Department+of+mechanical+engineering

-

KAIST Develops Customized Tactile Sensor That Can Detect Light Breath, Pressure and Sound

< Photo 1. (From left) Professor Inkyu Park of KAIST Department of Mechanical Engineering (ME), Dr. Jungrak Choi of ETRI, Ph.D. Candidate Donho Lee and M.S. Graduate Chankyu Han of KAIST ME >

When a robot grabs an object or a medical device detects a pulse, the tactile sensor is the technology that senses pressure like a fingertip. Existing sensors had disadvantages, such as slow responses or declining accuracy after repeated use, but Korean researchers have succeeded in developing a sensor that can quickly and accurately detect even light breath, pressure, and sound. This sensor can be used across a broad range — from everyday movements to medical diagnostics.

KAIST (represented by President Kwang Hyung Lee) announced on the 23rd of June that Professor Inkyu Park’s team from the Department of Mechanical Engineering, through a collaborative research project with the Electronics and Telecommunications Research Institute (ETRI, President Seung Chan Bang ) under the National Research Council of Science & Technology (NST, Chairman Young Sik Kim), has developed an innovative technology that overcomes the structural limitations of existing tactile sensors.

The core of this joint research is the implementation of a customized tactile sensor that simultaneously achieves flexibility, precision, and repeatable durability by applying Thermoformed 3D Electronics (T3DE).

< Figure 1. Comparative evaluation of soft elastomer–based 3D structure versus thermoforming-based 3D structure in terms of mechanical properties. >

In particular, soft elastomer-based sensors (rubber, silicone, etc. — materials that stretch and return to their original shape) have structural problems such as slow response times, high hysteresis*, and creep**, but this new platform operates precisely in diverse environments and overcomes these limitations.

*Hysteresis: A phenomenon where the previously applied force or change is retained like a “memory,” so that the same stimulus does not always produce the same result.

**Creep: The phenomenon where a material slowly deforms when a force is continuously applied.

T3DE sensors are manufactured by precisely forming electrodes on a 2D film, then thermoforming them into a 3D structure under heat and pressure. Specifically, the top electrodes and supporting pillar structures of the sensor are designed to allow the fine-tuning of the mechanical properties for different purposes. By adjusting microstructural parameters — such as the thickness, length, and number of support pillars — the sensor’s Young’s modulus* can be tuned across a broad range of 10 Pa to 1 MPa. This matches the stiffness of biological tissues like skin, muscle, and tendons, making them highly suitable as bio-interface sensors.

*Young’s modulus: An index representing a material's stiffness; this research can control this index to match various biological tissues.

The newly developed T3DE sensor uses air as a dielectric material to reduce power consumption and demonstrates outstanding performance in sensitivity, response time, thermal stability, and repeatable accuracy.

Experimental results showed that the sensor achieved △sensitivity of 5,884 kPa⁻¹, △response time of 0.1 ms (less than one-thousandth of a second), △hysteresis of less than 0.5%, and maintained a repeatable precision of 99.9% or higher even after 5,000 repeated measurements.

< Figure 2. Graphic Overview of thermoformed 3D electronics (T3DE) >

The research team also constructed a high-resolution 40×70 array, comprising a total of 2,800 densely packed sensors, to visualize the pressure distribution on the sole of the foot in real time during exercise and confirmed the possibility of using the sensor for wrist pulse measurement to assess vascular health. Furthermore, successful results were also achieved in sound-detection experiments at a level comparable to commercial acoustic sensors. In short, the sensor can precisely and quickly measure foot pressure, pulse, and sound, allowing it to be applied in areas such as sports, health, and sound sensing.

The T3DE technology was also applied to an augmented-reality(AR)-based surgical training system. By adjusting the stiffness of each sensor element to match that of biological tissues, the system provided real-time visual and tactile feedback according to the pressure applied during surgical incisions. It also offered real-time warnings if an incision was too deep or approached a risky area, making it a promising technology for enhancing immersion and accuracy in medical training.

KAIST Professor Inkyu Park stated, “Because this sensor can be precisely tuned from the design stage and operates reliably across diverse environments, it can be used not only in everyday life, but also in a variety of fields such as healthcare, rehabilitation, and virtual reality.”

The research was co-led as first authors by Dr. Jungrak Choi of ETRI, KAIST master’s student Chankyu Han, and Ph.D. candidate Donho Lee, under the overall guidance of Professor Inkyu Park. The research results were published in the May 2025 issue of ‘Science Advances’ and introduced to the global research community through the journal’s official SNS channels (Facebook, Twitter).

※ Thesis Title: Thermoforming 2D films into 3D electronics for high-performance, customizable tactile sensing

※ DOI: 10.1126/sciadv.adv0057

< Figure 3. The introduction of the study on the official SNS posting by Science Advances >

This research was supported by the Ministry of Trade, Industry and Energy, the National Research Foundation of Korea, and the Korea Institute for Advancement of Technology.

2025.06.23 View 1580

KAIST Develops Customized Tactile Sensor That Can Detect Light Breath, Pressure and Sound

< Photo 1. (From left) Professor Inkyu Park of KAIST Department of Mechanical Engineering (ME), Dr. Jungrak Choi of ETRI, Ph.D. Candidate Donho Lee and M.S. Graduate Chankyu Han of KAIST ME >

When a robot grabs an object or a medical device detects a pulse, the tactile sensor is the technology that senses pressure like a fingertip. Existing sensors had disadvantages, such as slow responses or declining accuracy after repeated use, but Korean researchers have succeeded in developing a sensor that can quickly and accurately detect even light breath, pressure, and sound. This sensor can be used across a broad range — from everyday movements to medical diagnostics.

KAIST (represented by President Kwang Hyung Lee) announced on the 23rd of June that Professor Inkyu Park’s team from the Department of Mechanical Engineering, through a collaborative research project with the Electronics and Telecommunications Research Institute (ETRI, President Seung Chan Bang ) under the National Research Council of Science & Technology (NST, Chairman Young Sik Kim), has developed an innovative technology that overcomes the structural limitations of existing tactile sensors.

The core of this joint research is the implementation of a customized tactile sensor that simultaneously achieves flexibility, precision, and repeatable durability by applying Thermoformed 3D Electronics (T3DE).

< Figure 1. Comparative evaluation of soft elastomer–based 3D structure versus thermoforming-based 3D structure in terms of mechanical properties. >

In particular, soft elastomer-based sensors (rubber, silicone, etc. — materials that stretch and return to their original shape) have structural problems such as slow response times, high hysteresis*, and creep**, but this new platform operates precisely in diverse environments and overcomes these limitations.

*Hysteresis: A phenomenon where the previously applied force or change is retained like a “memory,” so that the same stimulus does not always produce the same result.

**Creep: The phenomenon where a material slowly deforms when a force is continuously applied.

T3DE sensors are manufactured by precisely forming electrodes on a 2D film, then thermoforming them into a 3D structure under heat and pressure. Specifically, the top electrodes and supporting pillar structures of the sensor are designed to allow the fine-tuning of the mechanical properties for different purposes. By adjusting microstructural parameters — such as the thickness, length, and number of support pillars — the sensor’s Young’s modulus* can be tuned across a broad range of 10 Pa to 1 MPa. This matches the stiffness of biological tissues like skin, muscle, and tendons, making them highly suitable as bio-interface sensors.

*Young’s modulus: An index representing a material's stiffness; this research can control this index to match various biological tissues.

The newly developed T3DE sensor uses air as a dielectric material to reduce power consumption and demonstrates outstanding performance in sensitivity, response time, thermal stability, and repeatable accuracy.

Experimental results showed that the sensor achieved △sensitivity of 5,884 kPa⁻¹, △response time of 0.1 ms (less than one-thousandth of a second), △hysteresis of less than 0.5%, and maintained a repeatable precision of 99.9% or higher even after 5,000 repeated measurements.

< Figure 2. Graphic Overview of thermoformed 3D electronics (T3DE) >

The research team also constructed a high-resolution 40×70 array, comprising a total of 2,800 densely packed sensors, to visualize the pressure distribution on the sole of the foot in real time during exercise and confirmed the possibility of using the sensor for wrist pulse measurement to assess vascular health. Furthermore, successful results were also achieved in sound-detection experiments at a level comparable to commercial acoustic sensors. In short, the sensor can precisely and quickly measure foot pressure, pulse, and sound, allowing it to be applied in areas such as sports, health, and sound sensing.

The T3DE technology was also applied to an augmented-reality(AR)-based surgical training system. By adjusting the stiffness of each sensor element to match that of biological tissues, the system provided real-time visual and tactile feedback according to the pressure applied during surgical incisions. It also offered real-time warnings if an incision was too deep or approached a risky area, making it a promising technology for enhancing immersion and accuracy in medical training.

KAIST Professor Inkyu Park stated, “Because this sensor can be precisely tuned from the design stage and operates reliably across diverse environments, it can be used not only in everyday life, but also in a variety of fields such as healthcare, rehabilitation, and virtual reality.”

The research was co-led as first authors by Dr. Jungrak Choi of ETRI, KAIST master’s student Chankyu Han, and Ph.D. candidate Donho Lee, under the overall guidance of Professor Inkyu Park. The research results were published in the May 2025 issue of ‘Science Advances’ and introduced to the global research community through the journal’s official SNS channels (Facebook, Twitter).

※ Thesis Title: Thermoforming 2D films into 3D electronics for high-performance, customizable tactile sensing

※ DOI: 10.1126/sciadv.adv0057

< Figure 3. The introduction of the study on the official SNS posting by Science Advances >

This research was supported by the Ministry of Trade, Industry and Energy, the National Research Foundation of Korea, and the Korea Institute for Advancement of Technology.

2025.06.23 View 1580 -

RAIBO Runs over Walls with Feline Agility... Ready for Effortless Search over Mountaineous and Rough Terrains

< Photo 1. Research Team Photo (Professor Jemin Hwangbo, second from right in the front row) >

KAIST's quadrupedal robot, RAIBO, can now move at high speed across discontinuous and complex terrains such as stairs, gaps, walls, and debris. It has demonstrated its ability to run on vertical walls, leap over 1.3-meter-wide gaps, sprint at approximately 14.4 km/h over stepping stones, and move quickly and nimbly on terrain combining 30° slopes, stairs, and stepping stones. RAIBO is expected to be deployed soon for practical missions such as disaster site exploration and mountain searches.

Professor Jemin Hwangbo's research team in the Department of Mechanical Engineering at our university announced on June 3rd that they have developed a quadrupedal robot navigation framework capable of high-speed locomotion at 14.4 km/h (4m/s) even on discontinuous and complex terrains such as walls, stairs, and stepping stones.

The research team developed a quadrupedal navigation system that enables the robot to reach its target destination quickly and safely in complex and discontinuous terrain.

To achieve this, they approached the problem by breaking it down into two stages: first, developing a planner for planning foothold positions, and second, developing a tracker to accurately follow the planned foothold positions.

First, the planner module quickly searches for physically feasible foothold positions using a sampling-based optimization method with neural network-based heuristics and verifies the optimal path through simulation rollouts.

While existing methods considered various factors such as contact timing and robot posture in addition to foothold positions, this research significantly reduced computational complexity by setting only foothold positions as the search space. Furthermore, inspired by the walking method of cats, the introduction of a structure where the hind feet step on the same spots as the front feet further significantly reduced computational complexity.

< Figure 1. High-speed navigation across various discontinuous terrains >

Second, the tracker module is trained to accurately step on planned positions, and tracking training is conducted through a generative model that competes in environments of appropriate difficulty.

The tracker is trained through reinforcement learning to accurately step on planned plots, and during this process, a generative model called the 'map generator' provides the target distribution.

This generative model is trained simultaneously and adversarially with the tracker to allow the tracker to progressively adapt to more challenging difficulties. Subsequently, a sampling-based planner was designed to generate feasible foothold plans that can reflect the characteristics and performance of the trained tracker.

This hierarchical structure showed superior performance in both planning speed and stability compared to existing techniques, and experiments proved its high-speed locomotion capabilities across various obstacles and discontinuous terrains, as well as its general applicability to unseen terrains.

Professor Jemin Hwangbo stated, "We approached the problem of high-speed navigation in discontinuous terrain, which previously required a significantly large amount of computation, from the simple perspective of how to select the footprint positions. Inspired by the placements of cat's paw, allowing the hind feet to step where the front feet stepped drastically reduced computation. We expect this to significantly expand the range of discontinuous terrain that walking robots can overcome and enable them to traverse it at high speeds, contributing to the robot's ability to perform practical missions such as disaster site exploration and mountain searches."

This research achievement was published in the May 2025 issue of the international journal Science Robotics.

Paper Title: High-speed control and navigation for quadrupedal robots on complex and discrete terrain, (https://www.science.org/doi/10.1126/scirobotics.ads6192)YouTube Link: https://youtu.be/EZbM594T3c4?si=kfxLF2XnVUvYVIyk

2025.06.04 View 3887

RAIBO Runs over Walls with Feline Agility... Ready for Effortless Search over Mountaineous and Rough Terrains

< Photo 1. Research Team Photo (Professor Jemin Hwangbo, second from right in the front row) >

KAIST's quadrupedal robot, RAIBO, can now move at high speed across discontinuous and complex terrains such as stairs, gaps, walls, and debris. It has demonstrated its ability to run on vertical walls, leap over 1.3-meter-wide gaps, sprint at approximately 14.4 km/h over stepping stones, and move quickly and nimbly on terrain combining 30° slopes, stairs, and stepping stones. RAIBO is expected to be deployed soon for practical missions such as disaster site exploration and mountain searches.

Professor Jemin Hwangbo's research team in the Department of Mechanical Engineering at our university announced on June 3rd that they have developed a quadrupedal robot navigation framework capable of high-speed locomotion at 14.4 km/h (4m/s) even on discontinuous and complex terrains such as walls, stairs, and stepping stones.

The research team developed a quadrupedal navigation system that enables the robot to reach its target destination quickly and safely in complex and discontinuous terrain.

To achieve this, they approached the problem by breaking it down into two stages: first, developing a planner for planning foothold positions, and second, developing a tracker to accurately follow the planned foothold positions.

First, the planner module quickly searches for physically feasible foothold positions using a sampling-based optimization method with neural network-based heuristics and verifies the optimal path through simulation rollouts.

While existing methods considered various factors such as contact timing and robot posture in addition to foothold positions, this research significantly reduced computational complexity by setting only foothold positions as the search space. Furthermore, inspired by the walking method of cats, the introduction of a structure where the hind feet step on the same spots as the front feet further significantly reduced computational complexity.

< Figure 1. High-speed navigation across various discontinuous terrains >

Second, the tracker module is trained to accurately step on planned positions, and tracking training is conducted through a generative model that competes in environments of appropriate difficulty.

The tracker is trained through reinforcement learning to accurately step on planned plots, and during this process, a generative model called the 'map generator' provides the target distribution.

This generative model is trained simultaneously and adversarially with the tracker to allow the tracker to progressively adapt to more challenging difficulties. Subsequently, a sampling-based planner was designed to generate feasible foothold plans that can reflect the characteristics and performance of the trained tracker.

This hierarchical structure showed superior performance in both planning speed and stability compared to existing techniques, and experiments proved its high-speed locomotion capabilities across various obstacles and discontinuous terrains, as well as its general applicability to unseen terrains.

Professor Jemin Hwangbo stated, "We approached the problem of high-speed navigation in discontinuous terrain, which previously required a significantly large amount of computation, from the simple perspective of how to select the footprint positions. Inspired by the placements of cat's paw, allowing the hind feet to step where the front feet stepped drastically reduced computation. We expect this to significantly expand the range of discontinuous terrain that walking robots can overcome and enable them to traverse it at high speeds, contributing to the robot's ability to perform practical missions such as disaster site exploration and mountain searches."

This research achievement was published in the May 2025 issue of the international journal Science Robotics.

Paper Title: High-speed control and navigation for quadrupedal robots on complex and discrete terrain, (https://www.science.org/doi/10.1126/scirobotics.ads6192)YouTube Link: https://youtu.be/EZbM594T3c4?si=kfxLF2XnVUvYVIyk

2025.06.04 View 3887 -

KAIST, Galaxy Corporation Hold Signboard Ceremony for ‘AI Entertech Research Center’

KAIST (President Kwang-Hyung Lee) announced on the 9th that it will hold a signboard ceremony for the establishment of the ‘AI Entertech Research Center’ with the artificial intelligence entertech company, Galaxy Corporation (CEO Yong-ho Choi) at the main campus of KAIST.

< (Galaxy Corporation, from center to the left) CEO Yongho Choi, Director Hyunjung Kim and related persons / (KAIST, from center to the right) Professor SeungSeob Lee of the Department of Mechanical Engineering, Provost and Executive Vice President Gyun Min Lee, Dean Jung Kim of the Department of Mechanical Engineering and Professor Yong Jin Yoon of the same department >

This collaboration is a part of KAIST’s art convergence research strategy and is an extension of its efforts to lead future K-Culture through the development of creative cultural content based on science and technology. Beyond simple technological development, KAIST has been continuously implementing the convergence model of ‘Tech-Art’ that expands the horizon of the content industry through the fusion of emotional technology and cultural imagination.

Previously, KAIST established the ‘Sumi Jo Performing Arts Research Center’ in collaboration with world-renowned soprano Sumi Jo, a visiting professor, and has been leading the convergence research of art and engineering, such as AI-based interactive performance technology and immersive content. The establishment of the ‘AI Entertech Research Center’ this time is being evaluated as a new challenge for the technological expansion of the K-content industry.

In addition, the role of singer G-Dragon (real name Kwon Ji-yong), an artist affiliated with Galaxy Corporation and a visiting professor in the Department of Mechanical Engineering at KAIST, was also a major factor. Since being appointed to KAIST last year, Professor Kwon has been actively promoting the establishment of a research center and soliciting KAIST research projects through his agency to develop the ‘AI Entertech’ field, which fuses entertainment and cutting-edge technology.

< (Galaxy Corporation, from center to the left) CEO Yongho Choi, Director Hyunjung Kim and related persons / (KAIST, from center to the right) Professor SeungSeob Lee of the Department of Mechanical Engineering, Provost and Executive Vice President Gyun Min Lee, Dean Jung Kim of the Department of Mechanical Engineering and Professor Yong Jin Yoon of the same department >

The AI Entertech Research Center is scheduled to officially launch in the third quarter of this year, and this inauguration ceremony was held in line with Professor Kwon Ji-yong’s schedule to visit KAIST. Galaxy Corporation recently had a private meeting with Microsoft (MS) CEO Nadella as the only entertech company, and is actively promoting the globalization of AI entertech. In addition, since last year, it has established a cooperative relationship with KAIST and plans to actively seek the convergence of entertech and technology that transcends time and space through the establishment of a research center.

Professor Kwon Ji-yong will attend the ‘Innovate Korea 2025’ event co-hosted by KAIST, Herald Media Group, and the National Research Council of Science and Technology, held at the KAIST Lyu Keun-Chul Sports Complex in the afternoon of the same day, and will give a special talk on the topic of ‘The Future of AI Entertech.’ In addition to Professor Kwon, Professor SeungSeob Lee of the Department of Mechanical Engineering at KAIST, Professor Sang-gyun Kim of Kyunghee University, and CEO Yong-ho Choi of Galaxy Corporation will also participate in this talk show.

The two organizations signed an MOU last year to jointly research science and technology for the global spread of K-pop, and the establishment of this research center is the first tangible result of this. Once the research center is fully operational, various projects such as the development of an AI-based entertech platform and joint research on global content technology will be promoted.

< A photo of Professor Kwon Ji-yong (right) from at the talk show with KAIST President Kwang-Hyung Lee (left) from the previous year >

Yong-ho Choi, Galaxy Corporation CHO (Chief Happiness Officer), said, “This collaboration is the starting point for providing a completely new entertainment experience to fans around the world by grafting KAIST AI and cutting-edge technologies onto the fandom platform,” and added, “The convergence of AI and entertech is not just technological advancement; it is a driving force for innovation that enriches human life.”

Kwang-Hyung Lee, KAIST President, said, “I am confident that KAIST’s scientific and technological capabilities, combined with Professor Kwon Ji-yong’s global sensibility, will lead the technological evolution of K-culture,” and added, “I hope that KAIST’s spirit of challenge and research DNA will create a new wave in the entertech market.”

Meanwhile, Galaxy Corporation, the agency of Professor G-Dragon Kwon Ji-yong, is an AI entertainment technology company that presents a new paradigm based on IP, media, tech, and entertainment convergence technology. (End)

2025.04.09 View 4868

KAIST, Galaxy Corporation Hold Signboard Ceremony for ‘AI Entertech Research Center’

KAIST (President Kwang-Hyung Lee) announced on the 9th that it will hold a signboard ceremony for the establishment of the ‘AI Entertech Research Center’ with the artificial intelligence entertech company, Galaxy Corporation (CEO Yong-ho Choi) at the main campus of KAIST.

< (Galaxy Corporation, from center to the left) CEO Yongho Choi, Director Hyunjung Kim and related persons / (KAIST, from center to the right) Professor SeungSeob Lee of the Department of Mechanical Engineering, Provost and Executive Vice President Gyun Min Lee, Dean Jung Kim of the Department of Mechanical Engineering and Professor Yong Jin Yoon of the same department >

This collaboration is a part of KAIST’s art convergence research strategy and is an extension of its efforts to lead future K-Culture through the development of creative cultural content based on science and technology. Beyond simple technological development, KAIST has been continuously implementing the convergence model of ‘Tech-Art’ that expands the horizon of the content industry through the fusion of emotional technology and cultural imagination.

Previously, KAIST established the ‘Sumi Jo Performing Arts Research Center’ in collaboration with world-renowned soprano Sumi Jo, a visiting professor, and has been leading the convergence research of art and engineering, such as AI-based interactive performance technology and immersive content. The establishment of the ‘AI Entertech Research Center’ this time is being evaluated as a new challenge for the technological expansion of the K-content industry.

In addition, the role of singer G-Dragon (real name Kwon Ji-yong), an artist affiliated with Galaxy Corporation and a visiting professor in the Department of Mechanical Engineering at KAIST, was also a major factor. Since being appointed to KAIST last year, Professor Kwon has been actively promoting the establishment of a research center and soliciting KAIST research projects through his agency to develop the ‘AI Entertech’ field, which fuses entertainment and cutting-edge technology.

< (Galaxy Corporation, from center to the left) CEO Yongho Choi, Director Hyunjung Kim and related persons / (KAIST, from center to the right) Professor SeungSeob Lee of the Department of Mechanical Engineering, Provost and Executive Vice President Gyun Min Lee, Dean Jung Kim of the Department of Mechanical Engineering and Professor Yong Jin Yoon of the same department >

The AI Entertech Research Center is scheduled to officially launch in the third quarter of this year, and this inauguration ceremony was held in line with Professor Kwon Ji-yong’s schedule to visit KAIST. Galaxy Corporation recently had a private meeting with Microsoft (MS) CEO Nadella as the only entertech company, and is actively promoting the globalization of AI entertech. In addition, since last year, it has established a cooperative relationship with KAIST and plans to actively seek the convergence of entertech and technology that transcends time and space through the establishment of a research center.

Professor Kwon Ji-yong will attend the ‘Innovate Korea 2025’ event co-hosted by KAIST, Herald Media Group, and the National Research Council of Science and Technology, held at the KAIST Lyu Keun-Chul Sports Complex in the afternoon of the same day, and will give a special talk on the topic of ‘The Future of AI Entertech.’ In addition to Professor Kwon, Professor SeungSeob Lee of the Department of Mechanical Engineering at KAIST, Professor Sang-gyun Kim of Kyunghee University, and CEO Yong-ho Choi of Galaxy Corporation will also participate in this talk show.

The two organizations signed an MOU last year to jointly research science and technology for the global spread of K-pop, and the establishment of this research center is the first tangible result of this. Once the research center is fully operational, various projects such as the development of an AI-based entertech platform and joint research on global content technology will be promoted.

< A photo of Professor Kwon Ji-yong (right) from at the talk show with KAIST President Kwang-Hyung Lee (left) from the previous year >

Yong-ho Choi, Galaxy Corporation CHO (Chief Happiness Officer), said, “This collaboration is the starting point for providing a completely new entertainment experience to fans around the world by grafting KAIST AI and cutting-edge technologies onto the fandom platform,” and added, “The convergence of AI and entertech is not just technological advancement; it is a driving force for innovation that enriches human life.”

Kwang-Hyung Lee, KAIST President, said, “I am confident that KAIST’s scientific and technological capabilities, combined with Professor Kwon Ji-yong’s global sensibility, will lead the technological evolution of K-culture,” and added, “I hope that KAIST’s spirit of challenge and research DNA will create a new wave in the entertech market.”

Meanwhile, Galaxy Corporation, the agency of Professor G-Dragon Kwon Ji-yong, is an AI entertainment technology company that presents a new paradigm based on IP, media, tech, and entertainment convergence technology. (End)

2025.04.09 View 4868 -

KAIST Research Team Develops an AI Framework Capable of Overcoming the Strength-Ductility Dilemma in Additive-manufactured Titanium Alloys

<(From Left) Ph.D. Student Jaejung Park and Professor Seungchul Lee of KAIST Department of Mechanical Engineering and , Professor Hyoung Seop Kim of POSTECH, and M.S.–Ph.D. Integrated Program Student Jeong Ah Lee of POSTECH. >

The KAIST research team led by Professor Seungchul Lee from Department of Mechanical Engineering, in collaboration with Professor Hyoung Seop Kim’s team at POSTECH, successfully overcame the strength–ductility dilemma of Ti 6Al 4V alloy using artificial intelligence, enabling the production of high strength, high ductility metal products. The AI developed by the team accurately predicts mechanical properties based on various 3D printing process parameters while also providing uncertainty information, and it uses both to recommend process parameters that hold high promise for 3D printing.

Among various 3D printing technologies, laser powder bed fusion is an innovative method for manufacturing Ti-6Al-4V alloy, renowned for its high strength and bio-compatibility. However, this alloy made via 3D printing has traditionally faced challenges in simultaneously achieving high strength and high ductility. Although there have been attempts to address this issue by adjusting both the printing process parameters and heat treatment conditions, the vast number of possible combinations made it difficult to explore them all through experiments and simulations alone.

The active learning framework developed by the team quickly explores a wide range of 3D printing process parameters and heat treatment conditions to recommend those expected to improve both strength and ductility of the alloy. These recommendations are based on the AI model’s predictions of ultimate tensile strength and total elongation along with associated uncertainty information for each set of process parameters and heat treatment conditions. The recommended conditions are then validated by performing 3D printing and tensile tests to obtain the true mechanical property values. These new data are incorporated into further AI model training, and through iterative exploration, the optimal process parameters and heat treatment conditions for producing high-performance alloys were determined in only five iterations. With these optimized conditions, the 3D printed Ti-6Al-4V alloy achieved an ultimate tensile strength of 1190 MPa and a total elongation of 16.5%, successfully overcoming the strength–ductility dilemma.

Professor Seungchul Lee commented, “In this study, by optimizing the 3D printing process parameters and heat treatment conditions, we were able to develop a high-strength, high-ductility Ti-6Al-4V alloy with minimal experimentation trials. Compared to previous studies, we produced an alloy with a similar ultimate tensile strength but higher total elongation, as well as that with a similar elongation but greater ultimate tensile strength.” He added, “Furthermore, if our approach is applied not only to mechanical properties but also to other properties such as thermal conductivity and thermal expansion, we anticipate that it will enable efficient exploration of 3D printing process parameters and heat treatment conditions.”

This study was published in Nature Communications on January 22 (https://doi.org/10.1038/s41467-025-56267-1), and the research was supported by the National Research Foundation of Korea’s Nano & Material Technology Development Program and the Leading Research Center Program.

2025.02.21 View 6368

KAIST Research Team Develops an AI Framework Capable of Overcoming the Strength-Ductility Dilemma in Additive-manufactured Titanium Alloys

<(From Left) Ph.D. Student Jaejung Park and Professor Seungchul Lee of KAIST Department of Mechanical Engineering and , Professor Hyoung Seop Kim of POSTECH, and M.S.–Ph.D. Integrated Program Student Jeong Ah Lee of POSTECH. >

The KAIST research team led by Professor Seungchul Lee from Department of Mechanical Engineering, in collaboration with Professor Hyoung Seop Kim’s team at POSTECH, successfully overcame the strength–ductility dilemma of Ti 6Al 4V alloy using artificial intelligence, enabling the production of high strength, high ductility metal products. The AI developed by the team accurately predicts mechanical properties based on various 3D printing process parameters while also providing uncertainty information, and it uses both to recommend process parameters that hold high promise for 3D printing.

Among various 3D printing technologies, laser powder bed fusion is an innovative method for manufacturing Ti-6Al-4V alloy, renowned for its high strength and bio-compatibility. However, this alloy made via 3D printing has traditionally faced challenges in simultaneously achieving high strength and high ductility. Although there have been attempts to address this issue by adjusting both the printing process parameters and heat treatment conditions, the vast number of possible combinations made it difficult to explore them all through experiments and simulations alone.

The active learning framework developed by the team quickly explores a wide range of 3D printing process parameters and heat treatment conditions to recommend those expected to improve both strength and ductility of the alloy. These recommendations are based on the AI model’s predictions of ultimate tensile strength and total elongation along with associated uncertainty information for each set of process parameters and heat treatment conditions. The recommended conditions are then validated by performing 3D printing and tensile tests to obtain the true mechanical property values. These new data are incorporated into further AI model training, and through iterative exploration, the optimal process parameters and heat treatment conditions for producing high-performance alloys were determined in only five iterations. With these optimized conditions, the 3D printed Ti-6Al-4V alloy achieved an ultimate tensile strength of 1190 MPa and a total elongation of 16.5%, successfully overcoming the strength–ductility dilemma.

Professor Seungchul Lee commented, “In this study, by optimizing the 3D printing process parameters and heat treatment conditions, we were able to develop a high-strength, high-ductility Ti-6Al-4V alloy with minimal experimentation trials. Compared to previous studies, we produced an alloy with a similar ultimate tensile strength but higher total elongation, as well as that with a similar elongation but greater ultimate tensile strength.” He added, “Furthermore, if our approach is applied not only to mechanical properties but also to other properties such as thermal conductivity and thermal expansion, we anticipate that it will enable efficient exploration of 3D printing process parameters and heat treatment conditions.”

This study was published in Nature Communications on January 22 (https://doi.org/10.1038/s41467-025-56267-1), and the research was supported by the National Research Foundation of Korea’s Nano & Material Technology Development Program and the Leading Research Center Program.

2025.02.21 View 6368 -

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

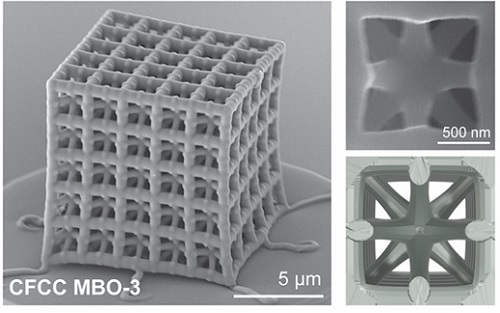

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 6131

Ultralight advanced material developed by KAIST and U of Toronto

< (From left) Professor Seunghwa Ryu of KAIST Department of Mechanical Engineering, Professor Tobin Filleter of the University of Toronto, Dr. Jinwook Yeo of KAIST, and Dr. Peter Serles of the University of Toronto >

Recently, in advanced industries such as automobiles, aerospace, and mobility, there has been increasing demand for materials that achieve weight reduction while maintaining excellent mechanical properties. An international joint research team has developed an ultralight, high-strength material utilizing nanostructures, presenting the potential for various industrial applications through customized design in the future.

KAIST (represented by President Kwang Hyung Lee) announced on the 18th of February that a research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering, in collaboration with Professor Tobin Filleter from the University of Toronto, has developed a nano-lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

In this study, the research team optimized the beam shape of the lattice structure to maintain its lightweight characteristics while maximizing stiffness and strength.

Particularly, using a multi-objective Bayesian optimization algorithm*, the team conducted an optimal design process that simultaneously considers tensile and shear stiffness improvement and weight reduction. They demonstrated that the optimal lattice structure could be predicted and designed with significantly less data (about 400 data points) compared to conventional methods.

*Multi-objective Bayesian optimization algorithm: A method that finds the optimal solution while considering multiple objectives simultaneously. It efficiently collects data and predicts results even under conditions of uncertainty.

< Figure 1. Multi-objective Bayesian optimization for generative design of carbon nanolattices with high compressive stiffness and strength at low density. The upper is the illustration of process workflow. The lower part shows top four MBO CFCC geometries with their 2D Bézier curves. (The optimized structure is predicted and designed with much less data (approximately 400) than the conventional method >

Furthermore, to maximize the effect where mechanical properties improve as size decreases at the nanoscale, the research team utilized pyrolytic carbon* material to implement an ultralight, high-strength, high-stiffness nano-lattice structure.

*Pyrolytic carbon: A carbon material obtained by decomposing organic substances at high temperatures. It has excellent heat resistance and strength, making it widely used in industries such as semiconductor equipment coatings and artificial joint coatings, where it must withstand high temperatures without deformation.

For this, the team applied two-photon polymerization (2PP) technology* to precisely fabricate complex nano-lattice structures, and mechanical performance evaluations confirmed that the developed structure simultaneously possesses strength comparable to steel and the lightness of Styrofoam.

*Two-photon polymerization (2PP) technology: An advanced optical manufacturing technique based on the principle that polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously.

Additionally, the research team demonstrated that multi-focus two-photon polymerization (multi-focus 2PP) technology enables the fabrication of millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Ryu explained, "This technology innovatively solves the stress concentration issue, which has been a limitation of conventional design methods, through three-dimensional nano-lattice structures, achieving both ultralight weight and high strength in material development."

< Figure 2. FESEM image of the fabricated nano-lattice structure and (bottom right) the macroscopic nanolattice resting on a bubble >

He further emphasized, "By integrating data-driven optimal design with precision 3D printing technology, this development not only meets the demand for lightweight materials in the aerospace and automotive industries but also opens possibilities for various industrial applications through customized design."

This study was led by Dr. Peter Serles of the Department of Mechanical & Industrial Engineering at University of Toronto and Dr. Jinwook Yeo from KAIST as co-first authors, with Professor Seunghwa Ryu and Professor Tobin Filleter as corresponding authors.

The research was published on January 23, 2025 in the international journal Advanced Materials (Paper title: “Ultrahigh Specific Strength by Bayesian Optimization of Lightweight Carbon Nanolattices”).

DOI: https://doi.org/10.1002/adma.202410651

This research was supported by the Multiphase Materials Innovation Manufacturing Research Center (an ERC program) funded by the Ministry of Science and ICT, the M3DT (Medical Device Digital Development Tool) project funded by the Ministry of Food and Drug Safety, and the KAIST International Collaboration Program.

2025.02.18 View 6131 -

KAIST Develops a Multifunctional Structural Battery Capable of Energy Storage and Load Support

Structural batteries are used in industries such as eco-friendly, energy-based automobiles, mobility, and aerospace, and they must simultaneously meet the requirements of high energy density for energy storage and high load-bearing capacity. Conventional structural battery technology has struggled to enhance both functions concurrently. However, KAIST researchers have succeeded in developing foundational technology to address this issue.

< Photo 1. (From left) Professor Seong Su Kim, PhD candidates Sangyoon Bae and Su Hyun Lim of the Department of Mechanical Engineering >

< Photo 2. (From left) Professor Seong Su Kim and Master's Graduate Mohamad A. Raja of KAIST Department of Mechanical Engineering >

KAIST (represented by President Kwang Hyung Lee) announced on the 19th of November that Professor Seong Su Kim's team from the Department of Mechanical Engineering has developed a thin, uniform, high-density, multifunctional structural carbon fiber composite battery* capable of supporting loads, and that is free from fire risks while offering high energy density.

*Multifunctional structural batteries: Refers to the ability of each material in the composite to simultaneously serve as a load-bearing structure and an energy storage element.

Early structural batteries involved embedding commercial lithium-ion batteries into layered composite materials. These batteries suffered from low integration of their mechanical and electrochemical properties, leading to challenges in material processing, assembly, and design optimization, making commercialization difficult.

To overcome these challenges, Professor Kim's team explored the concept of "energy-storing composite materials," focusing on interface and curing properties, which are critical in traditional composite design. This led to the development of high-density multifunctional structural carbon fiber composite batteries that maximize multifunctionality.

The team analyzed the curing mechanisms of epoxy resin, known for its strong mechanical properties, combined with ionic liquid and carbonate electrolyte-based solid polymer electrolytes. By controlling temperature and pressure, they were able to optimize the curing process.

The newly developed structural battery was manufactured through vacuum compression molding, increasing the volume fraction of carbon fibers—serving as both electrodes and current collectors—by over 160% compared to previous carbon-fiber-based batteries.

This greatly increased the contact area between electrodes and electrolytes, resulting in a high-density structural battery with improved electrochemical performance. Furthermore, the team effectively controlled air bubbles within the structural battery during the curing process, simultaneously enhancing the battery's mechanical properties.

Professor Seong Su Kim, the lead researcher, explained, “We proposed a framework for designing solid polymer electrolytes, a core material for high-stiffness, ultra-thin structural batteries, from both material and structural perspectives. These material-based structural batteries can serve as internal components in cars, drones, airplanes, and robots, significantly extending their operating time with a single charge. This represents a foundational technology for next-generation multifunctional energy storage applications.”

< Figure 2. Supplementary cover of ACS Applied Materials & Interfaces >

Mohamad A. Raja, a master’s graduate of KAIST’s Department of Mechanical Engineering, participated as the first author of this research, which was published in the prestigious journal ACS Applied Materials & Interfaces on September 10. The paper was recognized for its excellence and selected as a supplementary cover article. (Paper title: “Thin, Uniform, and Highly Packed Multifunctional Structural Carbon Fiber Composite Battery Lamina Informed by Solid Polymer Electrolyte Cure Kinetics.” https://doi.org/10.1021/acsami.4c08698)

This research was supported by the National Research Foundation of Korea’s Mid-Career Researcher Program and the National Semiconductor Research Laboratory Development Program.

2024.11.27 View 7009

KAIST Develops a Multifunctional Structural Battery Capable of Energy Storage and Load Support

Structural batteries are used in industries such as eco-friendly, energy-based automobiles, mobility, and aerospace, and they must simultaneously meet the requirements of high energy density for energy storage and high load-bearing capacity. Conventional structural battery technology has struggled to enhance both functions concurrently. However, KAIST researchers have succeeded in developing foundational technology to address this issue.

< Photo 1. (From left) Professor Seong Su Kim, PhD candidates Sangyoon Bae and Su Hyun Lim of the Department of Mechanical Engineering >

< Photo 2. (From left) Professor Seong Su Kim and Master's Graduate Mohamad A. Raja of KAIST Department of Mechanical Engineering >

KAIST (represented by President Kwang Hyung Lee) announced on the 19th of November that Professor Seong Su Kim's team from the Department of Mechanical Engineering has developed a thin, uniform, high-density, multifunctional structural carbon fiber composite battery* capable of supporting loads, and that is free from fire risks while offering high energy density.

*Multifunctional structural batteries: Refers to the ability of each material in the composite to simultaneously serve as a load-bearing structure and an energy storage element.

Early structural batteries involved embedding commercial lithium-ion batteries into layered composite materials. These batteries suffered from low integration of their mechanical and electrochemical properties, leading to challenges in material processing, assembly, and design optimization, making commercialization difficult.

To overcome these challenges, Professor Kim's team explored the concept of "energy-storing composite materials," focusing on interface and curing properties, which are critical in traditional composite design. This led to the development of high-density multifunctional structural carbon fiber composite batteries that maximize multifunctionality.

The team analyzed the curing mechanisms of epoxy resin, known for its strong mechanical properties, combined with ionic liquid and carbonate electrolyte-based solid polymer electrolytes. By controlling temperature and pressure, they were able to optimize the curing process.

The newly developed structural battery was manufactured through vacuum compression molding, increasing the volume fraction of carbon fibers—serving as both electrodes and current collectors—by over 160% compared to previous carbon-fiber-based batteries.

This greatly increased the contact area between electrodes and electrolytes, resulting in a high-density structural battery with improved electrochemical performance. Furthermore, the team effectively controlled air bubbles within the structural battery during the curing process, simultaneously enhancing the battery's mechanical properties.

Professor Seong Su Kim, the lead researcher, explained, “We proposed a framework for designing solid polymer electrolytes, a core material for high-stiffness, ultra-thin structural batteries, from both material and structural perspectives. These material-based structural batteries can serve as internal components in cars, drones, airplanes, and robots, significantly extending their operating time with a single charge. This represents a foundational technology for next-generation multifunctional energy storage applications.”

< Figure 2. Supplementary cover of ACS Applied Materials & Interfaces >

Mohamad A. Raja, a master’s graduate of KAIST’s Department of Mechanical Engineering, participated as the first author of this research, which was published in the prestigious journal ACS Applied Materials & Interfaces on September 10. The paper was recognized for its excellence and selected as a supplementary cover article. (Paper title: “Thin, Uniform, and Highly Packed Multifunctional Structural Carbon Fiber Composite Battery Lamina Informed by Solid Polymer Electrolyte Cure Kinetics.” https://doi.org/10.1021/acsami.4c08698)

This research was supported by the National Research Foundation of Korea’s Mid-Career Researcher Program and the National Semiconductor Research Laboratory Development Program.

2024.11.27 View 7009 -

KAIST’s RAIBO2 becomes the World’s First Robo-dog to Successfully Complete a Full-course Marathon

KAIST's quadrupedal walking robot "RAIBO", which can run seamlessly on sandy beaches, has now evolved into "RAIBO2"and achieved the groundbreaking milestone by becomeing the world's first quadrupedal robot to successfully complete a full-course marathon in an official event.

< Photo 1. A group photo of RAIBO2 and the team after completing the full-course marathon >

KAIST (President Kwang Hyung Lee) announced on the 17th of November that Professor Je Min Hwangbo's research team of the Department of Mechanical Engineering participated in the 22nd Sangju Dried-Persimmon Marathon and completed the full-course race (42.195 km) with a time of 4 hours 19 minutes and 52 seconds.

< Photo 2. RAIBO2 after completing the full-course marathon with its official record presented on the photo wall >

The Sangju Dried Persimmon Marathon is known for its challenging course featuring two 50 m elevation climbs, each at the 14 km and 28 km marks, making it defficult for amateur runners. This made it an especially demanding challenge for the walking robot, as unexpected losses in efficiency could occur.

< Photo 3. RAIBO2 with the completion medal around its neck >

To prepare RAIBO2, Professor Hwangbo's team developed a walking controller using reinforcement learning algorithms within their proprietary simulation environment "RaiSim". This simulator allowed the team to simlate diverse terrains such as slopes, stairs, and icy roads to ensure stable walking performance.

In particular, RAIBO2's high torque transparency joint mechanism enable the robot to efficiently harvest energy on the downhill slopes to regain some of the energy used in climbing up steep hill.

In addition, the stability of the robot was greatly improved through the collaboration with RAION ROBOTICS Inc., a company founded by the researchers from Professor Hwangbo’s lab.

< Figure 1. Conceptual diagram of power flow employed by the quadrupedal robot >

< Figure 2. The process of leg posture change of RAIBO2 walking at the most efficient walking speed of 3 m/s. By reducing the ground contact speed of the feet, the collision energy loss was reduced, and by minimizing the slipperiness of the foot upon contact, the body's kinetic energy was maintained towards the direction of the movement. >

Due to the nature of walking, pedal robots must employ highly complex systems that can withstand periodic vibrations from the frequent impacts that occur upon contact with the ground surface. Immediately after development, high efficiency was already recorded in short-distance experiments in the laboratory at the beginning of the year, but the manufacturing technology of RAION ROBOTICS significantly bolstered RAIBO's performance in running safely for a prolonged time of more than 4 hours among random pack of people in an actual marathon.

Compared to previous studies on improving walking efficiency, where external parts or software could not be changed and only limited improvements were made in some areas, Professor Hwangbo’s research team cited the fact that they were able to comprehensively solve problems by developing all steps and parts in-house, including mechanism design, electrical design, software, and artificial intelligence, as a key factor in improving efficiency.

Following the development of RAIBO1, the research team developed RAIBO2 and optimized all aspects of the robot. In particular, the team integrated the motor driver circuitry directly into the robot to minimize actuator losses and increase the control bandwidth, greatly improving walking efficiency and stability.

< Photo 4. RAIBO2 running the full-course marathon along human participants >

Choongin Lee, a Ph.D. Student that co-first author of the studies on RAIBO, said, “Through the marathon project, we demonstrated that RAIBO2 has the walking performance to stably execute services such as delivery and patrol in urban environments with many people and random objects,” and “In follow-up research, we will add autonomous navigation functions to RAIBO and strive to achieve the world’s best walking performance in mountainous and disaster environments.”

< Photo 5. RAIBO2 and co-first authors of the related research at the Ph.D. program of the Department of Mechanical Engineering at KAIST. (From left) Choongin Lee, Donghoon Youm, and Jeongsoo Park >

This research was conducted with the support of Samsung Electronics Future Technology Promotion Center and RAION ROBOTICS Inc.

2024.11.17 View 9597

KAIST’s RAIBO2 becomes the World’s First Robo-dog to Successfully Complete a Full-course Marathon

KAIST's quadrupedal walking robot "RAIBO", which can run seamlessly on sandy beaches, has now evolved into "RAIBO2"and achieved the groundbreaking milestone by becomeing the world's first quadrupedal robot to successfully complete a full-course marathon in an official event.

< Photo 1. A group photo of RAIBO2 and the team after completing the full-course marathon >

KAIST (President Kwang Hyung Lee) announced on the 17th of November that Professor Je Min Hwangbo's research team of the Department of Mechanical Engineering participated in the 22nd Sangju Dried-Persimmon Marathon and completed the full-course race (42.195 km) with a time of 4 hours 19 minutes and 52 seconds.

< Photo 2. RAIBO2 after completing the full-course marathon with its official record presented on the photo wall >

The Sangju Dried Persimmon Marathon is known for its challenging course featuring two 50 m elevation climbs, each at the 14 km and 28 km marks, making it defficult for amateur runners. This made it an especially demanding challenge for the walking robot, as unexpected losses in efficiency could occur.

< Photo 3. RAIBO2 with the completion medal around its neck >

To prepare RAIBO2, Professor Hwangbo's team developed a walking controller using reinforcement learning algorithms within their proprietary simulation environment "RaiSim". This simulator allowed the team to simlate diverse terrains such as slopes, stairs, and icy roads to ensure stable walking performance.

In particular, RAIBO2's high torque transparency joint mechanism enable the robot to efficiently harvest energy on the downhill slopes to regain some of the energy used in climbing up steep hill.

In addition, the stability of the robot was greatly improved through the collaboration with RAION ROBOTICS Inc., a company founded by the researchers from Professor Hwangbo’s lab.

< Figure 1. Conceptual diagram of power flow employed by the quadrupedal robot >

< Figure 2. The process of leg posture change of RAIBO2 walking at the most efficient walking speed of 3 m/s. By reducing the ground contact speed of the feet, the collision energy loss was reduced, and by minimizing the slipperiness of the foot upon contact, the body's kinetic energy was maintained towards the direction of the movement. >

Due to the nature of walking, pedal robots must employ highly complex systems that can withstand periodic vibrations from the frequent impacts that occur upon contact with the ground surface. Immediately after development, high efficiency was already recorded in short-distance experiments in the laboratory at the beginning of the year, but the manufacturing technology of RAION ROBOTICS significantly bolstered RAIBO's performance in running safely for a prolonged time of more than 4 hours among random pack of people in an actual marathon.

Compared to previous studies on improving walking efficiency, where external parts or software could not be changed and only limited improvements were made in some areas, Professor Hwangbo’s research team cited the fact that they were able to comprehensively solve problems by developing all steps and parts in-house, including mechanism design, electrical design, software, and artificial intelligence, as a key factor in improving efficiency.

Following the development of RAIBO1, the research team developed RAIBO2 and optimized all aspects of the robot. In particular, the team integrated the motor driver circuitry directly into the robot to minimize actuator losses and increase the control bandwidth, greatly improving walking efficiency and stability.

< Photo 4. RAIBO2 running the full-course marathon along human participants >

Choongin Lee, a Ph.D. Student that co-first author of the studies on RAIBO, said, “Through the marathon project, we demonstrated that RAIBO2 has the walking performance to stably execute services such as delivery and patrol in urban environments with many people and random objects,” and “In follow-up research, we will add autonomous navigation functions to RAIBO and strive to achieve the world’s best walking performance in mountainous and disaster environments.”

< Photo 5. RAIBO2 and co-first authors of the related research at the Ph.D. program of the Department of Mechanical Engineering at KAIST. (From left) Choongin Lee, Donghoon Youm, and Jeongsoo Park >

This research was conducted with the support of Samsung Electronics Future Technology Promotion Center and RAION ROBOTICS Inc.

2024.11.17 View 9597 -

KAIST’s Beach-Roaming Quadrupedal Robot “RAIBO” to Run a Marathon!

“RAIBO”, KAIST’s four-legged robot featuring remarkable agility even on challenging terrains like sandy beaches, is now set to be the first in the world to complete a full marathon.

< Photo 1. A group photo of the research team of Professor Je Min Hwangbo (second from the right in the front row) of the Department of Mechanical Engineering who participated in the marathon event at 2024 Geumsan Insam Festival last September >

On the 17th of November, KAIST (represented by President Kwang Hyung Lee) announced that Professor Je Min Hwangbo’s team from the Department of Mechanical Engineering has developed an upgraded version, “RAIBO2,” which will take on the full 42.195-kilometer course at the "Sangju Dried-Persimmon Marathon".

This is over double the previous maximum distance achieved by quadruped robots, which was limited to around 20 kilometers. The KAIST team has successfully developed a robot that can walk continuously for 43 kilometers on a single charge, completing the course in 4 hours and 40 minutes by following a GPS-guided path on the university’s main athletic field. Through this marathon, the team aims to demonstrate RAIBO2’s walking performance in an actual urban environment.

Previously, most measurements of walking robots’ travel distances were confined to controlled laboratory conditions or theoretical data. This marathon challenge is thus significant in that the robot will run alongside the general public in a real urban setting, marking the first attempt to validate the practical potential of four-legged robots in real environments.

Quadruped robots have shown advantages in challenging terrains, such as ice, sand, and mountainous areas, where they can walk stably. However, limited travel distance and running time have long been obstacles to wider applications.

< Figure 1. Conceptual diagram of power flow employed by the quadruped robot >

Professor Hwangbo’s team designed every component of the robot, from its actuators to its mechanical structure, to overcome these limitations. Notably, they implemented an efficient walking control system based on reinforcement learning using their proprietary dynamic simulator “RaiSim”.

The team also collected and analyzed walking data from outdoor environments, creating a model to address walking losses. This model was then used to iteratively improve walking efficiency over one full year.

< Figure 2. The leg posture change process of RAIBO2 walking at the most efficient walking speed of 3 m/s. By reducing the ground contact speed of the feet, the collision energy loss was reduced, and by minimizing the slipperiness of the foot upon contact, the body's kinetic energy was maintained towards the direction of the movement. >

This is the team’s second attempt. Their first was during the marathon event at “Geumsan Insam Festival” in September when the robot’s battery ran out at the 37-kilometer mark, falling short of completion. The battery drained 10 kilometers earlier than expected due to frequent speed changes as the robot adjusted to the pacing of other runners on the course.

Following the initial attempt, the team focused on technical improvements for a successful finish. They enhanced control efficiency by implementing joint stiffness control directly onto the motor actuator and increased battery capacity by 33% by refining the internal structure. These improvements enabled the robot to cover a maximum distance of 67 kilometers on straight paths.

< Figure 3. Data from completing 43 km on a single charge at the main sports field on campus. Left) GPS data of the driving course used during autonomous running. Middle) Covered distance by the hour. Right) Energy consumption by module >

Choongin Lee, a Ph.D. student of RAI Lab who is one of the co-first author of this study, explained, “Our comprehensive analysis of walking losses in terms of mechanics, electrical systems, and walking methods was crucial to improving walking efficiency. This research marks an important milestone in extending the operating range of quadruped robots to urban environments.”

< Photo 2. A Photo from Practice Run>

This research was supported by the Samsung Electronics Future Technology Development Center and RAION ROBOTICS Co., Ltd.

< Photo 3. A Photo from Practice Run >

2024.11.15 View 6401

KAIST’s Beach-Roaming Quadrupedal Robot “RAIBO” to Run a Marathon!

“RAIBO”, KAIST’s four-legged robot featuring remarkable agility even on challenging terrains like sandy beaches, is now set to be the first in the world to complete a full marathon.

< Photo 1. A group photo of the research team of Professor Je Min Hwangbo (second from the right in the front row) of the Department of Mechanical Engineering who participated in the marathon event at 2024 Geumsan Insam Festival last September >

On the 17th of November, KAIST (represented by President Kwang Hyung Lee) announced that Professor Je Min Hwangbo’s team from the Department of Mechanical Engineering has developed an upgraded version, “RAIBO2,” which will take on the full 42.195-kilometer course at the "Sangju Dried-Persimmon Marathon".

This is over double the previous maximum distance achieved by quadruped robots, which was limited to around 20 kilometers. The KAIST team has successfully developed a robot that can walk continuously for 43 kilometers on a single charge, completing the course in 4 hours and 40 minutes by following a GPS-guided path on the university’s main athletic field. Through this marathon, the team aims to demonstrate RAIBO2’s walking performance in an actual urban environment.

Previously, most measurements of walking robots’ travel distances were confined to controlled laboratory conditions or theoretical data. This marathon challenge is thus significant in that the robot will run alongside the general public in a real urban setting, marking the first attempt to validate the practical potential of four-legged robots in real environments.

Quadruped robots have shown advantages in challenging terrains, such as ice, sand, and mountainous areas, where they can walk stably. However, limited travel distance and running time have long been obstacles to wider applications.

< Figure 1. Conceptual diagram of power flow employed by the quadruped robot >

Professor Hwangbo’s team designed every component of the robot, from its actuators to its mechanical structure, to overcome these limitations. Notably, they implemented an efficient walking control system based on reinforcement learning using their proprietary dynamic simulator “RaiSim”.

The team also collected and analyzed walking data from outdoor environments, creating a model to address walking losses. This model was then used to iteratively improve walking efficiency over one full year.

< Figure 2. The leg posture change process of RAIBO2 walking at the most efficient walking speed of 3 m/s. By reducing the ground contact speed of the feet, the collision energy loss was reduced, and by minimizing the slipperiness of the foot upon contact, the body's kinetic energy was maintained towards the direction of the movement. >

This is the team’s second attempt. Their first was during the marathon event at “Geumsan Insam Festival” in September when the robot’s battery ran out at the 37-kilometer mark, falling short of completion. The battery drained 10 kilometers earlier than expected due to frequent speed changes as the robot adjusted to the pacing of other runners on the course.

Following the initial attempt, the team focused on technical improvements for a successful finish. They enhanced control efficiency by implementing joint stiffness control directly onto the motor actuator and increased battery capacity by 33% by refining the internal structure. These improvements enabled the robot to cover a maximum distance of 67 kilometers on straight paths.

< Figure 3. Data from completing 43 km on a single charge at the main sports field on campus. Left) GPS data of the driving course used during autonomous running. Middle) Covered distance by the hour. Right) Energy consumption by module >

Choongin Lee, a Ph.D. student of RAI Lab who is one of the co-first author of this study, explained, “Our comprehensive analysis of walking losses in terms of mechanics, electrical systems, and walking methods was crucial to improving walking efficiency. This research marks an important milestone in extending the operating range of quadruped robots to urban environments.”

< Photo 2. A Photo from Practice Run>

This research was supported by the Samsung Electronics Future Technology Development Center and RAION ROBOTICS Co., Ltd.

< Photo 3. A Photo from Practice Run >

2024.11.15 View 6401 -

Team KAIST Crowned Champion for their World’s Best Ironman, Winning their 2nd Consecutive Win at the Cyborg Olympics

< Group photo of our research team participating in the 3rd Cybathlon >

The Cybathlon is an international competition, which aims to help overcome disabilities through the use of robotics technology. KAIST researchers came in third, winning the bronze medal, at their 1st participation in 2016, won their first gold medal at the 2nd competition in 2020, and took back the gold medal at this year’s 3rd competition, successfully defending their champion title.

KAIST (President Kwang-Hyung Lee) announced on the 28th of October that the wearable robot ‘WalkON Suit F1’ developed by the joint research team of KAIST EXO-Lab, Move Lab, and Angel Robotics, led by Professor Kyoungchul Kong of the Department of Mechanical Engineering (Chairman of Angel Robotics), won gold medal in Cybathlon 2024 held on the 27th.

< Seunghwan Kim, the Paraplegic Pilot of Team KAIST, cheering after completing all the missions >

Cybathlon is an international competition first held in Switzerland that challenges teams to develop assistive technologies with the purpose of overcoming disabilities, and is also called the Cyborg Olympics. Right after each competition, the missions for the next competition are announced, and research teams from around the world research and develop the right assistive technology for next four years to accomplish the given mission.

Aside from the Exoskeleton Race, competitions in a total of eight disciplines are held, including Arm Prosthesis Race, Leg Prosthesis Race, and Wheelchair Race. A total of 71 teams from 26 countries participated in the 3rd Cybathlon event. Professor Kyoungchul Kong’s research team participated in the Exoskeleton Race, the same discipline they took part in the previous competition.

The Exoskeleton Race is the highlight of the event that can be called the core of the Cybathlon. In the prosthetic arm or leg events, disabled athletes wearing traditional assistive devices instead of powered devices often win depending more on the ability of the athletes rather than the technology behind the tools.

However, the exoskeleton event requires individuals with paraplegic disability to walk completely dependent on the robotic device to perform various missions, so the technical difficulty and the dependence on robotics technology is high.

In fact, many teams gave up on participating after seeing the missions for this competition, and more than half of the research teams declared withdrawal during the developmental process. In the end, only six teams from Korea, Thailands, Switzerland, Germany, and the Netherlands participated in the actual competition. Even the research team from the Swiss headquarters declared forfeiture midway as the competition date drew nearer.

< Cybathlon 2024 – Exoskeleton Race Mission Description >

The reason why many teams gave up in the exoskeleton discipline was because the difficulty of the missions was unusually high. Most research teams have the skills to make paraplegic athletes walk, but there were many other difficult tasks, such as making them walk without crutches or using both hands, while standing free on both legs on the exoskeleton, to cut a lump of sponge block, as in imitating food preparing process.

The reason why the difficulty of the missions increased like this is because Professor Kong's research team completed all the missions given to them too quickly in the last competition. In fact, in the last competition, there was even a question asked whether Kim Byeong-Uk (paraplegic) wearing the WalkON Suit F1 was really disabled.

Professor Kong's research team developed WalkON Suit F1 to successfully complete the missions. The number of motorized joints increased from six to twelve, and the output of the motor itself was more than doubled compared to the previous model that ran in the competition back in 2020. The 6-channel ground reaction force sensor on the foot measured the robot's balance 1,000 times per second to maintain balance. Cameras were installed to detect obstacles, and an AI board for implementation of AI neural network was also installed.