Magazine

-

KAIST Honors BMW and Hyundai with the 2022 Future Mobility of the Year Award

BMW ‘iVision Circular’, Commercial Vehicle-Hyundai Motors ‘Trailer Drone’ selected as winners of the international awards for concept cars established by KAIST Cho Chun Shik Graduate School of Mobility to honor car makers that strive to present new visions in the field of eco-friendly design of automobiles and unmanned logistics.

KAIST (President Kwang Hyung Lee) hosted the “2022 Future Mobility of the Year (FMOTY) Awards” at the Convention Hall of the BEXCO International Motor Show at Busan in the afternoon of the 14th.

The Future Mobility of the Year Awards is an award ceremony that selects a model that showcases useful transportation technology and innovative service concepts for the future society among the set of concept cars exhibited at the motor show.

As a one-of-a-kind international concept car awards established by KAIST's Cho Chun Shik Graduate School of Mobility (Headed by Professor Jang In-Gwon), the auto journalists from 11 countries were invited to be the jurors to select the winner. With the inaugural awards ceremony held in 2019, over the past three years, automakers from around the globe, including internationally renowned automakers, such as, Volvo/Toyota (2019), Honda/Hyundai (2020), and Renault (2021), even a new start-up car manufacturer like Canoo, the winner of last year’s award for commercial vehicles, were honored for their award-winning works.

At this year’s awards ceremony, the 4th of its kind, BMW's “iVision Circular” and Hyundai's “'Trailer Drone” were selected as the best concept cars of the year, the former from the Private Mobility category and the latter from the Public & Commercial Vehicles category.

The jury consisting of 16 domestic and foreign auto journalists, including BBC Top Gear's Paul Horrell and Car Magazine’s Georg Kacher, evaluated 53 concept car contestants that made their entry last year. The jurors’ general comment was that while the trend of the global automobile market flowing fast towards electric vehicles, this year's award-winning works presented a new vision in the field of eco-friendly design and unmanned logistics.

Private Mobility Categry Winner: BMW iVision Circular

BMW's 'iVision Circular', the winner of the Private Mobility category, is an eco-friendly compact car in which all parts of the vehicle are designed with recycled and/or natural materials. It has received favorable reviews for its in-depth implementation of the concept of a futuristic eco-friendly car by manufacturing the tires from natural rubber and adopting a design that made recycling of its parts very easily when the car is to be disposed of.

Public & Commercial Vehicles Categry Winner: Hyundai Trailer Drone

Hyundai Motor Company’s “Trailer Drone”, the winner of the Public & Commercial Vehicles category, is an eco-friendly autonomous driving truck that can transport large-scale logistics from a port to a destination without a human driver while two unmanned vehicles push and drag a trailer. The concept car won supports from a large number of judges for the blueprint it presented for a groundbreaking logistics service that applied both eco-friendly hydrogen fuel cell and fully autonomous driving technology.

Jurors from overseas congratulated the development team of BMW and Hyundai Motor Company via a video message for providing a new direction for the global automobile industry as it strives to transform in line with the changes in the post-pandemic era.

Professor Bo-won Kim, the Vice President for Planning and Budget of KAIST, who presented the awards, said, “It is time for the K-Mobility wave to sweep over the global mobility industry.” “KAIST will lead in the various fields of mobility technologies to support global automakers,” he added.

Splitting the center are KAIST Vice President Bo-Won Kim on the right, and Seong-Kwon Lee,

the Deputy Mayor of the City of Busan on the left. To Kim's left is the Senior VP of BMW Asia-Pacific, Eastern Europe, Middle East, Africa, Jean-Philippe Parain, and to Lee's Right is Sangyup Lee,

the Head of Hyundai Motor Design Center and the Executive VP of Hyundai Motors.

At the ceremony, along with KAIST officials, including Vice President Bo-Won Kim and Professor In-Gwon Jang, the Head of Cho Chun Shik Graduate School of Mobility, are the Deputy Mayor Seong-Kwon Lee of the City of Busan and the figures from the automobile industry, including Jean-Philippe Parain, the Senior Vice President of BMW Asia-Pacific, Eastern Europe, Middle East, Africa, who is visiting Korea to receive the '2022 Future Mobility' award, and Sangyup Lee, the Head of Hyundai Motor Design Center and the Executive Vice President of Hyundai Motor Company, were in the attendance.

More information about the awards ceremony and winning works are available at the official website of this year's Future Mobility Awards (www.fmoty.org).

Profile:In-Gwon Jang, Ph.D.Presidentthe Organizing Committeethe Future Mobility of the Year Awardshttp://www.fmoty.org/

Head ProfessorKAIST Cho Chun Shik Graduate School of Mobilityhttps://gt.kaist.ac.kr

2022.07.14 View 14191

KAIST Honors BMW and Hyundai with the 2022 Future Mobility of the Year Award

BMW ‘iVision Circular’, Commercial Vehicle-Hyundai Motors ‘Trailer Drone’ selected as winners of the international awards for concept cars established by KAIST Cho Chun Shik Graduate School of Mobility to honor car makers that strive to present new visions in the field of eco-friendly design of automobiles and unmanned logistics.

KAIST (President Kwang Hyung Lee) hosted the “2022 Future Mobility of the Year (FMOTY) Awards” at the Convention Hall of the BEXCO International Motor Show at Busan in the afternoon of the 14th.

The Future Mobility of the Year Awards is an award ceremony that selects a model that showcases useful transportation technology and innovative service concepts for the future society among the set of concept cars exhibited at the motor show.

As a one-of-a-kind international concept car awards established by KAIST's Cho Chun Shik Graduate School of Mobility (Headed by Professor Jang In-Gwon), the auto journalists from 11 countries were invited to be the jurors to select the winner. With the inaugural awards ceremony held in 2019, over the past three years, automakers from around the globe, including internationally renowned automakers, such as, Volvo/Toyota (2019), Honda/Hyundai (2020), and Renault (2021), even a new start-up car manufacturer like Canoo, the winner of last year’s award for commercial vehicles, were honored for their award-winning works.

At this year’s awards ceremony, the 4th of its kind, BMW's “iVision Circular” and Hyundai's “'Trailer Drone” were selected as the best concept cars of the year, the former from the Private Mobility category and the latter from the Public & Commercial Vehicles category.

The jury consisting of 16 domestic and foreign auto journalists, including BBC Top Gear's Paul Horrell and Car Magazine’s Georg Kacher, evaluated 53 concept car contestants that made their entry last year. The jurors’ general comment was that while the trend of the global automobile market flowing fast towards electric vehicles, this year's award-winning works presented a new vision in the field of eco-friendly design and unmanned logistics.

Private Mobility Categry Winner: BMW iVision Circular

BMW's 'iVision Circular', the winner of the Private Mobility category, is an eco-friendly compact car in which all parts of the vehicle are designed with recycled and/or natural materials. It has received favorable reviews for its in-depth implementation of the concept of a futuristic eco-friendly car by manufacturing the tires from natural rubber and adopting a design that made recycling of its parts very easily when the car is to be disposed of.

Public & Commercial Vehicles Categry Winner: Hyundai Trailer Drone

Hyundai Motor Company’s “Trailer Drone”, the winner of the Public & Commercial Vehicles category, is an eco-friendly autonomous driving truck that can transport large-scale logistics from a port to a destination without a human driver while two unmanned vehicles push and drag a trailer. The concept car won supports from a large number of judges for the blueprint it presented for a groundbreaking logistics service that applied both eco-friendly hydrogen fuel cell and fully autonomous driving technology.

Jurors from overseas congratulated the development team of BMW and Hyundai Motor Company via a video message for providing a new direction for the global automobile industry as it strives to transform in line with the changes in the post-pandemic era.

Professor Bo-won Kim, the Vice President for Planning and Budget of KAIST, who presented the awards, said, “It is time for the K-Mobility wave to sweep over the global mobility industry.” “KAIST will lead in the various fields of mobility technologies to support global automakers,” he added.

Splitting the center are KAIST Vice President Bo-Won Kim on the right, and Seong-Kwon Lee,

the Deputy Mayor of the City of Busan on the left. To Kim's left is the Senior VP of BMW Asia-Pacific, Eastern Europe, Middle East, Africa, Jean-Philippe Parain, and to Lee's Right is Sangyup Lee,

the Head of Hyundai Motor Design Center and the Executive VP of Hyundai Motors.

At the ceremony, along with KAIST officials, including Vice President Bo-Won Kim and Professor In-Gwon Jang, the Head of Cho Chun Shik Graduate School of Mobility, are the Deputy Mayor Seong-Kwon Lee of the City of Busan and the figures from the automobile industry, including Jean-Philippe Parain, the Senior Vice President of BMW Asia-Pacific, Eastern Europe, Middle East, Africa, who is visiting Korea to receive the '2022 Future Mobility' award, and Sangyup Lee, the Head of Hyundai Motor Design Center and the Executive Vice President of Hyundai Motor Company, were in the attendance.

More information about the awards ceremony and winning works are available at the official website of this year's Future Mobility Awards (www.fmoty.org).

Profile:In-Gwon Jang, Ph.D.Presidentthe Organizing Committeethe Future Mobility of the Year Awardshttp://www.fmoty.org/

Head ProfessorKAIST Cho Chun Shik Graduate School of Mobilityhttps://gt.kaist.ac.kr

2022.07.14 View 14191 -

Wall Climbing Quadcopter by KAIST Urban Robotics Lab

Popular Science, an American monthly magazine devoted to general readers of science and technology, published “Watch This Creepy Drone Climb A Wall” online describing a drone that can fly and climb walls on March 19, 2015. The drone is the product of research conducted by Professor Hyun Myung of the Department of Civil and Environmental Engineering at KAIST. The flying quadcopters can turn into wall-crawling robots, or vice versa, when carrying out such assignments as cleaning windows or inspecting a building’s infrastructure. Professor Myung leads the KAIST Urban Robotics Lab (http://urobot.kaist.ac.kr/). For a link to the article, see http://www.popsci.com/watch-drone-climb-wall-video.

Another Popular Science article (posted on April 3, 2015), entitled “South Korea Gets Ready for Drone-on-Drone Warfare with North Korea,” describes a combat system of drones against hostile drones. Professor Hyunchul Shim of the Aerospace Engineering Department at KAIST developed the anti-drone system. He currently heads the Unmanned System Research Group, FDCL, http://unmanned.kaist.ac.kr/) and the Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

2015.04.07 View 12902

Wall Climbing Quadcopter by KAIST Urban Robotics Lab

Popular Science, an American monthly magazine devoted to general readers of science and technology, published “Watch This Creepy Drone Climb A Wall” online describing a drone that can fly and climb walls on March 19, 2015. The drone is the product of research conducted by Professor Hyun Myung of the Department of Civil and Environmental Engineering at KAIST. The flying quadcopters can turn into wall-crawling robots, or vice versa, when carrying out such assignments as cleaning windows or inspecting a building’s infrastructure. Professor Myung leads the KAIST Urban Robotics Lab (http://urobot.kaist.ac.kr/). For a link to the article, see http://www.popsci.com/watch-drone-climb-wall-video.

Another Popular Science article (posted on April 3, 2015), entitled “South Korea Gets Ready for Drone-on-Drone Warfare with North Korea,” describes a combat system of drones against hostile drones. Professor Hyunchul Shim of the Aerospace Engineering Department at KAIST developed the anti-drone system. He currently heads the Unmanned System Research Group, FDCL, http://unmanned.kaist.ac.kr/) and the Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

2015.04.07 View 12902 -

Professor Shim Featured with His Drone System in IEEE Spectrum

The IEEE Spectrum, a technology and science magazine published by the Institute of Electrical and Electronics Engineers (IEEE), featured an article of KAIST’s autonomous unmanned aerial vehicles (UAVs) entitled “South Korea Prepares for Drone vs. Drone Combat,” posted on April 1, 2015.

The article introduces the anti-drone defense system being developed by Professor “David” Hyunchul Shim of the Department of Aerospace Engineering at KAIST. With the goal of developing guard drones that can detect and capture unknown UAVs, the anti-drone defense system consists of reconnaissance drones, agile multi-rotor UAVs equipped with nets which are dropped to snare enemy drones, and transport UAVs to carry smaller drones.

Professor Shim currently leads KAIST’s Unmanned System Research Group (USRG, http://unmanned.kaist.ac.kr/) and Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

For the article, please go to http://spectrum.ieee.org/automaton/robotics/aerial-robots/south-korea-drone-vs-drone.

2015.04.02 View 13863

Professor Shim Featured with His Drone System in IEEE Spectrum

The IEEE Spectrum, a technology and science magazine published by the Institute of Electrical and Electronics Engineers (IEEE), featured an article of KAIST’s autonomous unmanned aerial vehicles (UAVs) entitled “South Korea Prepares for Drone vs. Drone Combat,” posted on April 1, 2015.

The article introduces the anti-drone defense system being developed by Professor “David” Hyunchul Shim of the Department of Aerospace Engineering at KAIST. With the goal of developing guard drones that can detect and capture unknown UAVs, the anti-drone defense system consists of reconnaissance drones, agile multi-rotor UAVs equipped with nets which are dropped to snare enemy drones, and transport UAVs to carry smaller drones.

Professor Shim currently leads KAIST’s Unmanned System Research Group (USRG, http://unmanned.kaist.ac.kr/) and Center of Field Robotics for Innovation, Exploration, aNd Defense (C-FRIEND).

For the article, please go to http://spectrum.ieee.org/automaton/robotics/aerial-robots/south-korea-drone-vs-drone.

2015.04.02 View 13863 -

Interactions Features KAIST's Human-Computer Interaction Lab

Interactions, a bi-monthly magazine published by the Association for Computing Machinery (ACM), the largest educational and scientific computing society in the world, featured an article introducing Human-Computer Interaction (HCI) Lab at KAIST in the March/April 2015 issue (http://interactions.acm.org/archive/toc/march-april-2015).

Established in 2002, the HCI Lab (http://hcil.kaist.ac.kr/) is run by Professor Geehyuk Lee of the Computer Science Department at KAIST. The lab conducts various research projects to improve the design and operation of physical user interfaces and develops new interaction techniques for new types of computers. For the article, see the link below:

ACM Interactions, March and April 2015

Day in the Lab: Human-Computer Interaction Lab @ KAIST

http://interactions.acm.org/archive/view/march-april-2015/human-computer-interaction-lab-kaist

2015.03.02 View 10840

Interactions Features KAIST's Human-Computer Interaction Lab

Interactions, a bi-monthly magazine published by the Association for Computing Machinery (ACM), the largest educational and scientific computing society in the world, featured an article introducing Human-Computer Interaction (HCI) Lab at KAIST in the March/April 2015 issue (http://interactions.acm.org/archive/toc/march-april-2015).

Established in 2002, the HCI Lab (http://hcil.kaist.ac.kr/) is run by Professor Geehyuk Lee of the Computer Science Department at KAIST. The lab conducts various research projects to improve the design and operation of physical user interfaces and develops new interaction techniques for new types of computers. For the article, see the link below:

ACM Interactions, March and April 2015

Day in the Lab: Human-Computer Interaction Lab @ KAIST

http://interactions.acm.org/archive/view/march-april-2015/human-computer-interaction-lab-kaist

2015.03.02 View 10840 -

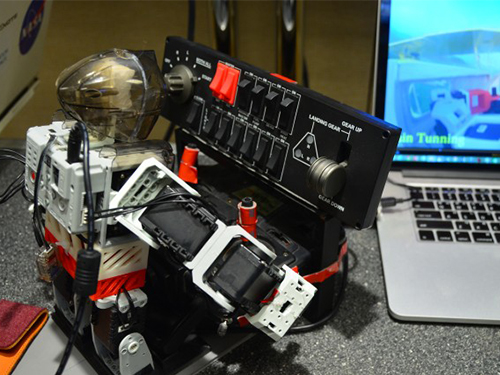

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14294

PIBOT, a small humanoid robot flies an aircraft

The 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014) took place in Chicago, Illinois, on September 14-18, 2014.

Professor David Hyunchul Shim and his students from the Department of Aerospace Engineering, KAIST, presented a research paper entitled “A Robot-machine Interface for Full-functionality Automation Using a Humanoid” at the conference.

The robot called “PIBOT,” a pint-sized, tiny humanoid robot, uses a mixture of flight data and visuals to fly an airplane, capable of identifying and operating all of the buttons and switches in the cockpit of a normal light aircraft designed for humans.

For now, the robot is only flying a simulator, but Professor Shim expects that “PIBOT will help us have a fully automated flight experience, eventually replacing human pilots.”

The IEEE Spectrum magazine published an article on PIBOT posted online September 18, 2014. Please follow the link below for the article:

IEEE Spectrum, September 18, 2014

Tiny Humanoid Robot Learning to Fly Real Airplanes

http://spectrum.ieee.org/automaton/robotics/humanoids/tiny-humanoid-robot-learning-to-fly-real-airplanes

2014.09.23 View 14294 -

KAIST Made Great Improvements of Nanogenerator Power Efficiency

The energy efficiency of a piezoelectric nanogenerator developed by KAIST has increased by almost 40 times, one step closer toward the commercialization of flexible energy harvesters that can supply power infinitely to wearable, implantable electronic devices.

NANOGENERATORS are innovative self-powered energy harvesters that convert kinetic energy created from vibrational and mechanical sources into electrical power, removing the need of external circuits or batteries for electronic devices. This innovation is vital in realizing sustainable energy generation in isolated, inaccessible, or indoor environments and even in the human body.

Nanogenerators, a flexible and lightweight energy harvester on a plastic substrate, can scavenge energy from the extremely tiny movements of natural resources and human body such as wind, water flow, heartbeats, and diaphragm and respiration activities to generate electrical signals. The generators are not only self-powered, flexible devices but also can provide permanent power sources to implantable biomedical devices, including cardiac pacemakers and deep brain stimulators.

However, poor energy efficiency and a complex fabrication process have posed challenges to the commercialization of nanogenerators. Keon Jae Lee, Associate Professor of Materials Science and Engineering at KAIST, and his colleagues have recently proposed a solution by developing a robust technique to transfer a high-quality piezoelectric thin film from bulk sapphire substrates to plastic substrates using laser lift-off (LLO).

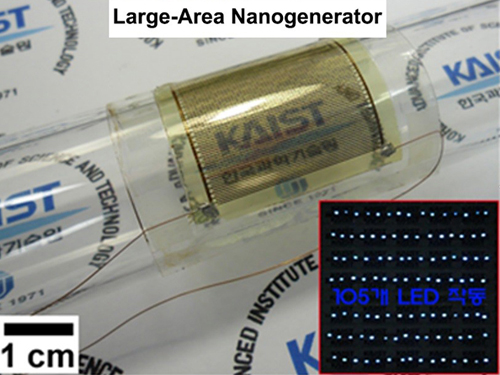

Applying the inorganic-based laser lift-off (LLO) process, the research team produced a large-area PZT thin film nanogenerators on flexible substrates (2cm x 2cm).

“We were able to convert a high-output performance of ~250 V from the slight mechanical deformation of a single thin plastic substrate. Such output power is just enough to turn on 100 LED lights,” Keon Jae Lee explained.

The self-powered nanogenerators can also work with finger and foot motions. For example, under the irregular and slight bending motions of a human finger, the measured current signals had a high electric power of ~8.7 μA. In addition, the piezoelectric nanogenerator has world-record power conversion efficiency, almost 40 times higher than previously reported similar research results, solving the drawbacks related to the fabrication complexity and low energy efficiency.

Lee further commented,

“Building on this concept, it is highly expected that tiny mechanical motions, including human body movements of muscle contraction and relaxation, can be readily converted into electrical energy and, furthermore, acted as eternal power sources.”

The research team is currently studying a method to build three-dimensional stacking of flexible piezoelectric thin films to enhance output power, as well as conducting a clinical experiment with a flexible nanogenerator.

This research result, entitled “Highly-efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates,” was published as the cover article of the April issue of Advanced Materials. (http://onlinelibrary.wiley.com/doi/10.1002/adma.201305659/abstract)

YouTube Link: http://www.youtube.com/watch?v=G_Fny7Xb9ig

Over 100 LEDs operated by self-powered flexible piezoelectric thin film nanogenerator

Flexible PZT thin film nanogenerator using inorganic-based laser lift-off process

Photograph of large-area PZT thin film nanogenerator (3.5cm × 3.5cm) on a curved glass tube and 105 commercial LEDs operated by self-powered flexible piezoelectric energy harvester

2014.05.19 View 15165

KAIST Made Great Improvements of Nanogenerator Power Efficiency

The energy efficiency of a piezoelectric nanogenerator developed by KAIST has increased by almost 40 times, one step closer toward the commercialization of flexible energy harvesters that can supply power infinitely to wearable, implantable electronic devices.

NANOGENERATORS are innovative self-powered energy harvesters that convert kinetic energy created from vibrational and mechanical sources into electrical power, removing the need of external circuits or batteries for electronic devices. This innovation is vital in realizing sustainable energy generation in isolated, inaccessible, or indoor environments and even in the human body.

Nanogenerators, a flexible and lightweight energy harvester on a plastic substrate, can scavenge energy from the extremely tiny movements of natural resources and human body such as wind, water flow, heartbeats, and diaphragm and respiration activities to generate electrical signals. The generators are not only self-powered, flexible devices but also can provide permanent power sources to implantable biomedical devices, including cardiac pacemakers and deep brain stimulators.

However, poor energy efficiency and a complex fabrication process have posed challenges to the commercialization of nanogenerators. Keon Jae Lee, Associate Professor of Materials Science and Engineering at KAIST, and his colleagues have recently proposed a solution by developing a robust technique to transfer a high-quality piezoelectric thin film from bulk sapphire substrates to plastic substrates using laser lift-off (LLO).

Applying the inorganic-based laser lift-off (LLO) process, the research team produced a large-area PZT thin film nanogenerators on flexible substrates (2cm x 2cm).

“We were able to convert a high-output performance of ~250 V from the slight mechanical deformation of a single thin plastic substrate. Such output power is just enough to turn on 100 LED lights,” Keon Jae Lee explained.

The self-powered nanogenerators can also work with finger and foot motions. For example, under the irregular and slight bending motions of a human finger, the measured current signals had a high electric power of ~8.7 μA. In addition, the piezoelectric nanogenerator has world-record power conversion efficiency, almost 40 times higher than previously reported similar research results, solving the drawbacks related to the fabrication complexity and low energy efficiency.

Lee further commented,

“Building on this concept, it is highly expected that tiny mechanical motions, including human body movements of muscle contraction and relaxation, can be readily converted into electrical energy and, furthermore, acted as eternal power sources.”

The research team is currently studying a method to build three-dimensional stacking of flexible piezoelectric thin films to enhance output power, as well as conducting a clinical experiment with a flexible nanogenerator.

This research result, entitled “Highly-efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates,” was published as the cover article of the April issue of Advanced Materials. (http://onlinelibrary.wiley.com/doi/10.1002/adma.201305659/abstract)

YouTube Link: http://www.youtube.com/watch?v=G_Fny7Xb9ig

Over 100 LEDs operated by self-powered flexible piezoelectric thin film nanogenerator

Flexible PZT thin film nanogenerator using inorganic-based laser lift-off process

Photograph of large-area PZT thin film nanogenerator (3.5cm × 3.5cm) on a curved glass tube and 105 commercial LEDs operated by self-powered flexible piezoelectric energy harvester

2014.05.19 View 15165 -

Professor Yoon Dong Ki becomes first Korean to Receive the Michi Nakata Prize

Professor Yoon Dong Ki (Graduate School of Nano Science and Technology) became the first Korean to receive the Michi Nakata Prize from the International Liquid Crystal Society.

The Awards Ceremony was held on the 23rd of August in Mainz, Germany in the 24th Annual International Liquid Crystal Conference.

The Michi Nakata Prize was initiated in 2008 and is rewarded every two years to a young scientist that made a ground breaking discovery or experimental result in the field of liquid crystal. Professor Yoon is the first Korean recipient of the Michi Nakata Prize.

Professor Yoon is the founder of the patterning field that utilizes the defect structure formed by smectic displays. He succeeded in large scale patterning complex chiral nano structures that make up bent-core molecules.

Professor Yoon’s experimental accomplishment was published in the Advanced Materials magazine and the Proc. Natl. Acad. Sci. U.S.A. and also as the cover dissertation of Liquid Crystals magazine.

Professor Yoon is currently working on Three Dimensional Nano Patterning of Supermolecular Liquid Crystal and is part of the World Class University organization.

2012.09.11 View 13142

Professor Yoon Dong Ki becomes first Korean to Receive the Michi Nakata Prize

Professor Yoon Dong Ki (Graduate School of Nano Science and Technology) became the first Korean to receive the Michi Nakata Prize from the International Liquid Crystal Society.

The Awards Ceremony was held on the 23rd of August in Mainz, Germany in the 24th Annual International Liquid Crystal Conference.

The Michi Nakata Prize was initiated in 2008 and is rewarded every two years to a young scientist that made a ground breaking discovery or experimental result in the field of liquid crystal. Professor Yoon is the first Korean recipient of the Michi Nakata Prize.

Professor Yoon is the founder of the patterning field that utilizes the defect structure formed by smectic displays. He succeeded in large scale patterning complex chiral nano structures that make up bent-core molecules.

Professor Yoon’s experimental accomplishment was published in the Advanced Materials magazine and the Proc. Natl. Acad. Sci. U.S.A. and also as the cover dissertation of Liquid Crystals magazine.

Professor Yoon is currently working on Three Dimensional Nano Patterning of Supermolecular Liquid Crystal and is part of the World Class University organization.

2012.09.11 View 13142 -

Liver Damage Mechanism of Hepatitis C Proven

KAIST researchers found mechanics behind a Hepatitis C virus, thereby taking a step closer to the development of a cure for Hepatitis C.

Professor Choi Chul Hui (Department of Biological and Brain Engineering) and Professor Shin Eui Chul (Graduate School of Medical Sciences) proved, for the first time in the world, the mechanism behind liver damage of a patient with Hepatitis C.

It is anticipated that this discovery will allow for the development of a Hepatitis C cure that has no side effects and little Liver damage.

Hepatitis C is an immune response of the body to the Hepatitis C virus and causes liver irritation.

Around 170million people are infected with Hepatitis C worldwide including 1% of the Korean population. Once infected, most cases turn into chronic cases and may lead to liver cancer.

However it was impossible to infect Hepatitis C within a test tube cell environment until 2005 and up till then Chimpanzees were used to study the virus which proved to be a huge barrier to research.

The research team used cells infected with Hepatitis C virus and found out that the virus works by increasing the destruction of cells by the TNF-a protein responsible for the cell’s immune response.

In addition the protein structure of the virus that causes this reaction was successfully found.

Conventionally the Hepatitis C medication focused on the suppressing the growth of the virus and therefore had many side effects.

The experimental results allow new medication aimed at suppressing the actual mechanism of liver damage to be discovered.

The result was selected as the cover dissertation of the September Edition of the Hepatolog magazine.

2012.09.11 View 13411

Liver Damage Mechanism of Hepatitis C Proven

KAIST researchers found mechanics behind a Hepatitis C virus, thereby taking a step closer to the development of a cure for Hepatitis C.

Professor Choi Chul Hui (Department of Biological and Brain Engineering) and Professor Shin Eui Chul (Graduate School of Medical Sciences) proved, for the first time in the world, the mechanism behind liver damage of a patient with Hepatitis C.

It is anticipated that this discovery will allow for the development of a Hepatitis C cure that has no side effects and little Liver damage.

Hepatitis C is an immune response of the body to the Hepatitis C virus and causes liver irritation.

Around 170million people are infected with Hepatitis C worldwide including 1% of the Korean population. Once infected, most cases turn into chronic cases and may lead to liver cancer.

However it was impossible to infect Hepatitis C within a test tube cell environment until 2005 and up till then Chimpanzees were used to study the virus which proved to be a huge barrier to research.

The research team used cells infected with Hepatitis C virus and found out that the virus works by increasing the destruction of cells by the TNF-a protein responsible for the cell’s immune response.

In addition the protein structure of the virus that causes this reaction was successfully found.

Conventionally the Hepatitis C medication focused on the suppressing the growth of the virus and therefore had many side effects.

The experimental results allow new medication aimed at suppressing the actual mechanism of liver damage to be discovered.

The result was selected as the cover dissertation of the September Edition of the Hepatolog magazine.

2012.09.11 View 13411 -

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 14393

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 14393 -

High Capacity Molecular Storage Technology Developed by KAIST Professor Omar M. Yaghi

KAIST research team has succeeded in developing the technology that allows high capacity protein storage.

Professor Omar M. Yaghi (Graduate School of EEWS) and his research team succeeded in developing the core technology that enables the storage of various types of proteins by developing a metal organic structure. The result of their research was published in the May edition of Science magazine.

The newly developed technology can store various types and sizes of proteins. This property is expected to pave way to: 1) development of high capacity, high integration drugs 2) development of virus separation compounds 3) selective removal of protein causing negative reactions in the body 4) permanent preservation of rare polymeric proteins, among other expectations.

In addition it becomes possible to selectively remove and preserve all the body’s cells including stem cells which will aid the development of cures for incurable diseases and increase life expectancy and medical technology in general.

Conventional metal-organic structure used 7 Angstrom large small single molecules and therefore could not be used in the storage of large molecules or proteins. Its usability was proven only as potential high capacity gas storage structure. In addition the internal structure of the metal organic structure is cross linked which made it even more difficult to store large proteins within the structure.

Professor Yaghi’s team used molecular structure over 5nm in length in the development of the metal-organic structure to solve the problem associated with size of structure. The ordered structure of the structure’s pore was observed for the first time using Transmission Electron Microscope.

The new structure enables the ordered storage of large proteins and was able to store vitamin and proteins like myoglobin at high capacity for the first time in the world.

2012.05.30 View 9384

High Capacity Molecular Storage Technology Developed by KAIST Professor Omar M. Yaghi

KAIST research team has succeeded in developing the technology that allows high capacity protein storage.

Professor Omar M. Yaghi (Graduate School of EEWS) and his research team succeeded in developing the core technology that enables the storage of various types of proteins by developing a metal organic structure. The result of their research was published in the May edition of Science magazine.

The newly developed technology can store various types and sizes of proteins. This property is expected to pave way to: 1) development of high capacity, high integration drugs 2) development of virus separation compounds 3) selective removal of protein causing negative reactions in the body 4) permanent preservation of rare polymeric proteins, among other expectations.

In addition it becomes possible to selectively remove and preserve all the body’s cells including stem cells which will aid the development of cures for incurable diseases and increase life expectancy and medical technology in general.

Conventional metal-organic structure used 7 Angstrom large small single molecules and therefore could not be used in the storage of large molecules or proteins. Its usability was proven only as potential high capacity gas storage structure. In addition the internal structure of the metal organic structure is cross linked which made it even more difficult to store large proteins within the structure.

Professor Yaghi’s team used molecular structure over 5nm in length in the development of the metal-organic structure to solve the problem associated with size of structure. The ordered structure of the structure’s pore was observed for the first time using Transmission Electron Microscope.

The new structure enables the ordered storage of large proteins and was able to store vitamin and proteins like myoglobin at high capacity for the first time in the world.

2012.05.30 View 9384 -

Professor Choi Chul Hui appointed as editor-in-chief of Nanobiosensors in a disease diagnosis magazine

Professor Choi Chul Hui of the Department of Biological and Brain Engineering has been appointed the editor-in-chief of Nanobiosensors, an international medical magazine that concentrates on disease diagnosis.

As the editor-in-chief, Professor Choi will be involved in dissertation evaluations and overall direction of the magazine.

Professor Choi is one of the leading authorities in the field of clinical medicine and has published 60 SCI level dissertations in the fields of cell biology, computational biology, and bio-optics.

He is also the executive director of the KAIST BioImaging Research Center, and his research lab focuses on cell signals and bio imaging. Professor Choi is researching the generation process of degenerative diseases like arteriosclerosis by taking a multidisciplinary approach.

Professor Choi has recently developed a new bio imaging technique that allows for the measurement of perfusion and a new technology for the drug delivery to nerves using ultra short wavelength laser beams.

2011.10.10 View 11238

Professor Choi Chul Hui appointed as editor-in-chief of Nanobiosensors in a disease diagnosis magazine

Professor Choi Chul Hui of the Department of Biological and Brain Engineering has been appointed the editor-in-chief of Nanobiosensors, an international medical magazine that concentrates on disease diagnosis.

As the editor-in-chief, Professor Choi will be involved in dissertation evaluations and overall direction of the magazine.

Professor Choi is one of the leading authorities in the field of clinical medicine and has published 60 SCI level dissertations in the fields of cell biology, computational biology, and bio-optics.

He is also the executive director of the KAIST BioImaging Research Center, and his research lab focuses on cell signals and bio imaging. Professor Choi is researching the generation process of degenerative diseases like arteriosclerosis by taking a multidisciplinary approach.

Professor Choi has recently developed a new bio imaging technique that allows for the measurement of perfusion and a new technology for the drug delivery to nerves using ultra short wavelength laser beams.

2011.10.10 View 11238 -

Scientists develop highly efficient industrial catalyst

http://english.yonhapnews.co.kr/business/2011/07/14/48/0501000000AEN20110714009600320F.HTML

SEOUL, July 15 (Yonhap) -- South Korean scientists said Friday that they have developed a highly efficient nanoporous industrial catalyst that can have a considerable impact on chemical and oil-refining sectors.

The team of scientists led by Ryoo Ryong, a chemistry professor at the Korea Advanced Institute of Science and Technology (KAIST), said the solid zeolite compound developed in the laboratory has a reaction speed five to 10 times faster than that of conventional materials.

Zeolite, which is made from silica and aluminium, is frequently used as an absorbent, water purifier and in nuclear reprocessing, although it is mainly employed in the chemical industry.

The annual size of the zeolite market is estimated at US$2.5 billion with output using the material topping $30 billion. At present, 41 percent of all catalysts used in the chemical sector are nano-scale zeolite materials.

The KAIST team said that because the new zeolite is made up of different sized pores, the material can be used as a catalyst when existing materials are unable to act as a changing agent.

"Existing zeolites only have pores under 1 nanometer in diameter, but the new material has holes that range from 1 nanometer to 3.5 nanometers, which are all arranged in a regular honeycomb arrangement," Ryoo said. A nanometer is one-billionth of a meter.

He said the ability to have both micro- and meso-sized pores is key to the faster reaction speed that is an integral part of raising efficiency. The South Korean researchers used a so-called surfactant process to make the different sizes of pores.

The development is a breakthrough because researchers and companies such as Exxon Mobil Corp. have been trying to build zeolite with different sizes of pores for the past two decades without making serious headway. There are more than 200 different types of zeolites in the world.

Ryoo, who received funding from the government, has requested intellectual property rights for the discovery, which has been published in the latest issue of Science magazine. He also developed another zeolite in the past that can transform methanol to gasoline up to 10 times more efficiently than existing catalysts.

Exxon Mobil has expressed interest in the two zeolites made by Ryoo"s team. Undisclosed South Korean petrochemical companies have also made inquiries that may lead to commercial development in the future.

"There are some technical issues to resolve, mainly related with mass production and stability," the scientist said.

He said full-fledge production will be determined by how much companies are willing to spend on research to speed up development that can bring down overall production costs.

The KAIST team said it took two years to make the new zeolite, which can be custom made to meet specific needs.

(END)

2011.07.15 View 13048

Scientists develop highly efficient industrial catalyst

http://english.yonhapnews.co.kr/business/2011/07/14/48/0501000000AEN20110714009600320F.HTML

SEOUL, July 15 (Yonhap) -- South Korean scientists said Friday that they have developed a highly efficient nanoporous industrial catalyst that can have a considerable impact on chemical and oil-refining sectors.

The team of scientists led by Ryoo Ryong, a chemistry professor at the Korea Advanced Institute of Science and Technology (KAIST), said the solid zeolite compound developed in the laboratory has a reaction speed five to 10 times faster than that of conventional materials.

Zeolite, which is made from silica and aluminium, is frequently used as an absorbent, water purifier and in nuclear reprocessing, although it is mainly employed in the chemical industry.

The annual size of the zeolite market is estimated at US$2.5 billion with output using the material topping $30 billion. At present, 41 percent of all catalysts used in the chemical sector are nano-scale zeolite materials.

The KAIST team said that because the new zeolite is made up of different sized pores, the material can be used as a catalyst when existing materials are unable to act as a changing agent.

"Existing zeolites only have pores under 1 nanometer in diameter, but the new material has holes that range from 1 nanometer to 3.5 nanometers, which are all arranged in a regular honeycomb arrangement," Ryoo said. A nanometer is one-billionth of a meter.

He said the ability to have both micro- and meso-sized pores is key to the faster reaction speed that is an integral part of raising efficiency. The South Korean researchers used a so-called surfactant process to make the different sizes of pores.

The development is a breakthrough because researchers and companies such as Exxon Mobil Corp. have been trying to build zeolite with different sizes of pores for the past two decades without making serious headway. There are more than 200 different types of zeolites in the world.

Ryoo, who received funding from the government, has requested intellectual property rights for the discovery, which has been published in the latest issue of Science magazine. He also developed another zeolite in the past that can transform methanol to gasoline up to 10 times more efficiently than existing catalysts.

Exxon Mobil has expressed interest in the two zeolites made by Ryoo"s team. Undisclosed South Korean petrochemical companies have also made inquiries that may lead to commercial development in the future.

"There are some technical issues to resolve, mainly related with mass production and stability," the scientist said.

He said full-fledge production will be determined by how much companies are willing to spend on research to speed up development that can bring down overall production costs.

The KAIST team said it took two years to make the new zeolite, which can be custom made to meet specific needs.

(END)

2011.07.15 View 13048