MCM

-

MCM Utilized at Residential Treatment Center in Gyeonggi

The Mobile Clinic Module (MCM) developed by the KAIST Action for Respiratory Epidemics was installed at special residential treatment center in Gyeonggi Province on September 13.

The MCM is an isolate negative pressure unit fitted with high-quality medical equipment, developed by Professor Taek-Jin Nam of the Department of Industrial Design under the KAIST New Deal R&D Initiative. This is also a part of the Korean Disease Control Package Development Project from last July.

In January, a ward with four beds for critical care was installed at the Korea Institute for Radiological & Medical Sciences in Seoul for a trial operation, and two mild cases were treated there. It was also implemented as an isolated negative pressure unit in the Daejeon Konyang University Hospital emergency room in June, and has treated 138 cases since.

The special residential treatment center installed in the Gyeonggi Provincial Academy gymnasium, which consists of 28 beds in 14 rooms (double occupancy) and a multipurpose room (for X-rays and treatment), is to remain open through October 10. Unlike existing treatment centers that have quarantined COVID-19 patients for two weeks, the Gyeonggi MCM will act as a self-treatment-associated short-term treatment center. While in self-treatment, patients showing symptoms requiring special attention will be moved to the MCM, followed by short-term hospitalization of 1-3 days for observation before further measures are taken.

Patients can be treated using the MCM’s own treatment capacities, including in-person and oxygen treatment, X-rays, and IVs. There are individual bathrooms in each room, and the pressure, ventilation, and the automatic opening and closing of the entrance can be centrally monitored and controlled. Patients showing symptoms during treatment will be moved to a specially designated hospital for critical care, and will return to the self-treatment center if no further abnormalities are reported.

The Gyeonggi Provincial Medical Center’s Ansung Hospital will take charge of operating the special treatment center. Each day, one or two doctors, three nurses, two nursing assistants, one administrative staff member, two or three disinfection specialists, and a medical imaging engineer will work in three shifts. There will also be about 20 additional specially designated staff members including KAIST researchers, firefighters, and police officers.

The MCM was internationally recognized as an excellent medical facility not only for its functionality, economic feasibility, and utility, but also for its unique design and aesthetics. It received two Best of Best awards at the Red Dot Award in product design and Communication Design in user interface.

By running this special treatment center, KAIST will conduct research on how to build an optimized model for efficient negative pressure medical units. This research is expected to lead to advances in waste water treatment systems, mobile bathrooms optimized for infectious cases, and MCM user interfaces for electronic devices, etc.

Professor Taek-Jin Nam, the general director of the project and design, said “if there is a gymnasium available, we can convert it into a special treatment center fitted with a waste water treatment system, and pressure equipment in two weeks even without additional infrastructure.”

The head of the KAIST New Deal R&D Initiative Choongsik Bae said, “our MCM research started in July of last year, and in just over a year, it has become a successful and innovative case that has undergone trials and become commercialized in a short period of time.” He added, “In response to COVID-19, KAIST is conducting research and empirical studies, not just in relation to the MCM, but in other areas of disease control as well.”

Based on the excellent disease control technologies developed by KAIST research teams, the KAIST Action for Respiratory Epidemics is conducting technology transfers and industrialization, and is developing a Korean disease control package model

2021.09.15 View 11384

MCM Utilized at Residential Treatment Center in Gyeonggi

The Mobile Clinic Module (MCM) developed by the KAIST Action for Respiratory Epidemics was installed at special residential treatment center in Gyeonggi Province on September 13.

The MCM is an isolate negative pressure unit fitted with high-quality medical equipment, developed by Professor Taek-Jin Nam of the Department of Industrial Design under the KAIST New Deal R&D Initiative. This is also a part of the Korean Disease Control Package Development Project from last July.

In January, a ward with four beds for critical care was installed at the Korea Institute for Radiological & Medical Sciences in Seoul for a trial operation, and two mild cases were treated there. It was also implemented as an isolated negative pressure unit in the Daejeon Konyang University Hospital emergency room in June, and has treated 138 cases since.

The special residential treatment center installed in the Gyeonggi Provincial Academy gymnasium, which consists of 28 beds in 14 rooms (double occupancy) and a multipurpose room (for X-rays and treatment), is to remain open through October 10. Unlike existing treatment centers that have quarantined COVID-19 patients for two weeks, the Gyeonggi MCM will act as a self-treatment-associated short-term treatment center. While in self-treatment, patients showing symptoms requiring special attention will be moved to the MCM, followed by short-term hospitalization of 1-3 days for observation before further measures are taken.

Patients can be treated using the MCM’s own treatment capacities, including in-person and oxygen treatment, X-rays, and IVs. There are individual bathrooms in each room, and the pressure, ventilation, and the automatic opening and closing of the entrance can be centrally monitored and controlled. Patients showing symptoms during treatment will be moved to a specially designated hospital for critical care, and will return to the self-treatment center if no further abnormalities are reported.

The Gyeonggi Provincial Medical Center’s Ansung Hospital will take charge of operating the special treatment center. Each day, one or two doctors, three nurses, two nursing assistants, one administrative staff member, two or three disinfection specialists, and a medical imaging engineer will work in three shifts. There will also be about 20 additional specially designated staff members including KAIST researchers, firefighters, and police officers.

The MCM was internationally recognized as an excellent medical facility not only for its functionality, economic feasibility, and utility, but also for its unique design and aesthetics. It received two Best of Best awards at the Red Dot Award in product design and Communication Design in user interface.

By running this special treatment center, KAIST will conduct research on how to build an optimized model for efficient negative pressure medical units. This research is expected to lead to advances in waste water treatment systems, mobile bathrooms optimized for infectious cases, and MCM user interfaces for electronic devices, etc.

Professor Taek-Jin Nam, the general director of the project and design, said “if there is a gymnasium available, we can convert it into a special treatment center fitted with a waste water treatment system, and pressure equipment in two weeks even without additional infrastructure.”

The head of the KAIST New Deal R&D Initiative Choongsik Bae said, “our MCM research started in July of last year, and in just over a year, it has become a successful and innovative case that has undergone trials and become commercialized in a short period of time.” He added, “In response to COVID-19, KAIST is conducting research and empirical studies, not just in relation to the MCM, but in other areas of disease control as well.”

Based on the excellent disease control technologies developed by KAIST research teams, the KAIST Action for Respiratory Epidemics is conducting technology transfers and industrialization, and is developing a Korean disease control package model

2021.09.15 View 11384 -

Research Day Highlights the Most Impactful Technologies of the Year

Technology Converting Full HD Image to 4-Times Higher UHD Via Deep Learning Cited as the Research of the Year

The technology converting a full HD image into a four-times higher UHD image in real time via AI deep learning was recognized as the Research of the Year. Professor Munchurl Kim from the School of Electrical Engineering who developed the technology won the Research of the Year Grand Prize during the 2021 KAIST Research Day ceremony on May 25. Professor Kim was lauded for conducting creative research on machine learning and deep learning-based image processing.

KAIST’s Research Day recognizes the most notable research outcomes of the year, while creating opportunities for researchers to immerse themselves into interdisciplinary research projects with their peers. The ceremony was broadcast online due to Covid-19 and announced the Ten R&D Achievement of the Year that are expected to make a significant impact.

To celebrate the award, Professor Kim gave a lecture on “Computational Imaging through Deep Learning for the Acquisition of High-Quality Images.” Focusing on the fact that advancements in artificial intelligence technology can show superior performance when used to convert low-quality videos to higher quality, he introduced some of the AI technologies that are currently being applied in the field of image restoration and quality improvement.

Professors Eui-Cheol Shin from the Graduate School of Medical Science and Engineering and In-Cheol Park from the School of Electrical Engineering each received Research Awards, and Professor Junyong Noh from the Graduate School of Culture Technology was selected for the Innovation Award. Professors Dong Ki Yoon from the Department of Chemistry and Hyungki Kim from the Department of Mechanical Engineering were awarded the Interdisciplinary Award as a team for their joint research.

Meanwhile, out of KAIST’s ten most notable R&D achievements, those from the field of natural and biological sciences included research on rare earth element-platinum nanoparticle catalysts by Professor Ryong Ryoo from the Department of Chemistry, real-time observations of the locational changes in all of the atoms in a molecule by Professor Hyotcherl Ihee from the Department of Chemistry, and an investigation on memory retention mechanisms after synapse removal from an astrocyte by Professor Won-Suk Chung from the Department of Biological Sciences.

Awardees from the engineering field were a wearable robot for paraplegics with the world’s best functionality and walking speed by Professor Kyoungchul Kong from the Department of Mechanical Engineering, fair machine learning by Professor Changho Suh from the School of Electrical Engineering, and a generative adversarial networks processing unit (GANPU), an AI semiconductor that can learn from even mobiles by processing multiple and deep networks by Professor Hoi-Jun Yoo from the School of Electrical Engineering.

Others selected as part of the ten research studies were the development of epigenetic reprogramming technology in tumour by Professor Pilnam Kim from the Department of Bio and Brain Engineering, the development of an original technology for reverse cell aging by Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, a heterogeneous metal element catalyst for atmospheric purification by Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering, and the Mobile Clinic Module (MCM): a negative pressure ward for epidemic hospitals by Professor Taek-jin Nam (reported at the Wall Street Journal) from the Department of Industrial Design.

2021.05.31 View 15300

Research Day Highlights the Most Impactful Technologies of the Year

Technology Converting Full HD Image to 4-Times Higher UHD Via Deep Learning Cited as the Research of the Year

The technology converting a full HD image into a four-times higher UHD image in real time via AI deep learning was recognized as the Research of the Year. Professor Munchurl Kim from the School of Electrical Engineering who developed the technology won the Research of the Year Grand Prize during the 2021 KAIST Research Day ceremony on May 25. Professor Kim was lauded for conducting creative research on machine learning and deep learning-based image processing.

KAIST’s Research Day recognizes the most notable research outcomes of the year, while creating opportunities for researchers to immerse themselves into interdisciplinary research projects with their peers. The ceremony was broadcast online due to Covid-19 and announced the Ten R&D Achievement of the Year that are expected to make a significant impact.

To celebrate the award, Professor Kim gave a lecture on “Computational Imaging through Deep Learning for the Acquisition of High-Quality Images.” Focusing on the fact that advancements in artificial intelligence technology can show superior performance when used to convert low-quality videos to higher quality, he introduced some of the AI technologies that are currently being applied in the field of image restoration and quality improvement.

Professors Eui-Cheol Shin from the Graduate School of Medical Science and Engineering and In-Cheol Park from the School of Electrical Engineering each received Research Awards, and Professor Junyong Noh from the Graduate School of Culture Technology was selected for the Innovation Award. Professors Dong Ki Yoon from the Department of Chemistry and Hyungki Kim from the Department of Mechanical Engineering were awarded the Interdisciplinary Award as a team for their joint research.

Meanwhile, out of KAIST’s ten most notable R&D achievements, those from the field of natural and biological sciences included research on rare earth element-platinum nanoparticle catalysts by Professor Ryong Ryoo from the Department of Chemistry, real-time observations of the locational changes in all of the atoms in a molecule by Professor Hyotcherl Ihee from the Department of Chemistry, and an investigation on memory retention mechanisms after synapse removal from an astrocyte by Professor Won-Suk Chung from the Department of Biological Sciences.

Awardees from the engineering field were a wearable robot for paraplegics with the world’s best functionality and walking speed by Professor Kyoungchul Kong from the Department of Mechanical Engineering, fair machine learning by Professor Changho Suh from the School of Electrical Engineering, and a generative adversarial networks processing unit (GANPU), an AI semiconductor that can learn from even mobiles by processing multiple and deep networks by Professor Hoi-Jun Yoo from the School of Electrical Engineering.

Others selected as part of the ten research studies were the development of epigenetic reprogramming technology in tumour by Professor Pilnam Kim from the Department of Bio and Brain Engineering, the development of an original technology for reverse cell aging by Professor Kwang-Hyun Cho from the Department of Bio and Brain Engineering, a heterogeneous metal element catalyst for atmospheric purification by Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering, and the Mobile Clinic Module (MCM): a negative pressure ward for epidemic hospitals by Professor Taek-jin Nam (reported at the Wall Street Journal) from the Department of Industrial Design.

2021.05.31 View 15300 -

Mobile Clinic Module Wins Red Dot and iF Design Awards

The Mobile Clinic Module (MCM), an inflatable negative pressure ward building system developed by the Korea Aid for Respiratory Epidemic (KARE) initiative at KAIST, gained international acclaim by winning the prestigious Red Dot Design Award and iF Design Award.

The MCM was recognized as one of the Red Dot Product Designs of the Year. It also won four iF Design Awards in communication design, interior architecture, user interface, and user experience. Winning the two most influential design awards demonstrates how product design can make a valuable contribution to help contain pandemics and reflects new consumer trends for dealing with pandemics.

Designed to be patient friendly, even in the extreme medical situations such as pandemics or triage, the MCM is the result of collaborations among researchers in a variety of fields including mechanical engineering, computing, industrial and systems engineering, medical hospitals, and engineering companies. The research team was led by Professor Tek-Jin Nam from the Department of Industrial Design.

The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-functional panels. Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air from inside. An internal air information monitoring system efficiently controls inside air pressure and purifies the air. It requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

MCMs are now located at the Korea Institute of Radiological & Medical Sciences and Jeju Vaccine Center and expect to be used at many other facilities. KARE is developing antiviral solutions and devices such as protective gear, sterilizers, and test kits to promptly respond to the pandemic. More than 100 researchers at KAIST are collaborating with industry and clinical hospitals to develop antiviral technologies that will improve preventive measures, diagnoses, and treatments.

Professor Nam said, “Our designers will continue to identify the most challenging issues, and try to resolve them by realizing user-friendly functions. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the globe.”

(END)

2021.04.21 View 9873

Mobile Clinic Module Wins Red Dot and iF Design Awards

The Mobile Clinic Module (MCM), an inflatable negative pressure ward building system developed by the Korea Aid for Respiratory Epidemic (KARE) initiative at KAIST, gained international acclaim by winning the prestigious Red Dot Design Award and iF Design Award.

The MCM was recognized as one of the Red Dot Product Designs of the Year. It also won four iF Design Awards in communication design, interior architecture, user interface, and user experience. Winning the two most influential design awards demonstrates how product design can make a valuable contribution to help contain pandemics and reflects new consumer trends for dealing with pandemics.

Designed to be patient friendly, even in the extreme medical situations such as pandemics or triage, the MCM is the result of collaborations among researchers in a variety of fields including mechanical engineering, computing, industrial and systems engineering, medical hospitals, and engineering companies. The research team was led by Professor Tek-Jin Nam from the Department of Industrial Design.

The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-functional panels. Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air from inside. An internal air information monitoring system efficiently controls inside air pressure and purifies the air. It requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

MCMs are now located at the Korea Institute of Radiological & Medical Sciences and Jeju Vaccine Center and expect to be used at many other facilities. KARE is developing antiviral solutions and devices such as protective gear, sterilizers, and test kits to promptly respond to the pandemic. More than 100 researchers at KAIST are collaborating with industry and clinical hospitals to develop antiviral technologies that will improve preventive measures, diagnoses, and treatments.

Professor Nam said, “Our designers will continue to identify the most challenging issues, and try to resolve them by realizing user-friendly functions. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the globe.”

(END)

2021.04.21 View 9873 -

Ushering in a New Era at the 50th Innoversary Ceremony

President Moon Jae-In declares KAIST the future of Korea

KAIST reaffirmed its goal of becoming an institute that can serve the world for the next century, marking its 50th anniversary on February 16. The KAIST community and distinguished guests gathered online during the official ceremony to commemorate KAIST’s anniversary and envisioned ways to serve the world, a major shift from its founding mission focusing on national growth.

The ceremony celebrated the legacy of KAIST, which has become a trailblazer by fostering the most competent scientists and engineers and making breakthroughs which led to the nation becoming a global high-tech leader.

President Moon Jae-In applauded KAIST as “the future of Korea” in his online congratulatory message, saying that “KAIST has made us feel proud when the nation stays ahead in science and technology. The dream of KAIST has been the dream of Korea. The passion of KAIST has been the passion of Korea. KAIST is the future of Korea.”

“KAIST has overcome challenges and created innovations for advancing the nation, from the first internet network to launching our first satellite in the early 80s to the Mobile Clinic Module (MCM), a negative pressure ward module in response to COVID-19. Whenever the nation faced a challenge, KAIST was there.”

President Moon also asked KAIST researchers to find sustainable ways to balance nature and humanity in this time of climate change and the Fourth Industrial Revolution.

Executive Chairman of the World Economic Forum Dr.Klaus Schwab also congratulated, saying "KAIST is a leader in ensuring social inclusion. Founded with the support of USAID, today it is paying it forward and sharing the same support through the Kenya-KAIST project."

The ceremony first brought Dr. KunMo Chung to the stage, the man who proposed the idea of founding the first advanced science and technology institute in Korea. His proposal to the then administrator of USAID John Hannah resulted in the Korean government meriting a 6 million USD loan for to start KAIST. He was the only Korean member of the USAID feasibility study team led by Dr. Frederick Terman, the former vice president of Stanford University. Dr. Chung wrote the Terman Report, which gave a green light to the establishment of KAIST in Korea in 1970.

Dr. Chung said the nation’s strong desire to escape from poverty through the advancement of science and technology was thoroughly realized by KAIST. “The Terman Report’s vision was perfectly realized. Now it’s time to envision the next dream of KAIST for another century.”

President Sung-Chul Shin said in his anniversary speech that KAIST has now transformed into a university that will serve the all of humanity by advancing science and technology while fostering new talents best fit for the new global environment. President Shin said that to fulfill KAIST’s second dream, the university will drive innovation in the five major areas of education, research, technology commercialization, globalization, and future strategy, under the C3 spirit of a Challenging spirit, Creativity, and Caring minds.

“In the next 50 years, KAIST hopes to fulfill the 10-10-10 Dream, that is, to have 10 Singularity Professors who have produced world-class achievements, 10 Decacorn startups valued at 10 trillion won, and global campuses in 10 countries.”

Then, four young KAIST professors who are conducting research in the flagship fields of mobility, new materials, post-AI, and bio-medicine presented their research vision and gave speeches. Professor Hae-Won Park from the Department of Mechanical Engineering and Professor Jihyeon Yeom from the Department of Materials Science and Engineering said the advent of new mobility combined with robotics and new nano-materials scaled down into spintronics, ‘KAISTronic materials’, will provide new momentum for the industry and the wellbeing of humanity. Professor Kijung Shin from the Graduate School of AI spoke on the new future transformed by quantum computers. Professor Young Seok Ju from the Graduate School of Medical Science and Engineering predicted a future in which cancer will no longer be a terminal disease and digital cells and the digitization of bio-medicine will significantly improve our quality of life. He said the combination of anti-aging and reverse aging studies will make a difference in our lives.

After the official ceremony, KAIST’s administrative leadership including President Shin and Dr. Kun-Mo Chung attended a ceremony to dedicate the sky lounge at the Academic Cultural Complex as the John Hannah Hall. Terman Hall, located in the Creative Learning Building, was dedicated in 2004 in honor of Dr. Frederick Terman.

2021.02.17 View 12938

Ushering in a New Era at the 50th Innoversary Ceremony

President Moon Jae-In declares KAIST the future of Korea

KAIST reaffirmed its goal of becoming an institute that can serve the world for the next century, marking its 50th anniversary on February 16. The KAIST community and distinguished guests gathered online during the official ceremony to commemorate KAIST’s anniversary and envisioned ways to serve the world, a major shift from its founding mission focusing on national growth.

The ceremony celebrated the legacy of KAIST, which has become a trailblazer by fostering the most competent scientists and engineers and making breakthroughs which led to the nation becoming a global high-tech leader.

President Moon Jae-In applauded KAIST as “the future of Korea” in his online congratulatory message, saying that “KAIST has made us feel proud when the nation stays ahead in science and technology. The dream of KAIST has been the dream of Korea. The passion of KAIST has been the passion of Korea. KAIST is the future of Korea.”

“KAIST has overcome challenges and created innovations for advancing the nation, from the first internet network to launching our first satellite in the early 80s to the Mobile Clinic Module (MCM), a negative pressure ward module in response to COVID-19. Whenever the nation faced a challenge, KAIST was there.”

President Moon also asked KAIST researchers to find sustainable ways to balance nature and humanity in this time of climate change and the Fourth Industrial Revolution.

Executive Chairman of the World Economic Forum Dr.Klaus Schwab also congratulated, saying "KAIST is a leader in ensuring social inclusion. Founded with the support of USAID, today it is paying it forward and sharing the same support through the Kenya-KAIST project."

The ceremony first brought Dr. KunMo Chung to the stage, the man who proposed the idea of founding the first advanced science and technology institute in Korea. His proposal to the then administrator of USAID John Hannah resulted in the Korean government meriting a 6 million USD loan for to start KAIST. He was the only Korean member of the USAID feasibility study team led by Dr. Frederick Terman, the former vice president of Stanford University. Dr. Chung wrote the Terman Report, which gave a green light to the establishment of KAIST in Korea in 1970.

Dr. Chung said the nation’s strong desire to escape from poverty through the advancement of science and technology was thoroughly realized by KAIST. “The Terman Report’s vision was perfectly realized. Now it’s time to envision the next dream of KAIST for another century.”

President Sung-Chul Shin said in his anniversary speech that KAIST has now transformed into a university that will serve the all of humanity by advancing science and technology while fostering new talents best fit for the new global environment. President Shin said that to fulfill KAIST’s second dream, the university will drive innovation in the five major areas of education, research, technology commercialization, globalization, and future strategy, under the C3 spirit of a Challenging spirit, Creativity, and Caring minds.

“In the next 50 years, KAIST hopes to fulfill the 10-10-10 Dream, that is, to have 10 Singularity Professors who have produced world-class achievements, 10 Decacorn startups valued at 10 trillion won, and global campuses in 10 countries.”

Then, four young KAIST professors who are conducting research in the flagship fields of mobility, new materials, post-AI, and bio-medicine presented their research vision and gave speeches. Professor Hae-Won Park from the Department of Mechanical Engineering and Professor Jihyeon Yeom from the Department of Materials Science and Engineering said the advent of new mobility combined with robotics and new nano-materials scaled down into spintronics, ‘KAISTronic materials’, will provide new momentum for the industry and the wellbeing of humanity. Professor Kijung Shin from the Graduate School of AI spoke on the new future transformed by quantum computers. Professor Young Seok Ju from the Graduate School of Medical Science and Engineering predicted a future in which cancer will no longer be a terminal disease and digital cells and the digitization of bio-medicine will significantly improve our quality of life. He said the combination of anti-aging and reverse aging studies will make a difference in our lives.

After the official ceremony, KAIST’s administrative leadership including President Shin and Dr. Kun-Mo Chung attended a ceremony to dedicate the sky lounge at the Academic Cultural Complex as the John Hannah Hall. Terman Hall, located in the Creative Learning Building, was dedicated in 2004 in honor of Dr. Frederick Terman.

2021.02.17 View 12938 -

KAIST Mobile Clinic Module to Fill Negative Pressure Ward Shortage

Efficient versatile ready-for-rapid building system of MCM will serve as both a triage unit and bridge center in emergency medical situations

A team from KAIST has developed a low-cost and ready-for-rapid-production negative pressure room called a Mobile Clinic Module (MCM). The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-function panels.

The MCM expects to quickly meet the high demand for negative pressure beds in the nation and eventually many other countries where the third wave of COVID-19 is raging. The module is now ready to be rolled out after a three-week test period at the Korea Cancer Center Hospital.

Professor Tek-Jin Nam’s team swung into action, rapidly working together with researchers, engineers with expertise in mechanical design, and a team of clinical doctors to complete the MCM as one of KAIST’s New Deal R&D initiatives launched last July.

Professor Nam cites ‘expandability’ as the key feature of the MCM. Eventually, it will serve as both a triage unit and bridge center in emergency medical situations.

“The module is a very efficient and versatile unit building system. It takes approximately two hours to build the basic MCM unit, which comprises four negative pressure bed rooms, nurse’s station, locker room, and treatment room. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms,” said Professor Nam.

“It will also be helpful for managing less-severe patients who need to be monitored daily in quarantined rooms or as bridge stations where on-site medical staff can provide treatment and daily monitoring before hospitalization. These wards can be efficiently deployed either inside or outside existing hospitals.”

The research team specially designed the negative pressure frame to ensure safety level A for the negative pressure room, which is made of a multi-function panel wall and roofed with an air tent. The multi-function panels can hold medical appliances such as ventilators, oxygen and bio-signal monitors.

Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air. An internal air information monitoring system efficiently controls room air pressure and purifies the air.

While a conventional negative pressure bed is reported to cost approximately 3.5 billion KRW (50 billion won for a ward), this module is estimated to cost 0.75 billion won each (10 billion won for a ward), cutting the costs by approximately 80%.

The MCM is designed to be easily transported and relocated due to its volume, weight, and maintainability. This module requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

“We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the world.”

Professor Nam’s team is also developing antiviral solutions and devices such as protective gear, sterilizers, and test kits under the KAIST New Deal R&D Initiative that was launched to promptly and proactively respond to the epidemic. More than 45 faculty members and researchers at KAIST are collaborating with industry and clinical hospitals to develop the antiviral technology that will improve preventive measures, diagnoses, and treatment.

2021.01.07 View 12040

KAIST Mobile Clinic Module to Fill Negative Pressure Ward Shortage

Efficient versatile ready-for-rapid building system of MCM will serve as both a triage unit and bridge center in emergency medical situations

A team from KAIST has developed a low-cost and ready-for-rapid-production negative pressure room called a Mobile Clinic Module (MCM). The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-function panels.

The MCM expects to quickly meet the high demand for negative pressure beds in the nation and eventually many other countries where the third wave of COVID-19 is raging. The module is now ready to be rolled out after a three-week test period at the Korea Cancer Center Hospital.

Professor Tek-Jin Nam’s team swung into action, rapidly working together with researchers, engineers with expertise in mechanical design, and a team of clinical doctors to complete the MCM as one of KAIST’s New Deal R&D initiatives launched last July.

Professor Nam cites ‘expandability’ as the key feature of the MCM. Eventually, it will serve as both a triage unit and bridge center in emergency medical situations.

“The module is a very efficient and versatile unit building system. It takes approximately two hours to build the basic MCM unit, which comprises four negative pressure bed rooms, nurse’s station, locker room, and treatment room. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms,” said Professor Nam.

“It will also be helpful for managing less-severe patients who need to be monitored daily in quarantined rooms or as bridge stations where on-site medical staff can provide treatment and daily monitoring before hospitalization. These wards can be efficiently deployed either inside or outside existing hospitals.”

The research team specially designed the negative pressure frame to ensure safety level A for the negative pressure room, which is made of a multi-function panel wall and roofed with an air tent. The multi-function panels can hold medical appliances such as ventilators, oxygen and bio-signal monitors.

Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air. An internal air information monitoring system efficiently controls room air pressure and purifies the air.

While a conventional negative pressure bed is reported to cost approximately 3.5 billion KRW (50 billion won for a ward), this module is estimated to cost 0.75 billion won each (10 billion won for a ward), cutting the costs by approximately 80%.

The MCM is designed to be easily transported and relocated due to its volume, weight, and maintainability. This module requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

“We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the world.”

Professor Nam’s team is also developing antiviral solutions and devices such as protective gear, sterilizers, and test kits under the KAIST New Deal R&D Initiative that was launched to promptly and proactively respond to the epidemic. More than 45 faculty members and researchers at KAIST are collaborating with industry and clinical hospitals to develop the antiviral technology that will improve preventive measures, diagnoses, and treatment.

2021.01.07 View 12040 -

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 26658

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 26658 -

Making Graphene Using Laser-induced Phase Separation

IBS & KAIST researchers clarify how laser annealing technology can lead to the production of ultrathin nanomaterials

All our smart phones have shiny flat AMOLED (active-matrix organic light-emitting diode) displays. Behind each single pixel of these displays hides at least two silicon transistors which are mass-manufactured using laser annealing technology. While the traditional methods to make the transistors use temperature above 1,000°C, the laser technique reaches the same results at low temperatures even on plastic substrates (melting temperature below 300°C). Interestingly, a similar procedure can be used to generate crystals of graphene. Graphene is a strong and thin nano-material made of carbon, its electric and heat-conductive properties have attracted the attention of scientists worldwide.

Professor Keon Jae Lee of the Materials Science and Engineering Department at KAIST and his research group at the Center for Multidimensional Carbon Materials within the Institute for Basic Science (IBS), as well as Professor Sung-Yool Choi of the Electrical Engineering School at KAIST and his research team discovered graphene synthesis mechanism using laser-induced solid-state phase separation of single-crystal silicon carbide (SiC). This study, available in Nature Communications, clarifies how this laser technology can separate a complex compound (SiC) into its ultrathin elements of carbon and silicon.

Although several fundamental studies presented the effect of excimer lasers in transforming elemental materials like silicon, the laser interaction with more complex compounds like SiC has rarely been studied due to the complexity of compound phase transition and ultra-short processing time.

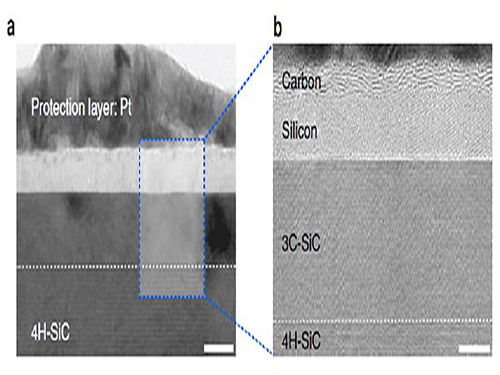

With high resolution microscope images and molecular dynamic simulations, scientists found that a single-pulse irradiation of xenon chloride excimer laser of 30 nanoseconds melts SiC, leading to the separation of a liquid SiC layer, a disordered carbon layer with graphitic domains (about 2.5 nm thick) on top surface and a polycrystalline silicon layer (about 5 nm) below carbon layer. Giving additional pulses causes the sublimation of the separated silicon, while the disordered carbon layer is transformed into a multilayer graphene.

"This research shows that the laser material interaction technology can be a powerful tool for the next generation of two dimensional nanomaterials," said Professor Lee.

Professor Choi added: "Using laser-induced phase separation of complex compounds, new types of two dimensional materials can be synthesized in the future."

High-resolution transmission electron microscopy shows that after just one laser pulse of 30 nanoseconds, the silicon carbide (SiC) substrate is melted and separates into a carbon and a silicon layer. More pulses cause the carbon layer to organize into graphene and the silicon to leave as gas.

Molecular dynamics simulates the graphene formation mechanism. The carbon layer on the top forms because the laser-induced liquid SiC (SiC (l)) is unstable.

(Press Release by Courtesy of the Institute for Basic Science (IBS))

2016.12.01 View 11595

Making Graphene Using Laser-induced Phase Separation

IBS & KAIST researchers clarify how laser annealing technology can lead to the production of ultrathin nanomaterials

All our smart phones have shiny flat AMOLED (active-matrix organic light-emitting diode) displays. Behind each single pixel of these displays hides at least two silicon transistors which are mass-manufactured using laser annealing technology. While the traditional methods to make the transistors use temperature above 1,000°C, the laser technique reaches the same results at low temperatures even on plastic substrates (melting temperature below 300°C). Interestingly, a similar procedure can be used to generate crystals of graphene. Graphene is a strong and thin nano-material made of carbon, its electric and heat-conductive properties have attracted the attention of scientists worldwide.

Professor Keon Jae Lee of the Materials Science and Engineering Department at KAIST and his research group at the Center for Multidimensional Carbon Materials within the Institute for Basic Science (IBS), as well as Professor Sung-Yool Choi of the Electrical Engineering School at KAIST and his research team discovered graphene synthesis mechanism using laser-induced solid-state phase separation of single-crystal silicon carbide (SiC). This study, available in Nature Communications, clarifies how this laser technology can separate a complex compound (SiC) into its ultrathin elements of carbon and silicon.

Although several fundamental studies presented the effect of excimer lasers in transforming elemental materials like silicon, the laser interaction with more complex compounds like SiC has rarely been studied due to the complexity of compound phase transition and ultra-short processing time.

With high resolution microscope images and molecular dynamic simulations, scientists found that a single-pulse irradiation of xenon chloride excimer laser of 30 nanoseconds melts SiC, leading to the separation of a liquid SiC layer, a disordered carbon layer with graphitic domains (about 2.5 nm thick) on top surface and a polycrystalline silicon layer (about 5 nm) below carbon layer. Giving additional pulses causes the sublimation of the separated silicon, while the disordered carbon layer is transformed into a multilayer graphene.

"This research shows that the laser material interaction technology can be a powerful tool for the next generation of two dimensional nanomaterials," said Professor Lee.

Professor Choi added: "Using laser-induced phase separation of complex compounds, new types of two dimensional materials can be synthesized in the future."

High-resolution transmission electron microscopy shows that after just one laser pulse of 30 nanoseconds, the silicon carbide (SiC) substrate is melted and separates into a carbon and a silicon layer. More pulses cause the carbon layer to organize into graphene and the silicon to leave as gas.

Molecular dynamics simulates the graphene formation mechanism. The carbon layer on the top forms because the laser-induced liquid SiC (SiC (l)) is unstable.

(Press Release by Courtesy of the Institute for Basic Science (IBS))

2016.12.01 View 11595 -

KAIST to support the Genetic Donguibogam Research Project for global market entry of a new natural drug produced by Green Cross Corporation HS

In the wake of the spread of the Middle East Respiratory Syndrome (MERS), sales of immune-enhancing products in Korea such as red and white ginseng have risen dramatically. Ginseng is one of Korea’s major health supplement it exports, but due to the lack of precise scientific knowledge of its mechanism, sales of ginseng account for less than 2% of the global market share.

The Genetic Donguibogam Research Project represents a group of research initiatives to study genes and environmental factors that contribute to diseases and to discover alternative treatments through Eastern medicine. The project is being led by KAIST’s Department of Bio & Brain Engineering Professor Do-Heon Lee.

Professor Lee and Chief Executive Officer Young-Hyo Yoo of Green Cross Corporation HS, a Korean pharmaceutical company, signed a memorandum of understanding (MOU), as well as a non-disclosure agreement (NDA) to develop a naturally derived drug with an enhanced ginsenoside, pharmacological compounds of ginseng, for the global market entry of BST204 on June 10, 2015.

Donguibogam is the traditional Korean source for the principles and practice of Eastern medicine, which was compiled by the royal physician Heo Jun and first published in 1613 during the Joseon Dynasty of Korea.

Cooperating with Green Cross Co., HS, KAIST researchers will use a multi-component, multi-target (MCMT)-based development platform to produce the new natural drug, BST204. This cooperation is expected to assist the entry of the drug into the European market.

Green Cross Co., HS has applied a bio-conversion technique to ginseng to develop BST204, which is a drug with enhanced active constituent of aginsenosides. The drug is the first produced by any Korean pharmaceutical company to complete the first phase of clinical trials in Germany and is about to start the second phase of trials.

Professor Do-Heon Lee, the Director of the project said, “Genetic Donguibogam Research Project seeks to create new innovative healthcare material for the future using integrated fundamental technologies such as virtual human body computer modelling and multi-omics to explain the mechanism in which natural ingredients affect the human body.” He continued, “Especially, by employing the virtual human body computer modelling, we can develop an innovative new technology that will greatly assist Korean pharmaceutical industry and make it the platform technology in entering global markets.”

Young-Hyo Yoo, the CEO of Green Cross Co., HS, said, “For a new naturally derived drug to be acknowledged in the global market, such as Europe and the US, its mechanism, as well as its effectiveness and safety, should be proven. However, it is difficult and costly to explain the mechanism in which the complex composition of a natural substance influences the body. Innovative technology is needed to solve this problem.”

Professor Do-Heon Lee (left in the picture), the Director of Genetic Donguibogam Research Project, stands abreast Young-Hyo Yoo (right in the picture), the CEO of Green Cross Co., HS.

2015.06.10 View 9276

KAIST to support the Genetic Donguibogam Research Project for global market entry of a new natural drug produced by Green Cross Corporation HS

In the wake of the spread of the Middle East Respiratory Syndrome (MERS), sales of immune-enhancing products in Korea such as red and white ginseng have risen dramatically. Ginseng is one of Korea’s major health supplement it exports, but due to the lack of precise scientific knowledge of its mechanism, sales of ginseng account for less than 2% of the global market share.

The Genetic Donguibogam Research Project represents a group of research initiatives to study genes and environmental factors that contribute to diseases and to discover alternative treatments through Eastern medicine. The project is being led by KAIST’s Department of Bio & Brain Engineering Professor Do-Heon Lee.

Professor Lee and Chief Executive Officer Young-Hyo Yoo of Green Cross Corporation HS, a Korean pharmaceutical company, signed a memorandum of understanding (MOU), as well as a non-disclosure agreement (NDA) to develop a naturally derived drug with an enhanced ginsenoside, pharmacological compounds of ginseng, for the global market entry of BST204 on June 10, 2015.

Donguibogam is the traditional Korean source for the principles and practice of Eastern medicine, which was compiled by the royal physician Heo Jun and first published in 1613 during the Joseon Dynasty of Korea.

Cooperating with Green Cross Co., HS, KAIST researchers will use a multi-component, multi-target (MCMT)-based development platform to produce the new natural drug, BST204. This cooperation is expected to assist the entry of the drug into the European market.

Green Cross Co., HS has applied a bio-conversion technique to ginseng to develop BST204, which is a drug with enhanced active constituent of aginsenosides. The drug is the first produced by any Korean pharmaceutical company to complete the first phase of clinical trials in Germany and is about to start the second phase of trials.

Professor Do-Heon Lee, the Director of the project said, “Genetic Donguibogam Research Project seeks to create new innovative healthcare material for the future using integrated fundamental technologies such as virtual human body computer modelling and multi-omics to explain the mechanism in which natural ingredients affect the human body.” He continued, “Especially, by employing the virtual human body computer modelling, we can develop an innovative new technology that will greatly assist Korean pharmaceutical industry and make it the platform technology in entering global markets.”

Young-Hyo Yoo, the CEO of Green Cross Co., HS, said, “For a new naturally derived drug to be acknowledged in the global market, such as Europe and the US, its mechanism, as well as its effectiveness and safety, should be proven. However, it is difficult and costly to explain the mechanism in which the complex composition of a natural substance influences the body. Innovative technology is needed to solve this problem.”

Professor Do-Heon Lee (left in the picture), the Director of Genetic Donguibogam Research Project, stands abreast Young-Hyo Yoo (right in the picture), the CEO of Green Cross Co., HS.

2015.06.10 View 9276 -

Prof. Kim Receives Lee Osheroff Prize

Professor Eun-Seong Kim of the Department of Physics has been selected as the winner of the Lee Osheroff Richardson Prize for 2008.

The award was established in honor of the 1996 Nobel Prize laureates in Physics David Lee, Douglas Osheroff, and Robert Richardson for their discovery in superfluidity in helium-3. The annual prize sponsored by Oxford Instruments NanoScience is awarded to a young scientist who has made a notable achievement in the field of low temperatures and high magnetic fields.

Kim was chosen as the winner of this prestigious award for his contributions to the understanding of solid helium. Through research, Professor Kim found superfluid-like behavior in solid helium and with this discovery it is shown that all three states of matter can exhibit superfluid behavior.

The Lee Osheroff Richardson Prize recipient is selected by the North American Prize Committee which is composed of prominent figures in the low temperature and high magnetic fields including Professor Bruce Gaulin of McMaster University, who chairs the Prize Committee. The award ceremony was held on March 11 in New Orleans.

2008.03.18 View 14385

Prof. Kim Receives Lee Osheroff Prize

Professor Eun-Seong Kim of the Department of Physics has been selected as the winner of the Lee Osheroff Richardson Prize for 2008.

The award was established in honor of the 1996 Nobel Prize laureates in Physics David Lee, Douglas Osheroff, and Robert Richardson for their discovery in superfluidity in helium-3. The annual prize sponsored by Oxford Instruments NanoScience is awarded to a young scientist who has made a notable achievement in the field of low temperatures and high magnetic fields.

Kim was chosen as the winner of this prestigious award for his contributions to the understanding of solid helium. Through research, Professor Kim found superfluid-like behavior in solid helium and with this discovery it is shown that all three states of matter can exhibit superfluid behavior.

The Lee Osheroff Richardson Prize recipient is selected by the North American Prize Committee which is composed of prominent figures in the low temperature and high magnetic fields including Professor Bruce Gaulin of McMaster University, who chairs the Prize Committee. The award ceremony was held on March 11 in New Orleans.

2008.03.18 View 14385