beam

-

KAIST Develops AI-Driven Performance Prediction Model to Advance Space Electric Propulsion Technology

< (From left) PhD candidate Youngho Kim, Professor Wonho Choe, and PhD candidate Jaehong Park from the Department of Nuclear and Quantum Engineering >

Hall thrusters, a key space technology for missions like SpaceX's Starlink constellation and NASA's Psyche asteroid mission, are high-efficiency electric propulsion devices using plasma technology*. The KAIST research team announced that the AI-designed Hall thruster developed for CubeSats will be installed on the KAIST-Hall Effect Rocket Orbiter (K-HERO) CubeSat to demonstrate its in-orbit performance during the fourth launch of the Korean Launch Vehicle called Nuri rocket (KSLV-2) scheduled for November this year.

*Plasma is one of the four states of matter, where gases are heated to high energies, causing them to separate into charged ions and electrons. Plasma is used not only in space electric propulsion but also in semiconductor manufacturing, display processes, and sterilization devices.

On February 3rd, the research team from the KAIST Department of Nuclear and Quantum Engineering’s Electric Propulsion Laboratory, led by Professor Wonho Choe, announced the development of an AI-based technique to accurately predict the performance of Hall thrusters, the engines of satellites and space probes.

Hall thrusters provide high fuel efficiency, requiring minimal propellant to achieve significant acceleration of spacecrafts or satellites while producing substantial thrust relative to power consumption. Due to these advantages, Hall thrusters are widely used in various space missions, including the formation flight of satellite constellations, deorbiting maneuvers for space debris mitigation, and deep space missions such as asteroid exploration.

As the space industry continues to grow during the NewSpace era, the demand for Hall thrusters suited to diverse missions is increasing. To rapidly develop highly efficient, mission-optimized Hall thrusters, it is essential to predict thruster performance accurately from the design phase.

However, conventional methods have limitations, as they struggle to handle the complex plasma phenomena within Hall thrusters or are only applicable under specific conditions, leading to lower prediction accuracy.

The research team developed an AI-based performance prediction technique with high accuracy, significantly reducing the time and cost associated with the iterative design, fabrication, and testing of thrusters. Since 2003, Professor Wonho Choe’s team has been leading research on electric propulsion development in Korea. The team applied a neural network ensemble model to predict thruster performance using 18,000 Hall thruster training data points generated from their in-house numerical simulation tool.

The in-house numerical simulation tool, developed to model plasma physics and thrust performance, played a crucial role in providing high-quality training data. The simulation’s accuracy was validated through comparisons with experimental data from ten KAIST in-house Hall thrusters, with an average prediction error of less than 10%.

< Figure 1. This research has been selected as the cover article for the March 2025 issue (Volume 7, Issue 3) of the AI interdisciplinary journal, Advanced Intelligent Systems. >

The trained neural network ensemble model acts as a digital twin, accurately predicting the Hall thruster performance within seconds based on thruster design variables.

Notably, it offers detailed analyses of performance parameters such as thrust and discharge current, accounting for Hall thruster design variables like propellant flow rate and magnetic field—factors that are challenging to evaluate using traditional scaling laws.

This AI model demonstrated an average prediction error of less than 5% for the in-house 700 W and 1 kW KAIST Hall thrusters and less than 9% for a 5 kW high-power Hall thruster developed by the University of Michigan and the U.S. Air Force Research Laboratory. This confirms the broad applicability of the AI prediction method across different power levels of Hall thrusters.

Professor Wonho Choe stated, “The AI-based prediction technique developed by our team is highly accurate and is already being utilized in the analysis of thrust performance and the development of highly efficient, low-power Hall thrusters for satellites and spacecraft. This AI approach can also be applied beyond Hall thrusters to various industries, including semiconductor manufacturing, surface processing, and coating, through ion beam sources.”

< Figure 2. The AI-based prediction technique developed by the research team accurately predicts thrust performance based on design variables, making it highly valuable for the development of high-efficiency Hall thrusters. The neural network ensemble processes design variables, such as channel geometry and magnetic field information, and outputs key performance metrics like thrust and prediction accuracy, enabling efficient thruster design and performance analysis. >

Additionally, Professor Choe mentioned, “The CubeSat Hall thruster, developed using the AI technique in collaboration with our lab startup—Cosmo Bee, an electric propulsion company—will be tested in orbit this November aboard the K-HERO 3U (30 x 10 x 10 cm) CubeSat, scheduled for launch on the fourth flight of the KSLV-2 Nuri rocket.”

This research was published online in Advanced Intelligent Systems on December 25, 2024 with PhD candidate Jaehong Park as the first author and was selected as the journal’s cover article, highlighting its innovation.

< Figure 3. Image of the 150 W low-power Hall thruster for small and micro satellites, developed in collaboration with Cosmo Bee and the KAIST team. The thruster will be tested in orbit on the K-HERO CubeSat during the KSLV-2 Nuri rocket’s fourth launch in Q4 2025. >

This research was supported by the National Research Foundation of Korea’s Space Pioneer Program (200mN High Thrust Electric Propulsion System Development).

(Paper Title: Predicting Performance of Hall Effect Ion Source Using Machine Learning, DOI: https://doi.org/10.1002/aisy.202400555 )

< Figure 4. Graphs of the predicted thrust and discharge current of KAIST’s 700 W Hall thruster using the AI model (HallNN). The left image shows the Hall thruster operating in KAIST Electric Propulsion Laboratory’s vacuum chamber, while the center and right graphs present the prediction results for thrust and discharge current based on anode mass flow rate. The red lines represent AI predictions, and the blue dots represent experimental results, with a prediction error of less than 5%. >

2025.02.03 View 7323

KAIST Develops AI-Driven Performance Prediction Model to Advance Space Electric Propulsion Technology

< (From left) PhD candidate Youngho Kim, Professor Wonho Choe, and PhD candidate Jaehong Park from the Department of Nuclear and Quantum Engineering >

Hall thrusters, a key space technology for missions like SpaceX's Starlink constellation and NASA's Psyche asteroid mission, are high-efficiency electric propulsion devices using plasma technology*. The KAIST research team announced that the AI-designed Hall thruster developed for CubeSats will be installed on the KAIST-Hall Effect Rocket Orbiter (K-HERO) CubeSat to demonstrate its in-orbit performance during the fourth launch of the Korean Launch Vehicle called Nuri rocket (KSLV-2) scheduled for November this year.

*Plasma is one of the four states of matter, where gases are heated to high energies, causing them to separate into charged ions and electrons. Plasma is used not only in space electric propulsion but also in semiconductor manufacturing, display processes, and sterilization devices.

On February 3rd, the research team from the KAIST Department of Nuclear and Quantum Engineering’s Electric Propulsion Laboratory, led by Professor Wonho Choe, announced the development of an AI-based technique to accurately predict the performance of Hall thrusters, the engines of satellites and space probes.

Hall thrusters provide high fuel efficiency, requiring minimal propellant to achieve significant acceleration of spacecrafts or satellites while producing substantial thrust relative to power consumption. Due to these advantages, Hall thrusters are widely used in various space missions, including the formation flight of satellite constellations, deorbiting maneuvers for space debris mitigation, and deep space missions such as asteroid exploration.

As the space industry continues to grow during the NewSpace era, the demand for Hall thrusters suited to diverse missions is increasing. To rapidly develop highly efficient, mission-optimized Hall thrusters, it is essential to predict thruster performance accurately from the design phase.

However, conventional methods have limitations, as they struggle to handle the complex plasma phenomena within Hall thrusters or are only applicable under specific conditions, leading to lower prediction accuracy.

The research team developed an AI-based performance prediction technique with high accuracy, significantly reducing the time and cost associated with the iterative design, fabrication, and testing of thrusters. Since 2003, Professor Wonho Choe’s team has been leading research on electric propulsion development in Korea. The team applied a neural network ensemble model to predict thruster performance using 18,000 Hall thruster training data points generated from their in-house numerical simulation tool.

The in-house numerical simulation tool, developed to model plasma physics and thrust performance, played a crucial role in providing high-quality training data. The simulation’s accuracy was validated through comparisons with experimental data from ten KAIST in-house Hall thrusters, with an average prediction error of less than 10%.

< Figure 1. This research has been selected as the cover article for the March 2025 issue (Volume 7, Issue 3) of the AI interdisciplinary journal, Advanced Intelligent Systems. >

The trained neural network ensemble model acts as a digital twin, accurately predicting the Hall thruster performance within seconds based on thruster design variables.

Notably, it offers detailed analyses of performance parameters such as thrust and discharge current, accounting for Hall thruster design variables like propellant flow rate and magnetic field—factors that are challenging to evaluate using traditional scaling laws.

This AI model demonstrated an average prediction error of less than 5% for the in-house 700 W and 1 kW KAIST Hall thrusters and less than 9% for a 5 kW high-power Hall thruster developed by the University of Michigan and the U.S. Air Force Research Laboratory. This confirms the broad applicability of the AI prediction method across different power levels of Hall thrusters.

Professor Wonho Choe stated, “The AI-based prediction technique developed by our team is highly accurate and is already being utilized in the analysis of thrust performance and the development of highly efficient, low-power Hall thrusters for satellites and spacecraft. This AI approach can also be applied beyond Hall thrusters to various industries, including semiconductor manufacturing, surface processing, and coating, through ion beam sources.”

< Figure 2. The AI-based prediction technique developed by the research team accurately predicts thrust performance based on design variables, making it highly valuable for the development of high-efficiency Hall thrusters. The neural network ensemble processes design variables, such as channel geometry and magnetic field information, and outputs key performance metrics like thrust and prediction accuracy, enabling efficient thruster design and performance analysis. >

Additionally, Professor Choe mentioned, “The CubeSat Hall thruster, developed using the AI technique in collaboration with our lab startup—Cosmo Bee, an electric propulsion company—will be tested in orbit this November aboard the K-HERO 3U (30 x 10 x 10 cm) CubeSat, scheduled for launch on the fourth flight of the KSLV-2 Nuri rocket.”

This research was published online in Advanced Intelligent Systems on December 25, 2024 with PhD candidate Jaehong Park as the first author and was selected as the journal’s cover article, highlighting its innovation.

< Figure 3. Image of the 150 W low-power Hall thruster for small and micro satellites, developed in collaboration with Cosmo Bee and the KAIST team. The thruster will be tested in orbit on the K-HERO CubeSat during the KSLV-2 Nuri rocket’s fourth launch in Q4 2025. >

This research was supported by the National Research Foundation of Korea’s Space Pioneer Program (200mN High Thrust Electric Propulsion System Development).

(Paper Title: Predicting Performance of Hall Effect Ion Source Using Machine Learning, DOI: https://doi.org/10.1002/aisy.202400555 )

< Figure 4. Graphs of the predicted thrust and discharge current of KAIST’s 700 W Hall thruster using the AI model (HallNN). The left image shows the Hall thruster operating in KAIST Electric Propulsion Laboratory’s vacuum chamber, while the center and right graphs present the prediction results for thrust and discharge current based on anode mass flow rate. The red lines represent AI predictions, and the blue dots represent experimental results, with a prediction error of less than 5%. >

2025.02.03 View 7323 -

KAIST researchers develops a tech to enable production of ultrahigh-resolution LED with sub-micrometer scale pixels

Ultrahigh-resolution displays are an essential element for developing next-generation electronic products such as virtual reality (VR), augmented reality (AR), and smart watches, and can be applied not only to head-mounted displays, but also to smart glasses and smart lenses. The technology developed through this research is expected to be used to make such next-generation ultrahigh-resolution displays and other various sub-micro optoelectronic devices.

KAIST (President Kwang Hyung Lee) announced on the 22nd that Professor Yong-Hoon Cho's research team of KAIST Department of Physics developed the core technology for an ultrahigh resolution light-emitting diode (LED) display that can realize 0.5 micron-scale pixels smaller than 1/100 of the average hair thickness (about 100 microns) using focused ion beams.

Commonly, pixelation of ultrahigh-resolution LED displays usually relies on the etching method that physically cuts the area around the pixel, but as the pixel becomes smaller due to the occurrence of various defects around it, leading to side-effects of having leakage of current increased and light-emission efficiency decreased. In addition, various complex processes such as patterning for pixelation and post-processing for prevention of leakage current are required.

Professor Yong-Hoon Cho's research team developed a technology that can create pixels down to the size of a microscale without the complicated pre- and post-processing using a focused ion beam. This method has the advantage of being able to freely set the shape of the emitting pixel without causing any structural deformation on the material surface by controlling the intensity of the focused ion beam.

The focused ion beam technology has been widely used for ultrahigh-magnification imaging and nanostructure fabrication in fields such as materials engineering and biology. However, when a focused ion beam is used on a light emitting body such as an LED, light emission of a portion hit by the beam and a surrounding area rapidly decreases, which has been a barrier to fabricating a nano-scale light emitting structure. Upon facing this issue, Professor Cho's research team began the research on the idea that if they turned things around to use these problematic phenomena, they can be used in ultra-fine pixelation method on a sub-micron scale.

The research team used a focused ion beam whose intensity was softened to the extent that the surface was not shaved, and found that not only the light-emission rapidly decreased in the area hit by the focused ion beam, but also the local resistance greatly increased. As a result, while the surface of the LED is kept flat, the portion hit by the focused ion beam is optically and electrically isolated, enabling pixelation for independent operation.

Professor Yong-Hoon Cho, who led the research, said, “We have newly developed a technology that can create sub-micron-scale pixels without complicated processes using a focused ion beam, which will be a base technology that can be applied to next-generation ultrahigh-resolution displays and nano-photoelectronic devices.”

This research in which the Master's student Ji-Hwan Moon and the Ph.D. student Baul Kim of KAIST Department of Physics participated as co-first authors, was carried out with the support of the National Research Foundation of Korea's Support Program for Mid-Career Researchers and the Institute of Information and Communications Technology Planning and Evaluation. It was published online in 'Advanced Materials' on February 13, and was also selected as the internal cover of the next offline edition. (Title: Electrically Driven Sub-Micron Light-Emitting Diode Arrays Using Maskless and Etching-Free Pixelation)

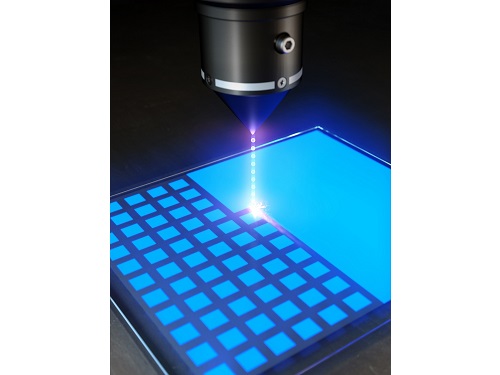

Figure 1. Schematic diagram of the technology for ultrahigh density sub-micron-sized pixels through He focused ion beam (FIB) irradiation on an LED device

Figure 2. Ultra-high-density pixelation technology of micro light-emitting diodes (μLED) through He focused ion beam (FIB) irradiation

Figure 3. Rectangular pixels of different sizes (surface structure picture and luminescence picture) realized by a focused ion beam. Luminescence pictures of pixel arrays ranging in size from 20 µm x 20 µm to 0.5 µm x 0.5 µm, with surface flatness maintained.

2023.03.08 View 9452

KAIST researchers develops a tech to enable production of ultrahigh-resolution LED with sub-micrometer scale pixels

Ultrahigh-resolution displays are an essential element for developing next-generation electronic products such as virtual reality (VR), augmented reality (AR), and smart watches, and can be applied not only to head-mounted displays, but also to smart glasses and smart lenses. The technology developed through this research is expected to be used to make such next-generation ultrahigh-resolution displays and other various sub-micro optoelectronic devices.

KAIST (President Kwang Hyung Lee) announced on the 22nd that Professor Yong-Hoon Cho's research team of KAIST Department of Physics developed the core technology for an ultrahigh resolution light-emitting diode (LED) display that can realize 0.5 micron-scale pixels smaller than 1/100 of the average hair thickness (about 100 microns) using focused ion beams.

Commonly, pixelation of ultrahigh-resolution LED displays usually relies on the etching method that physically cuts the area around the pixel, but as the pixel becomes smaller due to the occurrence of various defects around it, leading to side-effects of having leakage of current increased and light-emission efficiency decreased. In addition, various complex processes such as patterning for pixelation and post-processing for prevention of leakage current are required.

Professor Yong-Hoon Cho's research team developed a technology that can create pixels down to the size of a microscale without the complicated pre- and post-processing using a focused ion beam. This method has the advantage of being able to freely set the shape of the emitting pixel without causing any structural deformation on the material surface by controlling the intensity of the focused ion beam.

The focused ion beam technology has been widely used for ultrahigh-magnification imaging and nanostructure fabrication in fields such as materials engineering and biology. However, when a focused ion beam is used on a light emitting body such as an LED, light emission of a portion hit by the beam and a surrounding area rapidly decreases, which has been a barrier to fabricating a nano-scale light emitting structure. Upon facing this issue, Professor Cho's research team began the research on the idea that if they turned things around to use these problematic phenomena, they can be used in ultra-fine pixelation method on a sub-micron scale.

The research team used a focused ion beam whose intensity was softened to the extent that the surface was not shaved, and found that not only the light-emission rapidly decreased in the area hit by the focused ion beam, but also the local resistance greatly increased. As a result, while the surface of the LED is kept flat, the portion hit by the focused ion beam is optically and electrically isolated, enabling pixelation for independent operation.

Professor Yong-Hoon Cho, who led the research, said, “We have newly developed a technology that can create sub-micron-scale pixels without complicated processes using a focused ion beam, which will be a base technology that can be applied to next-generation ultrahigh-resolution displays and nano-photoelectronic devices.”

This research in which the Master's student Ji-Hwan Moon and the Ph.D. student Baul Kim of KAIST Department of Physics participated as co-first authors, was carried out with the support of the National Research Foundation of Korea's Support Program for Mid-Career Researchers and the Institute of Information and Communications Technology Planning and Evaluation. It was published online in 'Advanced Materials' on February 13, and was also selected as the internal cover of the next offline edition. (Title: Electrically Driven Sub-Micron Light-Emitting Diode Arrays Using Maskless and Etching-Free Pixelation)

Figure 1. Schematic diagram of the technology for ultrahigh density sub-micron-sized pixels through He focused ion beam (FIB) irradiation on an LED device

Figure 2. Ultra-high-density pixelation technology of micro light-emitting diodes (μLED) through He focused ion beam (FIB) irradiation

Figure 3. Rectangular pixels of different sizes (surface structure picture and luminescence picture) realized by a focused ion beam. Luminescence pictures of pixel arrays ranging in size from 20 µm x 20 µm to 0.5 µm x 0.5 µm, with surface flatness maintained.

2023.03.08 View 9452 -

Prof. Junil Choi Receives the Neal Shepherd Memorial Award

Professor Junil Choi of the School of Electrical Engineering received the 2021 Neal Shepherd Memorial Award from the IEEE Vehicular Technology Society. The award recognizes the most outstanding paper relating to radio propagation published in major journals over the previous five years.

Professor Cho, the recipient of the 2015 IEEE Signal Processing Society’s and the 2019 IEEE Communications Society’s Best Paper Award, was selected as the awardee for his paper titled “The Impact of Beamwidth on Temporal Channel Variation in Vehicular Channels and Its Implications” in IEEE Transaction on Vehicular Technology in 2017.

In this paper, Professor Choi and his team derived the channel coherence time for a wireless channel as a function of the beamwidth, taking both Doppler effect and pointing error into consideration. The results showed that a nonzero optimal beamwidth exists that maximizes the channel coherence time. To reduce the impact of the overhead of doing realignment in every channel coherence time, the paper showed that the beams should be realigned every beam coherence time for the best performance.

Professor Choi said, “It is quite an honor to receive this prestigious award following Professor Joonhyun Kang who won the IEEE VTS’s Jack Neubauer Memorial Award this year. It shows that our university’s pursuit of excellence in advanced research is being well recognized.”

2021.07.26 View 8339

Prof. Junil Choi Receives the Neal Shepherd Memorial Award

Professor Junil Choi of the School of Electrical Engineering received the 2021 Neal Shepherd Memorial Award from the IEEE Vehicular Technology Society. The award recognizes the most outstanding paper relating to radio propagation published in major journals over the previous five years.

Professor Cho, the recipient of the 2015 IEEE Signal Processing Society’s and the 2019 IEEE Communications Society’s Best Paper Award, was selected as the awardee for his paper titled “The Impact of Beamwidth on Temporal Channel Variation in Vehicular Channels and Its Implications” in IEEE Transaction on Vehicular Technology in 2017.

In this paper, Professor Choi and his team derived the channel coherence time for a wireless channel as a function of the beamwidth, taking both Doppler effect and pointing error into consideration. The results showed that a nonzero optimal beamwidth exists that maximizes the channel coherence time. To reduce the impact of the overhead of doing realignment in every channel coherence time, the paper showed that the beams should be realigned every beam coherence time for the best performance.

Professor Choi said, “It is quite an honor to receive this prestigious award following Professor Joonhyun Kang who won the IEEE VTS’s Jack Neubauer Memorial Award this year. It shows that our university’s pursuit of excellence in advanced research is being well recognized.”

2021.07.26 View 8339 -

Partnership with École Centrale Paris

Courtesy of École Centrale Paris News: http://www.ecp.fr/lang/en/home/news?actuID=48892

Strengthening of the partnership betwenn CentraleSupélec and KAIST University, South Korea

The two institutions signed a new agreement.

Hervé Biausser (left in the picture), Director of CentraleSupélec, has met Sung-Mo Steve Kang (right in the picture), the President of the Korea Advanced Institute of Science and Technology (KAIST). They signed an agreement aiming to strengthen the partnership between the two institutions concerning research and higher education.

CentraleSupélec and KAIST have cooperated since 2010 on research projects in the context of the Erasmus Mundus BEAM and EASED programs, which are coordinated by CentraleSupélec.

The next step is now the application of graduate academic mobility in the common fields of excellency of the institutions: energy, electronic, physics and mathematics.

2015.11.02 View 6847

Partnership with École Centrale Paris

Courtesy of École Centrale Paris News: http://www.ecp.fr/lang/en/home/news?actuID=48892

Strengthening of the partnership betwenn CentraleSupélec and KAIST University, South Korea

The two institutions signed a new agreement.

Hervé Biausser (left in the picture), Director of CentraleSupélec, has met Sung-Mo Steve Kang (right in the picture), the President of the Korea Advanced Institute of Science and Technology (KAIST). They signed an agreement aiming to strengthen the partnership between the two institutions concerning research and higher education.

CentraleSupélec and KAIST have cooperated since 2010 on research projects in the context of the Erasmus Mundus BEAM and EASED programs, which are coordinated by CentraleSupélec.

The next step is now the application of graduate academic mobility in the common fields of excellency of the institutions: energy, electronic, physics and mathematics.

2015.11.02 View 6847 -

Ultra High Speed Nanomaterial Synthesis Process Developed Using Laser

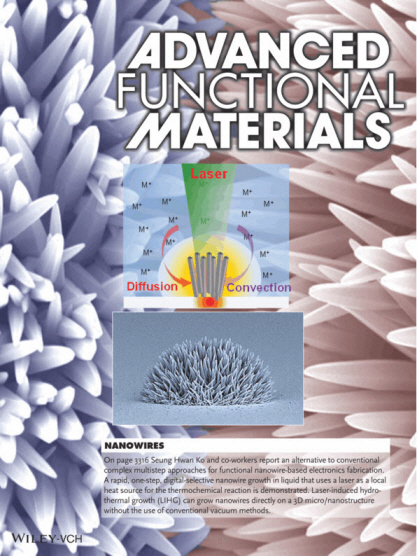

Dr. Jun-Yeop, Yeo and the research team led by Professor Seung-Hwan, Ko (both of the Department of Mechanical Engineering) successfully developed a process enabling the location-determinable, ultra high speed synthesis of nanomaterials using concentrated laser beams.

The result of the research effort was published as the frontispiece in the July 9th issue of Advanced Functional Materials, a world renowned material science and engineering academic journal.

Application of the technology reduced the time needed to process nanomaterial synthesis from a few hours to a mere five minutes. In addition, unlike conventional nanomaterial synthesis processes, it is simple enough to enable mass production and commercialization.

Conventional processes require the high temperatures of 900~1,000 °C and the use of toxic or explosive vapors. Complex processes such as separation after synthesis and patterning are needed for application in electronic devices. The multi-step, expensive, environmentally unfriendly characteristics of nanomaterial synthesis served as road blocks to its mass production and commercialization.

Exposing the precursor to concentrated continuous laser beam (green wavelength) resulted in the synthesis of nanowires in the desired location; the first instance in the world to accomplish this feat. The technology, according to the research team, makes possible the production, integration and patterning of nanomaterials using a single process. Applicable to various surfaces and substrates, nanowires have been successfully synthesized on flexible plastic substrates and controlled patterning on the surface of 3-dimensional structures.

Dr. Yeo commented that the research effort has “yielded the creation of a nanomaterial synthesis process capable of synthesis, integration, pattern, and material production using light energy” and has “reduced the synthesis process time of nanomaterial to one tenths of the conventional process.” Dr. Yeo continues to devise steps to commercialize the new multifunctional electronic material and methods for mass production.

The research effort, led by Dr. Yeo and Professor Ko, received contribution from Professor Hyung-Jin Sung (KAIST Department of Mechanical Engineering), Seok-Joon Hong, a Ph.D. candidate, Hyun-Wook Kang, also a Ph.D. candidate, Professor Costas Grigoropoulos of UC Berkeley, and Dr. Dae Ho Lee. In addition, the team received support from the National Research Foundation, Ministry of Knowledge Economy, Global Frontier Program, and KAIST EEWS.

Picture I: Synthesized nanomaterials produced at a desirable location by laser beams

Picture 2: Synthesized nanomaterials built on the 3D structure by using the developed technology

Picture 3: Functional electric circuit made with synthesized nanomaterials

Picture 4: Cover page of July 9th issue of Advanced Functional Materials

2013.08.23 View 11846

Ultra High Speed Nanomaterial Synthesis Process Developed Using Laser

Dr. Jun-Yeop, Yeo and the research team led by Professor Seung-Hwan, Ko (both of the Department of Mechanical Engineering) successfully developed a process enabling the location-determinable, ultra high speed synthesis of nanomaterials using concentrated laser beams.

The result of the research effort was published as the frontispiece in the July 9th issue of Advanced Functional Materials, a world renowned material science and engineering academic journal.

Application of the technology reduced the time needed to process nanomaterial synthesis from a few hours to a mere five minutes. In addition, unlike conventional nanomaterial synthesis processes, it is simple enough to enable mass production and commercialization.

Conventional processes require the high temperatures of 900~1,000 °C and the use of toxic or explosive vapors. Complex processes such as separation after synthesis and patterning are needed for application in electronic devices. The multi-step, expensive, environmentally unfriendly characteristics of nanomaterial synthesis served as road blocks to its mass production and commercialization.

Exposing the precursor to concentrated continuous laser beam (green wavelength) resulted in the synthesis of nanowires in the desired location; the first instance in the world to accomplish this feat. The technology, according to the research team, makes possible the production, integration and patterning of nanomaterials using a single process. Applicable to various surfaces and substrates, nanowires have been successfully synthesized on flexible plastic substrates and controlled patterning on the surface of 3-dimensional structures.

Dr. Yeo commented that the research effort has “yielded the creation of a nanomaterial synthesis process capable of synthesis, integration, pattern, and material production using light energy” and has “reduced the synthesis process time of nanomaterial to one tenths of the conventional process.” Dr. Yeo continues to devise steps to commercialize the new multifunctional electronic material and methods for mass production.

The research effort, led by Dr. Yeo and Professor Ko, received contribution from Professor Hyung-Jin Sung (KAIST Department of Mechanical Engineering), Seok-Joon Hong, a Ph.D. candidate, Hyun-Wook Kang, also a Ph.D. candidate, Professor Costas Grigoropoulos of UC Berkeley, and Dr. Dae Ho Lee. In addition, the team received support from the National Research Foundation, Ministry of Knowledge Economy, Global Frontier Program, and KAIST EEWS.

Picture I: Synthesized nanomaterials produced at a desirable location by laser beams

Picture 2: Synthesized nanomaterials built on the 3D structure by using the developed technology

Picture 3: Functional electric circuit made with synthesized nanomaterials

Picture 4: Cover page of July 9th issue of Advanced Functional Materials

2013.08.23 View 11846 -

Using Light to Deliver Drugs to the Brain

The cerebral blood vessels have a unique blood-brain barrier. Using this unique structure, Professor Choi Chul Hee (Department of Bio-Brain Engineering) developed a technique to deliver drugs safely to the brain using lasers to alter the diffusivity of the blood-brain barrier.

The blood-brain barrier allows the entry of only those drugs related to metabolic functions which made the entry of other drugs difficult.

Due to this property it was difficult to administer the drug to a patient and have it affect the patient. Therefore the question was is it possible to maintain the effectiveness of the drug and allow it to pass through the barrier?

The conventional method was to actually alter the structure of the drug or drill of small hole in the head and administering the drug directly, but these methods proved to be high risk and expensive.

Professor Choi’s team used an ultra-short frequency laser beam on the barrier for 1/1000th of a second on the barrier to temporarily inhibit its function thereby allowing the drug to enter the brain safely.

2011.06.20 View 10999

Using Light to Deliver Drugs to the Brain

The cerebral blood vessels have a unique blood-brain barrier. Using this unique structure, Professor Choi Chul Hee (Department of Bio-Brain Engineering) developed a technique to deliver drugs safely to the brain using lasers to alter the diffusivity of the blood-brain barrier.

The blood-brain barrier allows the entry of only those drugs related to metabolic functions which made the entry of other drugs difficult.

Due to this property it was difficult to administer the drug to a patient and have it affect the patient. Therefore the question was is it possible to maintain the effectiveness of the drug and allow it to pass through the barrier?

The conventional method was to actually alter the structure of the drug or drill of small hole in the head and administering the drug directly, but these methods proved to be high risk and expensive.

Professor Choi’s team used an ultra-short frequency laser beam on the barrier for 1/1000th of a second on the barrier to temporarily inhibit its function thereby allowing the drug to enter the brain safely.

2011.06.20 View 10999