Nano+Energy

-

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 14052

Sturdy Fabric-Based Piezoelectric Energy Harvester Takes Us One Step Closer to Wearable Electronics

KAIST researchers presented a highly flexible but sturdy wearable piezoelectric harvester using the simple and easy fabrication process of hot pressing and tape casting. This energy harvester, which has record high interfacial adhesion strength, will take us one step closer to being able to manufacture embedded wearable electronics.

A research team led by Professor Seungbum Hong said that the novelty of this result lies in its simplicity, applicability, durability, and its new characterization of wearable electronic devices.

Wearable devices are increasingly being used in a wide array of applications from small electronics to embedded devices such as sensors, actuators, displays, and energy harvesters.

Despite their many advantages, high costs and complex fabrication processes remained challenges for reaching commercialization. In addition, their durability was frequently questioned. To address these issues, Professor Hong’s team developed a new fabrication process and analysis technology for testing the mechanical properties of affordable wearable devices.

For this process, the research team used a hot pressing and tape casting procedure to connect the fabric structures of polyester and a polymer film. Hot pressing has usually been used when making batteries and fuel cells due to its high adhesiveness. Above all, the process takes only two to three minutes.

The newly developed fabrication process will enable the direct application of a device into general garments using hot pressing just as graphic patches can be attached to garments using a heat press.

In particular, when the polymer film is hot pressed onto a fabric below its crystallization temperature, it transforms into an amorphous state. In this state, it compactly attaches to the concave surface of the fabric and infiltrates into the gaps between the transverse wefts and longitudinal warps. These features result in high interfacial adhesion strength. For this reason, hot pressing has the potential to reduce the cost of fabrication through the direct application of fabric-based wearable devices to common garments.

In addition to the conventional durability test of bending cycles, the newly introduced surface and interfacial cutting analysis system proved the high mechanical durability of the fabric-based wearable device by measuring the high interfacial adhesion strength between the fabric and the polymer film. Professor Hong said the study lays a new foundation for the manufacturing process and analysis of wearable devices using fabrics and polymers.

He added that his team first used the surface and interfacial cutting analysis system (SAICAS) in the field of wearable electronics to test the mechanical properties of polymer-based wearable devices. Their surface and interfacial cutting analysis system is more precise than conventional methods (peel test, tape test, and microstretch test) because it qualitatively and quantitatively measures the adhesion strength.

Professor Hong explained, “This study could enable the commercialization of highly durable wearable devices based on the analysis of their interfacial adhesion strength. Our study lays a new foundation for the manufacturing process and analysis of other devices using fabrics and polymers. We look forward to fabric-based wearable electronics hitting the market very soon.”

The results of this study were registered as a domestic patent in Korea last year, and published in Nano Energy this month. This study has been conducted through collaboration with Professor Yong Min Lee in the Department of Energy Science and Engineering at DGIST, Professor Kwangsoo No in the Department of Materials Science and Engineering at KAIST, and Professor Seunghwa Ryu in the Department of Mechanical Engineering at KAIST.

This study was supported by the High-Risk High-Return Project and the Global Singularity Research Project at KAIST, the National Research Foundation, and the Ministry of Science and ICT in Korea.

-Publication:

Jaegyu Kim, Seoungwoo Byun, Sangryun Lee, Jeongjae Ryu, Seongwoo Cho, Chungik Oh, Hongjun Kim, Kwangsoo No, Seunghwa Ryu, Yong Min Lee, Seungbum Hong*, Nano Energy 75 (2020), 104992.

https://doi.org/10.1016/j.nanoen.2020.104992

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2020.09.17 View 14052 -

Flexible Drug Delivery Microdevice to Advance Precision Medicine

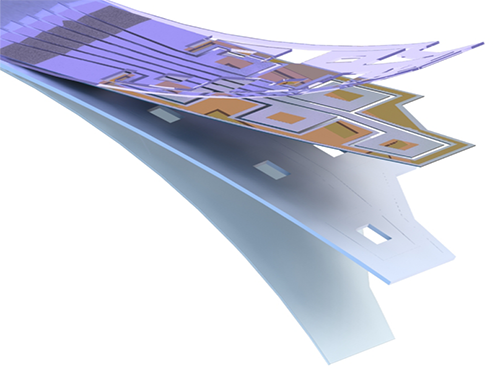

(Schematic view of flexible microdevice: The flexible drug delivery device for controlled release fabricated via inorganic laser lift off.)

A KAIST research team has developed a flexible drug delivery device with controlled release for personalized medicine, blazing the path toward theragnosis.

Theragnosis, an emerging medical technology, is gaining attention as key factor to advance precision medicine for its featuring simultaneous diagnosis and therapeutics. Theragnosis devices including smart contact lenses and microneedle patches integrate physiological data sensors and drug delivery devices. The controlled drug delivery boasts fewer side-effects, uniform therapeutic results, and minimal dosages compared to oral ingestion. Recently, some research groups conducted in-human applications of controlled-release bulky microchips for osteoporosis treatment. However they failed to demonstrate successful human-friendly flexible drug delivery systems for controlled release.

For this microdevice, the team under Professor Daesoo Kim from the Department of Biological Science and Professor Keon Jae Lee from the Department of Materials Science and Engineering, fabricated a device on a rigid substrate and transferred a 50 µm-thick active drug delivery layer to the flexible substrate via inorganic laser lift off. The fabricated device shows mechanical flexibility while maintaining the capability of precise administration of exact dosages at desired times. The core technology is to produce a freestanding gold capping layer directly on top of the microreservoir with the drugs inside, which had been regarded as impossible in conventional microfabrication.

The developed flexible drug delivery system can be applied to smart contact lenses or the brain disease treatments by implanting them into cramped and corrugated organs. In addition, when powered wirelessly, it will represent a novel platform for personalized medicine. The team already proved through animal experimentation that treatment for brain epilepsy made progress by releasing anti-epileptic medication through the device.

Professor Lee believes the flexible microdevice will further expand the applications of smart contact lenses, therapeutic treatments for brain disease, and subcutaneous implantations for daily healthcare system. This study “Flexible Wireless Powered Drug Delivery System for Targeted Administration on Cerebral Cortex” was described in the June online issue of Nano Energy.

(Photo: The flexible drug delivery device for contolled relase attached on a glass rod.)

2018.08.13 View 9324

Flexible Drug Delivery Microdevice to Advance Precision Medicine

(Schematic view of flexible microdevice: The flexible drug delivery device for controlled release fabricated via inorganic laser lift off.)

A KAIST research team has developed a flexible drug delivery device with controlled release for personalized medicine, blazing the path toward theragnosis.

Theragnosis, an emerging medical technology, is gaining attention as key factor to advance precision medicine for its featuring simultaneous diagnosis and therapeutics. Theragnosis devices including smart contact lenses and microneedle patches integrate physiological data sensors and drug delivery devices. The controlled drug delivery boasts fewer side-effects, uniform therapeutic results, and minimal dosages compared to oral ingestion. Recently, some research groups conducted in-human applications of controlled-release bulky microchips for osteoporosis treatment. However they failed to demonstrate successful human-friendly flexible drug delivery systems for controlled release.

For this microdevice, the team under Professor Daesoo Kim from the Department of Biological Science and Professor Keon Jae Lee from the Department of Materials Science and Engineering, fabricated a device on a rigid substrate and transferred a 50 µm-thick active drug delivery layer to the flexible substrate via inorganic laser lift off. The fabricated device shows mechanical flexibility while maintaining the capability of precise administration of exact dosages at desired times. The core technology is to produce a freestanding gold capping layer directly on top of the microreservoir with the drugs inside, which had been regarded as impossible in conventional microfabrication.

The developed flexible drug delivery system can be applied to smart contact lenses or the brain disease treatments by implanting them into cramped and corrugated organs. In addition, when powered wirelessly, it will represent a novel platform for personalized medicine. The team already proved through animal experimentation that treatment for brain epilepsy made progress by releasing anti-epileptic medication through the device.

Professor Lee believes the flexible microdevice will further expand the applications of smart contact lenses, therapeutic treatments for brain disease, and subcutaneous implantations for daily healthcare system. This study “Flexible Wireless Powered Drug Delivery System for Targeted Administration on Cerebral Cortex” was described in the June online issue of Nano Energy.

(Photo: The flexible drug delivery device for contolled relase attached on a glass rod.)

2018.08.13 View 9324 -

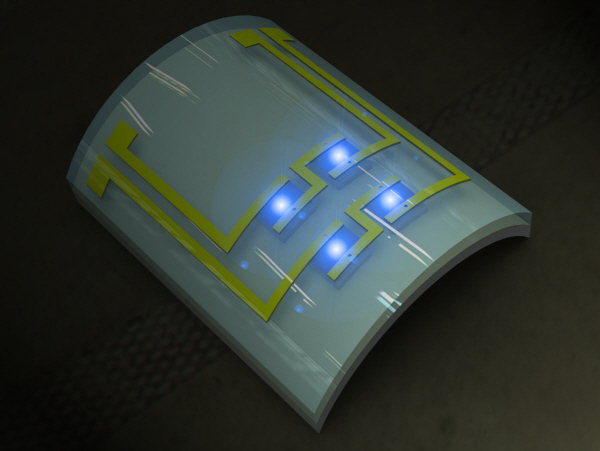

Cancer detection from an implantable, flexible LED

Professor Keon Jae Lee

A KAIST research team has developed a new type of biocompatible and bendable GaN LED biosensor.

Daejeon, the Republic of Korea, August 8, 2011—Can a flexible LED conformably placed on the human heart, situated on the corrugated surface of the human brain, or rolled upon the blood vessels, diagnose or even treat various diseases? These things might be a reality in the near future.

The team of Professor Keon Jae Lee (Department of Materials Science and Engineering, KAIST) has developed a new concept: a biocompatible, flexible Gallium Nitride (GaN) LED that can detect prostate cancer.

GaN LED, a highly efficient light emitting device, has been commercialized in LED TVs and in the lighting industry. Until now, it has been difficult to use this semiconductor material to fabricate flexible electronic systems due to its brittleness. The research team, however, has succeeded in developing a highly efficient, flexible GaN LED and in detecting cancer using a flexible LED biosensor.

Prof. Lee was involved in the first co-invention of "High Performance Flexible Single Crystal GaN" during his PhD course at the University of Illinois at Urbana-Champaign (UIUC). This flexible GaN LED biosensor utilized a similar protocol to transfer thin GaN LED films onto flexible substrates, followed by a biocompatible packaging process; the system’s overall potential for use in implantable biomedical applications was demonstrated.

Professor John Roger (Department of Materials Science and Engineering, UIUC) said,

“Bio-integrated LEDs represent an exciting, new technology with strong potential to address important challenges in human health. This present work represents a very nice contribution to this emerging field.”

This paper was published in the online issue of Nano Energy Elsevier Journal (Editor, Prof. Zhong Lin Wang) dated September 16, 2011.

Flexible GaN LED produces blue light.

2011.09.20 View 12393

Cancer detection from an implantable, flexible LED

Professor Keon Jae Lee

A KAIST research team has developed a new type of biocompatible and bendable GaN LED biosensor.

Daejeon, the Republic of Korea, August 8, 2011—Can a flexible LED conformably placed on the human heart, situated on the corrugated surface of the human brain, or rolled upon the blood vessels, diagnose or even treat various diseases? These things might be a reality in the near future.

The team of Professor Keon Jae Lee (Department of Materials Science and Engineering, KAIST) has developed a new concept: a biocompatible, flexible Gallium Nitride (GaN) LED that can detect prostate cancer.

GaN LED, a highly efficient light emitting device, has been commercialized in LED TVs and in the lighting industry. Until now, it has been difficult to use this semiconductor material to fabricate flexible electronic systems due to its brittleness. The research team, however, has succeeded in developing a highly efficient, flexible GaN LED and in detecting cancer using a flexible LED biosensor.

Prof. Lee was involved in the first co-invention of "High Performance Flexible Single Crystal GaN" during his PhD course at the University of Illinois at Urbana-Champaign (UIUC). This flexible GaN LED biosensor utilized a similar protocol to transfer thin GaN LED films onto flexible substrates, followed by a biocompatible packaging process; the system’s overall potential for use in implantable biomedical applications was demonstrated.

Professor John Roger (Department of Materials Science and Engineering, UIUC) said,

“Bio-integrated LEDs represent an exciting, new technology with strong potential to address important challenges in human health. This present work represents a very nice contribution to this emerging field.”

This paper was published in the online issue of Nano Energy Elsevier Journal (Editor, Prof. Zhong Lin Wang) dated September 16, 2011.

Flexible GaN LED produces blue light.

2011.09.20 View 12393