university-industry

-

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

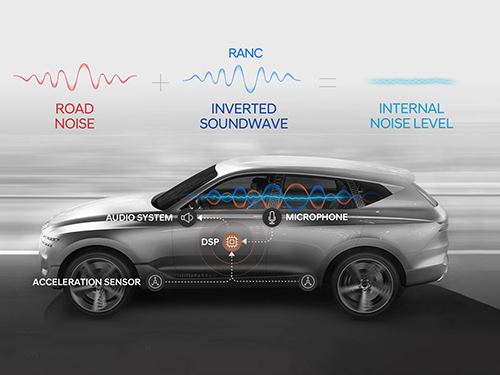

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 13164

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 13164 -

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9177

KAIST Awarded the IPBC R&D Institution Team of the Year

KAIST was awarded the R&D Institution Team of the Year during the annual IPBC (Intellectual Property Business Congress) Asia 2019 held in Tokyo October 28-30. IPBC is a conference dedicated to IP value creation strategies hosted by IAM Media, a world’s leading IP business media platform.

IPBC Asia 2019 recognized the institutions and businesses that employed innovative IP strategies and management to produce the greatest IP value in 11 categories covering automotive, electronics, healthcare and biotechnology, internet and software, R&D institutions, semiconductors, industrials, mobile and telecommunications, Asia IP deals, Asia teams, and Asia individuals. This year, KAIST was recognized as one of the most active patentees in the Asia-Pacific region by significantly increasing its IP value through licensing and tech transfers.

Associate Vice President Kyung Cheol Choi of the Office of University-Industry Cooperation remarked, “We are so delighted to prove the strong research capacity of KAIST. This will help us accomplish our vision of being a leading university that creates global impact.”

2019.12.04 View 9177 -

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 7861

KAIST to Transfer Core Tech to Domestic Companies amid Japan's Export Curbs

< Associate Vice President Kyung-Cheol Choi of the Office of University-Industry Cooperation (OUIC) at KAIST >

KAIST will transfer four core technologies related to materials, parts, and equipment to domestic companies to help them combat the latest export curbs triggered by Korea’s removal from Japan’s ‘white list’ of preferential trade partners. In addition, KAIST’s five patented technologies in the field of artificial intelligence (AI) and materials and parts will also be transferred to the companies in order to reduce the reliance on Japan and achieve technological independence through the ‘localization’ of key technologies.

KAIST announced these university-industry cooperation promotion plans at the ‘2019 KAIST Core Tech Transfer Day Conference’ held in Seoul on September 17. More than 200 entrepreneurs and investors attended the briefing and on-site consulting sessions delivered by nine KAIST professors who led the development of the technologies.

The four technologies were presented at the conference as those that can replace Japanese technologies subject to the export curbs. They include:

1. ‘Transparent fluorinated polyimide with low thermal expansion’ developed by Professor Sang-Youl Kim of the Department of Chemistry

2. ‘A non-destructive electromagnetic performance testing system’ developed by Professor Jung-Ryul Lee of the Department of Aerospace Engineering

3. ‘A nanotechnology-based electrode material for use in advanced secondary batteries’ developed by Professor Do-Kyung Kim of the Department of Materials Science and Engineering

4. ‘A high-resolution photoresist’ developed by Professor Emeritus Jin-Baek Kim of the Department of Chemistry.

Of particular interest is the non-destructive electromagnetic performance testing system technology developed by Professor Jung-Ryul Lee. This new cost-effective technology enables tests that were impossible to carry out using conventional technologies and yields a cost reduction of more than 50 percent compared to foreign technologies.

By introducing Professor Do-Kyung Kim’s new electrode material technology, the efficiency of electric vehicles can be increased. As this technology uses relatively low-cost sodium ion batteries, industries can prepare for the possible jump from the more expensive lithium batteries currently being used.

Another five patented AI and materials and parts technologies disclosed at the conference include:

1. ‘Enhanced HTTP adaptive streaming with CNN-based super-resolution’ developed by Professor Dong-soo Han of the School of Electrical Engineering

2. ‘Method and apparatus of brain-computer interface design for estimating choice behavior and decision strategy’ developed by Professor Sang-Wan Lee of the Department of Bio and Brain Engineering

3. ‘Eco-friendly fabrication of metal oxide nanoparticles and fabrication of non-toxic polymer sunscreen ingredients by electron irradiation’ developed by Professor Sung-Oh Cho of the Department of Nuclear and Quantum Engineering

4. ‘High-density nanofiber yarn-based coloricmetric gas sensors’ developed by Professor Il-Doo Kim of the Department of Materials Science and Engineering

5. ‘Silicon-pocket energy storage electrode with high energy density and its manufacturing technology’ developed by Professor Jeung-Ku Kang of the Graduate school of EEWS.

The patented nanofiber-based coloricmetric gas sensor technology developed by Professor Il-Doo Kim allows for the diagnosis of diseases by only using the patient’s respiration. Due to its high productivity and processability, it is expected to be applied to various fields in the fast-growing disease diagnosis sensor market, which includes mobile devices and wearable sensors.

Moreover, Professor Dong-soo Han’s patented adaptive streaming technology attracted attention along with the ever-growing Over The Top (OTT) and Video On Demand (VOD) service markets, since it has significant potential for improving the streaming quality of videos and reducing costs for video providers.

Professor Kyung-Cheol Choi, the Associate Vice President of the Office of University-Industry Cooperation (OUIC) at KAIST, said, “KAIST OUIC and KAIST Advisors on Materials and Parts (KAMP) have been working tirelessly to help Korean companies cope with the recent Japanese export restrictions. KAIST’s efforts will enhance the competitiveness and growth of the Korean industry and economy, turning this national crisis into opportunity.”

(END)

2019.09.20 View 7861