professor Kim is an expert in marine physics and environmental fluids, with a focus on coastal circulation and dynamics, mesoscale and submesoscale eddies, integrated coastal ocean observing system, and statistical and dynamic data analysis.

2014.06.18 View 9287

Professor Sung Yong Kim Appointed as Committee Member to Serve PICES

The Pacific International Council for the Exploration of the Sea: North Pacific Marine Science Organization (PICES) is an intergovernmental organization, which was established in 1992 to promote and coordinate marine research in the North Pacific and adjacent areas. Currently, the United States, Canada, Japan, China, Russia, and Korea are members of the organization.

Professor Sung Yong Kim of Ocean Systems Engineering, KAIST, has been appointed to serve the Scientific and Technical Committees of PICES. He will begin his stint from July 1, 2014. During his assignment, Professor Kim will identify the need for observation of the North Pacific marine environment, develop observation methodology, and publish an annual report on the observation.

Professor Kim is an expert in marine physics and environmental fluids, with a focus on coastal circulation and dynamics, mesoscale and submesoscale eddies, integrated coastal ocean observing system, and statistical and dynamic data analysis.

2014.06.18 View 9287 -

Professor Ki Jun Jeong Selected As the Winner of the 'Young Asian Biotechnologist Prize'

Professor Ki Jun Jeong from the Department of Chemical and Biomolecular Engineering, KAIST, has been selected as the winner of this year’s Young Asian Biotechnologist Prize.

Professor Jeong was invited to the 66th Japan Biotechnology and Bioengineering Society Conference scheduled in September 9th-11th, 2014, in Sapporo, Japan, where his award ceremony will be held.

The award is presented to Professor Jeong in recognition of his outstanding research on microbial-based production of antibodies and efficiency improvement.

The Young Asian Biotechnologist Prize is awarded annually by the Japan Biotechnology and Bioengineering Society to the researchers in Asia under the age of 45, who have achieved excellent research results in the field of bioengineering.

2014.06.14 View 10053

Professor Ki Jun Jeong Selected As the Winner of the 'Young Asian Biotechnologist Prize'

Professor Ki Jun Jeong from the Department of Chemical and Biomolecular Engineering, KAIST, has been selected as the winner of this year’s Young Asian Biotechnologist Prize.

Professor Jeong was invited to the 66th Japan Biotechnology and Bioengineering Society Conference scheduled in September 9th-11th, 2014, in Sapporo, Japan, where his award ceremony will be held.

The award is presented to Professor Jeong in recognition of his outstanding research on microbial-based production of antibodies and efficiency improvement.

The Young Asian Biotechnologist Prize is awarded annually by the Japan Biotechnology and Bioengineering Society to the researchers in Asia under the age of 45, who have achieved excellent research results in the field of bioengineering.

2014.06.14 View 10053 -

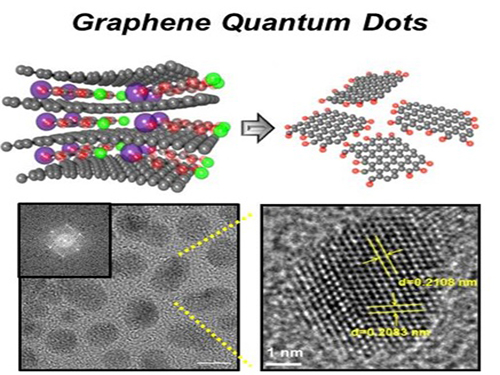

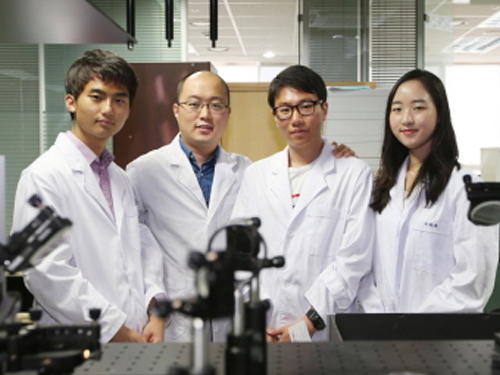

Professor YongKeun Park Produces Undergraduate Students with International Achievements

Three undergraduate students under the supervision of Professor YongKeun Park from the Department of Physics, KAIST, have published papers in globally renowned academic journals.

The most recent publication was made by YoungJu Jo, a senior in physics. Jo’s paper entitled “Angle-resolved light scattering of individual rod-shaped bacteria based on Fourier transform light scattering” was published in the May 28th edition of Scientific Reports.

Analyzing bacteria is a very important task in the field of health and food hygiene, but using the conventional biochemical methods of analysis takes days. However, observation with Jo’s newly developed method using light scattering analyzes bacteria within a matter of seconds.

SangYeon Cho from the Department of Chemistry also published papers in Cell (2012) and Nature (2013), respectively, under the guidance of Professor Park. SangYeon Cho’s outstanding research achievements were recognized by Harvard and MIT. He was accepted with a full scholarship to Harvard-MIT Health Sciences and Technology Graduate School. He will begin his graduate studies at Harvard-MIT this September.

Last March, SeoEun Lee from the Department of Biology was the recipient of the Best Paper Award by the Optical Society of Korea. She plans to pursue a doctoral degree at the College of Physicians and Surgeons, Columbia University in New York.

Professor Park said, “Undergraduate students, who are learning a variety of subjects concurrently, are at the most creative time of their lives. KAIST has offered many opportunities to undergraduate students to partake in various research programs.”

- Picture (a) and (b): Rod-shaped bacteria’s phase image and light-scattering patterns

- Picture (c): Quantitative analysis to illustrate the extraction of information from bacteria

2014.06.03 View 13681

Professor YongKeun Park Produces Undergraduate Students with International Achievements

Three undergraduate students under the supervision of Professor YongKeun Park from the Department of Physics, KAIST, have published papers in globally renowned academic journals.

The most recent publication was made by YoungJu Jo, a senior in physics. Jo’s paper entitled “Angle-resolved light scattering of individual rod-shaped bacteria based on Fourier transform light scattering” was published in the May 28th edition of Scientific Reports.

Analyzing bacteria is a very important task in the field of health and food hygiene, but using the conventional biochemical methods of analysis takes days. However, observation with Jo’s newly developed method using light scattering analyzes bacteria within a matter of seconds.

SangYeon Cho from the Department of Chemistry also published papers in Cell (2012) and Nature (2013), respectively, under the guidance of Professor Park. SangYeon Cho’s outstanding research achievements were recognized by Harvard and MIT. He was accepted with a full scholarship to Harvard-MIT Health Sciences and Technology Graduate School. He will begin his graduate studies at Harvard-MIT this September.

Last March, SeoEun Lee from the Department of Biology was the recipient of the Best Paper Award by the Optical Society of Korea. She plans to pursue a doctoral degree at the College of Physicians and Surgeons, Columbia University in New York.

Professor Park said, “Undergraduate students, who are learning a variety of subjects concurrently, are at the most creative time of their lives. KAIST has offered many opportunities to undergraduate students to partake in various research programs.”

- Picture (a) and (b): Rod-shaped bacteria’s phase image and light-scattering patterns

- Picture (c): Quantitative analysis to illustrate the extraction of information from bacteria

2014.06.03 View 13681 -

Professor Sang-Yup Lee Named the Winner of the Ho-Am Prize in 2014

The Ho-Am Prize, awarded by Samsung Group’s Ho-Am Foundation, was announced on April 2, 2014 in Seoul. Professor Sang-Yup Lee of Chemical and Biomolecular Engineering at KAIST was among the five recipients.

The prize is presented to Koreans who have made great contributions to the development of Korea in the field of science, engineering, medicine, arts, and philanthropy.

Professor Lee received the award in recognition of his pioneering research on systems metabolic engineering.

For the story written by Korea Joongang Daily, please go to the link below:

Ho-Am Foundation Names Annual Prize Winners

Korea Joongang Daily

April 3, 2014

http://koreajoongangdaily.joins.com/news/article/Article.aspx?aid=2987332

2014.04.03 View 10462

Professor Sang-Yup Lee Named the Winner of the Ho-Am Prize in 2014

The Ho-Am Prize, awarded by Samsung Group’s Ho-Am Foundation, was announced on April 2, 2014 in Seoul. Professor Sang-Yup Lee of Chemical and Biomolecular Engineering at KAIST was among the five recipients.

The prize is presented to Koreans who have made great contributions to the development of Korea in the field of science, engineering, medicine, arts, and philanthropy.

Professor Lee received the award in recognition of his pioneering research on systems metabolic engineering.

For the story written by Korea Joongang Daily, please go to the link below:

Ho-Am Foundation Names Annual Prize Winners

Korea Joongang Daily

April 3, 2014

http://koreajoongangdaily.joins.com/news/article/Article.aspx?aid=2987332

2014.04.03 View 10462 -

Tae-Wan Kim, a doctoral candidate, receives the best paper award from ECTC

The 2014 Electronic Components and Technology Conference (ECTC) will take place on May 27-30 in Florida, USA. Tae-Wan Kim, a Ph.D. candidate at the Department of Materials Science Engineering (MSE), KAIST, will receive the Intel Best Student Paper Award at the conference.ECTC is the premier international conference that brings together the best researchers and engineers in packaging, components and microelectronic systems science, technology and education in an environment of cooperation and technical exchange. The conference is sponsored by the Components, Packaging and Manufacturing Technology (CPMT) Society of IEEE (Institute of Electrical and Electronics Engineering).The paper describes research on novel nanofiber anisotropic conductive films for ultra fine pitch electronic package application, which was written under the guidance of Professor Kyung-Wook Paik of the MSE Department. In the past ten years, two of his students have received the best paper award from ECTC.

2014.03.14 View 12156

Tae-Wan Kim, a doctoral candidate, receives the best paper award from ECTC

The 2014 Electronic Components and Technology Conference (ECTC) will take place on May 27-30 in Florida, USA. Tae-Wan Kim, a Ph.D. candidate at the Department of Materials Science Engineering (MSE), KAIST, will receive the Intel Best Student Paper Award at the conference.ECTC is the premier international conference that brings together the best researchers and engineers in packaging, components and microelectronic systems science, technology and education in an environment of cooperation and technical exchange. The conference is sponsored by the Components, Packaging and Manufacturing Technology (CPMT) Society of IEEE (Institute of Electrical and Electronics Engineering).The paper describes research on novel nanofiber anisotropic conductive films for ultra fine pitch electronic package application, which was written under the guidance of Professor Kyung-Wook Paik of the MSE Department. In the past ten years, two of his students have received the best paper award from ECTC.

2014.03.14 View 12156 -

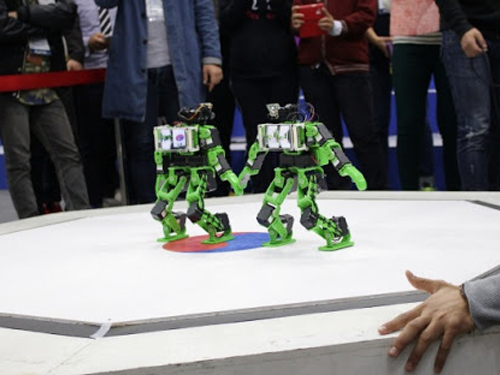

KAIST Holds the 2014 System on Chip (SoC) Robot War in August and October

Domestic and international competitions for robots with artificial intelligence are organized by Professor Hoi-Jun Yoo of Electrical Engineering.

KAIST will host two robot competitions this year: The Robot Integration Festival will be held in August at the Convention Center in Daejeon and the International Robot Contest in October at the Kintex in Ilsan. Participating robots are developed based on the System on Chip (SoC).

SoC robots refer to an autonomous robot that has a processor, a memory, peripheral devices, logic, and other system components combined on a single chip, which enables the robots to handle tasks and make decisions without human intervention.

The competitions include three entries: Taekwon Robot, HURO-competition, and SoC Drone which was added for the first time this year.

The Taekwon Robot involves a one-on-one sparring match, using a Korean traditional martial art, between two robots. Competitors score points based on front and side kicks, as well as punching. The HURO-competition pits robots in a competition to perform assignments such as hurdling, barricade clearing, crossing bridges, and overcoming other obstacles. The SoC Drone evaluates robots' capability to track miniature cars and navigate between buildings while in flight. The drone should have two cameras and a SoC brainboard equipped to offer autonomous, remote-controlled flight.

The director of the competitions, Professor Hoi-Jun Yoo of Electrical Engineering at KAIST, commented that with the integration of Korea’s world-class semiconductor technology, the competitions would lead to improvements in robotics engineering and unmanned aerial vehicle technology.

The competitions are open to anyone interested in SoC robots and unmanned aerial vehicles. For more information about the competitions, please visit http://www.socrobotwar.org . The application deadline is April 15, 2014.

2014.03.11 View 11095

KAIST Holds the 2014 System on Chip (SoC) Robot War in August and October

Domestic and international competitions for robots with artificial intelligence are organized by Professor Hoi-Jun Yoo of Electrical Engineering.

KAIST will host two robot competitions this year: The Robot Integration Festival will be held in August at the Convention Center in Daejeon and the International Robot Contest in October at the Kintex in Ilsan. Participating robots are developed based on the System on Chip (SoC).

SoC robots refer to an autonomous robot that has a processor, a memory, peripheral devices, logic, and other system components combined on a single chip, which enables the robots to handle tasks and make decisions without human intervention.

The competitions include three entries: Taekwon Robot, HURO-competition, and SoC Drone which was added for the first time this year.

The Taekwon Robot involves a one-on-one sparring match, using a Korean traditional martial art, between two robots. Competitors score points based on front and side kicks, as well as punching. The HURO-competition pits robots in a competition to perform assignments such as hurdling, barricade clearing, crossing bridges, and overcoming other obstacles. The SoC Drone evaluates robots' capability to track miniature cars and navigate between buildings while in flight. The drone should have two cameras and a SoC brainboard equipped to offer autonomous, remote-controlled flight.

The director of the competitions, Professor Hoi-Jun Yoo of Electrical Engineering at KAIST, commented that with the integration of Korea’s world-class semiconductor technology, the competitions would lead to improvements in robotics engineering and unmanned aerial vehicle technology.

The competitions are open to anyone interested in SoC robots and unmanned aerial vehicles. For more information about the competitions, please visit http://www.socrobotwar.org . The application deadline is April 15, 2014.

2014.03.11 View 11095 -

Book Announcement: Sound Visualization and Manipulation

The movie

Gravity

won seven Oscar awards this year, one of which was for its outstanding 3D sound mixing, immersing viewers in the full experience of the troubled space expedition.

3D audio effects are generated by manipulating the sound produced by speakers, speaker-arrays, or headphones to place a virtual sound source at a desired location in 3D space such as behind, above, or below the listener's head.

Two professors from the Department of Mechanical Engineering at KAIST have recently published a book that explains two important technologies related to 3D sound effects: sound visualization and manipulation.

Professor Yang-Hann Kim, an eminent scholar in sound engineering, and Professor Jung-Woo Choi collaborated to write Sound Visualization and Manipulation (Wily 2013), which uniquely addresses the two most important problems in the field in a unified way.

The book introduces general concepts and theories and describes a number of techniques in sound visualization and manipulation, offering an interrelated approach to two very different topics: sound field visualization techniques based on microphone arrays and controlled sound field generation techniques using loudspeaker arrays.

The authors also display a solid understanding of the associated physical and mathematical concepts applied to solve the visualization and manipulation problems and provide extensive examples demonstrating the benefits and drawbacks of various applications, including beamforming and acoustic holography technology.

The book will be an excellent reference for graduate students, researchers, and professionals in acoustic engineering, as well as in audio and noise control system development.

For detailed descriptions of the book:

http://as.wiley.com/WileyCDA/WileyTitle/productCd-1118368479.html

2014.03.10 View 14073

Book Announcement: Sound Visualization and Manipulation

The movie

Gravity

won seven Oscar awards this year, one of which was for its outstanding 3D sound mixing, immersing viewers in the full experience of the troubled space expedition.

3D audio effects are generated by manipulating the sound produced by speakers, speaker-arrays, or headphones to place a virtual sound source at a desired location in 3D space such as behind, above, or below the listener's head.

Two professors from the Department of Mechanical Engineering at KAIST have recently published a book that explains two important technologies related to 3D sound effects: sound visualization and manipulation.

Professor Yang-Hann Kim, an eminent scholar in sound engineering, and Professor Jung-Woo Choi collaborated to write Sound Visualization and Manipulation (Wily 2013), which uniquely addresses the two most important problems in the field in a unified way.

The book introduces general concepts and theories and describes a number of techniques in sound visualization and manipulation, offering an interrelated approach to two very different topics: sound field visualization techniques based on microphone arrays and controlled sound field generation techniques using loudspeaker arrays.

The authors also display a solid understanding of the associated physical and mathematical concepts applied to solve the visualization and manipulation problems and provide extensive examples demonstrating the benefits and drawbacks of various applications, including beamforming and acoustic holography technology.

The book will be an excellent reference for graduate students, researchers, and professionals in acoustic engineering, as well as in audio and noise control system development.

For detailed descriptions of the book:

http://as.wiley.com/WileyCDA/WileyTitle/productCd-1118368479.html

2014.03.10 View 14073