LES

-

Scientists Develop Wireless Networks that Allow Brain Circuits to Be Controlled Remotely through the Internet

Wireless implantable devices and IoT could manipulate the brains of animals from anywhere around the world due to their minimalistic hardware, low setup cost, ease of use, and customizable versatility

A new study shows that researchers can remotely control the brain circuits of numerous animals simultaneously and independently through the internet. The scientists believe this newly developed technology can speed up brain research and various neuroscience studies to uncover basic brain functions as well as the underpinnings of various neuropsychiatric and neurological disorders.

A multidisciplinary team of researchers at KAIST, Washington University in St. Louis, and the University of Colorado, Boulder, created a wireless ecosystem with its own wireless implantable devices and Internet of Things (IoT) infrastructure to enable high-throughput neuroscience experiments over the internet. This innovative technology could enable scientists to manipulate the brains of animals from anywhere around the world. The study was published in the journal Nature Biomedical Engineering on November 25

“This novel technology is highly versatile and adaptive. It can remotely control numerous neural implants and laboratory tools in real-time or in a scheduled way without direct human interactions,” said Professor Jae-Woong Jeong of the School of Electrical Engineering at KAIST and a senior author of the study. “These wireless neural devices and equipment integrated with IoT technology have enormous potential for science and medicine.”

The wireless ecosystem only requires a mini-computer that can be purchased for under $45, which connects to the internet and communicates with wireless multifunctional brain probes or other types of conventional laboratory equipment using IoT control modules. By optimally integrating the versatility and modular construction of both unique IoT hardware and software within a single ecosystem, this wireless technology offers new applications that have not been demonstrated before by a single standalone technology. This includes, but is not limited to minimalistic hardware, global remote access, selective and scheduled experiments, customizable automation, and high-throughput scalability.

“As long as researchers have internet access, they are able to trigger, customize, stop, validate, and store the outcomes of large experiments at any time and from anywhere in the world. They can remotely perform large-scale neuroscience experiments in animals deployed in multiple countries,” said one of the lead authors, Dr. Raza Qazi, a researcher with KAIST and the University of Colorado, Boulder. “The low cost of this system allows it to be easily adopted and can further fuel innovation across many laboratories,” Dr. Qazi added.

One of the significant advantages of this IoT neurotechnology is its ability to be mass deployed across the globe due to its minimalistic hardware, low setup cost, ease of use, and customizable versatility. Scientists across the world can quickly implement this technology within their existing laboratories with minimal budget concerns to achieve globally remote access, scalable experimental automation, or both, thus potentially reducing the time needed to unravel various neuroscientific challenges such as those associated with intractable neurological conditions.

Another senior author on the study, Professor Jordan McCall from the Department of Anesthesiology and Center for Clinical Pharmacology at Washington University in St. Louis, said this technology has the potential to change how basic neuroscience studies are performed. “One of the biggest limitations when trying to understand how the mammalian brain works is that we have to study these functions in unnatural conditions. This technology brings us one step closer to performing important studies without direct human interaction with the study subjects.”

The ability to remotely schedule experiments moves toward automating these types of experiments. Dr. Kyle Parker, an instructor at Washington University in St. Louis and another lead author on the study added, “This experimental automation can potentially help us reduce the number of animals used in biomedical research by reducing the variability introduced by various experimenters. This is especially important given our moral imperative to seek research designs that enable this reduction.”

The researchers believe this wireless technology may open new opportunities for many applications including brain research, pharmaceuticals, and telemedicine to treat diseases in the brain and other organs remotely. This remote automation technology could become even more valuable when many labs need to shut down, such as during the height of the COVID-19 pandemic.

This work was supported by grants from the KAIST Global Singularity Research Program, the National Research Foundation of Korea, the United States National Institute of Health, and Oak Ridge Associated Universities.

-PublicationRaza Qazi, Kyle Parker, Choong Yeon Kim, Jordan McCall, Jae-Woong Jeong et al. “Scalable and modular wireless-network infrastructure for large-scale behavioral neuroscience,” Nature Biomedical Engineering, November 25 2021 (doi.org/10.1038/s41551-021-00814-w)

-ProfileProfessor Jae-Woong JeongBio-Integrated Electronics and Systems LabSchool of Electrical EngineeringKAIST

2021.11.29 View 18143

Scientists Develop Wireless Networks that Allow Brain Circuits to Be Controlled Remotely through the Internet

Wireless implantable devices and IoT could manipulate the brains of animals from anywhere around the world due to their minimalistic hardware, low setup cost, ease of use, and customizable versatility

A new study shows that researchers can remotely control the brain circuits of numerous animals simultaneously and independently through the internet. The scientists believe this newly developed technology can speed up brain research and various neuroscience studies to uncover basic brain functions as well as the underpinnings of various neuropsychiatric and neurological disorders.

A multidisciplinary team of researchers at KAIST, Washington University in St. Louis, and the University of Colorado, Boulder, created a wireless ecosystem with its own wireless implantable devices and Internet of Things (IoT) infrastructure to enable high-throughput neuroscience experiments over the internet. This innovative technology could enable scientists to manipulate the brains of animals from anywhere around the world. The study was published in the journal Nature Biomedical Engineering on November 25

“This novel technology is highly versatile and adaptive. It can remotely control numerous neural implants and laboratory tools in real-time or in a scheduled way without direct human interactions,” said Professor Jae-Woong Jeong of the School of Electrical Engineering at KAIST and a senior author of the study. “These wireless neural devices and equipment integrated with IoT technology have enormous potential for science and medicine.”

The wireless ecosystem only requires a mini-computer that can be purchased for under $45, which connects to the internet and communicates with wireless multifunctional brain probes or other types of conventional laboratory equipment using IoT control modules. By optimally integrating the versatility and modular construction of both unique IoT hardware and software within a single ecosystem, this wireless technology offers new applications that have not been demonstrated before by a single standalone technology. This includes, but is not limited to minimalistic hardware, global remote access, selective and scheduled experiments, customizable automation, and high-throughput scalability.

“As long as researchers have internet access, they are able to trigger, customize, stop, validate, and store the outcomes of large experiments at any time and from anywhere in the world. They can remotely perform large-scale neuroscience experiments in animals deployed in multiple countries,” said one of the lead authors, Dr. Raza Qazi, a researcher with KAIST and the University of Colorado, Boulder. “The low cost of this system allows it to be easily adopted and can further fuel innovation across many laboratories,” Dr. Qazi added.

One of the significant advantages of this IoT neurotechnology is its ability to be mass deployed across the globe due to its minimalistic hardware, low setup cost, ease of use, and customizable versatility. Scientists across the world can quickly implement this technology within their existing laboratories with minimal budget concerns to achieve globally remote access, scalable experimental automation, or both, thus potentially reducing the time needed to unravel various neuroscientific challenges such as those associated with intractable neurological conditions.

Another senior author on the study, Professor Jordan McCall from the Department of Anesthesiology and Center for Clinical Pharmacology at Washington University in St. Louis, said this technology has the potential to change how basic neuroscience studies are performed. “One of the biggest limitations when trying to understand how the mammalian brain works is that we have to study these functions in unnatural conditions. This technology brings us one step closer to performing important studies without direct human interaction with the study subjects.”

The ability to remotely schedule experiments moves toward automating these types of experiments. Dr. Kyle Parker, an instructor at Washington University in St. Louis and another lead author on the study added, “This experimental automation can potentially help us reduce the number of animals used in biomedical research by reducing the variability introduced by various experimenters. This is especially important given our moral imperative to seek research designs that enable this reduction.”

The researchers believe this wireless technology may open new opportunities for many applications including brain research, pharmaceuticals, and telemedicine to treat diseases in the brain and other organs remotely. This remote automation technology could become even more valuable when many labs need to shut down, such as during the height of the COVID-19 pandemic.

This work was supported by grants from the KAIST Global Singularity Research Program, the National Research Foundation of Korea, the United States National Institute of Health, and Oak Ridge Associated Universities.

-PublicationRaza Qazi, Kyle Parker, Choong Yeon Kim, Jordan McCall, Jae-Woong Jeong et al. “Scalable and modular wireless-network infrastructure for large-scale behavioral neuroscience,” Nature Biomedical Engineering, November 25 2021 (doi.org/10.1038/s41551-021-00814-w)

-ProfileProfessor Jae-Woong JeongBio-Integrated Electronics and Systems LabSchool of Electrical EngineeringKAIST

2021.11.29 View 18143 -

Professor Kang’s Team Receives the IEEE Jack Newbauer Memorial Award

Professor Joonhyuk Kang of the School of Electrical Engineering received the IEEE Vehicular Technology Society’s 2021 Jack Neubauer Memorial Award for his team’s paper published in IEEE Transactions on Vehicular Technology. The Jack Neubauer Memorial Award recognizes the best paper published in the IEEE Transactions on Vehicular Technology journal in the last five years.

The team of authors, Professor Kang, Professor Sung-Ah Chung at Kyungpook National University, and Professor Osvaldo Simeone of King's College London reported their research titled Mobile Edge Computing via a UAV-Mounted Cloudlet: Optimization of Bit Allocation and Path Planning in IEEE Transactions on Vehicular Technology, Vol. 67, No. 3, pp. 2049-2063, in March 2018.

Their paper shows how the trajectory of aircraft is optimized and resources are allocated when unmanned aerial vehicles perform edge computing to help mobile device calculations. This paper has currently recorded nearly 400 citations (based on Google Scholar). "We are very happy to see the results of proposing edge computing using unmanned aerial vehicles by applying optimization theory, and conducting research on trajectory and resource utilization of unmanned aerial vehicles that minimize power consumption," said Professor Kang.

2021.07.12 View 9777

Professor Kang’s Team Receives the IEEE Jack Newbauer Memorial Award

Professor Joonhyuk Kang of the School of Electrical Engineering received the IEEE Vehicular Technology Society’s 2021 Jack Neubauer Memorial Award for his team’s paper published in IEEE Transactions on Vehicular Technology. The Jack Neubauer Memorial Award recognizes the best paper published in the IEEE Transactions on Vehicular Technology journal in the last five years.

The team of authors, Professor Kang, Professor Sung-Ah Chung at Kyungpook National University, and Professor Osvaldo Simeone of King's College London reported their research titled Mobile Edge Computing via a UAV-Mounted Cloudlet: Optimization of Bit Allocation and Path Planning in IEEE Transactions on Vehicular Technology, Vol. 67, No. 3, pp. 2049-2063, in March 2018.

Their paper shows how the trajectory of aircraft is optimized and resources are allocated when unmanned aerial vehicles perform edge computing to help mobile device calculations. This paper has currently recorded nearly 400 citations (based on Google Scholar). "We are very happy to see the results of proposing edge computing using unmanned aerial vehicles by applying optimization theory, and conducting research on trajectory and resource utilization of unmanned aerial vehicles that minimize power consumption," said Professor Kang.

2021.07.12 View 9777 -

Distinguished Professor Sang Yup Lee Honored with Charles D. Scott Award

Vice President for Research Sang Yup Lee received the 2021 Charles D. Scott Award from the Society for Industrial Microbiology and Biotechnology. Distinguished Professor Lee from the Department of Chemical and Biomolecular Engineering at KAIST is the first Asian awardee.

The Charles D. Scott Award, initiated in 1995, recognizes individuals who have made significant contributions to enable and further the use of biotechnology to produce fuels and chemicals. The award is named in honor of Dr. Charles D. Scott, who founded the Symposium on Biomaterials, Fuels, and Chemicals and chaired the conference for its first ten years.

Professor Lee has pioneered systems metabolic engineering and developed various micro-organisms capable of producing a wide range of fuels, chemicals, materials, and natural compounds, many of them for the first time. Some of the breakthroughs include the microbial production of gasoline, diacids, diamines, PLA and PLGA polymers, and several natural products.

More recently, his team has developed a microbial strain capable of the mass production of succinic acid, a monomer for manufacturing polyester, with the highest production efficiency to date, as well as a Corynebacterium glutamicum strain capable of producing high-level glutaric acid. They also engineered for the first time a bacterium capable of producing carminic acid, a natural red colorant that is widely used for food and cosmetics.

Professor Lee is one of the Highly Cited Researchers (HCR), ranked in the top 1% by citations in their field by Clarivate Analytics for four consecutive years from 2017. He is the first Korean fellow ever elected into the National Academy of Inventors in the US and one of 13 scholars elected as an International Member of both the National Academy of Sciences and the National Academy of Engineering in the USA.

The awards ceremony will take place during the Symposium on Biomaterials, Fuels, and Chemicals held online from April 26.

2021.04.27 View 11512

Distinguished Professor Sang Yup Lee Honored with Charles D. Scott Award

Vice President for Research Sang Yup Lee received the 2021 Charles D. Scott Award from the Society for Industrial Microbiology and Biotechnology. Distinguished Professor Lee from the Department of Chemical and Biomolecular Engineering at KAIST is the first Asian awardee.

The Charles D. Scott Award, initiated in 1995, recognizes individuals who have made significant contributions to enable and further the use of biotechnology to produce fuels and chemicals. The award is named in honor of Dr. Charles D. Scott, who founded the Symposium on Biomaterials, Fuels, and Chemicals and chaired the conference for its first ten years.

Professor Lee has pioneered systems metabolic engineering and developed various micro-organisms capable of producing a wide range of fuels, chemicals, materials, and natural compounds, many of them for the first time. Some of the breakthroughs include the microbial production of gasoline, diacids, diamines, PLA and PLGA polymers, and several natural products.

More recently, his team has developed a microbial strain capable of the mass production of succinic acid, a monomer for manufacturing polyester, with the highest production efficiency to date, as well as a Corynebacterium glutamicum strain capable of producing high-level glutaric acid. They also engineered for the first time a bacterium capable of producing carminic acid, a natural red colorant that is widely used for food and cosmetics.

Professor Lee is one of the Highly Cited Researchers (HCR), ranked in the top 1% by citations in their field by Clarivate Analytics for four consecutive years from 2017. He is the first Korean fellow ever elected into the National Academy of Inventors in the US and one of 13 scholars elected as an International Member of both the National Academy of Sciences and the National Academy of Engineering in the USA.

The awards ceremony will take place during the Symposium on Biomaterials, Fuels, and Chemicals held online from April 26.

2021.04.27 View 11512 -

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.

The issue also emphasized the need for KAIST to enhance global cooperation and the exchange of ideas in the years to come, especially during the post-COVID era intertwined with the Fourth Industrial Revolution (4IR). In this regard, the issue cited the first ‘KAIST Emerging Materials e-Symposium (EMS)’, which was held online for five days in September of last year with a global audience of over 10,000 participating live via Zoom and YouTube, as a successful example of what academic collaboration could look like in the post-COVID and 4IR eras.

In addition, the “Science & Technology New Deal Project for COVID-19 Response,” a project conducted by KAIST with support from the Ministry of Science and ICT (MSIT) of South Korea, was also introduced as another excellent case of KAIST’s collective intelligence and technological innovation. The issue highlighted some key achievements from this project for overcoming the pandemic-driven crisis, such as: reusable anti-virus filters, negative-pressure ambulances for integrated patient transport and hospitalization, and movable and expandable negative-pressure ward modules.

“We hold our expectations high for the outstanding achievements and progress KAIST will have made by its centennial,” said Professor Kim on the background of curating the 14 review articles contributed by KAIST faculty from the fields of Materials Science and Engineering (MSE), Chemical and Biomolecular Engineering (CBE), Nuclear and Quantum Engineering (NQE), Electrical Engineering (EE), and Chemistry (Chem).

Review articles discussing emerging materials and their properties covered photonic carbon dots (Professor Chan Beum Park, MSE), single-atom and ensemble catalysts (Professor Hyunjoo Lee, CBE), and metal/metal oxide electrocatalysts (Professor Sung-Yoon Chung, MSE).

Review articles discussing materials processing covered 2D layered materials synthesis based on interlayer engineering (Professor Kibum Kang, MSE), eco-friendly methods for solar cell production (Professor Bumjoon J. Kim, CBE), an ex-solution process for the synthesis of highly stable catalysts (Professor WooChul Jung, MSE), and 3D light-patterning synthesis of ordered nanostructures (Professor Seokwoo Jeon, MSE, and Professor Dongchan Jang, NQE).

Review articles discussing advanced analysis techniques covered operando materials analyses (Professor Jeong Yeong Park, Chem), graphene liquid cell transmission electron microscopy (Professor Jong Min Yuk, MSE), and multiscale modeling and visualization of materials systems (Professor Seungbum Hong, MSE).

Review articles discussing practical state-of-the-art devices covered chemiresistive hydrogen sensors (Professor Il-Doo Kim, MSE), patient-friendly diagnostics and implantable treatment devices (Professor Steve Park, MSE), triboelectric nanogenerators (Professor Yang-Kyu Choi, EE), and next-generation lithium-air batteries (Professor Hye Ryung Byon, Chem, and Professor Il-Doo Kim, MSE).

In addition to Professor Il-Doo Kim, post-doctoral researcher Dr. Jaewan Ahn from the KAIST Applied Science Research Institute, Dean of the College of Engineering at KAIST Professor Choongsik Bae, and ACS Nano Editor-in-Chief Professor Paul S. Weiss from the University of California, Los Angeles also contributed to the publication of this ACS Nano special virtual issue.

The issue can be viewed and downloaded from the ACS Nano website at https://doi.org/10.1021/acsnano.1c01101.

Image credit: KAIST

Image usage restrictions: News organizations may use or redistribute this image,with proper attribution, as part of news coverage of this paper only.

Publication:

Ahn, J., et al. (2021) Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues. ACS Nano 15(3): 1895-1907. Available online at https://doi.org/10.1021/acsnano.1c01101

Profile:

Il-Doo Kim, Ph.D

Chair Professor

idkim@kaist.ac.kr

http://advnano.kaist.ac.kr

Advanced Nanomaterials and Energy Lab.

Department of Materials Science and Engineering

Membrane Innovation Center for Anti-Virus and Air-Quality Control

https://kaist.ac.kr/

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2021.03.05 View 35990

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.

The issue also emphasized the need for KAIST to enhance global cooperation and the exchange of ideas in the years to come, especially during the post-COVID era intertwined with the Fourth Industrial Revolution (4IR). In this regard, the issue cited the first ‘KAIST Emerging Materials e-Symposium (EMS)’, which was held online for five days in September of last year with a global audience of over 10,000 participating live via Zoom and YouTube, as a successful example of what academic collaboration could look like in the post-COVID and 4IR eras.

In addition, the “Science & Technology New Deal Project for COVID-19 Response,” a project conducted by KAIST with support from the Ministry of Science and ICT (MSIT) of South Korea, was also introduced as another excellent case of KAIST’s collective intelligence and technological innovation. The issue highlighted some key achievements from this project for overcoming the pandemic-driven crisis, such as: reusable anti-virus filters, negative-pressure ambulances for integrated patient transport and hospitalization, and movable and expandable negative-pressure ward modules.

“We hold our expectations high for the outstanding achievements and progress KAIST will have made by its centennial,” said Professor Kim on the background of curating the 14 review articles contributed by KAIST faculty from the fields of Materials Science and Engineering (MSE), Chemical and Biomolecular Engineering (CBE), Nuclear and Quantum Engineering (NQE), Electrical Engineering (EE), and Chemistry (Chem).

Review articles discussing emerging materials and their properties covered photonic carbon dots (Professor Chan Beum Park, MSE), single-atom and ensemble catalysts (Professor Hyunjoo Lee, CBE), and metal/metal oxide electrocatalysts (Professor Sung-Yoon Chung, MSE).

Review articles discussing materials processing covered 2D layered materials synthesis based on interlayer engineering (Professor Kibum Kang, MSE), eco-friendly methods for solar cell production (Professor Bumjoon J. Kim, CBE), an ex-solution process for the synthesis of highly stable catalysts (Professor WooChul Jung, MSE), and 3D light-patterning synthesis of ordered nanostructures (Professor Seokwoo Jeon, MSE, and Professor Dongchan Jang, NQE).

Review articles discussing advanced analysis techniques covered operando materials analyses (Professor Jeong Yeong Park, Chem), graphene liquid cell transmission electron microscopy (Professor Jong Min Yuk, MSE), and multiscale modeling and visualization of materials systems (Professor Seungbum Hong, MSE).

Review articles discussing practical state-of-the-art devices covered chemiresistive hydrogen sensors (Professor Il-Doo Kim, MSE), patient-friendly diagnostics and implantable treatment devices (Professor Steve Park, MSE), triboelectric nanogenerators (Professor Yang-Kyu Choi, EE), and next-generation lithium-air batteries (Professor Hye Ryung Byon, Chem, and Professor Il-Doo Kim, MSE).

In addition to Professor Il-Doo Kim, post-doctoral researcher Dr. Jaewan Ahn from the KAIST Applied Science Research Institute, Dean of the College of Engineering at KAIST Professor Choongsik Bae, and ACS Nano Editor-in-Chief Professor Paul S. Weiss from the University of California, Los Angeles also contributed to the publication of this ACS Nano special virtual issue.

The issue can be viewed and downloaded from the ACS Nano website at https://doi.org/10.1021/acsnano.1c01101.

Image credit: KAIST

Image usage restrictions: News organizations may use or redistribute this image,with proper attribution, as part of news coverage of this paper only.

Publication:

Ahn, J., et al. (2021) Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues. ACS Nano 15(3): 1895-1907. Available online at https://doi.org/10.1021/acsnano.1c01101

Profile:

Il-Doo Kim, Ph.D

Chair Professor

idkim@kaist.ac.kr

http://advnano.kaist.ac.kr

Advanced Nanomaterials and Energy Lab.

Department of Materials Science and Engineering

Membrane Innovation Center for Anti-Virus and Air-Quality Control

https://kaist.ac.kr/

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2021.03.05 View 35990 -

Wirelessly Rechargeable Soft Brain Implant Controls Brain Cells

Researchers have invented a smartphone-controlled soft brain implant that can be recharged wirelessly from outside the body. It enables long-term neural circuit manipulation without the need for periodic disruptive surgeries to replace the battery of the implant. Scientists believe this technology can help uncover and treat psychiatric disorders and neurodegenerative diseases such as addiction, depression, and Parkinson’s.

A group of KAIST researchers and collaborators have engineered a tiny brain implant that can be wirelessly recharged from outside the body to control brain circuits for long periods of time without battery replacement. The device is constructed of ultra-soft and bio-compliant polymers to help provide long-term compatibility with tissue. Geared with micrometer-sized LEDs (equivalent to the size of a grain of salt) mounted on ultrathin probes (the thickness of a human hair), it can wirelessly manipulate target neurons in the deep brain using light.

This study, led by Professor Jae-Woong Jeong, is a step forward from the wireless head-mounted implant neural device he developed in 2019. That previous version could indefinitely deliver multiple drugs and light stimulation treatment wirelessly by using a smartphone. For more, Manipulating Brain Cells by Smartphone.

For the new upgraded version, the research team came up with a fully implantable, soft optoelectronic system that can be remotely and selectively controlled by a smartphone. This research was published on January 22, 2021 in Nature Communications.

The new wireless charging technology addresses the limitations of current brain implants. Wireless implantable device technologies have recently become popular as alternatives to conventional tethered implants, because they help minimize stress and inflammation in freely-moving animals during brain studies, which in turn enhance the lifetime of the devices. However, such devices require either intermittent surgeries to replace discharged batteries, or special and bulky wireless power setups, which limit experimental options as well as the scalability of animal experiments.

“This powerful device eliminates the need for additional painful surgeries to replace an exhausted battery in the implant, allowing seamless chronic neuromodulation,” said Professor Jeong. “We believe that the same basic technology can be applied to various types of implants, including deep brain stimulators, and cardiac and gastric pacemakers, to reduce the burden on patients for long-term use within the body.”

To enable wireless battery charging and controls, researchers developed a tiny circuit that integrates a wireless energy harvester with a coil antenna and a Bluetooth low-energy chip. An alternating magnetic field can harmlessly penetrate through tissue, and generate electricity inside the device to charge the battery. Then the battery-powered Bluetooth implant delivers programmable patterns of light to brain cells using an “easy-to-use” smartphone app for real-time brain control.

“This device can be operated anywhere and anytime to manipulate neural circuits, which makes it a highly versatile tool for investigating brain functions,” said lead author Choong Yeon Kim, a researcher at KAIST.

Neuroscientists successfully tested these implants in rats and demonstrated their ability to suppress cocaine-induced behaviour after the rats were injected with cocaine. This was achieved by precise light stimulation of relevant target neurons in their brains using the smartphone-controlled LEDs. Furthermore, the battery in the implants could be repeatedly recharged while the rats were behaving freely, thus minimizing any physical interruption to the experiments.

“Wireless battery re-charging makes experimental procedures much less complicated,” said the co-lead author Min Jeong Ku, a researcher at Yonsei University’s College of Medicine.

“The fact that we can control a specific behaviour of animals, by delivering light stimulation into the brain just with a simple manipulation of smartphone app, watching freely moving animals nearby, is very interesting and stimulates a lot of imagination,” said Jeong-Hoon Kim, a professor of physiology at Yonsei University’s College of Medicine. “This technology will facilitate various avenues of brain research.”

The researchers believe this brain implant technology may lead to new opportunities for brain research and therapeutic intervention to treat diseases in the brain and other organs.

This work was supported by grants from the National Research Foundation of Korea and the KAIST Global Singularity Research Program.

-Profile

Professor Jae-Woong Jeong

https://www.jeongresearch.org/

School of Electrical Engineering

KAIST

2021.01.26 View 28285

Wirelessly Rechargeable Soft Brain Implant Controls Brain Cells

Researchers have invented a smartphone-controlled soft brain implant that can be recharged wirelessly from outside the body. It enables long-term neural circuit manipulation without the need for periodic disruptive surgeries to replace the battery of the implant. Scientists believe this technology can help uncover and treat psychiatric disorders and neurodegenerative diseases such as addiction, depression, and Parkinson’s.

A group of KAIST researchers and collaborators have engineered a tiny brain implant that can be wirelessly recharged from outside the body to control brain circuits for long periods of time without battery replacement. The device is constructed of ultra-soft and bio-compliant polymers to help provide long-term compatibility with tissue. Geared with micrometer-sized LEDs (equivalent to the size of a grain of salt) mounted on ultrathin probes (the thickness of a human hair), it can wirelessly manipulate target neurons in the deep brain using light.

This study, led by Professor Jae-Woong Jeong, is a step forward from the wireless head-mounted implant neural device he developed in 2019. That previous version could indefinitely deliver multiple drugs and light stimulation treatment wirelessly by using a smartphone. For more, Manipulating Brain Cells by Smartphone.

For the new upgraded version, the research team came up with a fully implantable, soft optoelectronic system that can be remotely and selectively controlled by a smartphone. This research was published on January 22, 2021 in Nature Communications.

The new wireless charging technology addresses the limitations of current brain implants. Wireless implantable device technologies have recently become popular as alternatives to conventional tethered implants, because they help minimize stress and inflammation in freely-moving animals during brain studies, which in turn enhance the lifetime of the devices. However, such devices require either intermittent surgeries to replace discharged batteries, or special and bulky wireless power setups, which limit experimental options as well as the scalability of animal experiments.

“This powerful device eliminates the need for additional painful surgeries to replace an exhausted battery in the implant, allowing seamless chronic neuromodulation,” said Professor Jeong. “We believe that the same basic technology can be applied to various types of implants, including deep brain stimulators, and cardiac and gastric pacemakers, to reduce the burden on patients for long-term use within the body.”

To enable wireless battery charging and controls, researchers developed a tiny circuit that integrates a wireless energy harvester with a coil antenna and a Bluetooth low-energy chip. An alternating magnetic field can harmlessly penetrate through tissue, and generate electricity inside the device to charge the battery. Then the battery-powered Bluetooth implant delivers programmable patterns of light to brain cells using an “easy-to-use” smartphone app for real-time brain control.

“This device can be operated anywhere and anytime to manipulate neural circuits, which makes it a highly versatile tool for investigating brain functions,” said lead author Choong Yeon Kim, a researcher at KAIST.

Neuroscientists successfully tested these implants in rats and demonstrated their ability to suppress cocaine-induced behaviour after the rats were injected with cocaine. This was achieved by precise light stimulation of relevant target neurons in their brains using the smartphone-controlled LEDs. Furthermore, the battery in the implants could be repeatedly recharged while the rats were behaving freely, thus minimizing any physical interruption to the experiments.

“Wireless battery re-charging makes experimental procedures much less complicated,” said the co-lead author Min Jeong Ku, a researcher at Yonsei University’s College of Medicine.

“The fact that we can control a specific behaviour of animals, by delivering light stimulation into the brain just with a simple manipulation of smartphone app, watching freely moving animals nearby, is very interesting and stimulates a lot of imagination,” said Jeong-Hoon Kim, a professor of physiology at Yonsei University’s College of Medicine. “This technology will facilitate various avenues of brain research.”

The researchers believe this brain implant technology may lead to new opportunities for brain research and therapeutic intervention to treat diseases in the brain and other organs.

This work was supported by grants from the National Research Foundation of Korea and the KAIST Global Singularity Research Program.

-Profile

Professor Jae-Woong Jeong

https://www.jeongresearch.org/

School of Electrical Engineering

KAIST

2021.01.26 View 28285 -

Extremely Stable Perovskite Nanoparticles Films for Next-Generation Displays

Researchers have reported an extremely stable cross-linked perovskite nanoparticle that maintains a high photoluminescence quantum yield (PLQY) for 1.5 years in air and harsh liquid environments. This stable material’s design strategies, which addressed one of the most critical problems limiting their practical application, provide a breakthrough for the commercialization of perovskite nanoparticles in next-generation displays and bio-related applications.

According to the research team led by Professor Byeong-Soo Bae, their development can survive in severe environments such as water, various polar solvents, and high temperature with high humidity without additional encapsulation. This development is expected to enable perovskite nanoparticles to be applied to high color purity display applications as a practical color converting material. This result was published as the inside front cover article in Advanced Materials.

Perovskites, which consist of organics, metals, and halogen elements, have emerged as key elements in various optoelectronic applications. The power conversion efficiency of photovoltaic cells based on perovskites light absorbers has been rapidly increased. Perovskites are also great promise as a light emitter in display applications because of their low material cost, facile wavelength tunability, high (PLQY), very narrow emission band width, and wider color gamut than inorganic semiconducting nanocrystals and organic emitters. Thanks to these advantages, perovskites have been identified as a key color-converting material for next-generation high color-purity displays. In particular, perovskites are the only luminescence material that meets Rec. 2020 which is a new color standard in display industry.

However, perovskites are very unstable against heat, moisture, and light, which makes them almost impossible to use in practical applications. To solve these problems, many researchers have attempted to physically prevent perovskites from coming into contact with water molecules by passivating the perovskite grain and nanoparticle surfaces with organic ligands or inorganic shell materials, or by fabricating perovskite-polymer nanocomposites. These methods require complex processes and have limited stability in ambient air and water. Furthermore, stable perovskite nanoparticles in the various chemical environments and high temperatures with high humidity have not been reported yet.

The research team in collaboration with Seoul National University develops siloxane-encapsulated perovskite nanoparticle composite films. Here, perovskite nanoparticles are chemically crosslinked with thermally stable siloxane molecules, thereby significantly improving the stability of the perovskite nanoparticles without the need for any additional protecting layer.

Siloxane-encapsulated perovskite nanoparticle composite films exhibited a high PLQY (> 70%) value, which can be maintained over 600 days in water, various chemicals (alcohol, strong acidic and basic solutions), and high temperatures with high humidity (85℃/85%). The research team investigated the mechanisms impacting the chemical crosslinking and water molecule-induced stabilization of perovskite nanoparticles through various photo-physical analysis and density-functional theory calculation.

The research team confirmed that displays based on their siloxane-perovskite nanoparticle composite films exhibited higher PLQY and a wider color gamut than those of Cd-based quantum dots and demonstrated perfect color converting properties on commercial mobile phone screens. Unlike what was commonly believed in the halide perovskite field, the composite films showed excellent bio-compatibility because the siloxane matrix prevents the toxicity of Pb in perovskite nanoparticle.

By using this technology, the instability of perovskite materials, which is the biggest challenge for practical applications, is greatly improved through simple encapsulation method.

“Perovskite nanoparticle is the only photoluminescent material that can meet the next generation display color standard. Nevertheless, there has been reluctant to commercialize it due to its moisture vulnerability. The newly developed siloxane encapsulation technology will trigger more research on perovskite nanoparticles as color conversion materials and will accelerate early commercialization,” Professor Bae said.

This work was supported by the Wearable Platform Materials Technology Center (WMC) of the Engineering Research Center (ERC) Project, and the Leadership Research Program funded by the National Research Foundation of Korea.

-Publication:

Junho Jang, Young-Hoon Kim, Sunjoon Park, Dongsuk Yoo, Hyunjin Cho, Jinhyeong Jang, Han Beom Jeong, Hyunhwan Lee, Jong Min Yuk, Chan Beum Park, Duk Young Jeon, Yong-Hyun Kim, Byeong-Soo Bae, and Tae-Woo Lee. “Extremely Stable Luminescent Crosslinked Perovskite Nanoparticles under Harsh Environments over 1.5 Years” Advanced Materials, 2020, 2005255. https://doi.org/10.1002/adma.202005255.

Link to download the full-text paper:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202005255

-Profile: Prof. Byeong-Soo Bae (Corresponding author)

bsbae@kaist.ac.kr

Lab. of Optical Materials & Coating

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

2020.12.29 View 16103

Extremely Stable Perovskite Nanoparticles Films for Next-Generation Displays

Researchers have reported an extremely stable cross-linked perovskite nanoparticle that maintains a high photoluminescence quantum yield (PLQY) for 1.5 years in air and harsh liquid environments. This stable material’s design strategies, which addressed one of the most critical problems limiting their practical application, provide a breakthrough for the commercialization of perovskite nanoparticles in next-generation displays and bio-related applications.

According to the research team led by Professor Byeong-Soo Bae, their development can survive in severe environments such as water, various polar solvents, and high temperature with high humidity without additional encapsulation. This development is expected to enable perovskite nanoparticles to be applied to high color purity display applications as a practical color converting material. This result was published as the inside front cover article in Advanced Materials.

Perovskites, which consist of organics, metals, and halogen elements, have emerged as key elements in various optoelectronic applications. The power conversion efficiency of photovoltaic cells based on perovskites light absorbers has been rapidly increased. Perovskites are also great promise as a light emitter in display applications because of their low material cost, facile wavelength tunability, high (PLQY), very narrow emission band width, and wider color gamut than inorganic semiconducting nanocrystals and organic emitters. Thanks to these advantages, perovskites have been identified as a key color-converting material for next-generation high color-purity displays. In particular, perovskites are the only luminescence material that meets Rec. 2020 which is a new color standard in display industry.

However, perovskites are very unstable against heat, moisture, and light, which makes them almost impossible to use in practical applications. To solve these problems, many researchers have attempted to physically prevent perovskites from coming into contact with water molecules by passivating the perovskite grain and nanoparticle surfaces with organic ligands or inorganic shell materials, or by fabricating perovskite-polymer nanocomposites. These methods require complex processes and have limited stability in ambient air and water. Furthermore, stable perovskite nanoparticles in the various chemical environments and high temperatures with high humidity have not been reported yet.

The research team in collaboration with Seoul National University develops siloxane-encapsulated perovskite nanoparticle composite films. Here, perovskite nanoparticles are chemically crosslinked with thermally stable siloxane molecules, thereby significantly improving the stability of the perovskite nanoparticles without the need for any additional protecting layer.

Siloxane-encapsulated perovskite nanoparticle composite films exhibited a high PLQY (> 70%) value, which can be maintained over 600 days in water, various chemicals (alcohol, strong acidic and basic solutions), and high temperatures with high humidity (85℃/85%). The research team investigated the mechanisms impacting the chemical crosslinking and water molecule-induced stabilization of perovskite nanoparticles through various photo-physical analysis and density-functional theory calculation.

The research team confirmed that displays based on their siloxane-perovskite nanoparticle composite films exhibited higher PLQY and a wider color gamut than those of Cd-based quantum dots and demonstrated perfect color converting properties on commercial mobile phone screens. Unlike what was commonly believed in the halide perovskite field, the composite films showed excellent bio-compatibility because the siloxane matrix prevents the toxicity of Pb in perovskite nanoparticle.

By using this technology, the instability of perovskite materials, which is the biggest challenge for practical applications, is greatly improved through simple encapsulation method.

“Perovskite nanoparticle is the only photoluminescent material that can meet the next generation display color standard. Nevertheless, there has been reluctant to commercialize it due to its moisture vulnerability. The newly developed siloxane encapsulation technology will trigger more research on perovskite nanoparticles as color conversion materials and will accelerate early commercialization,” Professor Bae said.

This work was supported by the Wearable Platform Materials Technology Center (WMC) of the Engineering Research Center (ERC) Project, and the Leadership Research Program funded by the National Research Foundation of Korea.

-Publication:

Junho Jang, Young-Hoon Kim, Sunjoon Park, Dongsuk Yoo, Hyunjin Cho, Jinhyeong Jang, Han Beom Jeong, Hyunhwan Lee, Jong Min Yuk, Chan Beum Park, Duk Young Jeon, Yong-Hyun Kim, Byeong-Soo Bae, and Tae-Woo Lee. “Extremely Stable Luminescent Crosslinked Perovskite Nanoparticles under Harsh Environments over 1.5 Years” Advanced Materials, 2020, 2005255. https://doi.org/10.1002/adma.202005255.

Link to download the full-text paper:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202005255

-Profile: Prof. Byeong-Soo Bae (Corresponding author)

bsbae@kaist.ac.kr

Lab. of Optical Materials & Coating

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

2020.12.29 View 16103 -

Mystery Solved with Math: Cytoplasmic Traffic Jam Disrupts Sleep-Wake Cycles

KAIST mathematicians and their collaborators at Florida State University have identified the principle of how aging and diseases like dementia and obesity cause sleep disorders. A combination of mathematical modelling and experiments demonstrated that the cytoplasmic congestion caused by aging, dementia, and/or obesity disrupts the circadian rhythms in the human body and leads to irregular sleep-wake cycles. This finding suggests new treatment strategies for addressing unstable sleep-wake cycles.

Human bodies adjust sleep schedules in accordance with the ‘circadian rhythms’, which are regulated by our time keeping system, the ‘circadian clock’. This clock tells our body when to rest by generating the 24-hour rhythms of a protein called PERIOD (PER) (See Figure 1).

The amount of the PER protein increases for half of the day and then decreases for the remaining half. The principle is that the PER protein accumulating in the cytoplasm for several hours enters the cell nucleus all at once, hindering the transcription of PER genes and thereby reducing the amount of PER.

However, it has remained a mystery how thousands of PER molecules can simultaneously enter into the nucleus in a complex cell environment where a variety of materials co-exist and can interfere with the motion of PER. This would be like finding a way for thousands of employees from all over New York City to enter an office building at the same time every day.

A group of researchers led by Professor Jae Kyoung Kim from the KAIST Department of Mathematical Sciences solved the mystery by developing a spatiotemporal and probabilistic model that describes the motion of PER molecules in a cell environment.

This study was conducted in collaboration with Professor Choogon Lee’s group from Florida State University, where the experiments were carried out, and the results were published in the Proceedings of the National Academy of Sciences (PNAS) last month.

The joint research team’s spatial stochastic model (See Figure 2) described the motion of PER molecules in cells and demonstrated that the PER molecule should be sufficiently condensed around the cell nucleus to be phosphorylated simultaneously and enter the nucleus together (See Figure 3 Left). Thanks to this phosphorylation synchronization switch, thousands of PER molecules can enter the nucleus at the same time every day and maintain stable circadian rhythms.

However, when aging and/or diseases including dementia and obesity cause the cytoplasm to become congested with increased cytoplasmic obstacles such as protein aggregates and fat vacuoles, it hinders the timely condensation of PER molecules around the cell nucleus (See Figure 3 Right). As a result, the phosphorylation synchronization switch does not work and PER proteins enter into the nucleus at irregular times, making the circadian rhythms and sleep-wake cycles unstable, the study revealed.

Professor Kim said, “As a mathematician, I am excited to help enable the advancement of new treatment strategies that can improve the lives of so many patients who suffer from irregular sleep-wake cycles. Taking these findings as an opportunity, I hope to see more active interchanges of ideas and collaboration between mathematical and biological sciences.”

This work was supported by the National Institutes of Health and the National Science Foundation in the US, and the International Human Frontiers Science Program Organization and the National Research Foundation of Korea.

Publication:

Beesley, S. and Kim, D. W, et al. (2020) Wake-sleep cycles are severely disrupted by diseases affecting cytoplasmic homeostasis. Proceedings of the National Academy of Sciences (PNAS), Vol. 117, No. 45, 28402-28411. Available online at https://doi.org/10.1073/pnas.2003524117

Profile:

Jae Kyoung Kim, Ph.D.

Associate Professor

jaekkim@kaist.ac.kr

http://mathsci.kaist.ac.kr/~jaekkim

@umichkim on Twitter

Department of Mathematical Sciences

Korea Advanced Institute of Science and Technology (KAIST)

Daejeon, Republic of Korea

Profile:

Choogon Lee, Ph.D.

Associate Professor

clee@neuro.fsu.edu

https://med.fsu.edu/biosci/lee-lab

Department of Biomedical Sciences

Florida State University

Florida, USA

(END)

2020.12.11 View 12661

Mystery Solved with Math: Cytoplasmic Traffic Jam Disrupts Sleep-Wake Cycles

KAIST mathematicians and their collaborators at Florida State University have identified the principle of how aging and diseases like dementia and obesity cause sleep disorders. A combination of mathematical modelling and experiments demonstrated that the cytoplasmic congestion caused by aging, dementia, and/or obesity disrupts the circadian rhythms in the human body and leads to irregular sleep-wake cycles. This finding suggests new treatment strategies for addressing unstable sleep-wake cycles.

Human bodies adjust sleep schedules in accordance with the ‘circadian rhythms’, which are regulated by our time keeping system, the ‘circadian clock’. This clock tells our body when to rest by generating the 24-hour rhythms of a protein called PERIOD (PER) (See Figure 1).

The amount of the PER protein increases for half of the day and then decreases for the remaining half. The principle is that the PER protein accumulating in the cytoplasm for several hours enters the cell nucleus all at once, hindering the transcription of PER genes and thereby reducing the amount of PER.

However, it has remained a mystery how thousands of PER molecules can simultaneously enter into the nucleus in a complex cell environment where a variety of materials co-exist and can interfere with the motion of PER. This would be like finding a way for thousands of employees from all over New York City to enter an office building at the same time every day.

A group of researchers led by Professor Jae Kyoung Kim from the KAIST Department of Mathematical Sciences solved the mystery by developing a spatiotemporal and probabilistic model that describes the motion of PER molecules in a cell environment.

This study was conducted in collaboration with Professor Choogon Lee’s group from Florida State University, where the experiments were carried out, and the results were published in the Proceedings of the National Academy of Sciences (PNAS) last month.

The joint research team’s spatial stochastic model (See Figure 2) described the motion of PER molecules in cells and demonstrated that the PER molecule should be sufficiently condensed around the cell nucleus to be phosphorylated simultaneously and enter the nucleus together (See Figure 3 Left). Thanks to this phosphorylation synchronization switch, thousands of PER molecules can enter the nucleus at the same time every day and maintain stable circadian rhythms.

However, when aging and/or diseases including dementia and obesity cause the cytoplasm to become congested with increased cytoplasmic obstacles such as protein aggregates and fat vacuoles, it hinders the timely condensation of PER molecules around the cell nucleus (See Figure 3 Right). As a result, the phosphorylation synchronization switch does not work and PER proteins enter into the nucleus at irregular times, making the circadian rhythms and sleep-wake cycles unstable, the study revealed.

Professor Kim said, “As a mathematician, I am excited to help enable the advancement of new treatment strategies that can improve the lives of so many patients who suffer from irregular sleep-wake cycles. Taking these findings as an opportunity, I hope to see more active interchanges of ideas and collaboration between mathematical and biological sciences.”

This work was supported by the National Institutes of Health and the National Science Foundation in the US, and the International Human Frontiers Science Program Organization and the National Research Foundation of Korea.

Publication:

Beesley, S. and Kim, D. W, et al. (2020) Wake-sleep cycles are severely disrupted by diseases affecting cytoplasmic homeostasis. Proceedings of the National Academy of Sciences (PNAS), Vol. 117, No. 45, 28402-28411. Available online at https://doi.org/10.1073/pnas.2003524117

Profile:

Jae Kyoung Kim, Ph.D.

Associate Professor

jaekkim@kaist.ac.kr

http://mathsci.kaist.ac.kr/~jaekkim

@umichkim on Twitter

Department of Mathematical Sciences

Korea Advanced Institute of Science and Technology (KAIST)

Daejeon, Republic of Korea

Profile:

Choogon Lee, Ph.D.

Associate Professor

clee@neuro.fsu.edu

https://med.fsu.edu/biosci/lee-lab

Department of Biomedical Sciences

Florida State University

Florida, USA

(END)

2020.12.11 View 12661 -

3D Hierarchically Porous Nanostructured Catalyst Helps Efficiently Reduce CO2

- This new catalyst will bring CO2 one step closer to serving as a sustainable energy source. -

KAIST researchers developed a three-dimensional (3D) hierarchically porous nanostructured catalyst with carbon dioxide (CO2) to carbon monoxide (CO) conversion rate up to 3.96 times higher than that of conventional nanoporous gold catalysts. This new catalyst helps overcome the existing limitations of the mass transport that has been a major cause of decreases in the CO2 conversion rate, holding a strong promise for the large-scale and cost-effective electrochemical conversion of CO2 into useful chemicals.

As CO2 emissions increase and fossil fuels deplete globally, reducing and converting CO2 to clean energy electrochemically has attracted a great deal of attention as a promising technology. Especially due to the fact that the CO2 reduction reaction occurs competitively with hydrogen evolution reactions (HER) at similar redox potentials, the development of an efficient electrocatalyst for selective and robust CO2 reduction reactions has remained a key technological issue.

Gold (Au) is one of the most commonly used catalysts in CO2 reduction reactions, but the high cost and scarcity of Au pose obstacles for mass commercial applications. The development of nanostructures has been extensively studied as a potential approach to improving the selectivity for target products and maximizing the number of active stable sites, thus enhancing the energy efficiency.

However, the nanopores of the previously reported complex nanostructures were easily blocked by gaseous CO bubbles during aqueous reactions. The CO bubbles hindered mass transport of the reactants through the electrolyte, resulting in low CO2 conversion rates.

In the study published in the Proceedings of the National Academy of Sciences of the USA (PNAS) on March 4, a research group at KAIST led by Professor Seokwoo Jeon and Professor Jihun Oh from the Department of Materials Science and Engineering designed a 3D hierarchically porous Au nanostructure with two different sizes of macropores and nanopores. The team used proximity-field nanopatterning (PnP) and electroplating techniques that are effective for fabricating the 3D well-ordered nanostructures.

The proposed nanostructure, comprised of interconnected macroporous channels 200 to 300 nanometers (nm) wide and 10 nm nanopores, induces efficient mass transport through the interconnected macroporous channels as well as high selectivity by producing highly active stable sites from numerous nanopores.

As a result, its electrodes show a high CO selectivity of 85.8% at a low overpotential of 0.264 V and efficient mass activity that is up to 3.96 times higher than that of de-alloyed nanoporous Au electrodes.

“These results are expected to solve the problem of mass transfer in the field of similar electrochemical reactions and can be applied to a wide range of green energy applications for the efficient utilization of electrocatalysts,” said the researchers.

This work was supported by the National Research Foundation (NRF) of Korea.

Image credit: Professor Seokwoo Jeon and Professor Jihun Oh, KAIST

Image usage restrictions: News organizations may use or redistribute this image, with proper attribution, as part of news coverage of this paper only.

Publication:

Hyun et al. (2020) Hierarchically porous Au nanostructures with interconnected channels for efficient mass transport in electrocatalytic CO2 reduction. Proceedings of the National Academy of Sciences of the USA (PNAS). Available online at https://doi.org/10.1073/pnas.1918837117

Profile:

Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

http://fdml.kaist.ac.kr

Department of Materials Science and Engineering (MSE)

https://www.kaist.ac.kr

Korea Advanced Institute of Science and Technology (KAIST)Daejeon, Republic of Korea

Profile:

Jihun Oh, PhD

Associate Professor

jihun.oh@kaist.ac.kr

http://les.kaist.ac.kr

Department of Materials Science and Engineering (MSE)

Department of Energy, Environment, Water and Sustainability (EEWS)

KAIST

Profile:

Gayea Hyun

PhD Candidate

cldywkd93@kaist.ac.kr

http://fdml.kaist.ac.kr

Flexible Devices and Metamaterials Laboratory (FDML)

Department of Materials Science and Engineering (MSE)

KAIST

Profile:

Jun Tae Song, PhD

Assistant Professor

song.juntae@cstf.kyushu-u.ac.jp

http://www.cstf.kyushu-u.ac.jp/~ishihara-lab/

Department of Applied Chemistry

https://www.kyushu-u.ac.jp

Kyushu UniversityFukuoka, Japan

(END)

2020.03.13 View 20392

3D Hierarchically Porous Nanostructured Catalyst Helps Efficiently Reduce CO2

- This new catalyst will bring CO2 one step closer to serving as a sustainable energy source. -

KAIST researchers developed a three-dimensional (3D) hierarchically porous nanostructured catalyst with carbon dioxide (CO2) to carbon monoxide (CO) conversion rate up to 3.96 times higher than that of conventional nanoporous gold catalysts. This new catalyst helps overcome the existing limitations of the mass transport that has been a major cause of decreases in the CO2 conversion rate, holding a strong promise for the large-scale and cost-effective electrochemical conversion of CO2 into useful chemicals.

As CO2 emissions increase and fossil fuels deplete globally, reducing and converting CO2 to clean energy electrochemically has attracted a great deal of attention as a promising technology. Especially due to the fact that the CO2 reduction reaction occurs competitively with hydrogen evolution reactions (HER) at similar redox potentials, the development of an efficient electrocatalyst for selective and robust CO2 reduction reactions has remained a key technological issue.

Gold (Au) is one of the most commonly used catalysts in CO2 reduction reactions, but the high cost and scarcity of Au pose obstacles for mass commercial applications. The development of nanostructures has been extensively studied as a potential approach to improving the selectivity for target products and maximizing the number of active stable sites, thus enhancing the energy efficiency.

However, the nanopores of the previously reported complex nanostructures were easily blocked by gaseous CO bubbles during aqueous reactions. The CO bubbles hindered mass transport of the reactants through the electrolyte, resulting in low CO2 conversion rates.

In the study published in the Proceedings of the National Academy of Sciences of the USA (PNAS) on March 4, a research group at KAIST led by Professor Seokwoo Jeon and Professor Jihun Oh from the Department of Materials Science and Engineering designed a 3D hierarchically porous Au nanostructure with two different sizes of macropores and nanopores. The team used proximity-field nanopatterning (PnP) and electroplating techniques that are effective for fabricating the 3D well-ordered nanostructures.

The proposed nanostructure, comprised of interconnected macroporous channels 200 to 300 nanometers (nm) wide and 10 nm nanopores, induces efficient mass transport through the interconnected macroporous channels as well as high selectivity by producing highly active stable sites from numerous nanopores.

As a result, its electrodes show a high CO selectivity of 85.8% at a low overpotential of 0.264 V and efficient mass activity that is up to 3.96 times higher than that of de-alloyed nanoporous Au electrodes.

“These results are expected to solve the problem of mass transfer in the field of similar electrochemical reactions and can be applied to a wide range of green energy applications for the efficient utilization of electrocatalysts,” said the researchers.

This work was supported by the National Research Foundation (NRF) of Korea.

Image credit: Professor Seokwoo Jeon and Professor Jihun Oh, KAIST

Image usage restrictions: News organizations may use or redistribute this image, with proper attribution, as part of news coverage of this paper only.

Publication:

Hyun et al. (2020) Hierarchically porous Au nanostructures with interconnected channels for efficient mass transport in electrocatalytic CO2 reduction. Proceedings of the National Academy of Sciences of the USA (PNAS). Available online at https://doi.org/10.1073/pnas.1918837117

Profile:

Seokwoo Jeon, PhD

Professor

jeon39@kaist.ac.kr

http://fdml.kaist.ac.kr

Department of Materials Science and Engineering (MSE)

https://www.kaist.ac.kr

Korea Advanced Institute of Science and Technology (KAIST)Daejeon, Republic of Korea

Profile:

Jihun Oh, PhD

Associate Professor

jihun.oh@kaist.ac.kr

http://les.kaist.ac.kr

Department of Materials Science and Engineering (MSE)

Department of Energy, Environment, Water and Sustainability (EEWS)

KAIST

Profile:

Gayea Hyun

PhD Candidate

cldywkd93@kaist.ac.kr

http://fdml.kaist.ac.kr

Flexible Devices and Metamaterials Laboratory (FDML)

Department of Materials Science and Engineering (MSE)

KAIST

Profile:

Jun Tae Song, PhD

Assistant Professor

song.juntae@cstf.kyushu-u.ac.jp

http://www.cstf.kyushu-u.ac.jp/~ishihara-lab/

Department of Applied Chemistry

https://www.kyushu-u.ac.jp

Kyushu UniversityFukuoka, Japan

(END)

2020.03.13 View 20392 -

Professor Junil Choi Receives Stephen O. Rice Prize

< Professor Junil Choi (second from the left) >

Professor Junil Choi from the School of Electrical Engineering received the Stephen O. Rice Prize at the Global Communications Conference (GLOBECOM) hosted by the Institute of Electrical and Electronics Engineers (IEEE) in Hawaii on December 10, 2019.

The Stephen O. Rice Prize is awarded to only one paper of exceptional merit every year. The IEEE Communications Society evaluates all papers published in the IEEE Transactions on Communications journal within the last three years, and marks each paper by aggregating its scores on originality, the number of citations, impact, and peer evaluation.

Professor Choi won the prize for his research on one-bit analog-to-digital converters (ADCs) for multiuser massive multiple-input and multiple-output (MIMO) antenna systems published in 2016. In his paper, Professor Choi proposed a technology that can drastically reduce the power consumption of the multiuser massive MIMO antenna systems, which are the core technology for 5G and future wireless communication. Professor Choi’s paper has been cited more than 230 times in various academic journals and conference papers since its publication, and multiple follow-up studies are actively ongoing.

In 2015, Professor Choi received the IEEE Signal Processing Society Best Paper Award, an award equals to the Stephen O. Rice Prize. He was also selected as the winner of the 15th Haedong Young Engineering Researcher Award presented by the Korean Institute of Communications and Information Sciences (KICS) on December 6, 2019 for his outstanding academic achievements, including 34 international journal publications and 26 US patent registrations.

(END)

2019.12.23 View 13999

Professor Junil Choi Receives Stephen O. Rice Prize

< Professor Junil Choi (second from the left) >

Professor Junil Choi from the School of Electrical Engineering received the Stephen O. Rice Prize at the Global Communications Conference (GLOBECOM) hosted by the Institute of Electrical and Electronics Engineers (IEEE) in Hawaii on December 10, 2019.

The Stephen O. Rice Prize is awarded to only one paper of exceptional merit every year. The IEEE Communications Society evaluates all papers published in the IEEE Transactions on Communications journal within the last three years, and marks each paper by aggregating its scores on originality, the number of citations, impact, and peer evaluation.

Professor Choi won the prize for his research on one-bit analog-to-digital converters (ADCs) for multiuser massive multiple-input and multiple-output (MIMO) antenna systems published in 2016. In his paper, Professor Choi proposed a technology that can drastically reduce the power consumption of the multiuser massive MIMO antenna systems, which are the core technology for 5G and future wireless communication. Professor Choi’s paper has been cited more than 230 times in various academic journals and conference papers since its publication, and multiple follow-up studies are actively ongoing.

In 2015, Professor Choi received the IEEE Signal Processing Society Best Paper Award, an award equals to the Stephen O. Rice Prize. He was also selected as the winner of the 15th Haedong Young Engineering Researcher Award presented by the Korean Institute of Communications and Information Sciences (KICS) on December 6, 2019 for his outstanding academic achievements, including 34 international journal publications and 26 US patent registrations.

(END)

2019.12.23 View 13999 -

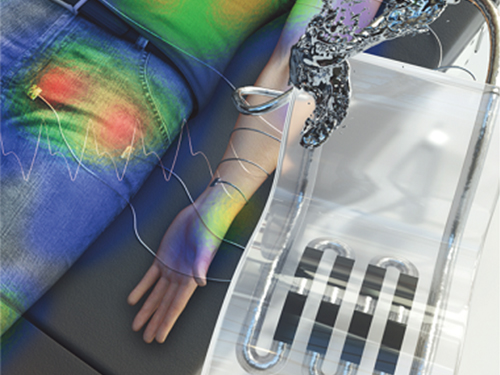

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 17114

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.