nano-fiber

-

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 6686

Professor Il-Doo Kim Receives the Science Minister’s Award

Professor Il-Doo Kim from the Department of Materials Science and Engineering received the Science and ICT Minister’s Award in recognition of his commercialization and technology transfer achievements during the Day of IP celebration.

Professor Kim, who has made over 222 patents application and registration home and abroad, has advanced toxic gas detection and breath gas sensor technology by arraying nanosensor fibers. His technological advances in micro-electro-mechanical systems (MEMS) helped to advance the commercialization of the MEMS-related sensor and improve its overall competitiveness.

He founded the Il-Doo Kim Research Center in 2019 and focuses on the commercialization of nanofiber manufacturing through electrospinning and highly efficient nanofiber filters. For instance, he succeeded in manufacturing a nano-filter recyclable mask that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nanometers in orthogonal or unidirectional directions.

Professor Kim also serves as an associate editor at ACS Nano. He said, “The importance of IP goes without saying. I look forward to the registration and application of more KAIST patents leading to commercialization, paving the way for national technological competitiveness.”

2021.09.15 View 6686 -

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 12229

Antivirus Industry the Centerpiece of New Deal R&D Initiatives

- KAIST launches post-COVID-19 R&D initiatives for smart mobile medical systems. -

KAIST will make the antivirus industry the centerpiece of what it is touting as the KAIST New Deal R&D initiative, which will drive new growth engines for preparing for the post-coronavirus era.

According to the new initiative, KAIST will concentrate on creating antivirus technologies, infectious disease-related big data management, and non-contact services platforms as key future R&D projects.

President Sung-Chul Shin launched the COVID-19 R&D Initiative task force last month, composed of more than 50 professors from the Graduate School of Medical Science and Engineering, the Department of Biological Sciences, the College of Engineering, and the Department of Industrial Design. The task force came up with key research agendas that will promote smart mobile medical systems in the years ahead.

“We will devote all of our R&D capacities to pursue a smart healthcare society,” said President Shin. “Our competitiveness in the fields of AI, ICT, materials, and bio-technology holds significant potential for building a healthy society powered by smart medical systems in Korea,” he added.

The smart medical systems focus mainly on building an Epidemic Mitigating Mobile Module (EMMM). The EMMM will manage epidemics via the three phases of prevention, emergency response, and treatment, with the development of each phase’s technological modules. The EMMM will also build an AI big data platform to assist with clinical applications and epidemic management.

Technologies applicable for the prevention phase include developing recyclable antivirus masks, plasma virus sterilizers, and smart breathable protective gowns. KAIST researchers will also focus on developing diagnosis modules that will identify epidemics more quickly and accurately.

Most significantly, KAIST aims to develop technologies for anti-infection medical services such as the transformable negative pressure ambulance module and negative pressure room, which are specially developed for respiratory infections.

The new R&D initiatives will center on virus therapies and treatments, specifically pushing forward vaccine and robotics studies. As caring robots and delivery robots will become common as main caregivers via noncontact services, research focusing on robotics will be significantly enhanced.

Even before launching the new R&D initiatives, researchers have started to present new technologies to help address the pandemic. Professor Il-Doo Kim’s team in the Department of Materials Science and Engineering developed a washable nano-fiber filtered face mask that is preparing for commercialization.

GPS tracking of infections has expanded comprehensively to detect both indoor and outdoor activities of infected patients. Professor Dong-Soo Han from the School of Computing developed Wi-Fi positioning software built into mobile phones that can trace both activities and is now preparing to roll it out.

Virologist Ui-Cheol Shin from the Graduate School of Medical Science and Engineering is carrying out research on a universal T-cell vaccine that can block the Betacoronaviruses. It is reported that that new epidemics such as SARS, MERS, and COVID-19 carry Betacoronaviruses.

Research teams in the Graduate School of AI are conducting various research projects on building prediction models for outbreaks and spreads using big data.

(END)

2020.05.20 View 12229 -

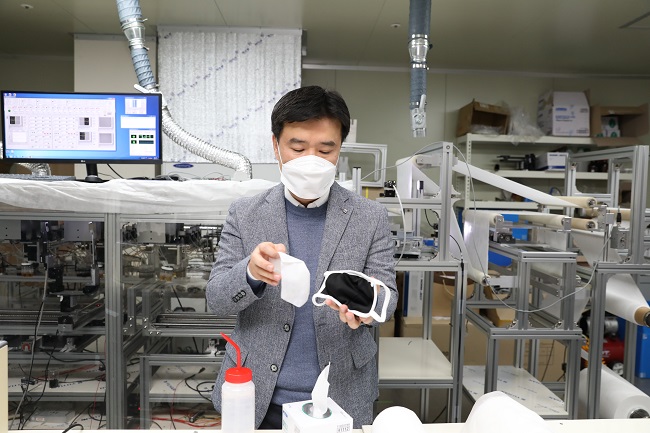

Recyclable Nano-Fiber Filtered Face Masks a Boon for Supply Fiasco

Wearing a face mask is a common sight in Korea during the COVID-19 outbreak. Due to the overwhelming demand, last week the government started to ration two masks per person per week, as a drastic measure to address the supply fiasco.

The face masks most commonly used are disposable ones, originally made for filtering out up to 94 or 95 percent of fine dust, referred to as N94 or N95 masks.

A KAIST research team announced that they have developed a nano-filter that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nm in orthogonal or unidirectional directions. This reusable nano-filtered face mask could help to relieve the challenges arising from the supply shortage of face masks.

Professor Il-Doo Kim’s nano-fiber filtered mask will maintain its sturdy frame and filtering function even after being washed more than 20 times. Professor Kim, who has continued to study the filtering of fine dust using nano-filters, is now awaiting final approval from the Ministry of Food and Drug Safety to bring his product into the market.

Professor Kim used an insulation block electrospinning process to manufacture orthogonal nanofibers by controlling the alignment of nanofibers. This structure can minimize delivering of the pressure toward the air filter and maximize the filtration efficiency, which is different from existing disposable masks without nano-fibers.

Existing masks also fail to maintain their air filtering function because their electrostatic function disappears when exposed to water. Thus, their filtering efficiency is reduced significantly, making it almost impossible to reuse them. However, this nano-fiber design was proven to be water resistant with more than 94% filtering efficiency in 20 repeated bactericidal tests with ethanol. The nano-fiber mask also showed no deformation in its nano-membrane structure despite the 20 hand washes. In particular, it was confirmed that there were no deformations in the membrane, even after soaking in ethanol more than three hours.

Professor Kim said, “We believe that this mask can be reusable for about a month even after washing in ethanol. The inner filter can also be replaced.” He added, “We found that the mask filters out up to 80 percent of 600-nanometer particles even after undergoing a bending test more than 4,000 times.”

Professor Kim established his startup company, the “Kim Il-Doo Research Institute,” last February. It can currently produce 1,500 nano-fiber filters per day.

2020.03.17 View 22512

Recyclable Nano-Fiber Filtered Face Masks a Boon for Supply Fiasco

Wearing a face mask is a common sight in Korea during the COVID-19 outbreak. Due to the overwhelming demand, last week the government started to ration two masks per person per week, as a drastic measure to address the supply fiasco.

The face masks most commonly used are disposable ones, originally made for filtering out up to 94 or 95 percent of fine dust, referred to as N94 or N95 masks.

A KAIST research team announced that they have developed a nano-filter that maintains excellent filtering efficiency even after hand washing through the development of proprietary technology that aligns nanofibers with a diameter of 100~500 nm in orthogonal or unidirectional directions. This reusable nano-filtered face mask could help to relieve the challenges arising from the supply shortage of face masks.

Professor Il-Doo Kim’s nano-fiber filtered mask will maintain its sturdy frame and filtering function even after being washed more than 20 times. Professor Kim, who has continued to study the filtering of fine dust using nano-filters, is now awaiting final approval from the Ministry of Food and Drug Safety to bring his product into the market.

Professor Kim used an insulation block electrospinning process to manufacture orthogonal nanofibers by controlling the alignment of nanofibers. This structure can minimize delivering of the pressure toward the air filter and maximize the filtration efficiency, which is different from existing disposable masks without nano-fibers.

Existing masks also fail to maintain their air filtering function because their electrostatic function disappears when exposed to water. Thus, their filtering efficiency is reduced significantly, making it almost impossible to reuse them. However, this nano-fiber design was proven to be water resistant with more than 94% filtering efficiency in 20 repeated bactericidal tests with ethanol. The nano-fiber mask also showed no deformation in its nano-membrane structure despite the 20 hand washes. In particular, it was confirmed that there were no deformations in the membrane, even after soaking in ethanol more than three hours.

Professor Kim said, “We believe that this mask can be reusable for about a month even after washing in ethanol. The inner filter can also be replaced.” He added, “We found that the mask filters out up to 80 percent of 600-nanometer particles even after undergoing a bending test more than 4,000 times.”

Professor Kim established his startup company, the “Kim Il-Doo Research Institute,” last February. It can currently produce 1,500 nano-fiber filters per day.

2020.03.17 View 22512