Nano+Electronics

-

Professor Bumjoon Kim Named Scientist of the Month

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering won January’s Scientist of the Month Award presented by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF) on January 6. Professor Kim also received 10 million won in prize money.

Professor Kim was recognized for his research in the field of fuel cells. Since the first paper on fuel cells was published in 1839 by the German chemist Friedrich Schonbein, there has been an increase in the number of fields in which fuel cells are used, including national defense, aerospace engineering, and autonomous vehicles.

Professor Kim developed carbonized block copolymer particles with high durability and a high-performance fuel cell. Block copolymers are two different polymers cross-linked into a chain structure. Various nanostructures can be made effectively by using the attractive and repulsive forces between the chains.

Professor Kim used the membrane emulsification technique, employing a high-performance separation membrane to develop a platform that makes the mass production of highly durable carbonized particles possible, which he then used to develop high-performance energy devices like fuel cells.

The carbonized particles designed by Professor Kim and his research team were used to create the world’s more durable fuel cells that boast outstanding performance while using only five percent of the costly platinum needed for existing commercialized products.

The team’s research results were published in the Journal of the American Chemical Society and Energy Environmental Science in May and July of last year.

“We have developed a fuel cell that ticks all the boxes including performance, durability, and cost,” said Professor Kim. “Related techniques will not be limited to fuel cells, but could also be applied to the development of various energy devices like solar cells and secondary cells,” he added.

(END)

2021.01.22 View 12952

Professor Bumjoon Kim Named Scientist of the Month

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering won January’s Scientist of the Month Award presented by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF) on January 6. Professor Kim also received 10 million won in prize money.

Professor Kim was recognized for his research in the field of fuel cells. Since the first paper on fuel cells was published in 1839 by the German chemist Friedrich Schonbein, there has been an increase in the number of fields in which fuel cells are used, including national defense, aerospace engineering, and autonomous vehicles.

Professor Kim developed carbonized block copolymer particles with high durability and a high-performance fuel cell. Block copolymers are two different polymers cross-linked into a chain structure. Various nanostructures can be made effectively by using the attractive and repulsive forces between the chains.

Professor Kim used the membrane emulsification technique, employing a high-performance separation membrane to develop a platform that makes the mass production of highly durable carbonized particles possible, which he then used to develop high-performance energy devices like fuel cells.

The carbonized particles designed by Professor Kim and his research team were used to create the world’s more durable fuel cells that boast outstanding performance while using only five percent of the costly platinum needed for existing commercialized products.

The team’s research results were published in the Journal of the American Chemical Society and Energy Environmental Science in May and July of last year.

“We have developed a fuel cell that ticks all the boxes including performance, durability, and cost,” said Professor Kim. “Related techniques will not be limited to fuel cells, but could also be applied to the development of various energy devices like solar cells and secondary cells,” he added.

(END)

2021.01.22 View 12952 -

The 10th KINC Fusion Research Awardees

The KAIST Institute for NanoCentury (KINC) recognized three distinguished researchers whose convergence studies made significant impacts. The KINC presented the 10th KINC Fusion Research Awards during a ceremony that took place at KAIST’s main campus in Daejeon on May 19.

This year’s ‘best’ convergence research award went to a joint research group led by Professor Hee Tak Kim from the Department of Chemical and Biomolecular Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering. Their research, featured in the December 27 issue of Advanced Materials as a front cover article last year, introduced the world’s first high-energy efficiency, membraneless, flowless, zinc-bromine battery. This study, in which research professor Gyoung Hwa Jeong, postdoctoral researcher Yearin Byun, and PhD candidate Ju-Hyuck Lee took part as co-lead authors, is deemed as an example of a best practice in convergence research in which two groups’ respective expertise in the fields of carbon materials and electrochemical analysis created a synergistic effect.

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering was also recognized for having published the most interdisciplinary research papers on polymer electronics and nanomaterials at home and abroad.

Professor Hee-Tae Jung, the Director of KINC and the host of the KINC Fusion Research Awards, said, “The KINC is happy to announce the 10th awardees in nano-fusion research this year. Since convergence is crucial for making revolutionary changes, the importance of convergence studies should be recognized. Our institute will spare no effort to create a research environment suitable for convergence studies, which will be crucial for making a significant difference.”

The KINC was established in June 2006 under the KAIST Institute with the mission of facilitating convergence studies by tearing down boarders among departments and carrying out interdisciplinary joint research. Currently, the institute is comprised of approximately 90 professors from 13 departments. It aims to become a hub of university institutes for nano-fusion research.

(END)

2020.05.19 View 15017

The 10th KINC Fusion Research Awardees

The KAIST Institute for NanoCentury (KINC) recognized three distinguished researchers whose convergence studies made significant impacts. The KINC presented the 10th KINC Fusion Research Awards during a ceremony that took place at KAIST’s main campus in Daejeon on May 19.

This year’s ‘best’ convergence research award went to a joint research group led by Professor Hee Tak Kim from the Department of Chemical and Biomolecular Engineering and Professor Sang Ouk Kim from the Department of Materials Science and Engineering. Their research, featured in the December 27 issue of Advanced Materials as a front cover article last year, introduced the world’s first high-energy efficiency, membraneless, flowless, zinc-bromine battery. This study, in which research professor Gyoung Hwa Jeong, postdoctoral researcher Yearin Byun, and PhD candidate Ju-Hyuck Lee took part as co-lead authors, is deemed as an example of a best practice in convergence research in which two groups’ respective expertise in the fields of carbon materials and electrochemical analysis created a synergistic effect.

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering was also recognized for having published the most interdisciplinary research papers on polymer electronics and nanomaterials at home and abroad.

Professor Hee-Tae Jung, the Director of KINC and the host of the KINC Fusion Research Awards, said, “The KINC is happy to announce the 10th awardees in nano-fusion research this year. Since convergence is crucial for making revolutionary changes, the importance of convergence studies should be recognized. Our institute will spare no effort to create a research environment suitable for convergence studies, which will be crucial for making a significant difference.”

The KINC was established in June 2006 under the KAIST Institute with the mission of facilitating convergence studies by tearing down boarders among departments and carrying out interdisciplinary joint research. Currently, the institute is comprised of approximately 90 professors from 13 departments. It aims to become a hub of university institutes for nano-fusion research.

(END)

2020.05.19 View 15017 -

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

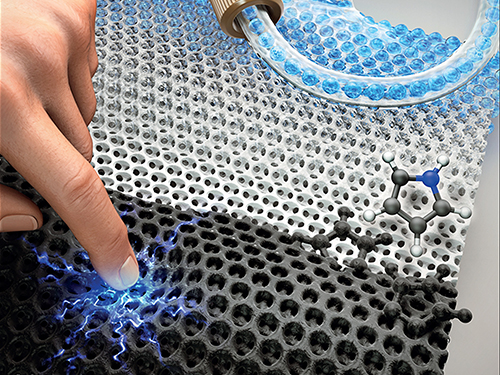

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 11732

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 11732 -

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 28809

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 28809 -

Research Day Highlights Most Outstanding Research Achievements

Professor Byung Jin Cho from the School of Electrical Engineering was selected as the Grand Research Prize Winner in recognition of his innovative research achievement in the fields of nano electric and flexible energy devices during the 2019 KAIST Research Day ceremony held on April 23 at the Chung Kunmo Conference Hall.

The ten most outstanding research achievements from the past year were also awarded in the three areas of Research, Innovation, Convergence Researches.

Professor Cho is an internationally recognized researcher in the field of future nano and energy device technology. Professor Cho’s team has continued to research on advanced CMOS (complementary metal-oxide semiconductors). CMOS has become his key research topic over the past three decades.

In 2014, he developed a glass fabric-based thermoelectric generator, which is extremely light and flexible and produces electricity from the heat of the human body. It is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles. His wearable thermoelectric generator was selected as one of the top ten most promising digital technologies by the Netexplo Forum in 2015.

He now is working on high-performance and ultra-flexible CMOS IC for biomedical applications, expanding his scope to thermal haptic technology in VR using graphene-CMOS hybrid integrated circuits; to self-powered wireless sensor nodes and self-powered ECG system using wearable thermoelectric generators .

In his special lecture at the ceremony, Professor Cho stressed the importance of collaboration in making scientific research and presented how he moved to future devices after focusing on scaling the devices.

“When I started the research on semiconductors, I focused on how to scale the device down as much as possible. For decades, we have conducted a number of procedures to produce tiny but efficient materials. Now we have shifted to develop flexible thermoelements and wearable devices,” said Professor Cho.

“We all thought the scaling down is the only way to create value-added technological breakthroughs. Now, the devices have been scaled down to 7nm and will go down to 5 nm soon. Over the past few years, I think we have gone through all the possible technological breakthroughs for reducing the size to 5nm. The semiconductor devices are made of more 1 billion transistors and go through 1,000 technological processes. So, there won’t be any possible way for a single genius to make a huge breakthrough. Without collaboration with others, it is nearly impossible to make any new technological breakthroughs.”

Professor Cho has published more than 240 papers in renowned academic journals and presented more than 300 papers at academic conferences. He has also registered approximately 50 patents in the field of semiconductor device technology.

The top ten research highlights of 2018 as follows:

- Rydberg-Atom Quantum Simulator Development by Professor Jaewook Ahn and Heung-Sun Sim from the Department of Physics

- From C-H to C-C Bonds at Room Temperature by Professor Mu-Hyun Baik from the Department of Chemistry

- The Role of Rodlike Counterions on the Interactions of DNAs by Professor Yong Woon Kim of the Graduate School of Nanoscience and Technology

- The Medal Preoptic Area Induces Hunting-Like Behaviors to Target Objects and Prey by Professor Daesoo Kim from the Department of Biological Sciences

- Identification of the Origin of Brain Tumors and New Therapeutic Strategy by Professor Jeong Ho Lee from the Graduate School of Medical Science and Engineering

- The Linear Frequency Conversion of Light at a Spatiotemporal Boundary by Professor Bumki Min from the Department of Mechanical Engineering

- An Industrial Grade Flexible Transparent Force Touch Sensor by Professor Jun-Bo Yoon from the School of Electrical Engineering

- The Detection and Clustering of Mixed-Type Defect Patterns in Wafer Bin Maps by Professor Heeyoung Kim from the Department of Industrial and Systems Engineering

- The Development of a Reconfigurable Spin-Based Logic Device by Professor Byong-Guk Park from the Department of Materials Science and Engineering

- The Development of a Miniaturized X-Ray Tube Based on Carbon Nanotube and Electronic Brachytherapy Device by Professor Sung Oh Cho from the Department of Nuclear and Quantum Engineering

Professor YongKeun Park from the Department of Physics and Professor In-Chel Park from the School of Electrical Engineering received the Research Award. For the Innovation Award, Professor Munchurl Kim from the School of Electrical Engineering was the recipient and the Convergence Research Awards was conferred to Professor Sung-Yool Choi from the School of Electrical Engineering, Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering, and Professor SangHee Park from the Department of Materials Science and Engineering during the ceremony.

For more on KAIST’s Top Research Achievements and Highlight of 2018, please refer to the attached below. click.

2019.04.25 View 17057

Research Day Highlights Most Outstanding Research Achievements

Professor Byung Jin Cho from the School of Electrical Engineering was selected as the Grand Research Prize Winner in recognition of his innovative research achievement in the fields of nano electric and flexible energy devices during the 2019 KAIST Research Day ceremony held on April 23 at the Chung Kunmo Conference Hall.

The ten most outstanding research achievements from the past year were also awarded in the three areas of Research, Innovation, Convergence Researches.

Professor Cho is an internationally recognized researcher in the field of future nano and energy device technology. Professor Cho’s team has continued to research on advanced CMOS (complementary metal-oxide semiconductors). CMOS has become his key research topic over the past three decades.

In 2014, he developed a glass fabric-based thermoelectric generator, which is extremely light and flexible and produces electricity from the heat of the human body. It is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles. His wearable thermoelectric generator was selected as one of the top ten most promising digital technologies by the Netexplo Forum in 2015.

He now is working on high-performance and ultra-flexible CMOS IC for biomedical applications, expanding his scope to thermal haptic technology in VR using graphene-CMOS hybrid integrated circuits; to self-powered wireless sensor nodes and self-powered ECG system using wearable thermoelectric generators .

In his special lecture at the ceremony, Professor Cho stressed the importance of collaboration in making scientific research and presented how he moved to future devices after focusing on scaling the devices.

“When I started the research on semiconductors, I focused on how to scale the device down as much as possible. For decades, we have conducted a number of procedures to produce tiny but efficient materials. Now we have shifted to develop flexible thermoelements and wearable devices,” said Professor Cho.

“We all thought the scaling down is the only way to create value-added technological breakthroughs. Now, the devices have been scaled down to 7nm and will go down to 5 nm soon. Over the past few years, I think we have gone through all the possible technological breakthroughs for reducing the size to 5nm. The semiconductor devices are made of more 1 billion transistors and go through 1,000 technological processes. So, there won’t be any possible way for a single genius to make a huge breakthrough. Without collaboration with others, it is nearly impossible to make any new technological breakthroughs.”

Professor Cho has published more than 240 papers in renowned academic journals and presented more than 300 papers at academic conferences. He has also registered approximately 50 patents in the field of semiconductor device technology.

The top ten research highlights of 2018 as follows:

- Rydberg-Atom Quantum Simulator Development by Professor Jaewook Ahn and Heung-Sun Sim from the Department of Physics

- From C-H to C-C Bonds at Room Temperature by Professor Mu-Hyun Baik from the Department of Chemistry

- The Role of Rodlike Counterions on the Interactions of DNAs by Professor Yong Woon Kim of the Graduate School of Nanoscience and Technology

- The Medal Preoptic Area Induces Hunting-Like Behaviors to Target Objects and Prey by Professor Daesoo Kim from the Department of Biological Sciences

- Identification of the Origin of Brain Tumors and New Therapeutic Strategy by Professor Jeong Ho Lee from the Graduate School of Medical Science and Engineering

- The Linear Frequency Conversion of Light at a Spatiotemporal Boundary by Professor Bumki Min from the Department of Mechanical Engineering

- An Industrial Grade Flexible Transparent Force Touch Sensor by Professor Jun-Bo Yoon from the School of Electrical Engineering

- The Detection and Clustering of Mixed-Type Defect Patterns in Wafer Bin Maps by Professor Heeyoung Kim from the Department of Industrial and Systems Engineering

- The Development of a Reconfigurable Spin-Based Logic Device by Professor Byong-Guk Park from the Department of Materials Science and Engineering

- The Development of a Miniaturized X-Ray Tube Based on Carbon Nanotube and Electronic Brachytherapy Device by Professor Sung Oh Cho from the Department of Nuclear and Quantum Engineering

Professor YongKeun Park from the Department of Physics and Professor In-Chel Park from the School of Electrical Engineering received the Research Award. For the Innovation Award, Professor Munchurl Kim from the School of Electrical Engineering was the recipient and the Convergence Research Awards was conferred to Professor Sung-Yool Choi from the School of Electrical Engineering, Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering, and Professor SangHee Park from the Department of Materials Science and Engineering during the ceremony.

For more on KAIST’s Top Research Achievements and Highlight of 2018, please refer to the attached below. click.

2019.04.25 View 17057 -

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

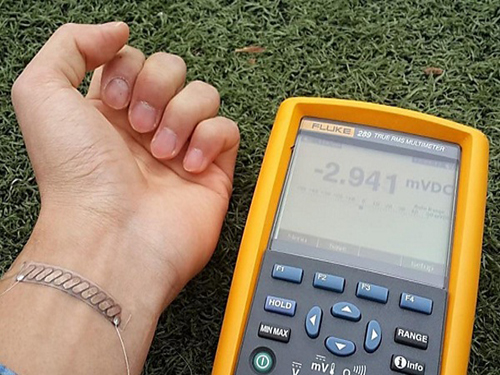

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 21228

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 21228 -

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 15454

Inexpensive Separation Method of Graphene Developed

The problem with commercializing graphene that is synthesized onto metals over a wide area is that it can not be separated from the metal. However, a groundbreaking separation technology which is both cheap and environment friendly has been developed.

Prof. Taek soo Kim and Prof. Byung Jin Cho"s research teams have conducted this research under the support of the Global Frontier program and Researcher Support Program initiated by The Ministry of Education and Science and Korea Research Foundation. The research results have been posted on the online news flash of Nano Letters on februrary 29th. (Thesis title: Direct Measurement of Adhesion Energy of Monolayer Graphene As-Grown on Copper and Its Application to Renewable Transfer Process)

The research has generated exact results on the interfacial adhesive energy of graphene and its surface material for the first time. Through this, the catalyst metal are no longer to be used just once, but will be used for an infinite number of times, thereby being ecofriendly and efficient.

Wide area graphine synthesized onto the catalyst meatal are used in various ways such as for display and for solar cells. There has been much research going on in this field. However, in order to use this wide area graphene, the graphene must be removed from the catalyst metal without damage.

Until now, the metal had been melted away through the use of chemical substances in order to separate the graphene. However, this method has been very problematic. The metal can not be reused, the costs are very high, much harmful wastes were created in the process of melting the metals, and the process was very complicated.

The research teams of Professors Taek Su Kim and Byung Jin Cho measured the interfacial adhesive energy of the synthesized graphene and learned that it could be easily removed.

Also, the mechanically removed graphene was successfully used in creating molecular electronic devices directly. This has thus innovatively shortened the graphene manufacturing process. Also, it has been confirmed that the metalic board can be reused multiple times after the graphene is removed. A new, ecofriendly and cost friendly method of graphene manufacturing has been paved.

Through this discovery, it is expected that graphene will become easier to manufacture and that the period til the commercialization date of graphene will therefore be greatly reduced

Prof. Cho stated " This reserach has much academical meaning significance in that it has successfully defined the surfacial adhesive energy between the graphene and its catalyst material and it should receive much attention in that it solved the largest technical problem involved in the production of graphene.

2012.04.04 View 15454 -

Int'l Herald Tribune Carries Feature Story on KAIST

International Herald Tribune carried a feature story on KAIST"s ongoing reform efforts on the front page of its Jan. 19-20 edition. The following is the full text of the report.

http://www.iht.com/articles/2008/01/18/asia/school.php

South Korean science prepares to take on the world

By Choe Sang-Hun

Friday, January 18, 2008

DAEJEON, South Korea: In Professor Cho Dong Ho"s laboratory at Kaist, South Korea"s top science and technology university, researchers are trying to develop technology that could let you fold a notebook-size electronic display and carry it in your pocket like a handkerchief.

It"s too early to say when something like this might be commercially available. But the experiment has already achieved one important breakthrough: it has mobilized professors from eight departments to collaborate on an idea proposed by a student.

This arrangement is almost unheard of in South Korea, where the norm is for a senior professor to dictate research projects to his own cloistered team. But it"s only one change afoot at this government-financed university, which has ambitions to transform the culture of South Korean science, and more.

"When we first got the student"s idea on what a future display should look like, we thought it was crazy, stuff from science fiction," said Cho, director of Kaist"s Institute for Information Technology Convergence. "But under our new president, we are being urged to try things no one else is likely to."

That university president is Suh Nam Pyo, 71, a mechanical engineer who used to be an administrator at the Massachusetts Institute of Technology and who is spearheading closely watched changes that are expected to have ramifications far beyond this campus 90 minutes by car south of Seoul.

His moves so far, from requiring professors to teach in English to basing student admissions on factors other than test scores, are aimed at making the university, and by extension South Korean society, much more competitive on a world scale.

When the South Korean government hired Suh in 2006 to shake up the state-financed Korean Advanced Institute of Science and Technology (which formally changed its name to its acronym, Kaist, on Jan. 1) the country"s leading schools faced a crisis. The old system, which guaranteed free tuition to lure promising students into science and technology, the drivers of South Korea"s industrial growth, was no longer working as well as it used to.

Prosperity was allowing those young people to choose fields of study once viewed as luxuries, like literature and history. Worse, increasing numbers were choosing to study abroad, mostly in the United States, and then not returning home. The fear was that South Korean institutions and enterprises would be gutted of expertise.

That concern was voiced at a news conference Monday by the president-elect, Lee Myung Bak, who said the educational system "isn"t producing talent that can compete globally."

Kaist, which was established in 1971 with foreign aid, has a special place in South Korean education. The military strongman Park Chung Hee recruited the brightest young people to train there as scientists and engineers. Villagers put up a large banner to celebrate whenever a local child was admitted.

"When I was a student here in the mid-1980s, some students stopped before the national flag at the library in the morning and observed a moment of silence, vowing to dedicate ourselves to the nation"s industrial development," said Cho Byung Jin, a professor of electrical engineering.

Since his arrival, Suh has become the most talked-about campus reformer in South Korea by taking on some of Kaist"s most hallowed traditions.

In a first for a Korean university, Suh has insisted that all classes eventually be taught in English, starting with those aimed at freshmen.

"I want Kaist students to work all over the world," Suh said last week. "I don"t want them to be like other Koreans who attend international conferences and have a lunch among themselves because they are afraid of speaking in English."

The move to English supports another of his changes: opening undergraduate degree programs to talented non-Koreans. Last year Kaist filled 51 of its 700 admission slots with foreign students on full scholarships. Meanwhile, he has ended free tuition for all; any student whose grade average falls below a B must pay up to $16,000 a year.

"My dream is to make Kaist a globalized university, one of the best universities in the world," he said.

In what may have been his most daring move, the university denied tenure to 15 of the 35 professors who applied last September. Until then, few if any applicants had failed tenure review in the university"s 36-year history.

In this education-obsessed country, Suh"s actions have been watched intensely for their broader impact. More than 82 percent of all high school graduates go on to higher education. What university a South Korean attends in his 20s can determine his position and salary in his 50s, a factor behind recent expos?of prominent South Koreans who faked prestigious diplomas.

The system is widely deplored but seldom challenged. From kindergarten, a child"s life is shaped largely by a single goal: doing well in examinations, particularly the all-important national college entrance exam. High school students plod through rote learning from dawn to dusk. Tutoring by "exam doctors" is a multibillion-dollar industry. During vacations, students attend private cram schools, which numbered 33,000 in 2006.

One result is a disciplined and conformist work force, an advantage when South Korea rapidly industrialized by copying technology from others. But now, with the country trying to climb the innovation ladder, the rigid school system is proving a stumbling block.

The nation"s highly hierarchical ways are often cited to explain how Hwang Woo Suk, the disgraced South Korean scientist who claimed he had produced stems cells from a cloned human embryo, could fabricate research findings with the complicity of junior associates.

The ambitious head overseas. Last year, 62,392 South Korean students were enrolled in U.S. colleges and universities, making them the third-largest foreign student group, after Indians (83,833) and Chinese (67,723), according to the U.S. Institute of International Education.

Some start earlier. About 35,000 South Korean children below college age go abroad each year, most to the United States to learn English.

Against this backdrop, Kaist has been experimenting with test-free admissions. For this year"s class, it brought applicants in for interviews and debates and make presentations while professors looked for creativity and leadership.

"About 20 percent of the students who formerly would have won admission didn"t make it under our new guidelines," Suh said. "We are looking for rough diamonds."

Challenging the status quo can be risky.

The Science and Technology Ministry, which oversees Kaist, had first looked outside South Korea for someone to lead the changes, choosing the Nobel physics laureate Robert Laughlin, who became the first foreigner to head a South Korean university in 2004. But he returned to Stanford University within two years, after the faculty rebelled against him for attempting some of the same changes Suh has instituted, accusing him, among other things, of insensitivity to Korean ways.

Suh"s Korean roots and experience shield him from such charges. He did not emigrate to the United States until he was 18 and has worked at Korean universities as well as serving as assistant director at the U.S. National Science Foundation in the 1980s and head of MIT"s department of mechanical engineering from 1991 to 2001.

"Reform entails sacrifices, but even if we don"t reform, there will be sacrifices," Suh said. "The difference is that if we don"t reform and don"t encourage competition, it"s the best people who are sacrificed."

So far, Suh"s innovations have mostly received favorable reviews.

Education Minister Kim Shi Il called them a "very desirable way of making Korea"s universities more competitive globally." The newspaper JoongAng Daily (which publishes an English-language version in partnership with the IHT) praised him for "smashing the iron rice bowls" (ending guaranteed job security) for professors and said, "We must learn from Kaist."

Ewan Stewart, a British physicist who has taught at Kaist since 1999, said, "Many of the things President Suh is saying were things I felt should have been said a long time ago."

Chung Joo Yeon, a first-year student, said she accepted the need for classes in English, but complained that some professors had no experience teaching in the language.

But Cho, the electrical engineering professor, said: "It"s no longer a matter of choice. If we want to maintain our school"s standards, we must draw talents from countries around the world, and that means we must conduct our classes in English."

Meanwhile, Lee has promised that as president he will give universities more autonomy by taking the "government"s hands off" how they select their students.

2008.01.23 View 17944

Int'l Herald Tribune Carries Feature Story on KAIST

International Herald Tribune carried a feature story on KAIST"s ongoing reform efforts on the front page of its Jan. 19-20 edition. The following is the full text of the report.

http://www.iht.com/articles/2008/01/18/asia/school.php

South Korean science prepares to take on the world

By Choe Sang-Hun

Friday, January 18, 2008

DAEJEON, South Korea: In Professor Cho Dong Ho"s laboratory at Kaist, South Korea"s top science and technology university, researchers are trying to develop technology that could let you fold a notebook-size electronic display and carry it in your pocket like a handkerchief.

It"s too early to say when something like this might be commercially available. But the experiment has already achieved one important breakthrough: it has mobilized professors from eight departments to collaborate on an idea proposed by a student.

This arrangement is almost unheard of in South Korea, where the norm is for a senior professor to dictate research projects to his own cloistered team. But it"s only one change afoot at this government-financed university, which has ambitions to transform the culture of South Korean science, and more.

"When we first got the student"s idea on what a future display should look like, we thought it was crazy, stuff from science fiction," said Cho, director of Kaist"s Institute for Information Technology Convergence. "But under our new president, we are being urged to try things no one else is likely to."

That university president is Suh Nam Pyo, 71, a mechanical engineer who used to be an administrator at the Massachusetts Institute of Technology and who is spearheading closely watched changes that are expected to have ramifications far beyond this campus 90 minutes by car south of Seoul.

His moves so far, from requiring professors to teach in English to basing student admissions on factors other than test scores, are aimed at making the university, and by extension South Korean society, much more competitive on a world scale.

When the South Korean government hired Suh in 2006 to shake up the state-financed Korean Advanced Institute of Science and Technology (which formally changed its name to its acronym, Kaist, on Jan. 1) the country"s leading schools faced a crisis. The old system, which guaranteed free tuition to lure promising students into science and technology, the drivers of South Korea"s industrial growth, was no longer working as well as it used to.

Prosperity was allowing those young people to choose fields of study once viewed as luxuries, like literature and history. Worse, increasing numbers were choosing to study abroad, mostly in the United States, and then not returning home. The fear was that South Korean institutions and enterprises would be gutted of expertise.

That concern was voiced at a news conference Monday by the president-elect, Lee Myung Bak, who said the educational system "isn"t producing talent that can compete globally."

Kaist, which was established in 1971 with foreign aid, has a special place in South Korean education. The military strongman Park Chung Hee recruited the brightest young people to train there as scientists and engineers. Villagers put up a large banner to celebrate whenever a local child was admitted.

"When I was a student here in the mid-1980s, some students stopped before the national flag at the library in the morning and observed a moment of silence, vowing to dedicate ourselves to the nation"s industrial development," said Cho Byung Jin, a professor of electrical engineering.

Since his arrival, Suh has become the most talked-about campus reformer in South Korea by taking on some of Kaist"s most hallowed traditions.

In a first for a Korean university, Suh has insisted that all classes eventually be taught in English, starting with those aimed at freshmen.

"I want Kaist students to work all over the world," Suh said last week. "I don"t want them to be like other Koreans who attend international conferences and have a lunch among themselves because they are afraid of speaking in English."

The move to English supports another of his changes: opening undergraduate degree programs to talented non-Koreans. Last year Kaist filled 51 of its 700 admission slots with foreign students on full scholarships. Meanwhile, he has ended free tuition for all; any student whose grade average falls below a B must pay up to $16,000 a year.

"My dream is to make Kaist a globalized university, one of the best universities in the world," he said.

In what may have been his most daring move, the university denied tenure to 15 of the 35 professors who applied last September. Until then, few if any applicants had failed tenure review in the university"s 36-year history.

In this education-obsessed country, Suh"s actions have been watched intensely for their broader impact. More than 82 percent of all high school graduates go on to higher education. What university a South Korean attends in his 20s can determine his position and salary in his 50s, a factor behind recent expos?of prominent South Koreans who faked prestigious diplomas.

The system is widely deplored but seldom challenged. From kindergarten, a child"s life is shaped largely by a single goal: doing well in examinations, particularly the all-important national college entrance exam. High school students plod through rote learning from dawn to dusk. Tutoring by "exam doctors" is a multibillion-dollar industry. During vacations, students attend private cram schools, which numbered 33,000 in 2006.

One result is a disciplined and conformist work force, an advantage when South Korea rapidly industrialized by copying technology from others. But now, with the country trying to climb the innovation ladder, the rigid school system is proving a stumbling block.

The nation"s highly hierarchical ways are often cited to explain how Hwang Woo Suk, the disgraced South Korean scientist who claimed he had produced stems cells from a cloned human embryo, could fabricate research findings with the complicity of junior associates.

The ambitious head overseas. Last year, 62,392 South Korean students were enrolled in U.S. colleges and universities, making them the third-largest foreign student group, after Indians (83,833) and Chinese (67,723), according to the U.S. Institute of International Education.

Some start earlier. About 35,000 South Korean children below college age go abroad each year, most to the United States to learn English.

Against this backdrop, Kaist has been experimenting with test-free admissions. For this year"s class, it brought applicants in for interviews and debates and make presentations while professors looked for creativity and leadership.

"About 20 percent of the students who formerly would have won admission didn"t make it under our new guidelines," Suh said. "We are looking for rough diamonds."

Challenging the status quo can be risky.

The Science and Technology Ministry, which oversees Kaist, had first looked outside South Korea for someone to lead the changes, choosing the Nobel physics laureate Robert Laughlin, who became the first foreigner to head a South Korean university in 2004. But he returned to Stanford University within two years, after the faculty rebelled against him for attempting some of the same changes Suh has instituted, accusing him, among other things, of insensitivity to Korean ways.

Suh"s Korean roots and experience shield him from such charges. He did not emigrate to the United States until he was 18 and has worked at Korean universities as well as serving as assistant director at the U.S. National Science Foundation in the 1980s and head of MIT"s department of mechanical engineering from 1991 to 2001.

"Reform entails sacrifices, but even if we don"t reform, there will be sacrifices," Suh said. "The difference is that if we don"t reform and don"t encourage competition, it"s the best people who are sacrificed."

So far, Suh"s innovations have mostly received favorable reviews.

Education Minister Kim Shi Il called them a "very desirable way of making Korea"s universities more competitive globally." The newspaper JoongAng Daily (which publishes an English-language version in partnership with the IHT) praised him for "smashing the iron rice bowls" (ending guaranteed job security) for professors and said, "We must learn from Kaist."

Ewan Stewart, a British physicist who has taught at Kaist since 1999, said, "Many of the things President Suh is saying were things I felt should have been said a long time ago."

Chung Joo Yeon, a first-year student, said she accepted the need for classes in English, but complained that some professors had no experience teaching in the language.

But Cho, the electrical engineering professor, said: "It"s no longer a matter of choice. If we want to maintain our school"s standards, we must draw talents from countries around the world, and that means we must conduct our classes in English."

Meanwhile, Lee has promised that as president he will give universities more autonomy by taking the "government"s hands off" how they select their students.

2008.01.23 View 17944