project

-

High Resolution 3D Blood Vessel Endoscope System Developed

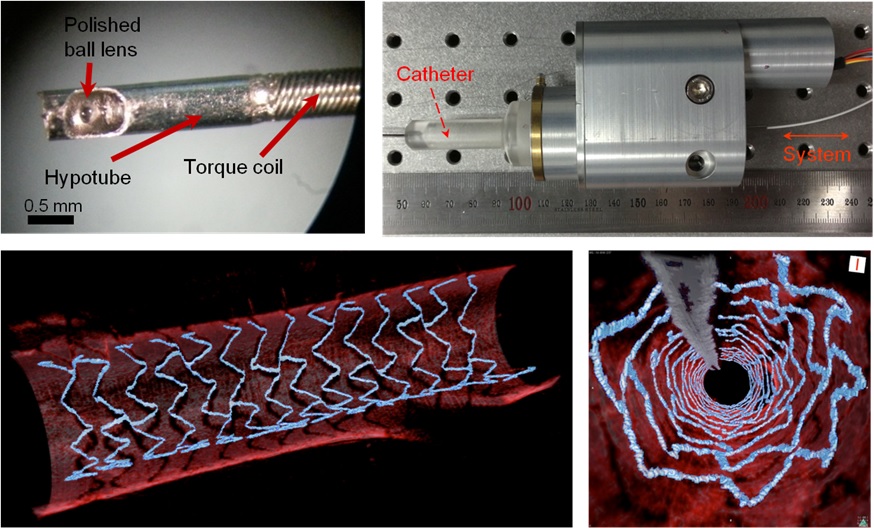

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 10243

High Resolution 3D Blood Vessel Endoscope System Developed

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 10243 -

Professor Yong-Tak Im of Mechanical Engineering Appointed as President of Korea Institute of Machinery and Materials

Yong-Tak Im, Professor of the Department of

Mechanical Engineering at KAIST, was sworn in on February 25, 2014 as

the 16th president of the Korea Institute of Machinery and Materials

(KIMM), a leading government-funded research institution in Korea. KIMM was

established in 1976 to contribute to the development of

Korea through the invention of source technology and technology transfer in

mechanical engineering.

President Im graduated from Seoul National

University, obtaining degrees of Bachelor of Science and Master’s in mechanical

engineering. He later studied at the University of California in Berkeley and

received a doctoral degree in mechanical engineering.

After working as an assistant professor of

the Industrial and Systems Engineering at the Ohio State University,

President Im joined KAIST as a professor of mechanical engineering in 1989.

President Im took many important posts at

KAIST, including Dean of Planning Office, Dean of External Affairs and Public

Relations Office, and Associate Vice President of Special Projects and

Institutional Relations, making a great addition to the university’s endeavors for

globalization.

Among the awards President Im received was the

William Johnson Award in 2007 presented by the Advances in Materials and

Processing Technologies, the Research Achievement Award in 2010 by the Global

Congress on Manufacturing and Management, and the Presidential Award in 2012 by

the Republic of Korea. He was also elected as the vice president of the Korean

Society of Mechanical Engineers, the largest association of professionals in

the mechanical engineering field in Korea.

President Im is currently a professor at

POSCO, an internationally known Korean steel company, and a member of the

Korean Academy of Science and Technology and the National Academy of

Engineering of Korea, respectively.

President Im will serve KIMM for three

years until February 24, 2017.

2014.02.25 View 9352

Professor Yong-Tak Im of Mechanical Engineering Appointed as President of Korea Institute of Machinery and Materials

Yong-Tak Im, Professor of the Department of

Mechanical Engineering at KAIST, was sworn in on February 25, 2014 as

the 16th president of the Korea Institute of Machinery and Materials

(KIMM), a leading government-funded research institution in Korea. KIMM was

established in 1976 to contribute to the development of

Korea through the invention of source technology and technology transfer in

mechanical engineering.

President Im graduated from Seoul National

University, obtaining degrees of Bachelor of Science and Master’s in mechanical

engineering. He later studied at the University of California in Berkeley and

received a doctoral degree in mechanical engineering.

After working as an assistant professor of

the Industrial and Systems Engineering at the Ohio State University,

President Im joined KAIST as a professor of mechanical engineering in 1989.

President Im took many important posts at

KAIST, including Dean of Planning Office, Dean of External Affairs and Public

Relations Office, and Associate Vice President of Special Projects and

Institutional Relations, making a great addition to the university’s endeavors for

globalization.

Among the awards President Im received was the

William Johnson Award in 2007 presented by the Advances in Materials and

Processing Technologies, the Research Achievement Award in 2010 by the Global

Congress on Manufacturing and Management, and the Presidential Award in 2012 by

the Republic of Korea. He was also elected as the vice president of the Korean

Society of Mechanical Engineers, the largest association of professionals in

the mechanical engineering field in Korea.

President Im is currently a professor at

POSCO, an internationally known Korean steel company, and a member of the

Korean Academy of Science and Technology and the National Academy of

Engineering of Korea, respectively.

President Im will serve KIMM for three

years until February 24, 2017.

2014.02.25 View 9352 -

New Year's Greeting Ceremony Held on January 2nd

The year 2014 is the Year of the Wooden Horse in Chinese astrology: A dynamic (Horse) and prosperous (Wood) New Year to all at KAIST!

President Steve Kang hosted a New Year’s greeting ceremony on January 2 nd at an auditorium on campus and gave a keynote speech on major administrative policies and academic programs to take effect for the year 2014. K-Valley and End-Run projects, as well as a review of efforts to decentralize the academic system in order to grant colleges and departments more autonomy in their operation of education and research programs were among the few discussed.

The K-Valley project will help KAIST and its neighboring research complex, the Daedeok Innopolis, build a leading multi-layered, innovative cluster of startups and new businesses in Korea through close collaborations among university, research institutes, and industry. The End-Run is a project to attract global investors and companies to Korea that will capitalize on the highest quality talents and technologies developed by KAIST.

President Steve Kang said that he would continue the last year’s campaign to make the campus “happier” throughout this year, encouraging members of the KAIST community to trust and respect and communicate better with each other.

2014.01.07 View 6720

New Year's Greeting Ceremony Held on January 2nd

The year 2014 is the Year of the Wooden Horse in Chinese astrology: A dynamic (Horse) and prosperous (Wood) New Year to all at KAIST!

President Steve Kang hosted a New Year’s greeting ceremony on January 2 nd at an auditorium on campus and gave a keynote speech on major administrative policies and academic programs to take effect for the year 2014. K-Valley and End-Run projects, as well as a review of efforts to decentralize the academic system in order to grant colleges and departments more autonomy in their operation of education and research programs were among the few discussed.

The K-Valley project will help KAIST and its neighboring research complex, the Daedeok Innopolis, build a leading multi-layered, innovative cluster of startups and new businesses in Korea through close collaborations among university, research institutes, and industry. The End-Run is a project to attract global investors and companies to Korea that will capitalize on the highest quality talents and technologies developed by KAIST.

President Steve Kang said that he would continue the last year’s campaign to make the campus “happier” throughout this year, encouraging members of the KAIST community to trust and respect and communicate better with each other.

2014.01.07 View 6720 -

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 7803

KAIST Takes Steps towards a Self-Sustainable Campus

KAIST has been selected for a $45-million national smart grid initiative organized under the Ministry of Trade, Industry and Energy. Ninteen institutions will participate in the 2-year-long initiative. The consortium’s work is expected to take place from 2015 to 2017 after a review by the Ministry of Strategy and Finance.

The Smart Grid Explansion Initiative which has been considered the future of electric power industry implements information and communications technology to conventional grid system to maximize energy efficiency. The ROK government has selected the Smart Grid Expansion Initiative as one of South Korea’s primary national projects and plans to implement it nationwide based on multiple demonstration projects in major cities including Jeju.

KAIST plans to invest $45 million in developing systems for renewable energy power plants, efficient energy management, smart grid data, and electric vehicles to build the energy self-sustainable campus. It also hopes to contribute to fostering specialized talents and companies in energy management.

Byoung-Yoon Kim, the vice-president for research at KAIST, expects that by 2017, KAIST will be able to dramatically improve its energy capacity especially during peak periods and gain energy efficiency around the campus. He hopes that the micro grid project at KAIST will set a new standard for the self-sustainable campus.

2013.12.11 View 7803 -

2013 International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST)

The International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST) is a global forum organized by KAIST undergraduate students to promote the exchange of ideas and facilitate the discussion of issues that are important to science, technology, society, and higher education. The ICISTS-KAIST conference has been held annually every summer since 2005, inviting distinguished speakers and guests from all around the world to share their insights and expertise with students gathered from Korea and abroad. Last year alone, more than 300 students from 22 nations and 40 speakers participated in the event.

Originally, the ICISTS-KAIST was established by KAIST students who were inspired by the Harvard Project for Asian and International Relations (HPAIR), which is one of the Harvard’s largest annual student conferences in Asia.

This year, 335 students from 103 universities in 22 countries joined the conference that was held on August 5th-9th in Daejeon, making the 2013 ICISTS-KAIST the biggest science and engineering gathering hosted by university students in Asia. About 36% of the participants were international students.

The theme of the conference was “Perfect Alliance: Coexistence for Human Society,” in which students and speakers addressed issues on how to harmonize the speed of scientific progress with the development of important values in society, as well as to explore solutions to overcome the chasm, if any, between the boundaries of science and society.

In his opening remarks, President Steve Kang said, “Creativity and innovation are born out of openness. Therefore, it is essential for young scientists and engineers to communicate with people from different cultural and political backgrounds. Through this kind of global interaction and exchange of ideas and views, students will have an opportunity to deepen their understanding of the world and to better examine the purpose of their intellectual exploration in science and technology.” At the 2013 ICISTS-KAIST, 25 distinguished speakers participated including Walter Bender, a former director of the Media Lab at MIT and David Christian, a professor of Macquarie University in Australia.

2013.08.08 View 9641

2013 International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST)

The International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST) is a global forum organized by KAIST undergraduate students to promote the exchange of ideas and facilitate the discussion of issues that are important to science, technology, society, and higher education. The ICISTS-KAIST conference has been held annually every summer since 2005, inviting distinguished speakers and guests from all around the world to share their insights and expertise with students gathered from Korea and abroad. Last year alone, more than 300 students from 22 nations and 40 speakers participated in the event.

Originally, the ICISTS-KAIST was established by KAIST students who were inspired by the Harvard Project for Asian and International Relations (HPAIR), which is one of the Harvard’s largest annual student conferences in Asia.

This year, 335 students from 103 universities in 22 countries joined the conference that was held on August 5th-9th in Daejeon, making the 2013 ICISTS-KAIST the biggest science and engineering gathering hosted by university students in Asia. About 36% of the participants were international students.

The theme of the conference was “Perfect Alliance: Coexistence for Human Society,” in which students and speakers addressed issues on how to harmonize the speed of scientific progress with the development of important values in society, as well as to explore solutions to overcome the chasm, if any, between the boundaries of science and society.

In his opening remarks, President Steve Kang said, “Creativity and innovation are born out of openness. Therefore, it is essential for young scientists and engineers to communicate with people from different cultural and political backgrounds. Through this kind of global interaction and exchange of ideas and views, students will have an opportunity to deepen their understanding of the world and to better examine the purpose of their intellectual exploration in science and technology.” At the 2013 ICISTS-KAIST, 25 distinguished speakers participated including Walter Bender, a former director of the Media Lab at MIT and David Christian, a professor of Macquarie University in Australia.

2013.08.08 View 9641 -

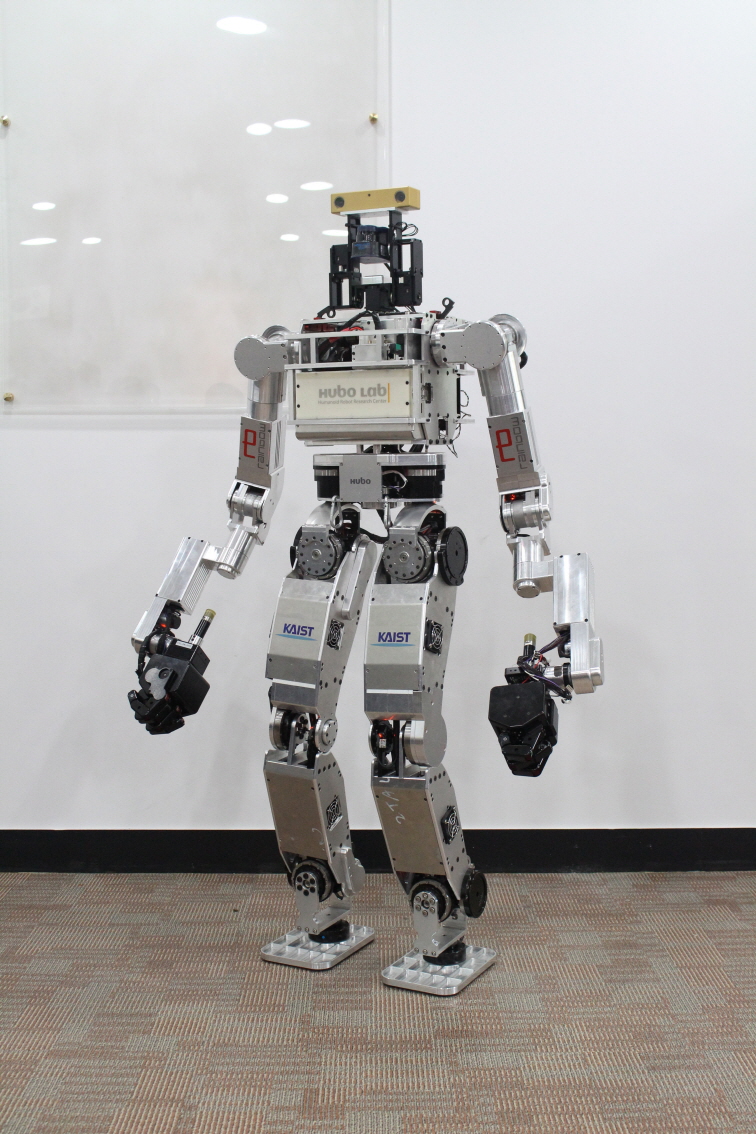

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 13332

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 13332 -

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 7858

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 7858 -

Synthesis of a New Organic Supermolecule Succeeded

From left to right: Prof.Stoddart, Prof.Goddard and Prof.Jang Wook Choi

KAIST EEWS graduate school’s research team led by Prof. Stoddart, Prof. Goddard and Prof. Jang Wook Choi has succeeded the synthesis of a new organic supermolecule that is stable in a radical condition under room temperature.

Prof. Stoddart, who mainly led this research, is the world’s great scholar on orgaic molecular structure especially on catenane with an interconnection of several ring structures. Catenane is originated from Latin “catenane” referring to “chain”. The brief structure of the synthesized catenane is as following:

Usually radicals are known to be unstable since they are electronically neutral and have very high reactivity. However, the radicals from this research showed air- and water- stability. It also showed a reversible change in oxidation number from o to +8 through chemical/electrochemical oxidation-reduction reaction. The phenomenon where paramagnetic and diamagnetic characteristics change according to the oxidation number has also been observed.

Thus, the research like this - on the molecules showing various characteristics with stable radical - is expected to give a new direction to the next-generation electromemory system, semiconductor and energy storage system research.

Meanwhile, this research, led by Prof.Stoddart team with Prof.Goddard and Prof. Jang Wook Choi’s team, is conducted under the support of Science and Technology’s World Class University project by Ministry of Education and published in ‘Science’ on 25th of Jan.

2013.02.24 View 9946

Synthesis of a New Organic Supermolecule Succeeded

From left to right: Prof.Stoddart, Prof.Goddard and Prof.Jang Wook Choi

KAIST EEWS graduate school’s research team led by Prof. Stoddart, Prof. Goddard and Prof. Jang Wook Choi has succeeded the synthesis of a new organic supermolecule that is stable in a radical condition under room temperature.

Prof. Stoddart, who mainly led this research, is the world’s great scholar on orgaic molecular structure especially on catenane with an interconnection of several ring structures. Catenane is originated from Latin “catenane” referring to “chain”. The brief structure of the synthesized catenane is as following:

Usually radicals are known to be unstable since they are electronically neutral and have very high reactivity. However, the radicals from this research showed air- and water- stability. It also showed a reversible change in oxidation number from o to +8 through chemical/electrochemical oxidation-reduction reaction. The phenomenon where paramagnetic and diamagnetic characteristics change according to the oxidation number has also been observed.

Thus, the research like this - on the molecules showing various characteristics with stable radical - is expected to give a new direction to the next-generation electromemory system, semiconductor and energy storage system research.

Meanwhile, this research, led by Prof.Stoddart team with Prof.Goddard and Prof. Jang Wook Choi’s team, is conducted under the support of Science and Technology’s World Class University project by Ministry of Education and published in ‘Science’ on 25th of Jan.

2013.02.24 View 9946 -

New BioFactory Technique Developed using sRNAs

Professor Sang Yup Lee

- published on the online edition of Nature Biotechnology. “Expected as a new strategy for the bio industry that may replace the chemical industry.”-

KAIST Chemical & Biomolecular engineering department’s Professor Sang Yup Lee and his team has developed a new technology that utilizes the synthetic small regulatory RNAs (sRNAs) to implement the BioFactory in a larger scale with more effectiveness.

* BioFactory: Microbial-based production system which creates the desired compound in mass by manipulating the genes of the cell.

In order to solve the problems of modern society, such as environmental pollution caused by the exhaustion of fossil fuels and usage of petrochemical products, an eco-friendly and sustainable bio industry is on the rise. BioFactory development technology has especially attracted the attention world-wide, with its ability to produce bio-energy, pharmaceuticals, eco-friendly materials and more.

For the development of an excellent BioFactory, selection for the gene that produces the desired compounds must be accompanied by finding the microorganism with high production efficiency; however, the previous research method had a complicated and time-consuming problem of having to manipulate the genes of the microorganism one by one.

Professor Sang Yup Lee’s research team, including Dr. Dokyun Na and Dr. Seung Min Yoo, has produced the synthetic sRNAs and utilized it to overcome the technical limitations mentioned above.

In particular, unlike the existing method, this technology using synthetic sRNAs exhibits no strain specificity which can dramatically shorten the experiment that used to take months to just a few days.

The research team applied the synthetic small regulatory RNA technology to the production of the tyrosine*, which is used as the precursor of the medicinal compound, and cadaverine**, widely utilized in a variety of petrochemical products, and has succeeded developing BioFactory with the world’s highest yield rate (21.9g /L, 12.6g / L each).

*tyrosine: amino acid known to control stress and improve concentration

**cadaverine: base material used in many petrochemical products, such as polyurethane

Professor Sang Yup Lee highlighted the significance of this research: “it is expected the synthetic small regulatory RNA technology will stimulate the BioFactory development and also serve as a catalyst which can make the chemical industry, currently represented by its petroleum energy, transform into bio industry.”

The study was carried out with the support of Global Frontier Project (Intelligent Bio-Systems Design and Synthesis Research Unit (Chief Seon Chang Kim)) and the findings have been published on January 20th in the online edition of the worldwide journal Nature Biotechnology.

2013.02.21 View 9915

New BioFactory Technique Developed using sRNAs

Professor Sang Yup Lee

- published on the online edition of Nature Biotechnology. “Expected as a new strategy for the bio industry that may replace the chemical industry.”-

KAIST Chemical & Biomolecular engineering department’s Professor Sang Yup Lee and his team has developed a new technology that utilizes the synthetic small regulatory RNAs (sRNAs) to implement the BioFactory in a larger scale with more effectiveness.

* BioFactory: Microbial-based production system which creates the desired compound in mass by manipulating the genes of the cell.

In order to solve the problems of modern society, such as environmental pollution caused by the exhaustion of fossil fuels and usage of petrochemical products, an eco-friendly and sustainable bio industry is on the rise. BioFactory development technology has especially attracted the attention world-wide, with its ability to produce bio-energy, pharmaceuticals, eco-friendly materials and more.

For the development of an excellent BioFactory, selection for the gene that produces the desired compounds must be accompanied by finding the microorganism with high production efficiency; however, the previous research method had a complicated and time-consuming problem of having to manipulate the genes of the microorganism one by one.

Professor Sang Yup Lee’s research team, including Dr. Dokyun Na and Dr. Seung Min Yoo, has produced the synthetic sRNAs and utilized it to overcome the technical limitations mentioned above.

In particular, unlike the existing method, this technology using synthetic sRNAs exhibits no strain specificity which can dramatically shorten the experiment that used to take months to just a few days.

The research team applied the synthetic small regulatory RNA technology to the production of the tyrosine*, which is used as the precursor of the medicinal compound, and cadaverine**, widely utilized in a variety of petrochemical products, and has succeeded developing BioFactory with the world’s highest yield rate (21.9g /L, 12.6g / L each).

*tyrosine: amino acid known to control stress and improve concentration

**cadaverine: base material used in many petrochemical products, such as polyurethane

Professor Sang Yup Lee highlighted the significance of this research: “it is expected the synthetic small regulatory RNA technology will stimulate the BioFactory development and also serve as a catalyst which can make the chemical industry, currently represented by its petroleum energy, transform into bio industry.”

The study was carried out with the support of Global Frontier Project (Intelligent Bio-Systems Design and Synthesis Research Unit (Chief Seon Chang Kim)) and the findings have been published on January 20th in the online edition of the worldwide journal Nature Biotechnology.

2013.02.21 View 9915 -

Commercialization of Carbon Capture and Storage Technology Speeds up

KAIST research team successfully developed the ideal method for carbon dioxide transportation, which is crucial in the capturing and underground storage of carbon dioxide technology.

Professor Jang Dae Joon of the department of Ocean Systems Engineering developed a carbon dioxide transportation that minimizes evaporative gases.

The new technology is the final piece of the three part carbon capture storage which involves capture, transportation, and storage of carbon dioxide. The completion of the three part technology will allow for commercialization in the near future.

Carbon Capture and Storage technology is regarded as the technology that will reduce carbon dioxide levels. It captures the carbon dioxide emitted from power plants and factories and storing them permanently in empty oil fields underground.

If the post Kyoto Protocol was to be implemented from 2013, Korea will not be able to shirk from the need to reduce carbon emissions. Therefore the Korean government set out to reduce 32 million tons of carbon dioxide (10% of predicted carbon reduction) until 2030. In response to the government’s efforts to reduce carbon dioxide emissions, Korean research teams like KAIST have responded.

Professor Jang’s team succeeded in developing the core technology for underground storage in the 2009 ‘Carbon dioxide Transport and Injection Terminal Project’. And as the final piece of the puzzle the team developed an optimization solution that addressed the evaporating gases emitted from carbon dioxide during transportation.

Professor Jang’s team focused on the required low temperature and high pressure conditions in liquid carbon dioxide transport.

The problem lies in the temperature gradient which can cause the transport canister to explode.

The solution developed by the team is to evaporate carbon dioxide in a pressurized contained which is then re-liquidated.

External variables like price of oil, carbon taxation, etc. have been considered and the process was optimized accordingly.

The result of Professor Jang’s team’s solution to Carbon Capture and Storage was stored in the online edition of International Journal of Greenhouse Gas Control.

2012.07.26 View 8894

Commercialization of Carbon Capture and Storage Technology Speeds up

KAIST research team successfully developed the ideal method for carbon dioxide transportation, which is crucial in the capturing and underground storage of carbon dioxide technology.

Professor Jang Dae Joon of the department of Ocean Systems Engineering developed a carbon dioxide transportation that minimizes evaporative gases.

The new technology is the final piece of the three part carbon capture storage which involves capture, transportation, and storage of carbon dioxide. The completion of the three part technology will allow for commercialization in the near future.

Carbon Capture and Storage technology is regarded as the technology that will reduce carbon dioxide levels. It captures the carbon dioxide emitted from power plants and factories and storing them permanently in empty oil fields underground.

If the post Kyoto Protocol was to be implemented from 2013, Korea will not be able to shirk from the need to reduce carbon emissions. Therefore the Korean government set out to reduce 32 million tons of carbon dioxide (10% of predicted carbon reduction) until 2030. In response to the government’s efforts to reduce carbon dioxide emissions, Korean research teams like KAIST have responded.

Professor Jang’s team succeeded in developing the core technology for underground storage in the 2009 ‘Carbon dioxide Transport and Injection Terminal Project’. And as the final piece of the puzzle the team developed an optimization solution that addressed the evaporating gases emitted from carbon dioxide during transportation.

Professor Jang’s team focused on the required low temperature and high pressure conditions in liquid carbon dioxide transport.

The problem lies in the temperature gradient which can cause the transport canister to explode.

The solution developed by the team is to evaporate carbon dioxide in a pressurized contained which is then re-liquidated.

External variables like price of oil, carbon taxation, etc. have been considered and the process was optimized accordingly.

The result of Professor Jang’s team’s solution to Carbon Capture and Storage was stored in the online edition of International Journal of Greenhouse Gas Control.

2012.07.26 View 8894 -

Korea's First MOU between a University Education Volunteer Work Group and Local Government

- 200 Adolescents from Yuseong-gu to Receive Education Community Services

Midam Scholarship committee which is composed of KAIST"s students and graduates, will draw up a contract that states that it will work together with the Yuseong-gu municipality for the development of the district education services on the 14th at the Yuseong-gu office.

Both sides will together ▲mentor the local students, ▲cooperate to run and develop creative programs, ▲exchange work for the development of the KAIST Midam Scholarship Committee, ▲conduct various other projects.

From now, the Midam Scholarship Committee will teach about 200 students in Yuseong-gu. The drawing of this contract has much meaning in that it is the first of its kind.

The Midam Scholarship Committee was founded on 2009 by students in KAIST to teach math, english, and science to students from families with low income levels.

This committee has made educational pacts with middle and high schools located in Daejeong such as Chungnam High School and Beobdong High School, and has not only taught these students but also has given scholarships to the selected students.

On one hand, the Midam Scholarship Committee has also supported 10 students in KAIST who were in need with 300000won each on the 6th. This fund was raised through the donations of alumni and mentoring projects.

The Midam Scholarship Committee has been recognized for its positive impacts on the society and has received an award from the Yuseong-gu municipality office.

2012.05.10 View 8410

Korea's First MOU between a University Education Volunteer Work Group and Local Government

- 200 Adolescents from Yuseong-gu to Receive Education Community Services

Midam Scholarship committee which is composed of KAIST"s students and graduates, will draw up a contract that states that it will work together with the Yuseong-gu municipality for the development of the district education services on the 14th at the Yuseong-gu office.

Both sides will together ▲mentor the local students, ▲cooperate to run and develop creative programs, ▲exchange work for the development of the KAIST Midam Scholarship Committee, ▲conduct various other projects.

From now, the Midam Scholarship Committee will teach about 200 students in Yuseong-gu. The drawing of this contract has much meaning in that it is the first of its kind.

The Midam Scholarship Committee was founded on 2009 by students in KAIST to teach math, english, and science to students from families with low income levels.

This committee has made educational pacts with middle and high schools located in Daejeong such as Chungnam High School and Beobdong High School, and has not only taught these students but also has given scholarships to the selected students.

On one hand, the Midam Scholarship Committee has also supported 10 students in KAIST who were in need with 300000won each on the 6th. This fund was raised through the donations of alumni and mentoring projects.

The Midam Scholarship Committee has been recognized for its positive impacts on the society and has received an award from the Yuseong-gu municipality office.

2012.05.10 View 8410 -

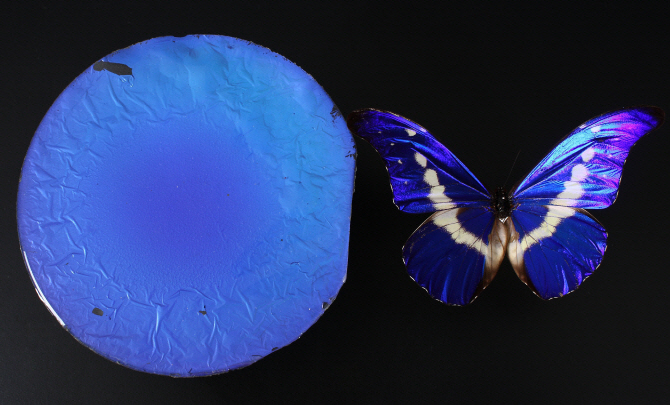

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 13400

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 13400