Small

-

High-Resolution Spectrometer that Fits into Smartphones Developed by KAIST Researchers

- Professor Mooseok Jang's research team at the Department of Bio and Brain Engineering develops an ultra-compact, high-resolution spectrometer using 'double-layer disordered metasurfaces' that generate unique random patterns depending on light's color.

- Unlike conventional dispersion-based spectrometers that were difficult to apply to portable devices, this new concept spectrometer technology achieves 1nm-level high resolution in a device smaller than 1cm, comparable in size to a fingernail.

- It can be utilized as a built-in spectrometer in smartphones and wearable devices in the future, and can be expanded to advanced optical technologies such as hyperspectral imaging and ultrafast imaging.

< Photo 1. (From left) Professor Mooseok Jang, Dong-gu Lee (Ph.D. candidate), Gookho Song (Ph.D. candidate) >

Color, as the way light's wavelength is perceived by the human eye, goes beyond a simple aesthetic element, containing important scientific information like a substance's composition or state. Spectrometers are optical devices that analyze material properties by decomposing light into its constituent wavelengths, and they are widely used in various scientific and industrial fields, including material analysis, chemical component detection, and life science research. Existing high-resolution spectrometers were large and complex, making them difficult for widespread daily use. However, thanks to the ultra-compact, high-resolution spectrometer developed by KAIST researchers, it is now expected that light's color information can be utilized even within smartphones or wearable devices.

KAIST (President Kwang Hyung Lee) announced on the 13th that Professor Mooseok Jang's research team at the Department of Bio and Brain Engineering has successfully developed a reconstruction-based spectrometer technology using double-layer disordered metasurfaces*.

*Double-layer disordered metasurface: An innovative optical device that complexly scatters light through two layers of disordered nanostructures, creating unique and predictable speckle patterns for each wavelength.

Existing high-resolution spectrometers have a large form factor, on the order of tens of centimeters, and require complex calibration processes to maintain accuracy. This fundamentally stems from the operating principle of traditional dispersive elements, such as gratings and prisms, which separate light wavelengths along the propagation direction, much like a rainbow separates colors. Consequently, despite the potential for light's color information to be widely useful in daily life, spectroscopic technology has been limited to laboratory or industrial manufacturing environments.

< Figure 1. Through a simple structure consisting of a double layer of disordered metasurfaces and an image sensor, it was shown that speckles of predictable spectral channels with high spectral resolution can be generated in a compact form factor. The high similarity between the measured and calculated speckles was used to solve the inverse problem and verify the ability to reconstruct the spectrum. >

The research team devised a method that departs from the conventional spectroscopic paradigm of using diffraction gratings or prisms, which establish a one-to-one correspondence between light's color information and its propagation direction, by utilizing designed disordered structures as optical components. In this process, they employed metasurfaces, which can freely control the light propagation process using structures tens to hundreds of nanometers in size, to accurately implement 'complex random patterns (speckle*)'.

*Speckle: An irregular pattern of light intensity created by the interference of multiple wavefronts of light.

Specifically, they developed a method that involves implementing a double-layer disordered metasurface to generate wavelength-specific speckle patterns and then reconstructing precise color information (wavelength) of the light from the random patterns measured by a camera.

As a result, they successfully developed a new concept spectrometer technology that can accurately measure light across a broad range of visible to infrared (440-1,300nm) with a high resolution of 1 nanometer (nm) in a device smaller than a fingernail (less than 1cm) using only a single image capture.

< Figure 2. A disordered metasurface is a metasurface with irregularly arranged structures ranging from tens to hundreds of nanometers in size. In a double-layer structure, a propagation space is placed between the two metasurfaces to control the output speckle with high degrees of freedom, thereby achieving a spectral resolution of 1 nm even in a form factor smaller than 1 cm. >

Dong-gu Lee, a lead author of this study, stated, "This technology is implemented in a way that is directly integrated with commercial image sensors, and we expect that it will enable easy acquisition and utilization of light's wavelength information in daily life when built into mobile devices in the future."

Professor Mooseok Jang said, "This technology overcomes the limitations of existing RGB three-color based machine vision fields, which only distinguish and recognize three color components (red, green, blue), and has diverse applications. We anticipate various applied research for this technology, which expands the horizon of laboratory-level technology to daily-level machine vision technology for applications such as food component analysis, crop health diagnosis, skin health measurement, environmental pollution detection, and bio/medical diagnostics." He added, "Furthermore, it can be extended to various advanced optical technologies such as hyperspectral imaging, which records wavelength and spatial information simultaneously with high resolution, 3D optical trapping technology, which precisely controls light of multiple wavelengths into desired forms, and ultrafast imaging technology, which captures phenomena occurring in very short periods."

This research was collaboratively led by Dong-gu Lee (Ph.D. candidate) and Gookho Song (Ph.D. candidate) from the KAIST Department of Bio and Brain Engineering as co-first authors, with Professor Mooseok Jang as the corresponding author. The findings were published online in the international journal Science Advances on May 28, 2025.* Paper Title: Reconstructive spectrometer using double-layer disordered metasurfaces* DOI: 10.1126/sciadv.adv2376

This research was supported by the Samsung Research Funding and Incubation Center of Samsung Electronics grant, the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT), and the Bio & Medical Technology Development Program of the National Research Foundation (NRF) funded by the Korean government (MSIT).

2025.06.13 View 2748

High-Resolution Spectrometer that Fits into Smartphones Developed by KAIST Researchers

- Professor Mooseok Jang's research team at the Department of Bio and Brain Engineering develops an ultra-compact, high-resolution spectrometer using 'double-layer disordered metasurfaces' that generate unique random patterns depending on light's color.

- Unlike conventional dispersion-based spectrometers that were difficult to apply to portable devices, this new concept spectrometer technology achieves 1nm-level high resolution in a device smaller than 1cm, comparable in size to a fingernail.

- It can be utilized as a built-in spectrometer in smartphones and wearable devices in the future, and can be expanded to advanced optical technologies such as hyperspectral imaging and ultrafast imaging.

< Photo 1. (From left) Professor Mooseok Jang, Dong-gu Lee (Ph.D. candidate), Gookho Song (Ph.D. candidate) >

Color, as the way light's wavelength is perceived by the human eye, goes beyond a simple aesthetic element, containing important scientific information like a substance's composition or state. Spectrometers are optical devices that analyze material properties by decomposing light into its constituent wavelengths, and they are widely used in various scientific and industrial fields, including material analysis, chemical component detection, and life science research. Existing high-resolution spectrometers were large and complex, making them difficult for widespread daily use. However, thanks to the ultra-compact, high-resolution spectrometer developed by KAIST researchers, it is now expected that light's color information can be utilized even within smartphones or wearable devices.

KAIST (President Kwang Hyung Lee) announced on the 13th that Professor Mooseok Jang's research team at the Department of Bio and Brain Engineering has successfully developed a reconstruction-based spectrometer technology using double-layer disordered metasurfaces*.

*Double-layer disordered metasurface: An innovative optical device that complexly scatters light through two layers of disordered nanostructures, creating unique and predictable speckle patterns for each wavelength.

Existing high-resolution spectrometers have a large form factor, on the order of tens of centimeters, and require complex calibration processes to maintain accuracy. This fundamentally stems from the operating principle of traditional dispersive elements, such as gratings and prisms, which separate light wavelengths along the propagation direction, much like a rainbow separates colors. Consequently, despite the potential for light's color information to be widely useful in daily life, spectroscopic technology has been limited to laboratory or industrial manufacturing environments.

< Figure 1. Through a simple structure consisting of a double layer of disordered metasurfaces and an image sensor, it was shown that speckles of predictable spectral channels with high spectral resolution can be generated in a compact form factor. The high similarity between the measured and calculated speckles was used to solve the inverse problem and verify the ability to reconstruct the spectrum. >

The research team devised a method that departs from the conventional spectroscopic paradigm of using diffraction gratings or prisms, which establish a one-to-one correspondence between light's color information and its propagation direction, by utilizing designed disordered structures as optical components. In this process, they employed metasurfaces, which can freely control the light propagation process using structures tens to hundreds of nanometers in size, to accurately implement 'complex random patterns (speckle*)'.

*Speckle: An irregular pattern of light intensity created by the interference of multiple wavefronts of light.

Specifically, they developed a method that involves implementing a double-layer disordered metasurface to generate wavelength-specific speckle patterns and then reconstructing precise color information (wavelength) of the light from the random patterns measured by a camera.

As a result, they successfully developed a new concept spectrometer technology that can accurately measure light across a broad range of visible to infrared (440-1,300nm) with a high resolution of 1 nanometer (nm) in a device smaller than a fingernail (less than 1cm) using only a single image capture.

< Figure 2. A disordered metasurface is a metasurface with irregularly arranged structures ranging from tens to hundreds of nanometers in size. In a double-layer structure, a propagation space is placed between the two metasurfaces to control the output speckle with high degrees of freedom, thereby achieving a spectral resolution of 1 nm even in a form factor smaller than 1 cm. >

Dong-gu Lee, a lead author of this study, stated, "This technology is implemented in a way that is directly integrated with commercial image sensors, and we expect that it will enable easy acquisition and utilization of light's wavelength information in daily life when built into mobile devices in the future."

Professor Mooseok Jang said, "This technology overcomes the limitations of existing RGB three-color based machine vision fields, which only distinguish and recognize three color components (red, green, blue), and has diverse applications. We anticipate various applied research for this technology, which expands the horizon of laboratory-level technology to daily-level machine vision technology for applications such as food component analysis, crop health diagnosis, skin health measurement, environmental pollution detection, and bio/medical diagnostics." He added, "Furthermore, it can be extended to various advanced optical technologies such as hyperspectral imaging, which records wavelength and spatial information simultaneously with high resolution, 3D optical trapping technology, which precisely controls light of multiple wavelengths into desired forms, and ultrafast imaging technology, which captures phenomena occurring in very short periods."

This research was collaboratively led by Dong-gu Lee (Ph.D. candidate) and Gookho Song (Ph.D. candidate) from the KAIST Department of Bio and Brain Engineering as co-first authors, with Professor Mooseok Jang as the corresponding author. The findings were published online in the international journal Science Advances on May 28, 2025.* Paper Title: Reconstructive spectrometer using double-layer disordered metasurfaces* DOI: 10.1126/sciadv.adv2376

This research was supported by the Samsung Research Funding and Incubation Center of Samsung Electronics grant, the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT), and the Bio & Medical Technology Development Program of the National Research Foundation (NRF) funded by the Korean government (MSIT).

2025.06.13 View 2748 -

KAIST’s Next-Generation Small Satellite-2 Completes a Two-Year Mission – the Successful Observation of Arctic and Forest Changes

KAIST (President Kwang-Hyung Lee) announced on the 25th of May that the Next-Generation Small Satellite-2 developed by the Satellite Technology Research Center (SaTReC, Director Jaeheung Han) and launched aboard the third Nuri rocket from the Naro Space Center at 18:24 on May 25, 2023, has successfully completed its two-year core mission of verifying homegrown Synthetic Aperture Radar (SAR) technology and conducting all-weather Earth observations.

The SAR system onboard the satellite was designed, manufactured, and tested domestically for the first time by KAIST’s Satellite Research Center. As of May 25, 2025, it has successfully completed its two-year in-orbit technology demonstration mission.

Particularly noteworthy is the fact that the SAR system was mounted on the 100 kg-class Next-Generation Small Satellite-2, marking a major step forward in the miniaturization and weight reduction of spaceborne radar systems and strengthening Korea’s competitiveness in satellite technology.

< Figure 1. Conceptual diagram of Earth observation by the Next-Generation Small Satellite No. 2's synthetic aperture radar >

The developed SAR is an active sensor that uses electromagnetic waves, allowing all-weather image acquisition regardless of time of day or weather conditions. This makes it especially useful for monitoring regions like the Korean Peninsula, which frequently experiences rain and cloud cover, as it can observe even in cloudy and rainy conditions or darkness.

Since its launch, the satellite has carried out three to four image acquisitions per day on average, undergoing functionality checks and technology verifications. To date, it has completed over 1,200 Earth observations and the SAR continues to perform stably, supporting ongoing observation tasks even beyond its designated mission lifespan.

< Photo 1. Researchers of the Next-Generation Small Satellite No. 2 at SatRec, taken at the KAIST ground station. (From left) Sung-Og Park, Jung-soo Lee, Hongyoung Park, TaeSeong Jang (Next-Generation Small Satellite No. 2 Project Manager), Seyeon Kim, Mi Young Park, Yongmin Kim, DongGuk Kim >

Although still in the domestic technology verification stage, KAIST’s Satellite Research Center has been collaborating with the Korea Polar Research Institute (Director Hyoung Chul Shin) and the Korea National Park Research Institute (Director Jin Tae Kim) since March 2024 to prioritize imaging of areas of interest related to Arctic ice changes and forest ecosystem monitoring.

KAIST’s Satellite Research Center is conducting repeated observations of Arctic sea ice, and the Remote Sensing and Cryosphere Information Center of the Korea Polar Research Institute is analyzing the results using time-series data to precisely track changes in sea ice area and structure due to climate change.

< Photo 2. Radar Images from Observations on July 24, 2024 - Around the Atchafalaya River in Louisiana, USA. The Wax Lake Delta is seen growing like a leaf. >

Recently, the Korea Polar Research Institute (KOPRI), by integrating observation data from the Next-Generation Small Satellite No. 2 and the European Space Agency's (ESA) Sentinel-1, detected a significant increase of 15 km² in the area of an ice lake behind Canada's Milne Ice Shelf (a massive, floating layer of ice where glaciers flow from land into the sea) between 2021 and 2025. This has exacerbated structural instability and is analyzed as an important sign indicating the acceleration of Arctic climate change.

Hyuncheol Kim, Director of the Remote Sensing and Cryosphere Information Center at the Korea Polar Research Institute, stated, “This research clearly demonstrates how vulnerable Arctic ice shelves are to climate change. We will continue to monitor and analyze Arctic environmental changes using the SAR aboard the Next-Generation Small Satellite-2 and promote international collaboration.” He added, “We also plan to present these findings at international academic conferences and expand educational and outreach efforts to raise public awareness about changes in the Arctic environment.”

< Photo 3. Sinduri Coastal Dune, Taean Coastal National Park, Taean-gun, Chungcheongnam-do >

In collaboration with the Climate Change Research Center of the National Park Research Institute, SAR imagery from the satellite is also being used to study phenological shifts due to climate change, the dieback of conifers in high-altitude zones, and landslide monitoring in forest ecosystems. Researchers are also analyzing the spatial distribution of carbon storage in forest areas using satellite data, comparing it with field measurements to improve accuracy.

Because SAR is unaffected by light and weather conditions, it can observe through fire and smoke during wildfires, making it an exceptionally effective tool for the regular monitoring of large protected areas. It is expected to play an important role in shaping future forest conservation policies.

In addition, KAIST’s Satellite Research Center is working on a system to convert the satellite’s technology demonstration data into standardized imagery products, with budget support from the Korea Aerospace Administration (Administrator Youngbin Yoon), making the data more accessible to research institutions and boosting the usability of the satellite’s observations.

< Photo 4. Jang Bogo Station, Antarctica >

Jaeheung Han, Director of the Satellite Research Center, said, “The significance of the Next-Generation Small Satellite-2 lies not only in the success of domestic development, but also in its direct contribution to real-world environmental analysis and national research efforts. We will continue to focus on expanding the application of SAR data from the satellite.”

KAIST President Kwang-Hyung Lee remarked, “This satellite is a product of KAIST’s advanced space technology and the innovation capacity of its researchers. Its success signals KAIST’s potential to lead in future space technology talent development and R&D, and we will continue to accelerate efforts in this direction.”

< Photo 5. Confirmation of changes in the expanded area of the Milne Ice Shelf lake using observation data from Next-Generation Small Satellite No. 2 and Sentinel-1 >

2025.05.25 View 3052

KAIST’s Next-Generation Small Satellite-2 Completes a Two-Year Mission – the Successful Observation of Arctic and Forest Changes

KAIST (President Kwang-Hyung Lee) announced on the 25th of May that the Next-Generation Small Satellite-2 developed by the Satellite Technology Research Center (SaTReC, Director Jaeheung Han) and launched aboard the third Nuri rocket from the Naro Space Center at 18:24 on May 25, 2023, has successfully completed its two-year core mission of verifying homegrown Synthetic Aperture Radar (SAR) technology and conducting all-weather Earth observations.

The SAR system onboard the satellite was designed, manufactured, and tested domestically for the first time by KAIST’s Satellite Research Center. As of May 25, 2025, it has successfully completed its two-year in-orbit technology demonstration mission.

Particularly noteworthy is the fact that the SAR system was mounted on the 100 kg-class Next-Generation Small Satellite-2, marking a major step forward in the miniaturization and weight reduction of spaceborne radar systems and strengthening Korea’s competitiveness in satellite technology.

< Figure 1. Conceptual diagram of Earth observation by the Next-Generation Small Satellite No. 2's synthetic aperture radar >

The developed SAR is an active sensor that uses electromagnetic waves, allowing all-weather image acquisition regardless of time of day or weather conditions. This makes it especially useful for monitoring regions like the Korean Peninsula, which frequently experiences rain and cloud cover, as it can observe even in cloudy and rainy conditions or darkness.

Since its launch, the satellite has carried out three to four image acquisitions per day on average, undergoing functionality checks and technology verifications. To date, it has completed over 1,200 Earth observations and the SAR continues to perform stably, supporting ongoing observation tasks even beyond its designated mission lifespan.

< Photo 1. Researchers of the Next-Generation Small Satellite No. 2 at SatRec, taken at the KAIST ground station. (From left) Sung-Og Park, Jung-soo Lee, Hongyoung Park, TaeSeong Jang (Next-Generation Small Satellite No. 2 Project Manager), Seyeon Kim, Mi Young Park, Yongmin Kim, DongGuk Kim >

Although still in the domestic technology verification stage, KAIST’s Satellite Research Center has been collaborating with the Korea Polar Research Institute (Director Hyoung Chul Shin) and the Korea National Park Research Institute (Director Jin Tae Kim) since March 2024 to prioritize imaging of areas of interest related to Arctic ice changes and forest ecosystem monitoring.

KAIST’s Satellite Research Center is conducting repeated observations of Arctic sea ice, and the Remote Sensing and Cryosphere Information Center of the Korea Polar Research Institute is analyzing the results using time-series data to precisely track changes in sea ice area and structure due to climate change.

< Photo 2. Radar Images from Observations on July 24, 2024 - Around the Atchafalaya River in Louisiana, USA. The Wax Lake Delta is seen growing like a leaf. >

Recently, the Korea Polar Research Institute (KOPRI), by integrating observation data from the Next-Generation Small Satellite No. 2 and the European Space Agency's (ESA) Sentinel-1, detected a significant increase of 15 km² in the area of an ice lake behind Canada's Milne Ice Shelf (a massive, floating layer of ice where glaciers flow from land into the sea) between 2021 and 2025. This has exacerbated structural instability and is analyzed as an important sign indicating the acceleration of Arctic climate change.

Hyuncheol Kim, Director of the Remote Sensing and Cryosphere Information Center at the Korea Polar Research Institute, stated, “This research clearly demonstrates how vulnerable Arctic ice shelves are to climate change. We will continue to monitor and analyze Arctic environmental changes using the SAR aboard the Next-Generation Small Satellite-2 and promote international collaboration.” He added, “We also plan to present these findings at international academic conferences and expand educational and outreach efforts to raise public awareness about changes in the Arctic environment.”

< Photo 3. Sinduri Coastal Dune, Taean Coastal National Park, Taean-gun, Chungcheongnam-do >

In collaboration with the Climate Change Research Center of the National Park Research Institute, SAR imagery from the satellite is also being used to study phenological shifts due to climate change, the dieback of conifers in high-altitude zones, and landslide monitoring in forest ecosystems. Researchers are also analyzing the spatial distribution of carbon storage in forest areas using satellite data, comparing it with field measurements to improve accuracy.

Because SAR is unaffected by light and weather conditions, it can observe through fire and smoke during wildfires, making it an exceptionally effective tool for the regular monitoring of large protected areas. It is expected to play an important role in shaping future forest conservation policies.

In addition, KAIST’s Satellite Research Center is working on a system to convert the satellite’s technology demonstration data into standardized imagery products, with budget support from the Korea Aerospace Administration (Administrator Youngbin Yoon), making the data more accessible to research institutions and boosting the usability of the satellite’s observations.

< Photo 4. Jang Bogo Station, Antarctica >

Jaeheung Han, Director of the Satellite Research Center, said, “The significance of the Next-Generation Small Satellite-2 lies not only in the success of domestic development, but also in its direct contribution to real-world environmental analysis and national research efforts. We will continue to focus on expanding the application of SAR data from the satellite.”

KAIST President Kwang-Hyung Lee remarked, “This satellite is a product of KAIST’s advanced space technology and the innovation capacity of its researchers. Its success signals KAIST’s potential to lead in future space technology talent development and R&D, and we will continue to accelerate efforts in this direction.”

< Photo 5. Confirmation of changes in the expanded area of the Milne Ice Shelf lake using observation data from Next-Generation Small Satellite No. 2 and Sentinel-1 >

2025.05.25 View 3052 -

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 30802

Highly Uniform and Low Hysteresis Pressure Sensor to Increase Practical Applicability

< Professor Steve Park (left) and the First Author Mr. Jinwon Oh (right) >

Researchers have designed a flexible pressure sensor that is expected to have a much wider applicability. A KAIST research team fabricated a piezoresistive pressure sensor of high uniformity with low hysteresis by chemically grafting a conductive polymer onto a porous elastomer template.

The team discovered that the uniformity of pore size and shape is directly related to the uniformity of the sensor. The team noted that by increasing pore size and shape variability, the variability of the sensor characteristics also increases.

Researchers led by Professor Steve Park from the Department of Materials Science and Engineering confirmed that compared to other sensors composed of randomly sized and shaped pores, which had a coefficient of variation in relative resistance change of 69.65%, their newly developed sensor exhibited much higher uniformity with a coefficient of variation of 2.43%. This study was reported in Small as the cover article on August 16.

Flexible pressure sensors have been actively researched and widely applied in electronic equipment such as touch screens, robots, wearable healthcare devices, electronic skin, and human-machine interfaces. In particular, piezoresistive pressure sensors based on elastomer‐conductive material composites hold significant potential due to their many advantages including a simple and low-cost fabrication process.

Various research results have been reported for ways to improve the performance of piezoresistive pressure sensors, most of which have been focused on increasing the sensitivity. Despite its significance, maximizing the sensitivity of composite-based piezoresistive pressure sensors is not necessary for many applications. On the other hand, sensor-to-sensor uniformity and hysteresis are two properties that are of critical importance to realize any application.

The importance of sensor-to-sensor uniformity is obvious. If the sensors manufactured under the same conditions have different properties, measurement reliability is compromised, and therefore the sensor cannot be used in a practical setting.

In addition, low hysteresis is also essential for improved measurement reliability. Hysteresis is a phenomenon in which the electrical readings differ depending on how fast or slow the sensor is being pressed, whether pressure is being released or applied, and how long and to what degree the sensor has been pressed. When a sensor has high hysteresis, the electrical readings will differ even under the same pressure, making the measurements unreliable.

Researchers said they observed a negligible hysteresis degree which was only 2%. This was attributed to the strong chemical bonding between the conductive polymer and the elastomer template, which prevents their relative sliding and displacement, and the porosity of the elastomer that enhances elastic behavior.

“This technology brings forth insight into how to address the two critical issues in pressure sensors: uniformity and hysteresis. We expect our technology to play an important role in increasing practical applications and the commercialization of pressure sensors in the near future,” said Professor Park.

This work was conducted as part of the KAIST‐funded Global Singularity Research Program for 2019, and also supported by the KUSTAR‐KAIST Institute.

Figure 1. Image of a porous elastomer template with uniform pore size and shape (left), Graph showing high uniformity in the sensors’ performance (right).

Figure 2. Hysteresis loops of the sensor at different pressure levels (left), and after a different number of cycles (right).

Figure 3. The cover page of Small Journal, Volume 15, Issue 33.

Publication:

Jinwon Oh, Jin‐Oh Kim, Yunjoo Kim, Han Byul Choi, Jun Chang Yang, Serin Lee, Mikhail Pyatykh, Jung Kim, Joo Yong Sim, and Steve Park. 2019. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small. Wiley-VCH Verlag GmbH & Co. KgaA, Weinheim, Germany, Volume No. 15, Issue No. 33, Full Paper No. 201901744, 8 pages. https://doi.org/10.1002/smll.201901744

Profile: Prof. Steve Park, MS, PhD

stevepark@kaist.ac.kr

http://steveparklab.kaist.ac.kr/

Assistant Professor

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon 34141, Korea

Profile: Mr. Jinwon Oh, MS

jwoh1701@gmail.com

http://steveparklab.kaist.ac.kr/

Researcher

Organic and Nano Electronics Laboratory

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Prof. Jung Kim, MS, PhD

jungkim@kaist.ac.kr

http://medev.kaist.ac.kr/

Professor

Biorobotics Laboratory

Department of Mechanical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr Daejeon 34141, Korea

Profile: Joo Yong Sim, PhD

jsim@etri.re.kr

Researcher

Bio-Medical IT Convergence Research Department

Electronics and Telecommunications Research Institute (ETRI)

https://www.etri.re.krDaejeon 34129, Korea

(END)

2019.08.19 View 30802 -

A High-Performance and Cost Effective Hydrogen Sensor

(Research team of Professor Park, Professor Jung, and research fellow Gao Min)

A KAIST research team reported a high-performance and cost effective hydrogen sensor using novel fabrication process based on the combination of polystyrene nanosphere lithography and semiconductor microfabrication processes.

The research team, led by Professor Inkyu Park in the Department of Mechanical Engineering and Professor Yeon Sik Jung in the Department of Materials Science and Engineering, fabricated a nanostructured high-performance hydrogen gas sensor based on a palladium-decorated silicon nanomesh structure made using a polystyrene nanosphere self-assembly method. Their study was featured as the front cover article of journal “Small” (Publisher: Wiley-VCH) on March 8, 2018.

The nanosphere lithography method utilizes the self-assembly of a nanosphere monolayer. This could be an alternative choice for achieving uniform and well-ordered nanopatterns with minimum sub-10 nanometer dimensions. The research team said that the small dimensions of the silicon enhanced the palladium-gating effect and thus dramatically improved the sensitivity.

Hydrogen gas is widely considered to be one of the most promising next-generation energy resources. Also, it is a very important material for various industrial applications such as hydrogen-cooled systems, petroleum refinement, and metallurgical processes. However, hydrogen, which is highly flammable, is colorless and odorless and thus difficult to detect with human senses. Therefore, developing hydrogen gas sensors with high sensitivity, fast response, high selectivity, and good stability is of significant importance for the rising hydrogen economy.

Silicon nanowire-based devices have been employed as efficient components in high-performance sensors for detecting gases and other chemical and biological components. Since the nanowires have a high surface-to-volume ratio, they respond more sensitively to the surrounding environment.

The research team’s gas sensor shows dramatically improved hydrogen gas sensitivity compared with a silicon thin film sensor without nanopatterns. Furthermore, a buffered oxide etchant (BOE) treatment of the silicon nanomesh structure results in an additional performance improvement through suspension of nanomesh strutures from the substrate and surface roughening. The sensor device shows a fast hydrogen response (response time < 5 seconds) and 10 times higher selectivity to hydrogen gas among other gases. Their sensing performance is stable and shows repeatable responses in both dry and high-humidity ambient environments.

Professor Park said that his approach will be very useful for the fabrication of low-cost, high-performance sensors for chemical and biological detection with applications to mobile and wearable devices in the coming era of internet of things (IoTs).

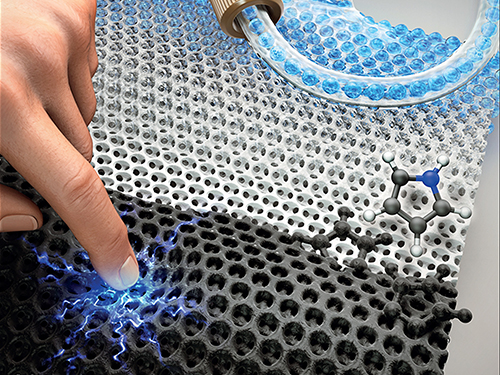

(Figure 1: The front cover image of Small dated on March 8.)

(Figure 2: Gas sensor responses upon the exposure to H2 at various concentrations.)

2018.05.21 View 10340

A High-Performance and Cost Effective Hydrogen Sensor

(Research team of Professor Park, Professor Jung, and research fellow Gao Min)

A KAIST research team reported a high-performance and cost effective hydrogen sensor using novel fabrication process based on the combination of polystyrene nanosphere lithography and semiconductor microfabrication processes.

The research team, led by Professor Inkyu Park in the Department of Mechanical Engineering and Professor Yeon Sik Jung in the Department of Materials Science and Engineering, fabricated a nanostructured high-performance hydrogen gas sensor based on a palladium-decorated silicon nanomesh structure made using a polystyrene nanosphere self-assembly method. Their study was featured as the front cover article of journal “Small” (Publisher: Wiley-VCH) on March 8, 2018.

The nanosphere lithography method utilizes the self-assembly of a nanosphere monolayer. This could be an alternative choice for achieving uniform and well-ordered nanopatterns with minimum sub-10 nanometer dimensions. The research team said that the small dimensions of the silicon enhanced the palladium-gating effect and thus dramatically improved the sensitivity.

Hydrogen gas is widely considered to be one of the most promising next-generation energy resources. Also, it is a very important material for various industrial applications such as hydrogen-cooled systems, petroleum refinement, and metallurgical processes. However, hydrogen, which is highly flammable, is colorless and odorless and thus difficult to detect with human senses. Therefore, developing hydrogen gas sensors with high sensitivity, fast response, high selectivity, and good stability is of significant importance for the rising hydrogen economy.

Silicon nanowire-based devices have been employed as efficient components in high-performance sensors for detecting gases and other chemical and biological components. Since the nanowires have a high surface-to-volume ratio, they respond more sensitively to the surrounding environment.

The research team’s gas sensor shows dramatically improved hydrogen gas sensitivity compared with a silicon thin film sensor without nanopatterns. Furthermore, a buffered oxide etchant (BOE) treatment of the silicon nanomesh structure results in an additional performance improvement through suspension of nanomesh strutures from the substrate and surface roughening. The sensor device shows a fast hydrogen response (response time < 5 seconds) and 10 times higher selectivity to hydrogen gas among other gases. Their sensing performance is stable and shows repeatable responses in both dry and high-humidity ambient environments.

Professor Park said that his approach will be very useful for the fabrication of low-cost, high-performance sensors for chemical and biological detection with applications to mobile and wearable devices in the coming era of internet of things (IoTs).

(Figure 1: The front cover image of Small dated on March 8.)

(Figure 2: Gas sensor responses upon the exposure to H2 at various concentrations.)

2018.05.21 View 10340 -

Samsung Electronics' Chairman Kwon Becomes the First Alumnus Honorary Doctorate

(Samsung Electronics' Chairman & CEO Kwon,left, and President Shin)

The semiconductor has bred innovation in Korea, as one of the staples of economic growth. Without the success of the semiconductor industry of Korea, it is hard to imagine the high tech dominance in the global market enjoyed by Korean companies.

It is said that one in every four Ph.D.s working in the semiconductor industry of Korea graduated from KAIST. Among them, Chairman and CEO Oh-Hyun Kwon of Samsung Electronics, Class of 1977, has arrived at the epitome of this top industry.

KAIST’s class of 1977 produced many movers and shakers in Korea’s innovation efforts. Now in their mid-60s, they were the players who embodied Korea’s ICT and helped it become a global powerhouse. They are the ones who worked for and witnessed the socio-economic transformation of Korea through innovation.

In recognition of his unsurpassable entrepreneurship, which made the remarkable strides in the semiconductor and electronics industry in Korea and beyond, Chairman Kwon was honored as the first recipient of an honorary doctorate from his alma mater on February 23 during the 2018 commencement ceremony.

After completing his Master's in Electrical Engineering at KAIST in 1977, he earned his Ph.D. in Electrical Engineering from Stanford University. The first honorary degree bestowed to an alumnus was conferred by the first alumnus President of KAIST Sung-Chul Shin. President Shin said that Chairman Kwon’s exceptional leadership has inspired the KAIST community and exemplified the spirit of KAIST.

Currently serving as chairman & CEO of Samsung Electronics and Samsung Advanced Institute of Technology (SAIT), Kwon has worked for Samsung in a variety of key positions in their semiconductor division since 1985.

In the mid-1980s, Japan was leading the global semiconductor market. At Samsung, Chairman Kwon, who was in charge of the memory semiconductor team, successfully developed 4M DRAM. Later in 1992, he played a leading role in the development of the world’s first 64M DRAM.

The success of 4M DRAM and 64M DRAM led Samsung to clinch the top position in the DRAM and NAND flash business around the world. This helped Samsung emerge as a global leader in the semiconductor industry.

As a result, Samsung, as well as the national economy, could gain significant momentum to build national competitiveness and economic growth. The outstanding technological leadership of Chairman Kwon led to the development of proprietary semiconductor design and processes technologies as well as numerous patents.

He also played a leadership role in creating a mutual growth environment among conglomerates rather than merely engaging in direct competition. Chairman Kwon made every effort to establish the cornerstone of mutual growth, especially in relationships with small and medium-sized enterprises (SMEs). His win-win collaboration initiatives among conglomerates and SMEs made a significant impact on the development of the entire industry of Korea.

In his acceptance speech, he charged the graduates to embrace challenges, to collaborate with peers, and create their own future.

The full text of his speech is printed below.

Graduates and distinguished guests! I extend my sincere congratulations to my fellow graduates, as you are awarded degrees for your deep efforts, as well as to the parents and family members who have supported you.

In 1977, I received my Master’s degree in Electrical Engineering from KAIST. Today, as the first honorary doctor among KAIST graduates, I am truly honored to be here. I am deeply grateful to all of you, including President Sung-Chul Shin and the Chairman of the Board of Trustees, Jang-Moo Lee.

Today, I want to tell you about the experiences and lessons I have learned from my 40 years of corporate management experience.

First, you should lead and drive changes by yourself. In the process of realizing a dream, the situation and circumstances do not always proceed as you planned.

I started my career as a researcher. However, I had to continuously transform myself into a project leader, business team leader, and CEO. It was challenging every time, due to a lack of preparing and my insufficient ability. However, I have always accomplished the intended goal through the mindset of embracing changes and studying new things.

It is said that the survivors are not always the strongest nor the most intelligent, but the ones who are the most adaptive to changes. We can only be the last survivor if we have the character to see those small signs that signal changes are coming and cope with changes well. Take changes positively and actively and then, transform yourself to match a given situation.

In addition, it is important to understand others. When it comes to one’s career, there is nothing that you can do alone without the assistance of others. If it is not possible to do everything by yourself, you will need to supplement your efforts through the help of others. To do this, you need to understand your colleagues, bosses, and customers first.

People, who work in tech tend to cage themselves in their own silos. But in an era of destructive innovation, where boundaries of industries and technologies are collapsing at a breakneck pace, scientists also need to enhance their understanding of various areas such as culture, art, and the humanities.

This is a famous verse from a poem by Chun-Soo Kim.

Before I called his name,

He was nothing but a gesture.

When I called his name, He came to me and became a flower.

Make wonderful synergy by making your partner a flower and complementing each other. When you first notice the true value of another person and interact with them, the value of the individual will be doubled and will bring about a greater impact.

Finally, we all need to cooperate with each other. All of you here, including myself, are people who have benefited from society. We must cooperate with each other and give back to society for the best results.

A biologist once said that incremental evolution comes from competition, but fundamental evolution comes from cooperation. Great leaders should achieve results through cooperation rather than competition.

You are the future leaders with top-class knowledge. I hope you will become great leaders who have wisdom that combines external resources with your abilities.

Now, graduates of 2018 who are standing at the starting line, we often worry about an unpredictable tomorrow. However, the smartest way to predict the future is to create the future for ourselves. Moreover, we can try again even though we sometimes make mistakes. I urge you to make future you are hoping for.

Once again, I would like to thank you for this honorary doctorate and extend my sincere wishes for the endless development of KAIST and the best of luck to the futures of these graduates. Thank you.

2018.02.26 View 9471

Samsung Electronics' Chairman Kwon Becomes the First Alumnus Honorary Doctorate

(Samsung Electronics' Chairman & CEO Kwon,left, and President Shin)

The semiconductor has bred innovation in Korea, as one of the staples of economic growth. Without the success of the semiconductor industry of Korea, it is hard to imagine the high tech dominance in the global market enjoyed by Korean companies.

It is said that one in every four Ph.D.s working in the semiconductor industry of Korea graduated from KAIST. Among them, Chairman and CEO Oh-Hyun Kwon of Samsung Electronics, Class of 1977, has arrived at the epitome of this top industry.

KAIST’s class of 1977 produced many movers and shakers in Korea’s innovation efforts. Now in their mid-60s, they were the players who embodied Korea’s ICT and helped it become a global powerhouse. They are the ones who worked for and witnessed the socio-economic transformation of Korea through innovation.

In recognition of his unsurpassable entrepreneurship, which made the remarkable strides in the semiconductor and electronics industry in Korea and beyond, Chairman Kwon was honored as the first recipient of an honorary doctorate from his alma mater on February 23 during the 2018 commencement ceremony.

After completing his Master's in Electrical Engineering at KAIST in 1977, he earned his Ph.D. in Electrical Engineering from Stanford University. The first honorary degree bestowed to an alumnus was conferred by the first alumnus President of KAIST Sung-Chul Shin. President Shin said that Chairman Kwon’s exceptional leadership has inspired the KAIST community and exemplified the spirit of KAIST.

Currently serving as chairman & CEO of Samsung Electronics and Samsung Advanced Institute of Technology (SAIT), Kwon has worked for Samsung in a variety of key positions in their semiconductor division since 1985.

In the mid-1980s, Japan was leading the global semiconductor market. At Samsung, Chairman Kwon, who was in charge of the memory semiconductor team, successfully developed 4M DRAM. Later in 1992, he played a leading role in the development of the world’s first 64M DRAM.

The success of 4M DRAM and 64M DRAM led Samsung to clinch the top position in the DRAM and NAND flash business around the world. This helped Samsung emerge as a global leader in the semiconductor industry.

As a result, Samsung, as well as the national economy, could gain significant momentum to build national competitiveness and economic growth. The outstanding technological leadership of Chairman Kwon led to the development of proprietary semiconductor design and processes technologies as well as numerous patents.

He also played a leadership role in creating a mutual growth environment among conglomerates rather than merely engaging in direct competition. Chairman Kwon made every effort to establish the cornerstone of mutual growth, especially in relationships with small and medium-sized enterprises (SMEs). His win-win collaboration initiatives among conglomerates and SMEs made a significant impact on the development of the entire industry of Korea.

In his acceptance speech, he charged the graduates to embrace challenges, to collaborate with peers, and create their own future.

The full text of his speech is printed below.

Graduates and distinguished guests! I extend my sincere congratulations to my fellow graduates, as you are awarded degrees for your deep efforts, as well as to the parents and family members who have supported you.

In 1977, I received my Master’s degree in Electrical Engineering from KAIST. Today, as the first honorary doctor among KAIST graduates, I am truly honored to be here. I am deeply grateful to all of you, including President Sung-Chul Shin and the Chairman of the Board of Trustees, Jang-Moo Lee.

Today, I want to tell you about the experiences and lessons I have learned from my 40 years of corporate management experience.

First, you should lead and drive changes by yourself. In the process of realizing a dream, the situation and circumstances do not always proceed as you planned.

I started my career as a researcher. However, I had to continuously transform myself into a project leader, business team leader, and CEO. It was challenging every time, due to a lack of preparing and my insufficient ability. However, I have always accomplished the intended goal through the mindset of embracing changes and studying new things.

It is said that the survivors are not always the strongest nor the most intelligent, but the ones who are the most adaptive to changes. We can only be the last survivor if we have the character to see those small signs that signal changes are coming and cope with changes well. Take changes positively and actively and then, transform yourself to match a given situation.

In addition, it is important to understand others. When it comes to one’s career, there is nothing that you can do alone without the assistance of others. If it is not possible to do everything by yourself, you will need to supplement your efforts through the help of others. To do this, you need to understand your colleagues, bosses, and customers first.

People, who work in tech tend to cage themselves in their own silos. But in an era of destructive innovation, where boundaries of industries and technologies are collapsing at a breakneck pace, scientists also need to enhance their understanding of various areas such as culture, art, and the humanities.

This is a famous verse from a poem by Chun-Soo Kim.

Before I called his name,

He was nothing but a gesture.

When I called his name, He came to me and became a flower.

Make wonderful synergy by making your partner a flower and complementing each other. When you first notice the true value of another person and interact with them, the value of the individual will be doubled and will bring about a greater impact.

Finally, we all need to cooperate with each other. All of you here, including myself, are people who have benefited from society. We must cooperate with each other and give back to society for the best results.

A biologist once said that incremental evolution comes from competition, but fundamental evolution comes from cooperation. Great leaders should achieve results through cooperation rather than competition.

You are the future leaders with top-class knowledge. I hope you will become great leaders who have wisdom that combines external resources with your abilities.

Now, graduates of 2018 who are standing at the starting line, we often worry about an unpredictable tomorrow. However, the smartest way to predict the future is to create the future for ourselves. Moreover, we can try again even though we sometimes make mistakes. I urge you to make future you are hoping for.

Once again, I would like to thank you for this honorary doctorate and extend my sincere wishes for the endless development of KAIST and the best of luck to the futures of these graduates. Thank you.

2018.02.26 View 9471 -

Professor Lee's Research Selected as Top 100 National R&D Projects

A research project, led by Research Professor Ju Yong Lee from the KAIST Institute for IT Convergence, was selected as one of the Top 100 National Research and Development Projects 2017.

This research project, titled LTE-A-based Single RF Small Base Station supporting Multiple Streams, developed 300Mbps low power, low complexity and broadband small base station technology that supports 4x4 MIMO (Multiple Input and Multiple Output) by proposing a new antenna structure and a new RF (Radio Frequency) structure based on LTE-A. Professors from the School of Electrical Engineering at KAIST, Dong Ho Cho, Songcheol Hong, and Yong Hoon Lee also collaborated on the project.

The existing heterodyne method of communication systems generates the problems of increasing unit price and system complexity.

In this project, however, Professor Lee directly modulated the baseband signal from the RF stage through an impedance loading-based RF chip. This method was designed to facilitate low power as well as low complexity while supporting broadband service. Based on this, his team developed source technology for RF that can be applied to fourth and even fifth generation networks.

Furthermore, this base station is smallest among the small-cell stations so far, providing an eco-friendly installation environment. It contributes to the market for fifth generation mobile communications by reducing power consumption significantly yet providing high-capacity services.

Professor Lee said, “This technology will contribute to creating a new market and additional jobs because business based on the fifth mobile generation can provide multi-functional services, including multiband. Requiring low power and providing high-capacity services anywhere at any time will enhance national competence and reduce costs for establishing a next generation mobile communication system. It is expected that this technology will help with disseminating mobile communication infrastructure through expanding information and communication system as well as the infrastructure of island areas.”

2017.11.08 View 11360

Professor Lee's Research Selected as Top 100 National R&D Projects

A research project, led by Research Professor Ju Yong Lee from the KAIST Institute for IT Convergence, was selected as one of the Top 100 National Research and Development Projects 2017.

This research project, titled LTE-A-based Single RF Small Base Station supporting Multiple Streams, developed 300Mbps low power, low complexity and broadband small base station technology that supports 4x4 MIMO (Multiple Input and Multiple Output) by proposing a new antenna structure and a new RF (Radio Frequency) structure based on LTE-A. Professors from the School of Electrical Engineering at KAIST, Dong Ho Cho, Songcheol Hong, and Yong Hoon Lee also collaborated on the project.

The existing heterodyne method of communication systems generates the problems of increasing unit price and system complexity.

In this project, however, Professor Lee directly modulated the baseband signal from the RF stage through an impedance loading-based RF chip. This method was designed to facilitate low power as well as low complexity while supporting broadband service. Based on this, his team developed source technology for RF that can be applied to fourth and even fifth generation networks.

Furthermore, this base station is smallest among the small-cell stations so far, providing an eco-friendly installation environment. It contributes to the market for fifth generation mobile communications by reducing power consumption significantly yet providing high-capacity services.

Professor Lee said, “This technology will contribute to creating a new market and additional jobs because business based on the fifth mobile generation can provide multi-functional services, including multiband. Requiring low power and providing high-capacity services anywhere at any time will enhance national competence and reduce costs for establishing a next generation mobile communication system. It is expected that this technology will help with disseminating mobile communication infrastructure through expanding information and communication system as well as the infrastructure of island areas.”

2017.11.08 View 11360 -

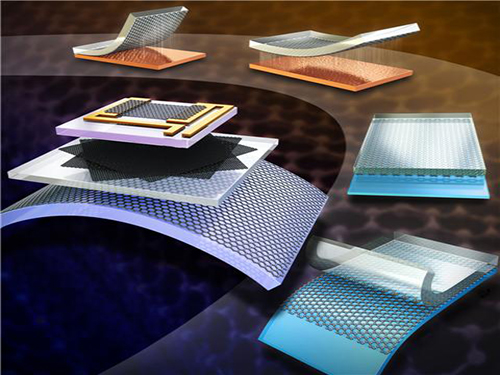

KAIST Develops a Method to Transfer Graphene by Stamping

Professor Sung-Yool Choi’s research team from KAIST's Department of Electrical Engineering has developed a technique that can produce a single-layer graphene from a metal etching. Through this, transferring a graphene layer onto a circuit board can be done as easily as stamping a seal on paper.

The research findings were published in the January 14th issue of Small as the lead article.

This technology will allow different types of wafer transfer methods such as transfer onto a surface of a device or a curved surface, and large surface transfer onto a 4 inch wafer. It will be applied in the field of wearable smart gadgets through commercialization of graphene electronic devices.

The traditional method used to transfer graphene onto a circuit board is a wet transfer. However, it has some drawbacks as the graphene layer can be damaged or contaminated during the transfer process from residue from the metal etching. This may affect the electrical properties of the transferred graphene.

After a graphene growth substrate formed on a catalytic metal substrate is pretreated in an aqueous poly vinyl alcohol (PVA) solution, a PVA film forms on the pretreated substrate. The substrate and the graphene layers bond strongly. The graphene is lifted from the growth substrate by means of an elastomeric stamp.

The delaminated graphene layer is isolated state from the elastomeric stamp and thus can be freely transferred onto a circuit board. As the catalytic metal substrate can be reused and does not contain harmful chemical substances, such transfer method is very eco-friendly.

Professor Choi said, “As the new graphene transfer method has a wide range of applications and allows a large surface transfer, it will contribute to the commercialization of graphene electronic devices.” He added that “because this technique has a high degree of freedom in transfer process, it has a variety of usages for graphene and 2 dimensional nano-devices.”

This research was sponsored by the Ministry of Science, ICT and Future Planning, the Republic of Korea.

Figure 1. Cover photo of the journal Small which illustrates the research findings

Figure 2. Above view of Graphene layer transferred through the new method

Figure 3. Large surface transfer of Graphene

2015.01.23 View 12949

KAIST Develops a Method to Transfer Graphene by Stamping

Professor Sung-Yool Choi’s research team from KAIST's Department of Electrical Engineering has developed a technique that can produce a single-layer graphene from a metal etching. Through this, transferring a graphene layer onto a circuit board can be done as easily as stamping a seal on paper.

The research findings were published in the January 14th issue of Small as the lead article.

This technology will allow different types of wafer transfer methods such as transfer onto a surface of a device or a curved surface, and large surface transfer onto a 4 inch wafer. It will be applied in the field of wearable smart gadgets through commercialization of graphene electronic devices.

The traditional method used to transfer graphene onto a circuit board is a wet transfer. However, it has some drawbacks as the graphene layer can be damaged or contaminated during the transfer process from residue from the metal etching. This may affect the electrical properties of the transferred graphene.

After a graphene growth substrate formed on a catalytic metal substrate is pretreated in an aqueous poly vinyl alcohol (PVA) solution, a PVA film forms on the pretreated substrate. The substrate and the graphene layers bond strongly. The graphene is lifted from the growth substrate by means of an elastomeric stamp.

The delaminated graphene layer is isolated state from the elastomeric stamp and thus can be freely transferred onto a circuit board. As the catalytic metal substrate can be reused and does not contain harmful chemical substances, such transfer method is very eco-friendly.

Professor Choi said, “As the new graphene transfer method has a wide range of applications and allows a large surface transfer, it will contribute to the commercialization of graphene electronic devices.” He added that “because this technique has a high degree of freedom in transfer process, it has a variety of usages for graphene and 2 dimensional nano-devices.”

This research was sponsored by the Ministry of Science, ICT and Future Planning, the Republic of Korea.

Figure 1. Cover photo of the journal Small which illustrates the research findings

Figure 2. Above view of Graphene layer transferred through the new method

Figure 3. Large surface transfer of Graphene

2015.01.23 View 12949 -

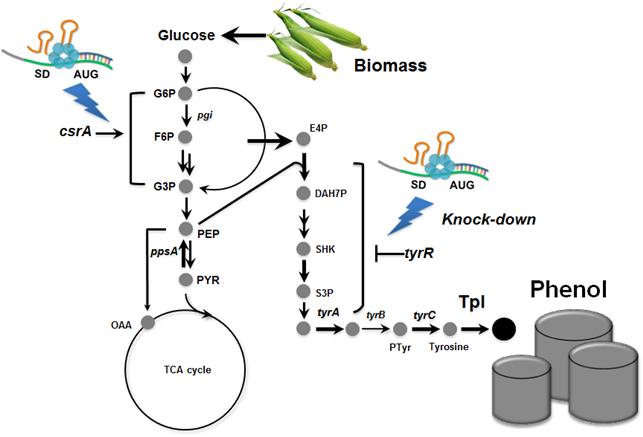

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 12162

Metabolically engineered E. coli producing phenol

Many chemicals we use in everyday life are derived from fossil resources. Due to the increasing concerns on the use of fossil resources, there has been much interest in producing chemicals from renewable resources through biotechnology.

Phenol is an important commodity chemical, and is a starting material for the production of numerous industrial chemicals and polymers, including bisphenol A and phenolic resins, and others. At present, the production of phenol entirely depends on the chemical synthesis from benzene, and its annual production exceeds 8 million tons worldwide. Microbial production of phenol seems to be a non-viable process considering the high toxicity of phenol to the cell.

In the paper published online in Biotechnology Journal, a Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering from the Korea Advanced Institute of Science and Technology (KAIST) reported the successful development of an engineered Escherichia coli (E. coli) strain which can produce phenol from glucose. E. coli has been a workhorse for biological production of various value-added compounds such as succinic acid and 1,4-butanediol in industrial scale. However, due to its low tolerance to phenol, E. coli was not considered a viable host strain for the biological production of phenol.

Professor Lee"s team, a leading research group in metabolic engineering, noted the genetic and physiological differences of various E. coli strains and investigated 18 different E. coli strains with respect to phenol tolerance and engineered all of the 18 strains simultaneously. If the traditional genetic engineering methods were used, this work would have taken years to do. To overcome this challenge, the research team used synthetic small RNA (sRNA) technology they recently developed (Nature Biotechnology, vol 31, pp 170-174, 2013). The sRNA technology allowed the team to screen 18 E. coli strains with respect to the phenol tolerance, and the activities of the metabolic pathway and enzyme involved in the production of phenol. The research team also metabolically engineered the E. coli strains to increase carbon flux toward phenol and finally generated an engineered E. coli strain which can produce phenol from glucose.

Furthermore, the team developed a biphasic extractive fermentation process to minimize the toxicity of phenol to E. coli cells. Glycerol tributyrate was found to have low toxicity to E. coli and allowed efficient extraction of phenol from the culture broth. Through the biphasic fed-batch fermentation using glycerol tributyrate as an in situ extractant, the final engineered E. coli strain produced phenol to the highest titer and productivity reported (3.8 g/L and 0.18 g/L/h, respectively). The strategy used for the strain development and the fermentation process will serve as a framework for metabolic engineering of microorganisms for the production of toxic chemicals from renewable resources.

This work was supported by the Intelligent Synthetic Biology Center through the Global Frontier Project (2011-0031963) of the Ministry of Science, ICT & Future Planning through the National Research Foundation of Korea.

Process of Phenol Production

2013.11.05 View 12162 -

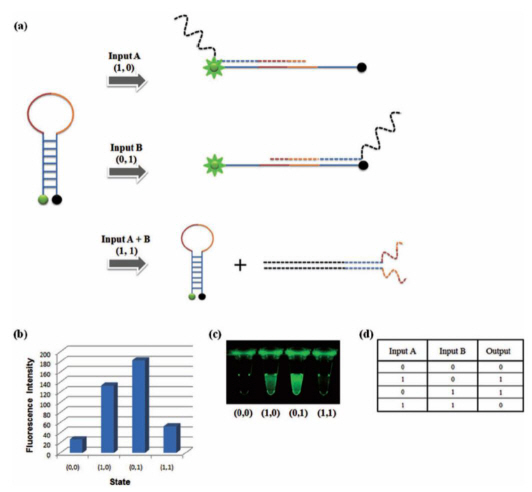

An efficient strategy for developing microbial cell factories by employing synthetic small regulatory RNAs

A new metabolic engineering tool that allows fine control of gene expression level by employing synthetic small regulatory RNAs was developed to efficiently construct microbial cell factories producing desired chemicals and materials

Biotechnologists have been working hard to address the climate change and limited fossil resource issues through the development of sustainable processes for the production of chemicals, fuels and materials from renewable non-food biomass. One promising sustainable technology is the use of microbial cell factories for the efficient production of desired chemicals and materials. When microorganisms are isolated from nature, the performance in producing our desired product is rather poor. That is why metabolic engineering is performed to improve the metabolic and cellular characteristics to achieve enhanced production of desired product at high yield and productivity. Since the performance of microbial cell factory is very important in lowering the overall production cost of the bioprocess, many different strategies and tools have been developed for the metabolic engineering of microorganisms.

One of the big challenges in metabolic engineering is to find the best platform organism and to find those genes to be engineered so as to maximize the production efficiency of the desired chemical. Even Escherichia coli, the most widely utilized simple microorganism, has thousands of genes, the expression of which is highly regulated and interconnected to finely control cellular and metabolic activities. Thus, the complexity of cellular genetic interactions is beyond our intuition and thus it is very difficult to find effective target genes to engineer. Together with gene amplification strategy, gene knockout strategy has been an essential tool in metabolic engineering to redirect the pathway fluxes toward our desired product formation. However, experiment to engineer many genes can be rather difficult due to the time and effort required; for example, gene deletion experiment can take a few weeks depending on the microorganisms. Furthermore, as certain genes are essential or play important roles for the survival of a microorganism, gene knockout experiments cannot be performed. Even worse, there are many different microbial strains one can employ. There are more than 50 different E. coli strains that metabolic engineer can consider to use. Since gene knockout experiment is hard-coded (that is, one should repeat the gene knockout experiments for each strain), the result cannot be easily transferred from one strain to another.

A paper published in Nature Biotechnology online today addresses this issue and suggests a new strategy for identifying gene targets to be knocked out or knocked down through the use of synthetic small RNA. A Korean research team led by Distinguished Professor Sang Yup Lee at the Department of Chemical and Biomolecular Engineering, Korea Advanced Institute of Science and Technology (KAIST), a prestigeous science and engineering university in Korea reported that synthetic small RNA can be employed for finely controlling the expression levels of multiple genes at the translation level. Already well-known for their systems metabolic engineering strategies, Professor Lee’s team added one more strategy to efficiently develop microbial cell factories for the production of chemicals and materials.

Gene expression works like this: the hard-coded blueprint (DNA) is transcribed into messenger RNA (mRNA), and the coding information in mRNA is read to produce protein by ribosomes. Conventional genetic engineering approaches have often targeted modification of the blueprint itself (DNA) to alter organism’s physiological characteristics. Again, engineering the blueprint itself takes much time and effort, and in addition, the results obtained cannot be transferred to another organism without repeating the whole set of experiments. This is why Professor Lee and his colleagues aimed at controlling the gene expression level at the translation stage through the use of synthetic small RNA. They created novel RNAs that can regulate the translation of multiple messenger RNAs (mRNA), and consequently varying the expression levels of multiple genes at the same time. Briefly, synthetic regulatory RNAs interrupt gene expression process from DNA to protein by destroying the messenger RNAs to different yet controllable extents. The advantages of taking this strategy of employing synthetic small regulatory RNAs include simple, easy and high-throughput identification of gene knockout or knockdown targets, fine control of gene expression levels, transferability to many different host strains, and possibility of identifying those gene targets that are essential.