AND

-

New and Highly Efficient Recycling Technology to Turn Used Tires into Raw Materials for Rubber and Nylon

< (From left) Kyungmin Choi (MS-Ph.D. integrated course, Department of Chemistry), Dr. Beomsoon Park, Professor Soon Hyeok Hong, Dr. Kyoungil Cho >

Approximately 1.5 billions of tires are discarded globally every year, and this is identified as one of the major causes of serious environmental pollution. The research team at the Department of Chemistry at KAIST has achieved a breakthrough by selectively converting waste tires into high-purity cyclic alkenes, valuable chemical building blocks used in the production of rubber and nylon fibers. This advance marks a new milestone in chemical recycling technology for waste tires.

The team, led by Professor Soon Hyeok Hong, has developed a dual-catalyst-based reaction system that overcomes the long-standing challenges associated with recycling vulcanized rubber materials.

Tires are composed of complex blends of synthetic and natural rubber, and their physical strength and durability are reinforced with additives such as silica, carbon black, and antioxidants. In particular, cross-linking between rubber chains is formed through the vulcanization process, giving them a structure resistant to heat and pressure, which is one of the main reasons why chemical recycling of waste tires is difficult.

Until now, waste tire recycling has mainly relied on pyrolysis or mechanical recycling methods. The pyrolysis method is a technology that decomposes polymer chains at high temperatures of 350-800°C to convert them into fuel oil, but it clearly has limitations such as high energy consumption, low selectivity, and the production of low-quality hydrocarbon mixtures.

To solve these problems, the research team developed a method to convert waste rubber into useful chemicals using dual catalysis. The first catalyst helps to break down rubber molecules by changing their bonding structure, and the second catalyst creates cyclic compounds through a ring-closing reaction.

This process shows high selectivity of up to 92% and a yield of 82%. The produced cyclopentene can be recycled into rubber, and cyclohexene can be used as a raw material for nylon fibers, making them industrially very valuable.

The research team successfully applied the developed system to discarded waste tires, achieving selective conversion into high-purity cyclic alkenes. Unlike the existing pyrolysis method, this is evaluated as a new turning point in the field of waste tire recycling as it can produce high-value chemicals through low-temperature precision catalytic reactions.

In addition, this catalytic platform is compatible with a wide range of synthetic and waste rubbers, positioning it as a promising foundation for scalable, circular solutions in the polymer and materials industries.

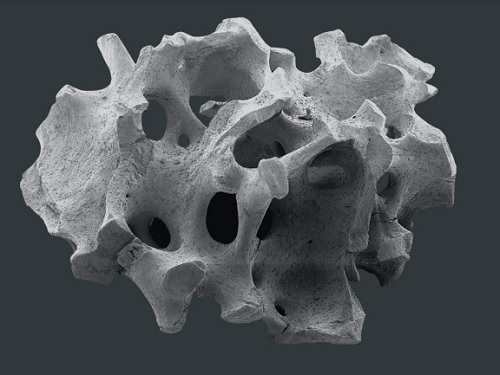

< Figure 1. Development of a Catalytic Method for Chemical Recycling of Waste Rubber >

Professor Hong stated, "This research offers an innovative solution for the chemical recycling of waste tires. We aim to develop next-generation high-efficiency catalysts and lay the groundwork for commercialization to enhance economic feasibility. Ultimately, our goal is to contribute to solving the broader waste plastic problem through fundamental chemistry."

This research, in which Beomsoon Park, Kyoungil Cho, and Kyungmin Choi participated, was supported by the National Research Foundation of Korea and was published online in the internationally renowned academic journal ‘Chem’ on June 18th.

※Paper Title: Catalytic and Selective Chemical Recycling of Post-Consumer Rubbers into Cycloalkenes

※DOI: 10.1016/j.chempr.2025.102625

2025.06.26 View 514

New and Highly Efficient Recycling Technology to Turn Used Tires into Raw Materials for Rubber and Nylon

< (From left) Kyungmin Choi (MS-Ph.D. integrated course, Department of Chemistry), Dr. Beomsoon Park, Professor Soon Hyeok Hong, Dr. Kyoungil Cho >

Approximately 1.5 billions of tires are discarded globally every year, and this is identified as one of the major causes of serious environmental pollution. The research team at the Department of Chemistry at KAIST has achieved a breakthrough by selectively converting waste tires into high-purity cyclic alkenes, valuable chemical building blocks used in the production of rubber and nylon fibers. This advance marks a new milestone in chemical recycling technology for waste tires.

The team, led by Professor Soon Hyeok Hong, has developed a dual-catalyst-based reaction system that overcomes the long-standing challenges associated with recycling vulcanized rubber materials.

Tires are composed of complex blends of synthetic and natural rubber, and their physical strength and durability are reinforced with additives such as silica, carbon black, and antioxidants. In particular, cross-linking between rubber chains is formed through the vulcanization process, giving them a structure resistant to heat and pressure, which is one of the main reasons why chemical recycling of waste tires is difficult.

Until now, waste tire recycling has mainly relied on pyrolysis or mechanical recycling methods. The pyrolysis method is a technology that decomposes polymer chains at high temperatures of 350-800°C to convert them into fuel oil, but it clearly has limitations such as high energy consumption, low selectivity, and the production of low-quality hydrocarbon mixtures.

To solve these problems, the research team developed a method to convert waste rubber into useful chemicals using dual catalysis. The first catalyst helps to break down rubber molecules by changing their bonding structure, and the second catalyst creates cyclic compounds through a ring-closing reaction.

This process shows high selectivity of up to 92% and a yield of 82%. The produced cyclopentene can be recycled into rubber, and cyclohexene can be used as a raw material for nylon fibers, making them industrially very valuable.

The research team successfully applied the developed system to discarded waste tires, achieving selective conversion into high-purity cyclic alkenes. Unlike the existing pyrolysis method, this is evaluated as a new turning point in the field of waste tire recycling as it can produce high-value chemicals through low-temperature precision catalytic reactions.

In addition, this catalytic platform is compatible with a wide range of synthetic and waste rubbers, positioning it as a promising foundation for scalable, circular solutions in the polymer and materials industries.

< Figure 1. Development of a Catalytic Method for Chemical Recycling of Waste Rubber >

Professor Hong stated, "This research offers an innovative solution for the chemical recycling of waste tires. We aim to develop next-generation high-efficiency catalysts and lay the groundwork for commercialization to enhance economic feasibility. Ultimately, our goal is to contribute to solving the broader waste plastic problem through fundamental chemistry."

This research, in which Beomsoon Park, Kyoungil Cho, and Kyungmin Choi participated, was supported by the National Research Foundation of Korea and was published online in the internationally renowned academic journal ‘Chem’ on June 18th.

※Paper Title: Catalytic and Selective Chemical Recycling of Post-Consumer Rubbers into Cycloalkenes

※DOI: 10.1016/j.chempr.2025.102625

2025.06.26 View 514 -

KAIST Succeeds in Real-Time Carbon Dioxide Monitoring Without Batteries or External Power

< (From left) Master's Student Gyurim Jang, Professor Kyeongha Kwon >

KAIST (President Kwang Hyung Lee) announced on June 9th that a research team led by Professor Kyeongha Kwon from the School of Electrical Engineering, in a joint study with Professor Hanjun Ryu's team at Chung-Ang University, has developed a self-powered wireless carbon dioxide (CO2) monitoring system. This innovative system harvests fine vibrational energy from its surroundings to periodically measure CO2 concentrations.

This breakthrough addresses a critical need in environmental monitoring: accurately understanding "how much" CO2 is being emitted to combat climate change and global warming. While CO2 monitoring technology is key to this, existing systems largely rely on batteries or wired power system, imposing limitations on installation and maintenance. The KAIST team tackled this by creating a self-powered wireless system that operates without external power.

The core of this new system is an "Inertia-driven Triboelectric Nanogenerator (TENG)" that converts vibrations (with amplitudes ranging from 20-4000 ㎛ and frequencies from 0-300 Hz) generated by industrial equipment or pipelines into electricity. This enables periodic CO2 concentration measurements and wireless transmission without the need for batteries.

< Figure 1. Concept and configuration of self-powered wireless CO2 monitoring system using fine vibration harvesting (a) System block diagram (b) Photo of fabricated system prototype >

The research team successfully amplified fine vibrations and induced resonance by combining spring-attached 4-stack TENGs. They achieved stable power production of 0.5 mW under conditions of 13 Hz and 0.56 g acceleration. The generated power was then used to operate a CO2 sensor and a Bluetooth Low Energy (BLE) system-on-a-chip (SoC).

Professor Kyeongha Kwon emphasized, "For efficient environmental monitoring, a system that can operate continuously without power limitations is essential." She explained, "In this research, we implemented a self-powered system that can periodically measure and wirelessly transmit CO2 concentrations based on the energy generated from an inertia-driven TENG." She added, "This technology can serve as a foundational technology for future self-powered environmental monitoring platforms integrating various sensors."

< Figure 2. TENG energy harvesting-based wireless CO2 sensing system operation results (c) Experimental setup (d) Measured CO2 concentration results powered by TENG and conventional DC power source >

This research was published on June 1st in the internationally renowned academic journal `Nano Energy (IF 16.8)`. Gyurim Jang, a master's student at KAIST, and Daniel Manaye Tiruneh, a master's student at Chung-Ang University, are the co-first authors of the paper.*Paper Title: Highly compact inertia-driven triboelectric nanogenerator for self-powered wireless CO2 monitoring via fine-vibration harvesting*DOI: 10.1016/j.nanoen.2025.110872

This research was supported by the Saudi Aramco-KAIST CO2 Management Center.

2025.06.09 View 46888

KAIST Succeeds in Real-Time Carbon Dioxide Monitoring Without Batteries or External Power

< (From left) Master's Student Gyurim Jang, Professor Kyeongha Kwon >

KAIST (President Kwang Hyung Lee) announced on June 9th that a research team led by Professor Kyeongha Kwon from the School of Electrical Engineering, in a joint study with Professor Hanjun Ryu's team at Chung-Ang University, has developed a self-powered wireless carbon dioxide (CO2) monitoring system. This innovative system harvests fine vibrational energy from its surroundings to periodically measure CO2 concentrations.

This breakthrough addresses a critical need in environmental monitoring: accurately understanding "how much" CO2 is being emitted to combat climate change and global warming. While CO2 monitoring technology is key to this, existing systems largely rely on batteries or wired power system, imposing limitations on installation and maintenance. The KAIST team tackled this by creating a self-powered wireless system that operates without external power.

The core of this new system is an "Inertia-driven Triboelectric Nanogenerator (TENG)" that converts vibrations (with amplitudes ranging from 20-4000 ㎛ and frequencies from 0-300 Hz) generated by industrial equipment or pipelines into electricity. This enables periodic CO2 concentration measurements and wireless transmission without the need for batteries.

< Figure 1. Concept and configuration of self-powered wireless CO2 monitoring system using fine vibration harvesting (a) System block diagram (b) Photo of fabricated system prototype >

The research team successfully amplified fine vibrations and induced resonance by combining spring-attached 4-stack TENGs. They achieved stable power production of 0.5 mW under conditions of 13 Hz and 0.56 g acceleration. The generated power was then used to operate a CO2 sensor and a Bluetooth Low Energy (BLE) system-on-a-chip (SoC).

Professor Kyeongha Kwon emphasized, "For efficient environmental monitoring, a system that can operate continuously without power limitations is essential." She explained, "In this research, we implemented a self-powered system that can periodically measure and wirelessly transmit CO2 concentrations based on the energy generated from an inertia-driven TENG." She added, "This technology can serve as a foundational technology for future self-powered environmental monitoring platforms integrating various sensors."

< Figure 2. TENG energy harvesting-based wireless CO2 sensing system operation results (c) Experimental setup (d) Measured CO2 concentration results powered by TENG and conventional DC power source >

This research was published on June 1st in the internationally renowned academic journal `Nano Energy (IF 16.8)`. Gyurim Jang, a master's student at KAIST, and Daniel Manaye Tiruneh, a master's student at Chung-Ang University, are the co-first authors of the paper.*Paper Title: Highly compact inertia-driven triboelectric nanogenerator for self-powered wireless CO2 monitoring via fine-vibration harvesting*DOI: 10.1016/j.nanoen.2025.110872

This research was supported by the Saudi Aramco-KAIST CO2 Management Center.

2025.06.09 View 46888 -

KAIST Professor Jee-Hwan Ryu Receives Global IEEE Robotics Journal Best Paper Award

- Professor Jee-Hwan Ryu of Civil and Environmental Engineering receives the Best Paper Award from the Institute of Electrical and Electronics Engineers (IEEE) Robotics Journal, officially presented at ICRA, a world-renowned robotics conference.

- This is the highest level of international recognition, awarded to only the top 5 papers out of approximately 1,500 published in 2024.

- Securing a new working channel technology for soft growing robots expands the practicality and application possibilities in the field of soft robotics.

< Professor Jee-Hwan Ryu (left), Nam Gyun Kim, Ph.D. Candidate (right) from the KAIST Department of Civil and Environmental Engineering and KAIST Robotics Program >

KAIST (President Kwang-Hyung Lee) announced on the 6th that Professor Jee-Hwan Ryu from the Department of Civil and Environmental Engineering received the 2024 Best Paper Award from the Robotics and Automation Letters (RA-L), a premier journal under the IEEE, at the '2025 IEEE International Conference on Robotics and Automation (ICRA)' held in Atlanta, USA, on May 22nd.

This Best Paper Award is a prestigious honor presented to only the top 5 papers out of approximately 1,500 published in 2024, boasting high international competition and authority.

The award-winning paper by Professor Ryu proposes a novel working channel securing mechanism that significantly expands the practicality and application possibilities of 'Soft Growing Robots,' which are based on soft materials that move or perform tasks through a growing motion similar to plant roots.

< IEEE Robotics Journal Award Ceremony >

Existing soft growing robots move by inflating or contracting their bodies through increasing or decreasing internal pressure, which can lead to blockages in their internal passages. In contrast, the newly developed soft growing robot achieves a growing function while maintaining the internal passage pressure equal to the external atmospheric pressure, thereby successfully securing an internal passage while retaining the robot's flexible and soft characteristics.

This structure allows various materials or tools to be freely delivered through the internal passage (working channel) within the robot and offers the advantage of performing multi-purpose tasks by flexibly replacing equipment according to the working environment.

The research team fabricated a prototype to prove the effectiveness of this technology and verified its performance through various experiments. Specifically, in the slide plate experiment, they confirmed whether materials or equipment could pass through the robot's internal channel without obstruction, and in the pipe pulling experiment, they verified if a long pipe-shaped tool could be pulled through the internal channel.

< Figure 1. Overall hardware structure of the proposed soft growing robot (left) and a cross-sectional view composing the inflatable structure (right) >

Experimental results demonstrated that the internal channel remained stable even while the robot was growing, serving as a key basis for supporting the technology's practicality and scalability.

Professor Jee-Hwan Ryu stated, "This award is very meaningful as it signifies the global recognition of Korea's robotics technology and academic achievements. Especially, it holds great significance in achieving technical progress that can greatly expand the practicality and application fields of soft growing robots. This achievement was possible thanks to the dedication and collaboration of the research team, and I will continue to contribute to the development of robotics technology through innovative research."

< Figure 2. Material supplying mechanism of the Soft Growing Robot >

This research was co-authored by Dongoh Seo, Ph.D. Candidate in Civil and Environmental Engineering, and Nam Gyun Kim, Ph.D. Candidate in Robotics. It was published in IEEE Robotics and Automation Letters on September 1, 2024.

(Paper Title: Inflatable-Structure-Based Working-Channel Securing Mechanism for Soft Growing Robots, DOI: 10.1109/LRA.2024.3426322)

This project was supported simultaneously by the National Research Foundation of Korea's Future Promising Convergence Technology Pioneer Research Project and Mid-career Researcher Project.

2025.06.09 View 1560

KAIST Professor Jee-Hwan Ryu Receives Global IEEE Robotics Journal Best Paper Award

- Professor Jee-Hwan Ryu of Civil and Environmental Engineering receives the Best Paper Award from the Institute of Electrical and Electronics Engineers (IEEE) Robotics Journal, officially presented at ICRA, a world-renowned robotics conference.

- This is the highest level of international recognition, awarded to only the top 5 papers out of approximately 1,500 published in 2024.

- Securing a new working channel technology for soft growing robots expands the practicality and application possibilities in the field of soft robotics.

< Professor Jee-Hwan Ryu (left), Nam Gyun Kim, Ph.D. Candidate (right) from the KAIST Department of Civil and Environmental Engineering and KAIST Robotics Program >

KAIST (President Kwang-Hyung Lee) announced on the 6th that Professor Jee-Hwan Ryu from the Department of Civil and Environmental Engineering received the 2024 Best Paper Award from the Robotics and Automation Letters (RA-L), a premier journal under the IEEE, at the '2025 IEEE International Conference on Robotics and Automation (ICRA)' held in Atlanta, USA, on May 22nd.

This Best Paper Award is a prestigious honor presented to only the top 5 papers out of approximately 1,500 published in 2024, boasting high international competition and authority.

The award-winning paper by Professor Ryu proposes a novel working channel securing mechanism that significantly expands the practicality and application possibilities of 'Soft Growing Robots,' which are based on soft materials that move or perform tasks through a growing motion similar to plant roots.

< IEEE Robotics Journal Award Ceremony >

Existing soft growing robots move by inflating or contracting their bodies through increasing or decreasing internal pressure, which can lead to blockages in their internal passages. In contrast, the newly developed soft growing robot achieves a growing function while maintaining the internal passage pressure equal to the external atmospheric pressure, thereby successfully securing an internal passage while retaining the robot's flexible and soft characteristics.

This structure allows various materials or tools to be freely delivered through the internal passage (working channel) within the robot and offers the advantage of performing multi-purpose tasks by flexibly replacing equipment according to the working environment.

The research team fabricated a prototype to prove the effectiveness of this technology and verified its performance through various experiments. Specifically, in the slide plate experiment, they confirmed whether materials or equipment could pass through the robot's internal channel without obstruction, and in the pipe pulling experiment, they verified if a long pipe-shaped tool could be pulled through the internal channel.

< Figure 1. Overall hardware structure of the proposed soft growing robot (left) and a cross-sectional view composing the inflatable structure (right) >

Experimental results demonstrated that the internal channel remained stable even while the robot was growing, serving as a key basis for supporting the technology's practicality and scalability.

Professor Jee-Hwan Ryu stated, "This award is very meaningful as it signifies the global recognition of Korea's robotics technology and academic achievements. Especially, it holds great significance in achieving technical progress that can greatly expand the practicality and application fields of soft growing robots. This achievement was possible thanks to the dedication and collaboration of the research team, and I will continue to contribute to the development of robotics technology through innovative research."

< Figure 2. Material supplying mechanism of the Soft Growing Robot >

This research was co-authored by Dongoh Seo, Ph.D. Candidate in Civil and Environmental Engineering, and Nam Gyun Kim, Ph.D. Candidate in Robotics. It was published in IEEE Robotics and Automation Letters on September 1, 2024.

(Paper Title: Inflatable-Structure-Based Working-Channel Securing Mechanism for Soft Growing Robots, DOI: 10.1109/LRA.2024.3426322)

This project was supported simultaneously by the National Research Foundation of Korea's Future Promising Convergence Technology Pioneer Research Project and Mid-career Researcher Project.

2025.06.09 View 1560 -

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

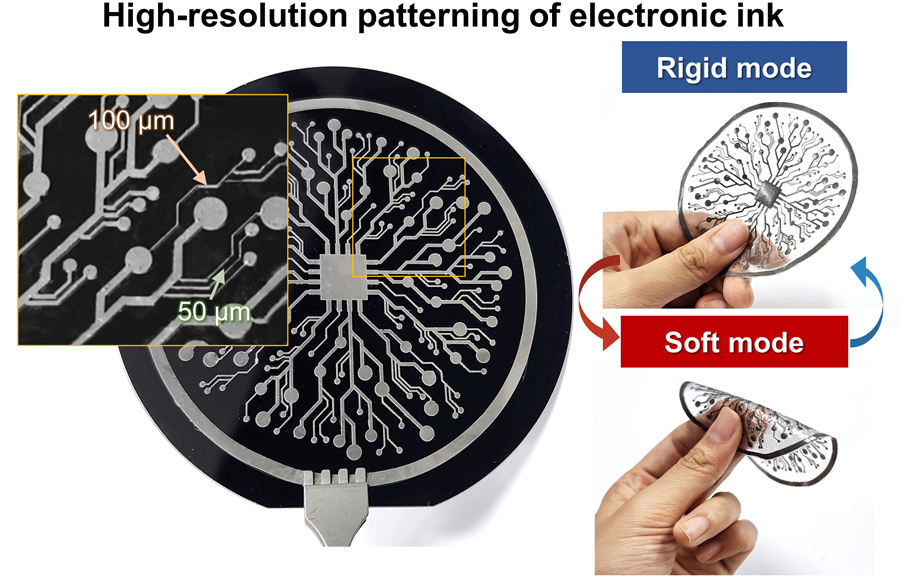

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 1886

KAIST Research Team Develops Electronic Ink for Room-Temperature Printing of High-Resolution, Variable-Stiffness Electronics

A team of researchers from KAIST and Seoul National University has developed a groundbreaking electronic ink that enables room-temperature printing of variable-stiffness circuits capable of switching between rigid and soft modes. This advancement marks a significant leap toward next-generation wearable, implantable, and robotic devices.

< Photo 1. (From left) Professor Jae-Woong Jeong and PhD candidate Simok Lee of the School of Electrical Engineering, (in separate bubbles, from left) Professor Gun-Hee Lee of Pusan National University, Professor Seongjun Park of Seoul National University, Professor Steve Park of the Department of Materials Science and Engineering>

Variable-stiffness electronics are at the forefront of adaptive technology, offering the ability for a single device to transition between rigid and soft modes depending on its use case. Gallium, a metal known for its high rigidity contrast between solid and liquid states, is a promising candidate for such applications. However, its use has been hindered by challenges including high surface tension, low viscosity, and undesirable phase transitions during manufacturing.

On June 4th, a research team led by Professor Jae-Woong Jeong from the School of Electrical Engineering at KAIST, Professor Seongjun Park from the Digital Healthcare Major at Seoul National University, and Professor Steve Park from the Department of Materials Science and Engineering at KAIST introduced a novel liquid metal electronic ink. This ink allows for micro-scale circuit printing – thinner than a human hair – at room temperature, with the ability to reversibly switch between rigid and soft modes depending on temperature.

The new ink combines printable viscosity with excellent electrical conductivity, enabling the creation of complex, high-resolution multilayer circuits comparable to commercial printed circuit boards (PCBs). These circuits can dynamically change stiffness in response to temperature, presenting new opportunities for multifunctional electronics, medical technologies, and robotics.

Conventional electronics typically have fixed form factors – either rigid for durability or soft for wearability. Rigid devices like smartphones and laptops offer robust performance but are uncomfortable when worn, while soft electronics are more comfortable but lack precise handling. As demand grows for devices that can adapt their stiffness to context, variable-stiffness electronics are becoming increasingly important.

< Figure 1. Fabrication process of stable, high-viscosity electronic ink by dispersing micro-sized gallium particles in a polymer matrix (left). High-resolution large-area circuit printing process through pH-controlled chemical sintering (right). >

To address this challenge, the researchers focused on gallium, which melts just below body temperature. Solid gallium is quite stiff, while its liquid form is fluid and soft. Despite its potential, gallium’s use in electronic printing has been limited by its high surface tension and instability when melted.

To overcome these issues, the team developed a pH-controlled liquid metal ink printing process. By dispersing micro-sized gallium particles into a hydrophilic polyurethane matrix using a neutral solvent (dimethyl sulfoxide, or DMSO), they created a stable, high-viscosity ink suitable for precision printing. During post-print heating, the DMSO decomposes to form an acidic environment, which removes the oxide layer on the gallium particles. This triggers the particles to coalesce into electrically conductive networks with tunable mechanical properties.

The resulting printed circuits exhibit fine feature sizes (~50 μm), high conductivity (2.27 × 10⁶ S/m), and a stiffness modulation ratio of up to 1,465 – allowing the material to shift from plastic-like rigidity to rubber-like softness. Furthermore, the ink is compatible with conventional printing techniques such as screen printing and dip coating, supporting large-area and 3D device fabrication.

< Figure 2. Key features of the electronic ink. (i) High-resolution printing and multilayer integration capability. (ii) Batch fabrication capability through large-area screen printing. (iii) Complex three-dimensional structure printing capability through dip coating. (iv) Excellent electrical conductivity and stiffness control capability.>

The team demonstrated this technology by developing a multi-functional device that operates as a rigid portable electronic under normal conditions but transforms into a soft wearable healthcare device when attached to the body. They also created a neural probe that remains stiff during surgical insertion for accurate positioning but softens once inside brain tissue to reduce inflammation – highlighting its potential for biomedical implants.

< Figure 3. Variable stiffness wearable electronics with high-resolution circuits and multilayer structure comparable to commercial printed circuit boards (PCBs). Functions as a rigid portable electronic device at room temperature, then transforms into a wearable healthcare device by softening at body temperature upon skin contact.>

“The core achievement of this research lies in overcoming the longstanding challenges of liquid metal printing through our innovative technology,” said Professor Jeong. “By controlling the ink’s acidity, we were able to electrically and mechanically connect printed gallium particles, enabling the room-temperature fabrication of high-resolution, large-area circuits with tunable stiffness. This opens up new possibilities for future personal electronics, medical devices, and robotics.”

< Figure 4. Body-temperature softening neural probe implemented by coating electronic ink on an optical waveguide structure. (Left) Remains rigid during surgery for precise manipulation and brain insertion, then softens after implantation to minimize mechanical stress on the brain and greatly enhance biocompatibility. (Right) >

This research was published in Science Advances under the title, “Phase-Change Metal Ink with pH-Controlled Chemical Sintering for Versatile and Scalable Fabrication of Variable Stiffness Electronics.” The work was supported by the National Research Foundation of Korea, the Boston-Korea Project, and the BK21 FOUR Program.

2025.06.04 View 1886 -

New 'Science Hall of Fame' Opens in Vision Hall, Highlighting Achievements of Modern and Contemporary Scientists

A portion of the existing exhibition space in the 'KAIST Vision Hall,' located at our university's main campus in Daejeon, has been reorganized as the 'KAIST Science Hall of Fame' and opened to the public.

Opened in March 2018 on the first floor of the Academic and Cultural Complex, the KAIST Vision Hall is a historical exhibition hall that has showcased KAIST's major history and research achievements from its establishment to the present. In particular, various materials that formed the foundation of KAIST's establishment are displayed, including the 'Survey Report on the Establishment of the Korea Advanced Institute of Science (also known as the Terman Report),' which was prepared through a due diligence conducted by the U.S. Agency for International Development (USAID) in 1970.

< Overall View of the Science Hall of Fame within Vision Hall >

Through this exhibition reorganization, Vision Hall has expanded its scope to not only trace KAIST's journey but also highlight prominent scientists who have made significant achievements across the entire Korean science and technology community.

The newly revamped 'KAIST Science Hall of Fame' consists of two main sections. The first section introduces modern and contemporary scientists who dedicated themselves to research even under challenging political and social conditions, such as during the Japanese colonial period. The second section focuses on the research achievements and international cooperation cases accomplished by KAIST researchers, built upon the efforts of these pioneering scientists.

< Overall View of the Science Hall of Fame within Vision Hall >

Professor Geun-bae Kim of the Department of Science at Jeonbuk National University, who advised on the exhibition reorganization, expressed his feelings, saying, "I am delighted that my efforts in researching modern and contemporary science history and the socio-history of science have been of even a small help in this reorganization of the KAIST Vision Hall exhibition."

Seung-Mok Son, Team Leader of the KAIST Arts & Culture Center, who oversaw the planning and operation of the exhibition space, stated, "This exhibition is a special composition that unpacks the history of Korean science through a human-centered narrative. We expect visitors to gain deep inspiration through the lives and visions of our scientific predecessors."

KAIST President Kwang-Hyung Lee remarked, "Just as a tall tree has deep roots, KAIST's ideals and achievements are rooted in the dedication of our scientific predecessors. We have newly established the Hall of Science and Technology Figures to honor their spirit and pass it on to future generations."

< Overall View of the Science Hall of Fame within Vision Hall >

Vision Hall operates from 10:00 AM to 5:00 PM on weekdays and is open to the general public as well as KAIST members free of charge. The newly established 'KAIST Science Hall of Fame' features actual exhibits such as research notes, historical photographs, degrees, newspaper articles, and handwritten manuscripts of pioneering scientists. Public viewing became available in the afternoon of the same day, following the opening ceremony held in the morning of the 2nd. More detailed information can be found on the official Vision Hall website: https://visionhall.kaist.ac.kr/.

※ Related Video: KAIST Science Hall of Fame Video at YouTube Channel "KAIST art museum" https://youtu.be/TlC93xMRfxU?si=3Lf0fzcWU3q1spKf

2025.06.02 View 198

New 'Science Hall of Fame' Opens in Vision Hall, Highlighting Achievements of Modern and Contemporary Scientists

A portion of the existing exhibition space in the 'KAIST Vision Hall,' located at our university's main campus in Daejeon, has been reorganized as the 'KAIST Science Hall of Fame' and opened to the public.

Opened in March 2018 on the first floor of the Academic and Cultural Complex, the KAIST Vision Hall is a historical exhibition hall that has showcased KAIST's major history and research achievements from its establishment to the present. In particular, various materials that formed the foundation of KAIST's establishment are displayed, including the 'Survey Report on the Establishment of the Korea Advanced Institute of Science (also known as the Terman Report),' which was prepared through a due diligence conducted by the U.S. Agency for International Development (USAID) in 1970.

< Overall View of the Science Hall of Fame within Vision Hall >

Through this exhibition reorganization, Vision Hall has expanded its scope to not only trace KAIST's journey but also highlight prominent scientists who have made significant achievements across the entire Korean science and technology community.

The newly revamped 'KAIST Science Hall of Fame' consists of two main sections. The first section introduces modern and contemporary scientists who dedicated themselves to research even under challenging political and social conditions, such as during the Japanese colonial period. The second section focuses on the research achievements and international cooperation cases accomplished by KAIST researchers, built upon the efforts of these pioneering scientists.

< Overall View of the Science Hall of Fame within Vision Hall >

Professor Geun-bae Kim of the Department of Science at Jeonbuk National University, who advised on the exhibition reorganization, expressed his feelings, saying, "I am delighted that my efforts in researching modern and contemporary science history and the socio-history of science have been of even a small help in this reorganization of the KAIST Vision Hall exhibition."

Seung-Mok Son, Team Leader of the KAIST Arts & Culture Center, who oversaw the planning and operation of the exhibition space, stated, "This exhibition is a special composition that unpacks the history of Korean science through a human-centered narrative. We expect visitors to gain deep inspiration through the lives and visions of our scientific predecessors."

KAIST President Kwang-Hyung Lee remarked, "Just as a tall tree has deep roots, KAIST's ideals and achievements are rooted in the dedication of our scientific predecessors. We have newly established the Hall of Science and Technology Figures to honor their spirit and pass it on to future generations."

< Overall View of the Science Hall of Fame within Vision Hall >

Vision Hall operates from 10:00 AM to 5:00 PM on weekdays and is open to the general public as well as KAIST members free of charge. The newly established 'KAIST Science Hall of Fame' features actual exhibits such as research notes, historical photographs, degrees, newspaper articles, and handwritten manuscripts of pioneering scientists. Public viewing became available in the afternoon of the same day, following the opening ceremony held in the morning of the 2nd. More detailed information can be found on the official Vision Hall website: https://visionhall.kaist.ac.kr/.

※ Related Video: KAIST Science Hall of Fame Video at YouTube Channel "KAIST art museum" https://youtu.be/TlC93xMRfxU?si=3Lf0fzcWU3q1spKf

2025.06.02 View 198 -

Professor Hyun Myung's Team Wins First Place in a Challenge at ICRA by IEEE

< Photo 1. (From left) Daebeom Kim (Team Leader, Ph.D. student), Seungjae Lee (Ph.D. student), Seoyeon Jang (Ph.D. student), Jei Kong (Master's student), Professor Hyun Myung >

A team of the Urban Robotics Lab, led by Professor Hyun Myung from the KAIST School of Electrical Engineering, achieved a remarkable first-place overall victory in the Nothing Stands Still Challenge (NSS Challenge) 2025, held at the 2025 IEEE International Conference on Robotics and Automation (ICRA), the world's most prestigious robotics conference, from May 19 to 23 in Atlanta, USA.

The NSS Challenge was co-hosted by HILTI, a global construction company based in Liechtenstein, and Stanford University's Gradient Spaces Group. It is an expanded version of the HILTI SLAM (Simultaneous Localization and Mapping)* Challenge, which has been held since 2021, and is considered one of the most prominent challenges at 2025 IEEE ICRA.*SLAM: Refers to Simultaneous Localization and Mapping, a technology where robots, drones, autonomous vehicles, etc., determine their own position and simultaneously create a map of their surroundings.

< Photo 2. A scene from the oral presentation on the winning team's technology (Speakers: Seungjae Lee and Seoyeon Jang, Ph.D. candidates of KAIST School of Electrical Engineering) >

This challenge primarily evaluates how accurately and robustly LiDAR scan data, collected at various times, can be registered in situations with frequent structural changes, such as construction and industrial environments. In particular, it is regarded as a highly technical competition because it deals with multi-session localization and mapping (Multi-session SLAM) technology that responds to structural changes occurring over multiple timeframes, rather than just single-point registration accuracy.

The Urban Robotics Lab team secured first place overall, surpassing National Taiwan University (3rd place) and Northwestern Polytechnical University of China (2nd place) by a significant margin, with their unique localization and mapping technology that solves the problem of registering LiDAR data collected across multiple times and spaces. The winning team will be awarded a prize of $4,000.

< Figure 1. Example of Multiway-Registration for Registering Multiple Scans >

The Urban Robotics Lab team independently developed a multiway-registration framework that can robustly register multiple scans even without prior connection information. This framework consists of an algorithm for summarizing feature points within scans and finding correspondences (CubicFeat), an algorithm for performing global registration based on the found correspondences (Quatro), and an algorithm for refining results based on change detection (Chamelion). This combination of technologies ensures stable registration performance based on fixed structures, even in highly dynamic industrial environments.

< Figure 2. Example of Change Detection Using the Chamelion Algorithm>

LiDAR scan registration technology is a core component of SLAM (Simultaneous Localization And Mapping) in various autonomous systems such as autonomous vehicles, autonomous robots, autonomous walking systems, and autonomous flying vehicles.

Professor Hyun Myung of the School of Electrical Engineering stated, "This award-winning technology is evaluated as a case that simultaneously proves both academic value and industrial applicability by maximizing the performance of precisely estimating the relative positions between different scans even in complex environments. I am grateful to the students who challenged themselves and never gave up, even when many teams abandoned due to the high difficulty."

< Figure 3. Competition Result Board, Lower RMSE (Root Mean Squared Error) Indicates Higher Score (Unit: meters)>

The Urban Robotics Lab team first participated in the SLAM Challenge in 2022, winning second place among academic teams, and in 2023, they secured first place overall in the LiDAR category and first place among academic teams in the vision category.

2025.05.30 View 2315

Professor Hyun Myung's Team Wins First Place in a Challenge at ICRA by IEEE

< Photo 1. (From left) Daebeom Kim (Team Leader, Ph.D. student), Seungjae Lee (Ph.D. student), Seoyeon Jang (Ph.D. student), Jei Kong (Master's student), Professor Hyun Myung >

A team of the Urban Robotics Lab, led by Professor Hyun Myung from the KAIST School of Electrical Engineering, achieved a remarkable first-place overall victory in the Nothing Stands Still Challenge (NSS Challenge) 2025, held at the 2025 IEEE International Conference on Robotics and Automation (ICRA), the world's most prestigious robotics conference, from May 19 to 23 in Atlanta, USA.

The NSS Challenge was co-hosted by HILTI, a global construction company based in Liechtenstein, and Stanford University's Gradient Spaces Group. It is an expanded version of the HILTI SLAM (Simultaneous Localization and Mapping)* Challenge, which has been held since 2021, and is considered one of the most prominent challenges at 2025 IEEE ICRA.*SLAM: Refers to Simultaneous Localization and Mapping, a technology where robots, drones, autonomous vehicles, etc., determine their own position and simultaneously create a map of their surroundings.

< Photo 2. A scene from the oral presentation on the winning team's technology (Speakers: Seungjae Lee and Seoyeon Jang, Ph.D. candidates of KAIST School of Electrical Engineering) >

This challenge primarily evaluates how accurately and robustly LiDAR scan data, collected at various times, can be registered in situations with frequent structural changes, such as construction and industrial environments. In particular, it is regarded as a highly technical competition because it deals with multi-session localization and mapping (Multi-session SLAM) technology that responds to structural changes occurring over multiple timeframes, rather than just single-point registration accuracy.

The Urban Robotics Lab team secured first place overall, surpassing National Taiwan University (3rd place) and Northwestern Polytechnical University of China (2nd place) by a significant margin, with their unique localization and mapping technology that solves the problem of registering LiDAR data collected across multiple times and spaces. The winning team will be awarded a prize of $4,000.

< Figure 1. Example of Multiway-Registration for Registering Multiple Scans >

The Urban Robotics Lab team independently developed a multiway-registration framework that can robustly register multiple scans even without prior connection information. This framework consists of an algorithm for summarizing feature points within scans and finding correspondences (CubicFeat), an algorithm for performing global registration based on the found correspondences (Quatro), and an algorithm for refining results based on change detection (Chamelion). This combination of technologies ensures stable registration performance based on fixed structures, even in highly dynamic industrial environments.

< Figure 2. Example of Change Detection Using the Chamelion Algorithm>

LiDAR scan registration technology is a core component of SLAM (Simultaneous Localization And Mapping) in various autonomous systems such as autonomous vehicles, autonomous robots, autonomous walking systems, and autonomous flying vehicles.

Professor Hyun Myung of the School of Electrical Engineering stated, "This award-winning technology is evaluated as a case that simultaneously proves both academic value and industrial applicability by maximizing the performance of precisely estimating the relative positions between different scans even in complex environments. I am grateful to the students who challenged themselves and never gave up, even when many teams abandoned due to the high difficulty."

< Figure 3. Competition Result Board, Lower RMSE (Root Mean Squared Error) Indicates Higher Score (Unit: meters)>

The Urban Robotics Lab team first participated in the SLAM Challenge in 2022, winning second place among academic teams, and in 2023, they secured first place overall in the LiDAR category and first place among academic teams in the vision category.

2025.05.30 View 2315 -

KAIST Develops Virtual Staining Technology for 3D Histopathology

Moving beyond traditional methods of observing thinly sliced and stained cancer tissues, a collaborative international research team led by KAIST has successfully developed a groundbreaking technology. This innovation uses advanced optical techniques combined with an artificial intelligence-based deep learning algorithm to create realistic, virtually stained 3D images of cancer tissue without the need for serial sectioning nor staining. This breakthrough is anticipated to pave the way for next-generation non-invasive pathological diagnosis.

< Photo 1. (From left) Juyeon Park (Ph.D. Candidate, Department of Physics), Professor YongKeun Park (Department of Physics) (Top left) Professor Su-Jin Shin (Gangnam Severance Hospital), Professor Tae Hyun Hwang (Vanderbilt University School of Medicine) >

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor YongKeun Park of the Department of Physics, in collaboration with Professor Su-Jin Shin's team at Yonsei University Gangnam Severance Hospital, Professor Tae Hyun Hwang's team at Mayo Clinic, and Tomocube's AI research team, has developed an innovative technology capable of vividly displaying the 3D structure of cancer tissues without separate staining.

For over 200 years, conventional pathology has relied on observing cancer tissues under a microscope, a method that only shows specific cross-sections of the 3D cancer tissue. This has limited the ability to understand the three-dimensional connections and spatial arrangements between cells.

To overcome this, the research team utilized holotomography (HT), an advanced optical technology, to measure the 3D refractive index information of tissues. They then integrated an AI-based deep learning algorithm to successfully generate virtual H&E* images.* H&E (Hematoxylin & Eosin): The most widely used staining method for observing pathological tissues. Hematoxylin stains cell nuclei blue, and eosin stains cytoplasm pink.

The research team quantitatively demonstrated that the images generated by this technology are highly similar to actual stained tissue images. Furthermore, the technology exhibited consistent performance across various organs and tissues, proving its versatility and reliability as a next-generation pathological analysis tool.

< Figure 1. Comparison of conventional 3D tissue pathology procedure and the 3D virtual H&E staining technology proposed in this study. The traditional method requires preparing and staining dozens of tissue slides, while the proposed technology can reduce the number of slides by up to 10 times and quickly generate H&E images without the staining process. >

Moreover, by validating the feasibility of this technology through joint research with hospitals and research institutions in Korea and the United States, utilizing Tomocube's holotomography equipment, the team demonstrated its potential for full-scale adoption in real-world pathological research settings.

Professor YongKeun Park stated, "This research marks a major advancement by transitioning pathological analysis from conventional 2D methods to comprehensive 3D imaging. It will greatly enhance biomedical research and clinical diagnostics, particularly in understanding cancer tumor boundaries and the intricate spatial arrangements of cells within tumor microenvironments."

< Figure 2. Results of AI-based 3D virtual H&E staining and quantitative analysis of pathological tissue. The virtually stained images enabled 3D reconstruction of key pathological features such as cell nuclei and glandular lumens. Based on this, various quantitative indicators, including cell nuclear distribution, volume, and surface area, could be extracted. >

This research, with Juyeon Park, a student of the Integrated Master’s and Ph.D. Program at KAIST, as the first author, was published online in the prestigious journal Nature Communications on May 22.

(Paper title: Revealing 3D microanatomical structures of unlabeled thick cancer tissues using holotomography and virtual H&E staining.

[https://doi.org/10.1038/s41467-025-59820-0]

This study was supported by the Leader Researcher Program of the National Research Foundation of Korea, the Global Industry Technology Cooperation Center Project of the Korea Institute for Advancement of Technology, and the Korea Health Industry Development Institute.

2025.05.26 View 2554

KAIST Develops Virtual Staining Technology for 3D Histopathology

Moving beyond traditional methods of observing thinly sliced and stained cancer tissues, a collaborative international research team led by KAIST has successfully developed a groundbreaking technology. This innovation uses advanced optical techniques combined with an artificial intelligence-based deep learning algorithm to create realistic, virtually stained 3D images of cancer tissue without the need for serial sectioning nor staining. This breakthrough is anticipated to pave the way for next-generation non-invasive pathological diagnosis.

< Photo 1. (From left) Juyeon Park (Ph.D. Candidate, Department of Physics), Professor YongKeun Park (Department of Physics) (Top left) Professor Su-Jin Shin (Gangnam Severance Hospital), Professor Tae Hyun Hwang (Vanderbilt University School of Medicine) >

KAIST (President Kwang Hyung Lee) announced on the 26th that a research team led by Professor YongKeun Park of the Department of Physics, in collaboration with Professor Su-Jin Shin's team at Yonsei University Gangnam Severance Hospital, Professor Tae Hyun Hwang's team at Mayo Clinic, and Tomocube's AI research team, has developed an innovative technology capable of vividly displaying the 3D structure of cancer tissues without separate staining.

For over 200 years, conventional pathology has relied on observing cancer tissues under a microscope, a method that only shows specific cross-sections of the 3D cancer tissue. This has limited the ability to understand the three-dimensional connections and spatial arrangements between cells.

To overcome this, the research team utilized holotomography (HT), an advanced optical technology, to measure the 3D refractive index information of tissues. They then integrated an AI-based deep learning algorithm to successfully generate virtual H&E* images.* H&E (Hematoxylin & Eosin): The most widely used staining method for observing pathological tissues. Hematoxylin stains cell nuclei blue, and eosin stains cytoplasm pink.

The research team quantitatively demonstrated that the images generated by this technology are highly similar to actual stained tissue images. Furthermore, the technology exhibited consistent performance across various organs and tissues, proving its versatility and reliability as a next-generation pathological analysis tool.

< Figure 1. Comparison of conventional 3D tissue pathology procedure and the 3D virtual H&E staining technology proposed in this study. The traditional method requires preparing and staining dozens of tissue slides, while the proposed technology can reduce the number of slides by up to 10 times and quickly generate H&E images without the staining process. >

Moreover, by validating the feasibility of this technology through joint research with hospitals and research institutions in Korea and the United States, utilizing Tomocube's holotomography equipment, the team demonstrated its potential for full-scale adoption in real-world pathological research settings.

Professor YongKeun Park stated, "This research marks a major advancement by transitioning pathological analysis from conventional 2D methods to comprehensive 3D imaging. It will greatly enhance biomedical research and clinical diagnostics, particularly in understanding cancer tumor boundaries and the intricate spatial arrangements of cells within tumor microenvironments."

< Figure 2. Results of AI-based 3D virtual H&E staining and quantitative analysis of pathological tissue. The virtually stained images enabled 3D reconstruction of key pathological features such as cell nuclei and glandular lumens. Based on this, various quantitative indicators, including cell nuclear distribution, volume, and surface area, could be extracted. >

This research, with Juyeon Park, a student of the Integrated Master’s and Ph.D. Program at KAIST, as the first author, was published online in the prestigious journal Nature Communications on May 22.

(Paper title: Revealing 3D microanatomical structures of unlabeled thick cancer tissues using holotomography and virtual H&E staining.

[https://doi.org/10.1038/s41467-025-59820-0]

This study was supported by the Leader Researcher Program of the National Research Foundation of Korea, the Global Industry Technology Cooperation Center Project of the Korea Institute for Advancement of Technology, and the Korea Health Industry Development Institute.

2025.05.26 View 2554 -

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 3033

KAIST to Develop a Korean-style ChatGPT Platform Specifically Geared Toward Medical Diagnosis and Drug Discovery

On May 23rd, KAIST (President Kwang-Hyung Lee) announced that its Digital Bio-Health AI Research Center (Director: Professor JongChul Ye of KAIST Kim Jaechul Graduate School of AI) has been selected for the Ministry of Science and ICT's 'AI Top-Tier Young Researcher Support Program (AI Star Fellowship Project).' With a total investment of ₩11.5 billion from May 2025 to December 2030, the center will embark on the full-scale development of AI technology and a platform capable of independently inferring and determining the kinds of diseases, and discovering new drugs.

< Photo. On May 20th, a kick-off meeting for the AI Star Fellowship Project was held at KAIST Kim Jaechul Graduate School of AI’s Yangjae Research Center with the KAIST research team and participating organizations of Samsung Medical Center, NAVER Cloud, and HITS. [From left to right in the front row] Professor Jaegul Joo (KAIST), Professor Yoonjae Choi (KAIST), Professor Woo Youn Kim (KAIST/HITS), Professor JongChul Ye (KAIST), Professor Sungsoo Ahn (KAIST), Dr. Haanju Yoo (NAVER Cloud), Yoonho Lee (KAIST), HyeYoon Moon (Samsung Medical Center), Dr. Su Min Kim (Samsung Medical Center) >

This project aims to foster an innovative AI research ecosystem centered on young researchers and develop an inferential AI agent that can utilize and automatically expand specialized knowledge systems in the bio and medical fields.

Professor JongChul Ye of the Kim Jaechul Graduate School of AI will serve as the lead researcher, with young researchers from KAIST including Professors Yoonjae Choi, Kimin Lee, Sungsoo Ahn, and Chanyoung Park, along with mid-career researchers like Professors Jaegul Joo and Woo Youn Kim, jointly undertaking the project. They will collaborate with various laboratories within KAIST to conduct comprehensive research covering the entire cycle from the theoretical foundations of AI inference to its practical application.

Specifically, the main goals include: - Building high-performance inference models that integrate diverse medical knowledge systems to enhance the precision and reliability of diagnosis and treatment. - Developing a convergence inference platform that efficiently combines symbol-based inference with neural network models. - Securing AI technology for new drug development and biomarker discovery based on 'cell ontology.'

Furthermore, through close collaboration with industry and medical institutions such as Samsung Medical Center, NAVER Cloud, and HITS Co., Ltd., the project aims to achieve: - Clinical diagnostic AI utilizing medical knowledge systems. - AI-based molecular target exploration for new drug development. - Commercialization of an extendible AI inference platform.

Professor JongChul Ye, Director of KAIST's Digital Bio-Health AI Research Center, stated, "At a time when competition in AI inference model development is intensifying, it is a great honor for KAIST to lead the development of AI technology specialized in the bio and medical fields with world-class young researchers." He added, "We will do our best to ensure that the participating young researchers reach a world-leading level in terms of research achievements after the completion of this seven-year project starting in 2025."

The AI Star Fellowship is a newly established program where post-doctoral researchers and faculty members within seven years of appointment participate as project leaders (PLs) to independently lead research. Multiple laboratories within a university and demand-side companies form a consortium to operate the program.

Through this initiative, KAIST plans to nurture bio-medical convergence AI talent and simultaneously promote the commercialization of core technologies in collaboration with Samsung Medical Center, NAVER Cloud, and HITS.

2025.05.26 View 3033 -

“For the First Time, We Shared a Meaningful Exchange”: KAIST Develops an AI App for Parents and Minimally Verbal Autistic Children Connect

• KAIST team up with NAVER AI Lab and Dodakim Child Development Center Develop ‘AAcessTalk’, an AI-driven Communication Tool bridging the gap Between Children with Autism and their Parents

• The project earned the prestigious Best Paper Award at the ACM CHI 2025, the Premier International Conference in Human-Computer Interaction

• Families share heartwarming stories of breakthrough communication and newfound understanding.

< Photo 1. (From left) Professor Hwajung Hong and Doctoral candidate Dasom Choi of the Department of Industrial Design with SoHyun Park and Young-Ho Kim of Naver Cloud AI Lab >

For many families of minimally verbal autistic (MVA) children, communication often feels like an uphill battle. But now, thanks to a new AI-powered app developed by researchers at KAIST in collaboration with NAVER AI Lab and Dodakim Child Development Center, parents are finally experiencing moments of genuine connection with their children.

On the 16th, the KAIST (President Kwang Hyung Lee) research team, led by Professor Hwajung Hong of the Department of Industrial Design, announced the development of ‘AAcessTalk,’ an artificial intelligence (AI)-based communication tool that enables genuine communication between children with autism and their parents.

This research was recognized for its human-centered AI approach and received international attention, earning the Best Paper Award at the ACM CHI 2025*, an international conference held in Yokohama, Japan.*ACM CHI (ACM Conference on Human Factors in Computing Systems) 2025: One of the world's most prestigious academic conference in the field of Human-Computer Interaction (HCI).

This year, approximately 1,200 papers were selected out of about 5,000 submissions, with the Best Paper Award given to only the top 1%. The conference, which drew over 5,000 researchers, was the largest in its history, reflecting the growing interest in ‘Human-AI Interaction.’

Called AACessTalk, the app offers personalized vocabulary cards tailored to each child’s interests and context, while guiding parents through conversations with customized prompts. This creates a space where children’s voices can finally be heard—and where parents and children can connect on a deeper level.

Traditional augmentative and alternative communication (AAC) tools have relied heavily on fixed card systems that often fail to capture the subtle emotions and shifting interests of children with autism. AACessTalk breaks new ground by integrating AI technology that adapts in real time to the child’s mood and environment.

< Figure. Schematics of AACessTalk system. It provides personalized vocabulary cards for children with autism and context-based conversation guides for parents to focus on practical communication. Large ‘Turn Pass Button’ is placed at the child’s side to allow the child to lead the conversation. >

Among its standout features is a large ‘Turn Pass Button’ that gives children control over when to start or end conversations—allowing them to lead with agency. Another feature, the “What about Mom/Dad?” button, encourages children to ask about their parents’ thoughts, fostering mutual engagement in dialogue, something many children had never done before.

One parent shared, “For the first time, we shared a meaningful exchange.” Such stories were common among the 11 families who participated in a two-week pilot study, where children used the app to take more initiative in conversations and parents discovered new layers of their children’s language abilities.

Parents also reported moments of surprise and joy when their children used unexpected words or took the lead in conversations, breaking free from repetitive patterns. “I was amazed when my child used a word I hadn’t heard before. It helped me understand them in a whole new way,” recalled one caregiver.

Professor Hwajung Hong, who led the research at KAIST’s Department of Industrial Design, emphasized the importance of empowering children to express their own voices. “This study shows that AI can be more than a communication aid—it can be a bridge to genuine connection and understanding within families,” she said.

Looking ahead, the team plans to refine and expand human-centered AI technologies that honor neurodiversity, with a focus on bringing practical solutions to socially vulnerable groups and enriching user experiences.

This research is the result of KAIST Department of Industrial Design doctoral student Dasom Choi's internship at NAVER AI Lab.* Thesis Title: AACessTalk: Fostering Communication between Minimally Verbal Autistic Children and Parents with Contextual Guidance and Card Recommendation* DOI: 10.1145/3706598.3713792* Main Author Information: Dasom Choi (KAIST, NAVER AI Lab, First Author), SoHyun Park (NAVER AI Lab) , Kyungah Lee (Dodakim Child Development Center), Hwajung Hong (KAIST), and Young-Ho Kim (NAVER AI Lab, Corresponding Author)

This research was supported by the NAVER AI Lab internship program and grants from the National Research Foundation of Korea: the Doctoral Student Research Encouragement Grant (NRF-2024S1A5B5A19043580) and the Mid-Career Researcher Support Program for the Development of a Generative AI-Based Augmentative and Alternative Communication System for Autism Spectrum Disorder (RS-2024-00458557).

2025.05.19 View 3460

“For the First Time, We Shared a Meaningful Exchange”: KAIST Develops an AI App for Parents and Minimally Verbal Autistic Children Connect

• KAIST team up with NAVER AI Lab and Dodakim Child Development Center Develop ‘AAcessTalk’, an AI-driven Communication Tool bridging the gap Between Children with Autism and their Parents

• The project earned the prestigious Best Paper Award at the ACM CHI 2025, the Premier International Conference in Human-Computer Interaction

• Families share heartwarming stories of breakthrough communication and newfound understanding.

< Photo 1. (From left) Professor Hwajung Hong and Doctoral candidate Dasom Choi of the Department of Industrial Design with SoHyun Park and Young-Ho Kim of Naver Cloud AI Lab >

For many families of minimally verbal autistic (MVA) children, communication often feels like an uphill battle. But now, thanks to a new AI-powered app developed by researchers at KAIST in collaboration with NAVER AI Lab and Dodakim Child Development Center, parents are finally experiencing moments of genuine connection with their children.

On the 16th, the KAIST (President Kwang Hyung Lee) research team, led by Professor Hwajung Hong of the Department of Industrial Design, announced the development of ‘AAcessTalk,’ an artificial intelligence (AI)-based communication tool that enables genuine communication between children with autism and their parents.

This research was recognized for its human-centered AI approach and received international attention, earning the Best Paper Award at the ACM CHI 2025*, an international conference held in Yokohama, Japan.*ACM CHI (ACM Conference on Human Factors in Computing Systems) 2025: One of the world's most prestigious academic conference in the field of Human-Computer Interaction (HCI).

This year, approximately 1,200 papers were selected out of about 5,000 submissions, with the Best Paper Award given to only the top 1%. The conference, which drew over 5,000 researchers, was the largest in its history, reflecting the growing interest in ‘Human-AI Interaction.’

Called AACessTalk, the app offers personalized vocabulary cards tailored to each child’s interests and context, while guiding parents through conversations with customized prompts. This creates a space where children’s voices can finally be heard—and where parents and children can connect on a deeper level.

Traditional augmentative and alternative communication (AAC) tools have relied heavily on fixed card systems that often fail to capture the subtle emotions and shifting interests of children with autism. AACessTalk breaks new ground by integrating AI technology that adapts in real time to the child’s mood and environment.

< Figure. Schematics of AACessTalk system. It provides personalized vocabulary cards for children with autism and context-based conversation guides for parents to focus on practical communication. Large ‘Turn Pass Button’ is placed at the child’s side to allow the child to lead the conversation. >

Among its standout features is a large ‘Turn Pass Button’ that gives children control over when to start or end conversations—allowing them to lead with agency. Another feature, the “What about Mom/Dad?” button, encourages children to ask about their parents’ thoughts, fostering mutual engagement in dialogue, something many children had never done before.

One parent shared, “For the first time, we shared a meaningful exchange.” Such stories were common among the 11 families who participated in a two-week pilot study, where children used the app to take more initiative in conversations and parents discovered new layers of their children’s language abilities.

Parents also reported moments of surprise and joy when their children used unexpected words or took the lead in conversations, breaking free from repetitive patterns. “I was amazed when my child used a word I hadn’t heard before. It helped me understand them in a whole new way,” recalled one caregiver.

Professor Hwajung Hong, who led the research at KAIST’s Department of Industrial Design, emphasized the importance of empowering children to express their own voices. “This study shows that AI can be more than a communication aid—it can be a bridge to genuine connection and understanding within families,” she said.

Looking ahead, the team plans to refine and expand human-centered AI technologies that honor neurodiversity, with a focus on bringing practical solutions to socially vulnerable groups and enriching user experiences.

This research is the result of KAIST Department of Industrial Design doctoral student Dasom Choi's internship at NAVER AI Lab.* Thesis Title: AACessTalk: Fostering Communication between Minimally Verbal Autistic Children and Parents with Contextual Guidance and Card Recommendation* DOI: 10.1145/3706598.3713792* Main Author Information: Dasom Choi (KAIST, NAVER AI Lab, First Author), SoHyun Park (NAVER AI Lab) , Kyungah Lee (Dodakim Child Development Center), Hwajung Hong (KAIST), and Young-Ho Kim (NAVER AI Lab, Corresponding Author)

This research was supported by the NAVER AI Lab internship program and grants from the National Research Foundation of Korea: the Doctoral Student Research Encouragement Grant (NRF-2024S1A5B5A19043580) and the Mid-Career Researcher Support Program for the Development of a Generative AI-Based Augmentative and Alternative Communication System for Autism Spectrum Disorder (RS-2024-00458557).

2025.05.19 View 3460 -