Structures

-

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 6211

KAIST Develops CamBio - a New Biotemplating Method

- Professor Jae-Byum Chang and Professor Yeon Sik Jung’s joint research team of the Department of Materials Science and Engineering developed a highly tunable bio-templating method “CamBio” that makes use of intracellular protein structures

- Substrate performance improvement of up to 230% demonstrated via surface-enhanced Raman spectroscopy (SERS)

- Expected to have price competitiveness over bio-templating method as it expands the range of biological samples

- Expected to expand the range of application of nanostructure synthesis technology by utilizing various biological structures

< Photo 1. (From left) Professor Yeon Sik Jung, Ph.D. candidate Dae-Hyeon Song, Professor Jae-Byum Chang, and (from top right) Dr. Chang Woo Song and Dr. Seunghee H. Cho of the Department of Materials Science and Engineering >

Biological structures have complex characteristics that are difficult to replicate artificially, but biotemplating methods* that directly utilize these biological structures have been used in various fields of application. The KAIST research team succeeded in utilizing previously unusable biological structures and expanding the areas in which biotemplate methods can be applied.

*Biotemplating: A method of using biotemplates as a mold to create functional structural materials, utilizing the functions of these biological structures, from viruses to the tissues and organs that make up our bodies

KAIST (President Kwang Hyung Lee) announced on the 10th that a joint research team of Professors Jae-Byum Chang and Professor Yeon Sik Jung of the Department of Materials Science and Engineering developed a biotemplating method that utilizes specific intracellular proteins in biological samples and has high tunability.

Existing biotemplate methods mainly utilize only the external surface of biological samples or have limitations in utilizing the structure-function correlation of various biological structures due to limited dimensions and sample sizes, making it difficult to create functional nanostructures.

To solve this problem, the research team studied a way to utilize various biological structures within the cells while retaining high tunability.

< Figure 1. CamBio utilizing microtubules, a intracellular protein structure. The silver nanoparticle chains synthesized along the microtubules that span the entire cell interior can be observed through an electron microscope, and it is shown that this can be used as a successful SERS substrate. >

As a result of the research, the team developed the “Conversion to advanced materials via labeled Biostructure”, shortened as “CamBio”, which enables the selective synthesis of nanostructures with various characteristics and sizes from specific protein structures composed of diverse proteins within biological specimens.

The CamBio method secures high tunability of functional nanostructures that can be manufactured from biological samples by merging various manufacturing and biological technologies.

Through the technology of repeatedly attaching antibodies, arranging cells in a certain shape, and thinly slicing tissue, the functional nanostructures made with CamBio showed improved performance on the surface-enhanced Raman spectroscopy (SERS)* substrate used for material detection.

*Surface-enhanced Raman spectroscopy (SERS): A technology that can detect very small amounts of substances using light, based on the principle that specific substances react to light and amplifies signals on surfaces of metals such as gold or silver.

The research team found that the nanoparticle chains made using the intracellular protein structures through the process of repeated labeling with antibodies allowed easier control, and improved SERS performance by up to 230%.

In addition, the research team expanded from utilizing the structures inside cells to obtaining samples of muscle tissues inside meat using a cryostat and successfully producing a substrate with periodic bands made of metal particles by performing the CamBio process. This method of producing a substrate not only allows large-scale production using biological samples, but also shows that it is a cost-effective method.

< Figure 2. A method for securing tunability using CamBio at the cell level. Examples of controlling characteristics by integrating iterative labeling and cell pattering techniques with CamBio are shown. >

The CamBio developed by the research team is expected to be used as a way to solve problems faced by various research fields as it is to expand the range of bio-samples that can be produced for various usage.

The first author, Dae-Hyeon Song, a Ph.D. candidate of KAIST Department of Materials Science and Engineering said, “Through CamBio, we have comprehensively accumulated biotemplating methods that can utilize more diverse protein structures,” and “If combined with the state-of-the-art biological technologies such as gene editing and 3D bioprinting and new material synthesis technologies, biostructures can be utilized in various fields of application.”

< Figure 3. A method for securing tunability using CamBio at the tissue level. In order to utilize proteins inside muscle tissue, the frozen tissue sectioning technology is combined, and through this, a substrate with a periodic nanoparticle band pattern is successfully produced, and it is shown that large-area acquisition of samples and price competitiveness can be achieved. >

This study, in which the Ph.D. candidate Dae-Hyeon Song along with Dr. Chang Woo Song, and Dr. Seunghee H. Cho of the same department participated as the first authors, was published online in the international academic journal, Advanced Science, on November 13th, 2024.

(Paper title: Highly Tunable, Nanomaterial-Functionalized Structural Templating of Intracellular Protein Structures Within Biological Species) https://doi.org/10.1002/advs.202406492

This study was conducted with a combination of support from various programs including the National Convergence Research of Scientific Challenges (National Research Foundation of Korea (NRF) 2024), Engineering Reseach Center (ERC) (Wearable Platform Materials Technology Center, NRF 2023), ERC (Global Bio-integrated Materials Center, NRF 2024), and the National Advanced Program for Biological Research Resources (Bioimaging Data Curation Center, NRF 2024) funded by Ministry of Science and ICT.

2025.01.10 View 6211 -

A 20-year-old puzzle solved: KAIST research team reveals the 'three-dimensional vortex' of zero-dimensional ferroelectrics

Materials that can maintain a magnetized state by themselves without an external magnetic field (i.e., permanent magnets) are called ferromagnets. Ferroelectrics can be thought of as the electric counterpart to ferromagnets, as they maintain a polarized state without an external electric field. It is well-known that ferromagnets lose their magnetic properties when reduced to nano sizes below a certain threshold. What happens when ferroelectrics are similarly made extremely small in all directions (i.e., into a zero-dimensional structure such as nanoparticles) has been a topic of controversy for a long time.

< (From left) Professor Yongsoo Yang, the corresponding author, and Chaehwa Jeong, the first author studying in the integrated master’s and doctoral program, of the KAIST Department of Physics >

The research team led by Dr. Yongsoo Yang from the Department of Physics at KAIST has, for the first time, experimentally clarified the three-dimensional, vortex-shaped polarization distribution inside ferroelectric nanoparticles through international collaborative research with POSTECH, SNU, KBSI, LBNL and University of Arkansas.

About 20 years ago, Prof. Laurent Bellaiche (currently at University of Arkansas) and his colleagues theoretically predicted that a unique form of polarization distribution, arranged in a toroidal vortex shape, could occur inside ferroelectric nanodots. They also suggested that if this vortex distribution could be properly controlled, it could be applied to ultra-high-density memory devices with capacities over 10,000 times greater than existing ones. However, experimental clarification had not been achieved due to the difficulty of measuring the three-dimensional polarization distribution within ferroelectric nanostructures.

The research team at KAIST successfully solved this 20-year-old challenge by implementing a technique called atomic electron tomography. This technique works by acquiring atomic-resolution transmission electron microscope images of the nanomaterials from multiple tilt angles, and then reconstructing them back into three-dimensional structures using advanced reconstruction algorithms. Electron tomography can be understood as essentially the same method with the CT scans used in hospitals to view internal organs in three dimensions; the KAIST team adapted it uniquely for nanomaterials, utilizing an electron microscope at the single-atom level.

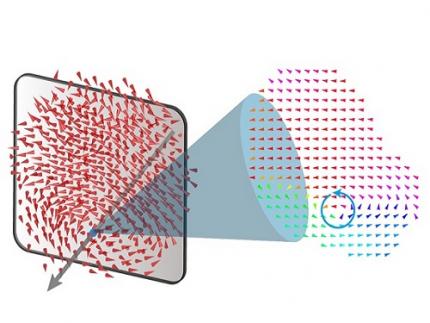

< Figure 1. Three-dimensional polarization distribution of BaTiO3 nanoparticles revealed by atomic electron tomography. >(Left) Schematic of the electron tomography technique, which involves acquiring transmission electron microscope images at multiple tilt angles and reconstructing them into 3D atomic structures.(Center) Experimentally determined three-dimensional polarization distribution inside a BaTiO3 nanoparticle via atomic electron tomography. A vortex-like structure is clearly visible near the bottom (blue dot).(Right) A two-dimensional cross-section of the polarization distribution, thinly sliced at the center of the vortex, with the color and arrows together indicating the direction of the polarization. A distinct vortex structure can be observed.

Using atomic electron tomography, the team completely measured the positions of cation atoms inside barium titanate (BaTiO3) nanoparticles, a well-known ferroelectric material, in three dimensions. From the precisely determined 3D atomic arrangements, they were able to further calculate the internal three-dimensional polarization distribution at the single-atom level. The analysis of the polarization distribution revealed, for the first time experimentally, that topological polarization orderings including vortices, anti-vortices, skyrmions, and a Bloch point occur inside the 0-dimensional ferroelectrics, as theoretically predicted 20 years ago. Furthermore, it was also found that the number of internal vortices can be controlled depending on their sizes.

Prof. Sergey Prosandeev and Prof. Bellaiche (who proposed with other co-workers the polar vortex ordering theoretically 20 years ago), joined this collaboration and further proved that the vortex distribution results obtained from experiments are consistent with theoretical calculations.

By controlling the number and orientation of these polarization distributions, it is expected that this can be utilized into next-generation high-density memory device that can store more than 10,000 times the amount of information in the same-sized device compared to existing ones.

Dr. Yang, who led the research, explained the significance of the results: “This result suggests that controlling the size and shape of ferroelectrics alone, without needing to tune the substrate or surrounding environmental effects such as epitaxial strain, can manipulate ferroelectric vortices or other topological orderings at the nano-scale. Further research could then be applied to the development of next-generation ultra-high-density memory.”

This research, with Chaehwa Jeong from the Department of Physics at KAIST as the first author, was published online in Nature Communications on May 8th (Title: Revealing the Three-Dimensional Arrangement of Polar Topology in Nanoparticles).

The study was mainly supported by the National Research Foundation of Korea (NRF) Grants funded by the Korean Government (MSIT).

2024.05.31 View 8661

A 20-year-old puzzle solved: KAIST research team reveals the 'three-dimensional vortex' of zero-dimensional ferroelectrics

Materials that can maintain a magnetized state by themselves without an external magnetic field (i.e., permanent magnets) are called ferromagnets. Ferroelectrics can be thought of as the electric counterpart to ferromagnets, as they maintain a polarized state without an external electric field. It is well-known that ferromagnets lose their magnetic properties when reduced to nano sizes below a certain threshold. What happens when ferroelectrics are similarly made extremely small in all directions (i.e., into a zero-dimensional structure such as nanoparticles) has been a topic of controversy for a long time.

< (From left) Professor Yongsoo Yang, the corresponding author, and Chaehwa Jeong, the first author studying in the integrated master’s and doctoral program, of the KAIST Department of Physics >

The research team led by Dr. Yongsoo Yang from the Department of Physics at KAIST has, for the first time, experimentally clarified the three-dimensional, vortex-shaped polarization distribution inside ferroelectric nanoparticles through international collaborative research with POSTECH, SNU, KBSI, LBNL and University of Arkansas.

About 20 years ago, Prof. Laurent Bellaiche (currently at University of Arkansas) and his colleagues theoretically predicted that a unique form of polarization distribution, arranged in a toroidal vortex shape, could occur inside ferroelectric nanodots. They also suggested that if this vortex distribution could be properly controlled, it could be applied to ultra-high-density memory devices with capacities over 10,000 times greater than existing ones. However, experimental clarification had not been achieved due to the difficulty of measuring the three-dimensional polarization distribution within ferroelectric nanostructures.

The research team at KAIST successfully solved this 20-year-old challenge by implementing a technique called atomic electron tomography. This technique works by acquiring atomic-resolution transmission electron microscope images of the nanomaterials from multiple tilt angles, and then reconstructing them back into three-dimensional structures using advanced reconstruction algorithms. Electron tomography can be understood as essentially the same method with the CT scans used in hospitals to view internal organs in three dimensions; the KAIST team adapted it uniquely for nanomaterials, utilizing an electron microscope at the single-atom level.

< Figure 1. Three-dimensional polarization distribution of BaTiO3 nanoparticles revealed by atomic electron tomography. >(Left) Schematic of the electron tomography technique, which involves acquiring transmission electron microscope images at multiple tilt angles and reconstructing them into 3D atomic structures.(Center) Experimentally determined three-dimensional polarization distribution inside a BaTiO3 nanoparticle via atomic electron tomography. A vortex-like structure is clearly visible near the bottom (blue dot).(Right) A two-dimensional cross-section of the polarization distribution, thinly sliced at the center of the vortex, with the color and arrows together indicating the direction of the polarization. A distinct vortex structure can be observed.

Using atomic electron tomography, the team completely measured the positions of cation atoms inside barium titanate (BaTiO3) nanoparticles, a well-known ferroelectric material, in three dimensions. From the precisely determined 3D atomic arrangements, they were able to further calculate the internal three-dimensional polarization distribution at the single-atom level. The analysis of the polarization distribution revealed, for the first time experimentally, that topological polarization orderings including vortices, anti-vortices, skyrmions, and a Bloch point occur inside the 0-dimensional ferroelectrics, as theoretically predicted 20 years ago. Furthermore, it was also found that the number of internal vortices can be controlled depending on their sizes.

Prof. Sergey Prosandeev and Prof. Bellaiche (who proposed with other co-workers the polar vortex ordering theoretically 20 years ago), joined this collaboration and further proved that the vortex distribution results obtained from experiments are consistent with theoretical calculations.

By controlling the number and orientation of these polarization distributions, it is expected that this can be utilized into next-generation high-density memory device that can store more than 10,000 times the amount of information in the same-sized device compared to existing ones.

Dr. Yang, who led the research, explained the significance of the results: “This result suggests that controlling the size and shape of ferroelectrics alone, without needing to tune the substrate or surrounding environmental effects such as epitaxial strain, can manipulate ferroelectric vortices or other topological orderings at the nano-scale. Further research could then be applied to the development of next-generation ultra-high-density memory.”

This research, with Chaehwa Jeong from the Department of Physics at KAIST as the first author, was published online in Nature Communications on May 8th (Title: Revealing the Three-Dimensional Arrangement of Polar Topology in Nanoparticles).

The study was mainly supported by the National Research Foundation of Korea (NRF) Grants funded by the Korean Government (MSIT).

2024.05.31 View 8661 -

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

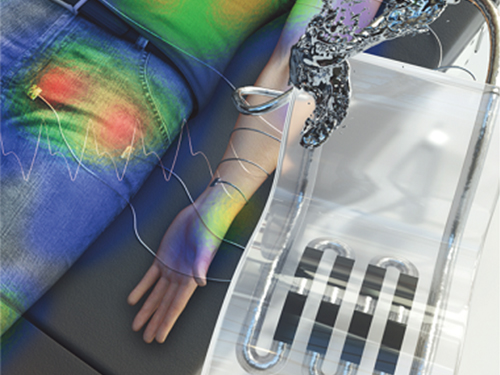

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 17234

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 17234 -

Hierarchical Porous Titanium Nitride Synthesized by Multiscale Phase Separation for LSBs

(from left: Professor Jinwoo Lee and PhD candidate Won-Gwang Lim)

A KAIST research team developed ultra-stable, high-rate lithium-sulfur batteries (LSBs) by using hierarchical porous titanium nitride as a sulfur host, and achieved superior cycle stability and high rate performance for LSBs.

The control of large amounts of energy is required for use in an electric vehicle or smart grid system. In this sense, the development of next-generation secondary batteries is in high demand. Theoretically, LSBs have an energy density seven times higher than commercial lithium ion batteries (LIBs). Also, their production cost can be reduced dramatically since sulfur can be obtained at a low price.

Despite these positive aspects, there have been several issues impeding the commercialization of LSBs, such as the low electric conductivity of sulfur, the dissolution of active materials during operation, and sluggish conversion reactions. These issues decrease the cycle stability and rate capability of batteries.

To tackle those issues, Professor Jinwoo Lee from the Department of Chemical and Biomolecular Engineering and his team synthesized a well-developed hierarchical macro/mesoporous titanium nitride as a host material for sulfur. The titanium nitride has a high chemical affinity for sulfur and high electrical conductivity. As a result, it prevents the dissolution of active materials and facilitates the charge transfer. Moreover, the synergistic effect of macropore and mesopore structures allows the stable accommodation of large amounts of sulfur and facilitates the electrolyte penetration.

Previously reported polar inorganic materials have a high affinity for sulfur, but it was challenging to control the porous architecture suitable to the sulfur host. This work breaks such limitations by developing a synthetic route to easily control the porous architecture of inorganic materials, which led to obtaining superior cycle stability and high rate capabilities.

Professor Lee said, “Some problems still remain in commercializing LSBs as next-generation batteries. Hence, there should be a continued research on this matter to solve the issues. Through this research, we secured a key technology for ultrastable, high-rate LSBs.”

This research was led by PhD candidate Won-Gwang Lim and collaborated on by Jeong Woo Han from POSTECH. It was chosen as the cover article of Advanced Materials on January 15, 2019.

Figure 1. Schematic illustration for the synthetic route of co-continuous h-TiN

Figure 2. The hierarchical multiscale porous structure is still retained without any collapse after the conversion to h-TiN. The good retention of the porous structure is attributed to the thick pore wall of the h-TiO₂derived from the block copolymer self-assembly

Figure 3. The cover page of Advanced Materials

2019.01.28 View 8322

Hierarchical Porous Titanium Nitride Synthesized by Multiscale Phase Separation for LSBs

(from left: Professor Jinwoo Lee and PhD candidate Won-Gwang Lim)

A KAIST research team developed ultra-stable, high-rate lithium-sulfur batteries (LSBs) by using hierarchical porous titanium nitride as a sulfur host, and achieved superior cycle stability and high rate performance for LSBs.

The control of large amounts of energy is required for use in an electric vehicle or smart grid system. In this sense, the development of next-generation secondary batteries is in high demand. Theoretically, LSBs have an energy density seven times higher than commercial lithium ion batteries (LIBs). Also, their production cost can be reduced dramatically since sulfur can be obtained at a low price.

Despite these positive aspects, there have been several issues impeding the commercialization of LSBs, such as the low electric conductivity of sulfur, the dissolution of active materials during operation, and sluggish conversion reactions. These issues decrease the cycle stability and rate capability of batteries.

To tackle those issues, Professor Jinwoo Lee from the Department of Chemical and Biomolecular Engineering and his team synthesized a well-developed hierarchical macro/mesoporous titanium nitride as a host material for sulfur. The titanium nitride has a high chemical affinity for sulfur and high electrical conductivity. As a result, it prevents the dissolution of active materials and facilitates the charge transfer. Moreover, the synergistic effect of macropore and mesopore structures allows the stable accommodation of large amounts of sulfur and facilitates the electrolyte penetration.

Previously reported polar inorganic materials have a high affinity for sulfur, but it was challenging to control the porous architecture suitable to the sulfur host. This work breaks such limitations by developing a synthetic route to easily control the porous architecture of inorganic materials, which led to obtaining superior cycle stability and high rate capabilities.

Professor Lee said, “Some problems still remain in commercializing LSBs as next-generation batteries. Hence, there should be a continued research on this matter to solve the issues. Through this research, we secured a key technology for ultrastable, high-rate LSBs.”

This research was led by PhD candidate Won-Gwang Lim and collaborated on by Jeong Woo Han from POSTECH. It was chosen as the cover article of Advanced Materials on January 15, 2019.

Figure 1. Schematic illustration for the synthetic route of co-continuous h-TiN

Figure 2. The hierarchical multiscale porous structure is still retained without any collapse after the conversion to h-TiN. The good retention of the porous structure is attributed to the thick pore wall of the h-TiO₂derived from the block copolymer self-assembly

Figure 3. The cover page of Advanced Materials

2019.01.28 View 8322 -

Professor Dai Gil Lee Recognized by the ICCS

Emeritus Professor Dai Gil Lee, from the School of Mechanical and Aerospace Engineering at KAIST, received a special achievement award from the 20th International Conference on Composite Structures (ICCS).

ICCS is a renowned conference in the field of applied composite structures, which highlights the practicality of composite structures. This year, the conference was held at the Conservatoire National des Arts et Métiers (CNAM), Paris, France from September 4 to 7. Approximately 650 papers were presented from 45 countries.

Especially, the conference honored Emeritus Professor Lee, who has been engaged in ICCS since 1993 and received best paper award twice. The ICCS recognized him for serving with distinction in science and technology in the fields of composite materials and structures. As a member of the Editorial Board for many years, he gave significant support to the journal Composite Structures. At the conference, he gave a special lecture titled ‘Lightweight Carbon Composite Proton Exchange Membrane Fuel Cells’.

Professor Lee said, “I will dedicate myself to innovate Vanadium Redox Flow Battery-ESS (VRFB) based on the research findings announced at the conference and related patents. I am hoping that these efforts will contribute to solving energy issues around the world.”

2017.10.19 View 9968

Professor Dai Gil Lee Recognized by the ICCS

Emeritus Professor Dai Gil Lee, from the School of Mechanical and Aerospace Engineering at KAIST, received a special achievement award from the 20th International Conference on Composite Structures (ICCS).

ICCS is a renowned conference in the field of applied composite structures, which highlights the practicality of composite structures. This year, the conference was held at the Conservatoire National des Arts et Métiers (CNAM), Paris, France from September 4 to 7. Approximately 650 papers were presented from 45 countries.

Especially, the conference honored Emeritus Professor Lee, who has been engaged in ICCS since 1993 and received best paper award twice. The ICCS recognized him for serving with distinction in science and technology in the fields of composite materials and structures. As a member of the Editorial Board for many years, he gave significant support to the journal Composite Structures. At the conference, he gave a special lecture titled ‘Lightweight Carbon Composite Proton Exchange Membrane Fuel Cells’.

Professor Lee said, “I will dedicate myself to innovate Vanadium Redox Flow Battery-ESS (VRFB) based on the research findings announced at the conference and related patents. I am hoping that these efforts will contribute to solving energy issues around the world.”

2017.10.19 View 9968 -

KAIST Team Develops Technology to Enable Unzipping of the Graphene Plane

Professor Sang-Wook Kim’s research team of the Material Science and Engineering Department has developed a technique, which enables unzipping of the graphene plane without uncontrollable damage. The research findings were published online on the January 22 issue of Nature Communications.

Graphene is a form of carbon in which its atoms form a honey-comb structure through chemical bonding. If this structure can be cut to a desired form, other carbon materials with nanostructure can be created. Many researchers have tried to obtain the accurate unzipping of graphene structures, but faced challenges doing so.

To break a very strong bond between carbon atoms, an equivalently strong chemical reaction must be induced. But the chemical reaction not only cuts out the desirable borders, but also damages the surrounding ones. Conventional techniques, which cut out graphene at once, damaged the chemical properties of the graphene structure after unzipping. This is similar to wearing out paper while manipulating it.

To solve this problem, the research team adopted “heteroatom doping.” The idea is similar to a sheet of paper being split following a groove drawn on the sheet. After making some regions of the structure unstable by doping other atoms such as nitrogen on a carbon plane, the regions are electrochemically stimulated to split the parts. Nitrogen or other atoms act as the groove on the grapheme plane.

The researchers finely controlled the amount of unzipping graphene by adjusting the amount of heteroatom dopants, from which they were able to create a quality nano graphene without any damage in its 2-dimensional crystalline structure. Using this technique, the researchers were able to obtain a capacitor with state-of-the-art energy transfer speed. The nano graphene can be combined with polymer, metal, and semiconductor nano molecules to form carbon composites.

Professor Kim said, “In order to commercialize this technique, heteroatom doping should be researched further. We plan to develop fabric-like carbon materials with excellent mechanical and electrical properties using this technique.”

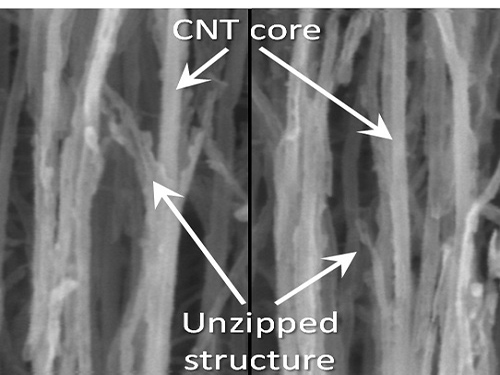

Picture 1: Unzipped Carbon Nano Tube

Picture 2: Development of Nano Graphene from Carbon Nano Tube Using Heteroatom Dopants

Korean descriptions translated into English:

Unzipping Process of Graphene

Carbon Nano Tube → Nano Graphen

Heteroatom

This process is similar to a paper being split in two from a tiny hole punched therein.

2016.03.22 View 9991

KAIST Team Develops Technology to Enable Unzipping of the Graphene Plane

Professor Sang-Wook Kim’s research team of the Material Science and Engineering Department has developed a technique, which enables unzipping of the graphene plane without uncontrollable damage. The research findings were published online on the January 22 issue of Nature Communications.

Graphene is a form of carbon in which its atoms form a honey-comb structure through chemical bonding. If this structure can be cut to a desired form, other carbon materials with nanostructure can be created. Many researchers have tried to obtain the accurate unzipping of graphene structures, but faced challenges doing so.

To break a very strong bond between carbon atoms, an equivalently strong chemical reaction must be induced. But the chemical reaction not only cuts out the desirable borders, but also damages the surrounding ones. Conventional techniques, which cut out graphene at once, damaged the chemical properties of the graphene structure after unzipping. This is similar to wearing out paper while manipulating it.

To solve this problem, the research team adopted “heteroatom doping.” The idea is similar to a sheet of paper being split following a groove drawn on the sheet. After making some regions of the structure unstable by doping other atoms such as nitrogen on a carbon plane, the regions are electrochemically stimulated to split the parts. Nitrogen or other atoms act as the groove on the grapheme plane.

The researchers finely controlled the amount of unzipping graphene by adjusting the amount of heteroatom dopants, from which they were able to create a quality nano graphene without any damage in its 2-dimensional crystalline structure. Using this technique, the researchers were able to obtain a capacitor with state-of-the-art energy transfer speed. The nano graphene can be combined with polymer, metal, and semiconductor nano molecules to form carbon composites.

Professor Kim said, “In order to commercialize this technique, heteroatom doping should be researched further. We plan to develop fabric-like carbon materials with excellent mechanical and electrical properties using this technique.”

Picture 1: Unzipped Carbon Nano Tube

Picture 2: Development of Nano Graphene from Carbon Nano Tube Using Heteroatom Dopants

Korean descriptions translated into English:

Unzipping Process of Graphene

Carbon Nano Tube → Nano Graphen

Heteroatom

This process is similar to a paper being split in two from a tiny hole punched therein.

2016.03.22 View 9991 -

Dong-Young Lee, a Doctoral Candidate, Receives the Best Paper Award

Dong-Young Lee, a Ph.D. candidate in the Mechanical Engineering Department, KAIST, received the Best Paper Award at the 18th International Conference on Composite Structures (ICCS). The event was held in Lisbon, Portugal, on June 15-18, 2015. Mr. Lee’s adviser is Professor Dai-Gil Lee of the same department.

The ICCS is held every other year, and is one of the largest and long-established conferences on composite materials and structures in the world. At this year’s conference, a total of 680 papers were presented, among which, two papers were chosen for the Best Paper Award, including Mr. Lee’s.

The paper, entitled “Gasket-integrated Carbon and Silicon Elastomer Composite Bipolar Plate for High-temperature PEMFC,” will be published in the September issue of Composite Structures which is one of the top journals in mechanical engineering as judged by the Google Scholar Metrics rankings.

Mr. Lee dropped the conventional method of PEMFC (Proton Exchange Membrane Fuel Cells) assembly and instead developed a gasket-integrated carbon and silicone elastomer composite bipolar plate. This technology significantly increased the energy efficiency of fuel cells and their productivity.

Mr. Lee said, “I would like to thank the many people who supported me, especially my Ph.D. adviser, Professor Dai-Gil Lee. Without their encouragement, I would have not won this award. I hope my research will contribute to solving energy problems in the future.”

In addition, Professor Joon-Woo Im from Chonbuk National University, Senior Researcher Il-Bum Choi from the Agency for Defense Development, and a fellow doctoral candidate Soo-Hyun Nam from KAIST participated in this research project.

2015.07.09 View 12028

Dong-Young Lee, a Doctoral Candidate, Receives the Best Paper Award

Dong-Young Lee, a Ph.D. candidate in the Mechanical Engineering Department, KAIST, received the Best Paper Award at the 18th International Conference on Composite Structures (ICCS). The event was held in Lisbon, Portugal, on June 15-18, 2015. Mr. Lee’s adviser is Professor Dai-Gil Lee of the same department.

The ICCS is held every other year, and is one of the largest and long-established conferences on composite materials and structures in the world. At this year’s conference, a total of 680 papers were presented, among which, two papers were chosen for the Best Paper Award, including Mr. Lee’s.

The paper, entitled “Gasket-integrated Carbon and Silicon Elastomer Composite Bipolar Plate for High-temperature PEMFC,” will be published in the September issue of Composite Structures which is one of the top journals in mechanical engineering as judged by the Google Scholar Metrics rankings.

Mr. Lee dropped the conventional method of PEMFC (Proton Exchange Membrane Fuel Cells) assembly and instead developed a gasket-integrated carbon and silicone elastomer composite bipolar plate. This technology significantly increased the energy efficiency of fuel cells and their productivity.

Mr. Lee said, “I would like to thank the many people who supported me, especially my Ph.D. adviser, Professor Dai-Gil Lee. Without their encouragement, I would have not won this award. I hope my research will contribute to solving energy problems in the future.”

In addition, Professor Joon-Woo Im from Chonbuk National University, Senior Researcher Il-Bum Choi from the Agency for Defense Development, and a fellow doctoral candidate Soo-Hyun Nam from KAIST participated in this research project.

2015.07.09 View 12028 -

Hierarchically-Porous Polymers with Fast Absorption

KAIST's Professor Myungeun Seo and his research team from the Graduate School of Nanoscience and Technology has developed a method to form micropores of less than 2 nanometers within porous polymers where 10 nanometers long mesopores connect like a net. The advantage of the porous polymers is fast absorption of molecules.

Porous polymers with micropores of less than 2 nanometers, like a zeolite, have a large surface area. They are used as a means to store hydrogen-based molecules or as a catalytic support that can be used as a surface to convert a material into a desired form. However, because the size of the pores in its path was too small for the molecules, it took a long time to spread into the pores and reach the surface.

To reach the surface efficiently, a lung cell or the vein of a leaf has a structure wherein the pores are subdivided into different sizes so that the molecule can spread throughout the organ. A technology that can create not only micropores but also bigger pores was necessary in order to create such structure.

The research team solved the issue by implementing a "self-assembly" of block polymers to easily form a net-like nanostructure from mesopores of 10 nanometers.

The team created hierarchically-porous polymers consisting of two different types of pores by using a hypercrosslinking reaction along with the "self-assembly" method. The reaction creates micropores within the chain after the polymer chain is confined by a chemical bond.

This porous polymer has micropores that are smaller than 2 nanometers on the walls of mesopores while 10 nanometers long mesopores forming 3-dimensional net structures. Because of the "self-assembly" method, the size of mesopores can be adjusted within the range of 6 to 15 nanometers.

This is the first case where a porous polymer has both well-defined mesopores and micropores. The research team verified the effect of hierarchically-porous structures on absorption of molecules by confirming that the porous polymer had faster absorption speeds than a polymer consisting only of micropores.

Professor Seo said, “The study has found a simple way to create different sizes of pores within a polymer.” He expected that the hierarchically-porous polymers can be used as a catalytic support in which fast diffusion of molecules is essential, or for molecule collection.

The research was sponsored by National Research Foundation of Korea and published online in the Journal of the American Chemical Society.

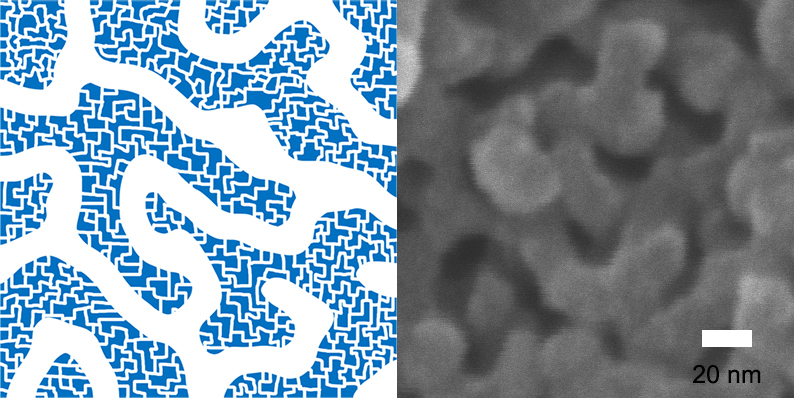

Figure 1 – Net-like Structure of Hierarchically-Porous Polymers with Mesopores and Micropores on the walls of Mesopores.

Figure 2 - Hierarchically-Porous Polymers

Figure 3 – Comparison of Porous-Polymers consisting of Mesopores only (left), and Mesopores and Micropores (right)

2015.01.13 View 9985

Hierarchically-Porous Polymers with Fast Absorption

KAIST's Professor Myungeun Seo and his research team from the Graduate School of Nanoscience and Technology has developed a method to form micropores of less than 2 nanometers within porous polymers where 10 nanometers long mesopores connect like a net. The advantage of the porous polymers is fast absorption of molecules.

Porous polymers with micropores of less than 2 nanometers, like a zeolite, have a large surface area. They are used as a means to store hydrogen-based molecules or as a catalytic support that can be used as a surface to convert a material into a desired form. However, because the size of the pores in its path was too small for the molecules, it took a long time to spread into the pores and reach the surface.

To reach the surface efficiently, a lung cell or the vein of a leaf has a structure wherein the pores are subdivided into different sizes so that the molecule can spread throughout the organ. A technology that can create not only micropores but also bigger pores was necessary in order to create such structure.

The research team solved the issue by implementing a "self-assembly" of block polymers to easily form a net-like nanostructure from mesopores of 10 nanometers.

The team created hierarchically-porous polymers consisting of two different types of pores by using a hypercrosslinking reaction along with the "self-assembly" method. The reaction creates micropores within the chain after the polymer chain is confined by a chemical bond.

This porous polymer has micropores that are smaller than 2 nanometers on the walls of mesopores while 10 nanometers long mesopores forming 3-dimensional net structures. Because of the "self-assembly" method, the size of mesopores can be adjusted within the range of 6 to 15 nanometers.

This is the first case where a porous polymer has both well-defined mesopores and micropores. The research team verified the effect of hierarchically-porous structures on absorption of molecules by confirming that the porous polymer had faster absorption speeds than a polymer consisting only of micropores.

Professor Seo said, “The study has found a simple way to create different sizes of pores within a polymer.” He expected that the hierarchically-porous polymers can be used as a catalytic support in which fast diffusion of molecules is essential, or for molecule collection.

The research was sponsored by National Research Foundation of Korea and published online in the Journal of the American Chemical Society.

Figure 1 – Net-like Structure of Hierarchically-Porous Polymers with Mesopores and Micropores on the walls of Mesopores.

Figure 2 - Hierarchically-Porous Polymers

Figure 3 – Comparison of Porous-Polymers consisting of Mesopores only (left), and Mesopores and Micropores (right)

2015.01.13 View 9985 -

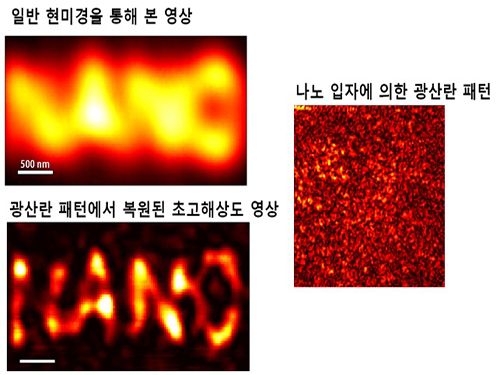

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 11760

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Ultra-high Resolution 2-dimentional Real-time Image Capture with Super Lens

Applications to high-precision semiconductor processing or intracellular structures observation are possible.

A joint research team led by Professors Yongkeun Park and Yong-Hoon Cho from the Department of Physics, KAIST, has succeeded in capturing real-time 2D images at a resolution of 100 nm (nanometers), which was impossible with optical lens due to the diffraction limit of light until now. Its future application includes high-precision semiconductor manufacturing process or observation of intracellular structures.

This research follows the past research of the super-lens developed by Professor Park last April, using paint spray to observe images that have three times higher resolution than those discovered by conventional optical lens.

Since optical lens utilize the refraction of light, the diffraction limit, which prevents achieving focus smaller than the wavelength of light, has always been a barrier for acquiring high-resolution images. In the past, it was impossible to observe objects less than the size of 200 to 300 nm in the visible light spectrum.

In order to solve the problem of near-field extinction due to scattering of light, the research team used spray paint consisting of nano-particles massed with dense scattering materials to obtain high-resolution information.

Then, by calculating and restoring the first scattering shape of light using the time reversibility of light, the researchers were able to overcome the diffraction limit. The original position of an object to be observed is obtained by deriving the complex trajectory of the light, and reversing the time to locate the particular position of the object.

Professor Park said, “This new technology can be used as the core technology in all fields which require optical measurement and control. The existing electron microscopy cannot observe cells without destroying them, but the new technology allows us to visualize at ultra-high resolution without destruction.”

The research results were published online in the 9th edition of Physical Review Letters, a prestigious international journal in the field of physics.

2014.09.23 View 11760 -

Professor Yang Named Recipient of Dupont Science & Technology Award

Professor Yang Named Recipient of Dupont Science & Technology Award

- Named as the recipient of Dupont Science & Technology Award of 2007- In recognition of his development of optical?bio-functional photonic crystal structures through Self-assembly of nanoparticles

Seung-Man Yang, a professor of Chemical and Biomolecular Engineering of KAIST (President Nam Pyo Suh) and the president of the National Creative Research Initiatives Center for Photon and Fluid Integrated Circuit by the Ministry of Science and Technology, has been named as the recipient of Dupont Science & Technology Award.

Dupont Korea, associate of Dupont, a world-class science firm, has established and conferred ‘Dupont Science & Technology Award’ since 2002 to promote basic sciences and industrial development of Korea. Dupont Science & Technology Awards are awarded to scientists of universities or state-run institutes who have made outstanding R&D achievements in the fields of Chemistry, Chemical Engineering, Material Science and Material Engineering within five years. Dupont Korea announced on May 2, 2007 that Professor Yang is the recipient of the award this year, following the strict examination by the Koran Academy of Science and Technology (KAST).

The reason for the award is Professor Yang’s development of prototype optical?bio-functional photonic crystal structures that can process a huge amount of data, resulting from a study that has discovered the principle of Self-assembly where multifunctional nanoparticles are manufactured and assembled for themselves.

Professor Yang’s recent research result about photon structures and nano patterns was published by Nature (February 2, 2006 edition); posted on Heart-Cut, the portal site of the American Chemistry Society (ACS), as highlight paper two times (November 4, 2002 and May 1, 2006); and introduced at Research/Researcher of MRS Bulletin by the U.S. Material Research Society (MRS) as main paper in December 2003. Professor Yang is very famous in Korea and abroad for the excellences of his research achievements and has made request seminars at Harvard University, University of Wisconsin, Caltech, University of California, etc. He is also invited speaker and session organizer of the MRS and the SPIE.

2007.05.08 View 22939

Professor Yang Named Recipient of Dupont Science & Technology Award

Professor Yang Named Recipient of Dupont Science & Technology Award

- Named as the recipient of Dupont Science & Technology Award of 2007- In recognition of his development of optical?bio-functional photonic crystal structures through Self-assembly of nanoparticles

Seung-Man Yang, a professor of Chemical and Biomolecular Engineering of KAIST (President Nam Pyo Suh) and the president of the National Creative Research Initiatives Center for Photon and Fluid Integrated Circuit by the Ministry of Science and Technology, has been named as the recipient of Dupont Science & Technology Award.

Dupont Korea, associate of Dupont, a world-class science firm, has established and conferred ‘Dupont Science & Technology Award’ since 2002 to promote basic sciences and industrial development of Korea. Dupont Science & Technology Awards are awarded to scientists of universities or state-run institutes who have made outstanding R&D achievements in the fields of Chemistry, Chemical Engineering, Material Science and Material Engineering within five years. Dupont Korea announced on May 2, 2007 that Professor Yang is the recipient of the award this year, following the strict examination by the Koran Academy of Science and Technology (KAST).

The reason for the award is Professor Yang’s development of prototype optical?bio-functional photonic crystal structures that can process a huge amount of data, resulting from a study that has discovered the principle of Self-assembly where multifunctional nanoparticles are manufactured and assembled for themselves.

Professor Yang’s recent research result about photon structures and nano patterns was published by Nature (February 2, 2006 edition); posted on Heart-Cut, the portal site of the American Chemistry Society (ACS), as highlight paper two times (November 4, 2002 and May 1, 2006); and introduced at Research/Researcher of MRS Bulletin by the U.S. Material Research Society (MRS) as main paper in December 2003. Professor Yang is very famous in Korea and abroad for the excellences of his research achievements and has made request seminars at Harvard University, University of Wisconsin, Caltech, University of California, etc. He is also invited speaker and session organizer of the MRS and the SPIE.

2007.05.08 View 22939 -

Gold prize for Sungkoo Yeo and silver prize for Youngsik Kim at 'Samsung Electrics paper contest'

Gold prize for Sungkoo Yeo and silver prize for Youngsik Kim at ‘Samsung Electrics paper contest’

Sungkoo Yeo, doctorate student at the division of Electrical Engineering, and Youngsik Kim, doctorate students at the division of Mechanical Engineering, won gold and silver prizes respectively at ‘the 2nd Inside edge paper contest’ organized by Samsung Electronics.

Yeo, under the supervisory of Professor Youngse Kwon, won the glory of gold prize in recognition of his highly evaluated researches in the fields of silicon-based micro mold manufacturing technologies and fine shaping technologies revealed by his paper of ‘"Fabrication of Microlens array Using PDMS Replica Molding and Oxidized Porous Silicon Bulk Micromachining’.

Kim, under the supervisory of Professor Seungwoo Kim, also won the silver prize for his research performances over the thickness pattern measuring technologies of transparent thin film coated on the pattern of an opaque metal in the field of optical technology unveiled by his paper of "Dispersive white-light interferometry for in-line inspection of thin-film layers on patterned structures".

Inside Edge paper contest is an academic paper contest organized by Samsung Electronics to reveal the fresh ideas and potential technologies of the young talented.

2006.11.27 View 20843

Gold prize for Sungkoo Yeo and silver prize for Youngsik Kim at 'Samsung Electrics paper contest'

Gold prize for Sungkoo Yeo and silver prize for Youngsik Kim at ‘Samsung Electrics paper contest’

Sungkoo Yeo, doctorate student at the division of Electrical Engineering, and Youngsik Kim, doctorate students at the division of Mechanical Engineering, won gold and silver prizes respectively at ‘the 2nd Inside edge paper contest’ organized by Samsung Electronics.

Yeo, under the supervisory of Professor Youngse Kwon, won the glory of gold prize in recognition of his highly evaluated researches in the fields of silicon-based micro mold manufacturing technologies and fine shaping technologies revealed by his paper of ‘"Fabrication of Microlens array Using PDMS Replica Molding and Oxidized Porous Silicon Bulk Micromachining’.

Kim, under the supervisory of Professor Seungwoo Kim, also won the silver prize for his research performances over the thickness pattern measuring technologies of transparent thin film coated on the pattern of an opaque metal in the field of optical technology unveiled by his paper of "Dispersive white-light interferometry for in-line inspection of thin-film layers on patterned structures".

Inside Edge paper contest is an academic paper contest organized by Samsung Electronics to reveal the fresh ideas and potential technologies of the young talented.

2006.11.27 View 20843