research

-

KAIST Made Great Improvements of Nanogenerator Power Efficiency

The energy efficiency of a piezoelectric nanogenerator developed by KAIST has increased by almost 40 times, one step closer toward the commercialization of flexible energy harvesters that can supply power infinitely to wearable, implantable electronic devices.

NANOGENERATORS are innovative self-powered energy harvesters that convert kinetic energy created from vibrational and mechanical sources into electrical power, removing the need of external circuits or batteries for electronic devices. This innovation is vital in realizing sustainable energy generation in isolated, inaccessible, or indoor environments and even in the human body.

Nanogenerators, a flexible and lightweight energy harvester on a plastic substrate, can scavenge energy from the extremely tiny movements of natural resources and human body such as wind, water flow, heartbeats, and diaphragm and respiration activities to generate electrical signals. The generators are not only self-powered, flexible devices but also can provide permanent power sources to implantable biomedical devices, including cardiac pacemakers and deep brain stimulators.

However, poor energy efficiency and a complex fabrication process have posed challenges to the commercialization of nanogenerators. Keon Jae Lee, Associate Professor of Materials Science and Engineering at KAIST, and his colleagues have recently proposed a solution by developing a robust technique to transfer a high-quality piezoelectric thin film from bulk sapphire substrates to plastic substrates using laser lift-off (LLO).

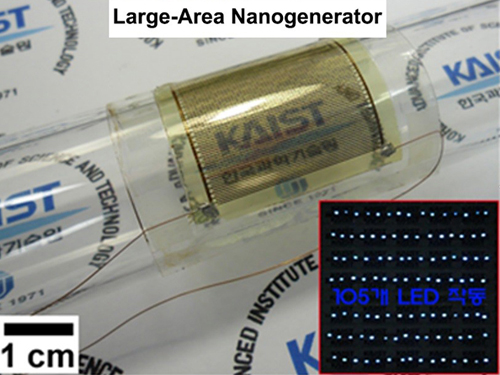

Applying the inorganic-based laser lift-off (LLO) process, the research team produced a large-area PZT thin film nanogenerators on flexible substrates (2cm x 2cm).

“We were able to convert a high-output performance of ~250 V from the slight mechanical deformation of a single thin plastic substrate. Such output power is just enough to turn on 100 LED lights,” Keon Jae Lee explained.

The self-powered nanogenerators can also work with finger and foot motions. For example, under the irregular and slight bending motions of a human finger, the measured current signals had a high electric power of ~8.7 μA. In addition, the piezoelectric nanogenerator has world-record power conversion efficiency, almost 40 times higher than previously reported similar research results, solving the drawbacks related to the fabrication complexity and low energy efficiency.

Lee further commented,

“Building on this concept, it is highly expected that tiny mechanical motions, including human body movements of muscle contraction and relaxation, can be readily converted into electrical energy and, furthermore, acted as eternal power sources.”

The research team is currently studying a method to build three-dimensional stacking of flexible piezoelectric thin films to enhance output power, as well as conducting a clinical experiment with a flexible nanogenerator.

This research result, entitled “Highly-efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates,” was published as the cover article of the April issue of Advanced Materials. (http://onlinelibrary.wiley.com/doi/10.1002/adma.201305659/abstract)

YouTube Link: http://www.youtube.com/watch?v=G_Fny7Xb9ig

Over 100 LEDs operated by self-powered flexible piezoelectric thin film nanogenerator

Flexible PZT thin film nanogenerator using inorganic-based laser lift-off process

Photograph of large-area PZT thin film nanogenerator (3.5cm × 3.5cm) on a curved glass tube and 105 commercial LEDs operated by self-powered flexible piezoelectric energy harvester

2014.05.19 View 13452

KAIST Made Great Improvements of Nanogenerator Power Efficiency

The energy efficiency of a piezoelectric nanogenerator developed by KAIST has increased by almost 40 times, one step closer toward the commercialization of flexible energy harvesters that can supply power infinitely to wearable, implantable electronic devices.

NANOGENERATORS are innovative self-powered energy harvesters that convert kinetic energy created from vibrational and mechanical sources into electrical power, removing the need of external circuits or batteries for electronic devices. This innovation is vital in realizing sustainable energy generation in isolated, inaccessible, or indoor environments and even in the human body.

Nanogenerators, a flexible and lightweight energy harvester on a plastic substrate, can scavenge energy from the extremely tiny movements of natural resources and human body such as wind, water flow, heartbeats, and diaphragm and respiration activities to generate electrical signals. The generators are not only self-powered, flexible devices but also can provide permanent power sources to implantable biomedical devices, including cardiac pacemakers and deep brain stimulators.

However, poor energy efficiency and a complex fabrication process have posed challenges to the commercialization of nanogenerators. Keon Jae Lee, Associate Professor of Materials Science and Engineering at KAIST, and his colleagues have recently proposed a solution by developing a robust technique to transfer a high-quality piezoelectric thin film from bulk sapphire substrates to plastic substrates using laser lift-off (LLO).

Applying the inorganic-based laser lift-off (LLO) process, the research team produced a large-area PZT thin film nanogenerators on flexible substrates (2cm x 2cm).

“We were able to convert a high-output performance of ~250 V from the slight mechanical deformation of a single thin plastic substrate. Such output power is just enough to turn on 100 LED lights,” Keon Jae Lee explained.

The self-powered nanogenerators can also work with finger and foot motions. For example, under the irregular and slight bending motions of a human finger, the measured current signals had a high electric power of ~8.7 μA. In addition, the piezoelectric nanogenerator has world-record power conversion efficiency, almost 40 times higher than previously reported similar research results, solving the drawbacks related to the fabrication complexity and low energy efficiency.

Lee further commented,

“Building on this concept, it is highly expected that tiny mechanical motions, including human body movements of muscle contraction and relaxation, can be readily converted into electrical energy and, furthermore, acted as eternal power sources.”

The research team is currently studying a method to build three-dimensional stacking of flexible piezoelectric thin films to enhance output power, as well as conducting a clinical experiment with a flexible nanogenerator.

This research result, entitled “Highly-efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates,” was published as the cover article of the April issue of Advanced Materials. (http://onlinelibrary.wiley.com/doi/10.1002/adma.201305659/abstract)

YouTube Link: http://www.youtube.com/watch?v=G_Fny7Xb9ig

Over 100 LEDs operated by self-powered flexible piezoelectric thin film nanogenerator

Flexible PZT thin film nanogenerator using inorganic-based laser lift-off process

Photograph of large-area PZT thin film nanogenerator (3.5cm × 3.5cm) on a curved glass tube and 105 commercial LEDs operated by self-powered flexible piezoelectric energy harvester

2014.05.19 View 13452 -

Immune Evasion Mechanism of Hepatitis C Virus Revealed

Professor Ui-Cheol Shin

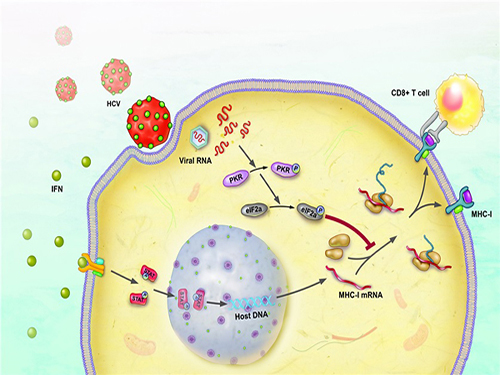

Inhibiting major histocompatibility complex [MHC] class I protein expression, T cell immune response is evaded.

The research will be a great help to the development of C hepatitis vaccine.

Roughly 1-2% of the population in Korea is known to be infected with Hepatitis C. Most Hepatitis C Virus (HCV) infections progress to a chronic disease and can cause liver cirrhosis or liver cancer, which may lead to death.

Unlike Hepatitis type A or B, there is no vaccine for Hepatitis C Virus and therefore avoiding exposure to the virus is the best known method of prevention. However, a team of researchers at KAIST has produced research results, which may contribute significantly to the vaccine development.

KAIST Graduate School of Medical Sciences & Engineering’ Professor Ui-Cheol Shin and his team have successfully identified why Hepatitis C Virus does not cause an immune response within the human body. The research results were published in the May edition of The Journal of Gastroenterology, a world-renowned journal in the field of gastroenterology.

The immune response occurs to eliminate the virus that has invaded our body. During this process, a major histocompatibility complex [MHC] class I plays a key role in inducing T cell response, which is needed for the elimination of virus-infected cells.

When a cell is infected by a virus, a substance called interferon causes the increased expression of major histocompatibility complex class I. T cell recognizes the increased MHC class I and therefore finds the virus-infected cells.

However, the effect that Hepatitis C Virus has on major histocompatibility complex class I has not been clearly identified until now.

The research team has revealed, using a cell culture for infection systems, that the Hepatitis C Virus suppresses the expression of major histocompatibility complex class I. Also, the mechanism to prove that HCV activates a protein called PKR within the cell to inhibit MHC class I protein expression was identified at a molecular level.

In this study, researchers established the hypothesis that regulating PKR protein in the cell can enhance the T cell immune response, which was then proved through experiments.

Professor Ui-Cheol Shin said, “There are a lot of new drugs to treat Hepatitis C Virus, while its vaccine has not been developed yet. Revealing the HCV immune evasion mechanism will help stimulate momentum for the HCV vaccine development.”

The first author of the journal, Dr. Won-Seok Kang is a graduate from Yonsei College of Medicine. After earning his medical degree, he has continued his training as a ‘doctor-scientist’ at KAIST Graduate School of Medical Sciences & Engineering to study Hepatitis C Virus immune evasion mechanism in this research.

Hepatitis C Virus activates PKR-eIF2a pathway, which inhibits the major histocompatibility complex class I, and therefore weakens the T cell activation to the viral activity.

2014.05.19 View 10356

Immune Evasion Mechanism of Hepatitis C Virus Revealed

Professor Ui-Cheol Shin

Inhibiting major histocompatibility complex [MHC] class I protein expression, T cell immune response is evaded.

The research will be a great help to the development of C hepatitis vaccine.

Roughly 1-2% of the population in Korea is known to be infected with Hepatitis C. Most Hepatitis C Virus (HCV) infections progress to a chronic disease and can cause liver cirrhosis or liver cancer, which may lead to death.

Unlike Hepatitis type A or B, there is no vaccine for Hepatitis C Virus and therefore avoiding exposure to the virus is the best known method of prevention. However, a team of researchers at KAIST has produced research results, which may contribute significantly to the vaccine development.

KAIST Graduate School of Medical Sciences & Engineering’ Professor Ui-Cheol Shin and his team have successfully identified why Hepatitis C Virus does not cause an immune response within the human body. The research results were published in the May edition of The Journal of Gastroenterology, a world-renowned journal in the field of gastroenterology.

The immune response occurs to eliminate the virus that has invaded our body. During this process, a major histocompatibility complex [MHC] class I plays a key role in inducing T cell response, which is needed for the elimination of virus-infected cells.

When a cell is infected by a virus, a substance called interferon causes the increased expression of major histocompatibility complex class I. T cell recognizes the increased MHC class I and therefore finds the virus-infected cells.

However, the effect that Hepatitis C Virus has on major histocompatibility complex class I has not been clearly identified until now.

The research team has revealed, using a cell culture for infection systems, that the Hepatitis C Virus suppresses the expression of major histocompatibility complex class I. Also, the mechanism to prove that HCV activates a protein called PKR within the cell to inhibit MHC class I protein expression was identified at a molecular level.

In this study, researchers established the hypothesis that regulating PKR protein in the cell can enhance the T cell immune response, which was then proved through experiments.

Professor Ui-Cheol Shin said, “There are a lot of new drugs to treat Hepatitis C Virus, while its vaccine has not been developed yet. Revealing the HCV immune evasion mechanism will help stimulate momentum for the HCV vaccine development.”

The first author of the journal, Dr. Won-Seok Kang is a graduate from Yonsei College of Medicine. After earning his medical degree, he has continued his training as a ‘doctor-scientist’ at KAIST Graduate School of Medical Sciences & Engineering to study Hepatitis C Virus immune evasion mechanism in this research.

Hepatitis C Virus activates PKR-eIF2a pathway, which inhibits the major histocompatibility complex class I, and therefore weakens the T cell activation to the viral activity.

2014.05.19 View 10356 -

Clear Display Technology Under Sunlight Developed

The late Professor Seung-Man Yang

The last paper of the late Professor Seung-Man Yang, who was a past master of colloids and fluid mechanics

Practical patterning technology of the next generation optical materials, photonic crystals

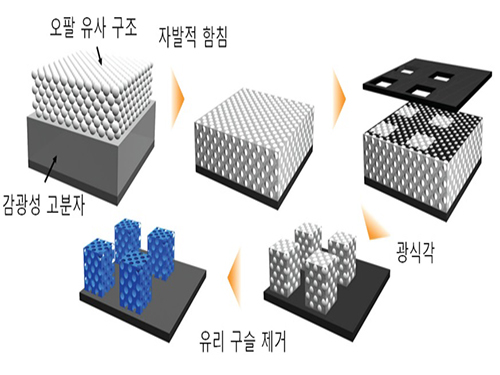

The mineral opal does not possess any pigments, but it appears colorful to our eyes. This is because only a particular wavelength is reflected due to the regular nano-structure of its surface. The material that causes selective reflection of the light is called photonic crystals.

The deceased Professor Seung-Man Yang and his research team from KAIST’s Chemical and Biomolecular Engineering Department ha ve developed micro-pattern technology using photolithographic process. This can accelerate the commercialization of photonic crystals, which is hailed as the next generation optics material.

The research results were published in the April 16th edition of Advanced Materials, known as the most prestigious world-renowned journal in the field of materials science.

The newly developed photonic crystal micro-pattern could be used as a core material for the next generation reflective display that is clearly visible even under sunlight. Since it does not require a separate light source, a single charge is enough to last for several days.

Until now, many scientists have endeavored to make photonic crystals artificially, however, most were produced in a lump and therefore lacked efficiency. Also, the low mechanical stability of the formed structure prevented from commercialization.

In order to solve these problems, the research team has copied the nano-structure of opals.

Glass beads were arranged in the same nano-structure as the opal on top of the photoresist material undergoing photocuring by ultraviolet light. The glass beads were installed in the photoresist materials, and UV light was selectively exposed on micro regions. The remaining region was developed by photolithographic process to successfully produce photonic crystals in micro-patterns.

The co-author of the research, KAIST Chemical and Biomolecular Engineering Department’s Professor Sin-Hyeon Kim, said, “Combining the semiconductor process technology with photonic crystal pattern technology can secure the practical applications for photonic crystals.”He also predicted “This technology can be used as the key optical material that configures the next generation reflective color display device with very low power consumption.”

The late Professor Seung-Man Yang was a world-renowned expert in the field of colloids and fluid mechanics. Professor Yang published over 193 papers in international journals and continued his research until his passing in last September.

He received Du Pont Science and Technology Award in 2007, KAIST Person of the Year 2008, Gyeong-Am Academy Award in 2009, as well as the President’s Award of the Republic of Korea in March 2014. The researchers devoted the achievement of this year’s research to Professor Yang in his honor.

Research was conducted by KAIST Photonic-fluidic Integrated Devices Research Team, as a part of the Creative Research Program funded by the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1. Opal [left] and the nano glass bead arrangement structure within the opal [right]

Figure 2. Process chart of the photonic crystal micro-pattern formation based on photolithography

Figure 3. Opal structure [left] and inverted structure of the opal [right]

Figure 4. Photonic crystal micro-pattern in solid colors

Figure 5. Photonic crystal micro-pattern that reflects two different crystals (Red, Green) [left] and pixelated pattern of photonic crystal in three primary colors (Red, Green, Blue) [right] that is applicable to reflective displays

2014.05.14 View 11198

Clear Display Technology Under Sunlight Developed

The late Professor Seung-Man Yang

The last paper of the late Professor Seung-Man Yang, who was a past master of colloids and fluid mechanics

Practical patterning technology of the next generation optical materials, photonic crystals

The mineral opal does not possess any pigments, but it appears colorful to our eyes. This is because only a particular wavelength is reflected due to the regular nano-structure of its surface. The material that causes selective reflection of the light is called photonic crystals.

The deceased Professor Seung-Man Yang and his research team from KAIST’s Chemical and Biomolecular Engineering Department ha ve developed micro-pattern technology using photolithographic process. This can accelerate the commercialization of photonic crystals, which is hailed as the next generation optics material.

The research results were published in the April 16th edition of Advanced Materials, known as the most prestigious world-renowned journal in the field of materials science.

The newly developed photonic crystal micro-pattern could be used as a core material for the next generation reflective display that is clearly visible even under sunlight. Since it does not require a separate light source, a single charge is enough to last for several days.

Until now, many scientists have endeavored to make photonic crystals artificially, however, most were produced in a lump and therefore lacked efficiency. Also, the low mechanical stability of the formed structure prevented from commercialization.

In order to solve these problems, the research team has copied the nano-structure of opals.

Glass beads were arranged in the same nano-structure as the opal on top of the photoresist material undergoing photocuring by ultraviolet light. The glass beads were installed in the photoresist materials, and UV light was selectively exposed on micro regions. The remaining region was developed by photolithographic process to successfully produce photonic crystals in micro-patterns.

The co-author of the research, KAIST Chemical and Biomolecular Engineering Department’s Professor Sin-Hyeon Kim, said, “Combining the semiconductor process technology with photonic crystal pattern technology can secure the practical applications for photonic crystals.”He also predicted “This technology can be used as the key optical material that configures the next generation reflective color display device with very low power consumption.”

The late Professor Seung-Man Yang was a world-renowned expert in the field of colloids and fluid mechanics. Professor Yang published over 193 papers in international journals and continued his research until his passing in last September.

He received Du Pont Science and Technology Award in 2007, KAIST Person of the Year 2008, Gyeong-Am Academy Award in 2009, as well as the President’s Award of the Republic of Korea in March 2014. The researchers devoted the achievement of this year’s research to Professor Yang in his honor.

Research was conducted by KAIST Photonic-fluidic Integrated Devices Research Team, as a part of the Creative Research Program funded by the Ministry of Science, ICT and Future Planning, Republic of Korea.

Figure 1. Opal [left] and the nano glass bead arrangement structure within the opal [right]

Figure 2. Process chart of the photonic crystal micro-pattern formation based on photolithography

Figure 3. Opal structure [left] and inverted structure of the opal [right]

Figure 4. Photonic crystal micro-pattern in solid colors

Figure 5. Photonic crystal micro-pattern that reflects two different crystals (Red, Green) [left] and pixelated pattern of photonic crystal in three primary colors (Red, Green, Blue) [right] that is applicable to reflective displays

2014.05.14 View 11198 -

Binding Regulatory Mechanism of Protein Biomolecules Revealed

Professor Hak-Sung Kim

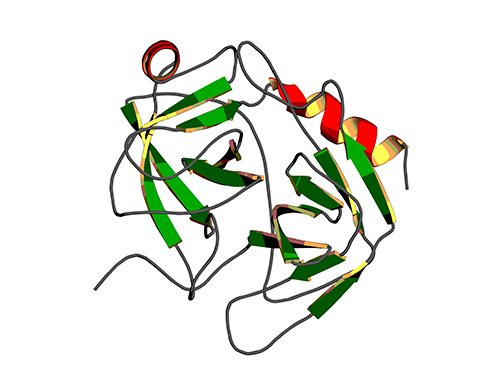

A research team led by Professor Hak-Sung Kim of Biological Sciences, KAIST, and Dr. Mun-Hyeong Seo, KAIST, has revealed a regulatory mechanism that controls the binding affinity of protein’s biomolecules, which is crucial for the protein to recognize molecules and carry out functions within the body.

The research results were published in the April 24th online edition of Nature Communications.

The protein, represented by enzyme, antibody, or hormones, specifically recognizes a variety of biomolecules in all organisms and implements signaling or immune response to precisely adjust and maintain important biological processes. The protein binding affinity of biomolecules plays a crucial role in determining the duration of the bond between two molecules, and hence to determine and control the in-vivo function of proteins.

The researchers have noted that, during the process of proteins’ recognizing biomolecules, the protein binding affinity of biomolecules is closely linked not only to the size of non-covalent interaction between two molecules, but also to the unique kinetic properties of proteins.

To identify the basic mechanism that determines the protein binding affinity of biomolecules, Professor Kim and his research team have made mutation in the allosteric site of protein to create a variety of mutant proteins with the same chemical binding surface, but with the binding affinity vastly differing from 10 to 100 times. The allosteric site of the protein refers to a region which does not directly bind with biomolecules, but crucially influences the biomolecule recognition site.

Using real-time analysis at the single-molecule level of unique kinetic properties of the produced mutant proteins, the researchers were able to identify that the protein binding affinity of biomolecules is directly associated with the protein’s specific kinetic characteristics, its structure opening rate.

Also, by proving that unique characteristics of the protein can be changed at the allosteric site, instead of protein’s direct binding site with biomolecules, the researchers have demonstrated a new methodology of regulating the in-vivo function of proteins.

The researchers expect that these results will contribute greatly to a deeper understanding of protein’s nature that governs various life phenomena and help evaluate the proof of interpreting protein binding affinity of biomolecules from the perspective of protein kinetics.

Professor Kim said, “Until now, the protein binding affinity of biomolecules was determined by a direct interaction between two molecules. Our research has identified an important fact that the structure opening rate of proteins also plays a crucial role in determining their binding affinity.”

[Picture]

A correlation graph of opening rate (kopening) and binding affinity (kd) between protein’s stable, open state and its unstable, partially closed state.

2014.05.02 View 9223

Binding Regulatory Mechanism of Protein Biomolecules Revealed

Professor Hak-Sung Kim

A research team led by Professor Hak-Sung Kim of Biological Sciences, KAIST, and Dr. Mun-Hyeong Seo, KAIST, has revealed a regulatory mechanism that controls the binding affinity of protein’s biomolecules, which is crucial for the protein to recognize molecules and carry out functions within the body.

The research results were published in the April 24th online edition of Nature Communications.

The protein, represented by enzyme, antibody, or hormones, specifically recognizes a variety of biomolecules in all organisms and implements signaling or immune response to precisely adjust and maintain important biological processes. The protein binding affinity of biomolecules plays a crucial role in determining the duration of the bond between two molecules, and hence to determine and control the in-vivo function of proteins.

The researchers have noted that, during the process of proteins’ recognizing biomolecules, the protein binding affinity of biomolecules is closely linked not only to the size of non-covalent interaction between two molecules, but also to the unique kinetic properties of proteins.

To identify the basic mechanism that determines the protein binding affinity of biomolecules, Professor Kim and his research team have made mutation in the allosteric site of protein to create a variety of mutant proteins with the same chemical binding surface, but with the binding affinity vastly differing from 10 to 100 times. The allosteric site of the protein refers to a region which does not directly bind with biomolecules, but crucially influences the biomolecule recognition site.

Using real-time analysis at the single-molecule level of unique kinetic properties of the produced mutant proteins, the researchers were able to identify that the protein binding affinity of biomolecules is directly associated with the protein’s specific kinetic characteristics, its structure opening rate.

Also, by proving that unique characteristics of the protein can be changed at the allosteric site, instead of protein’s direct binding site with biomolecules, the researchers have demonstrated a new methodology of regulating the in-vivo function of proteins.

The researchers expect that these results will contribute greatly to a deeper understanding of protein’s nature that governs various life phenomena and help evaluate the proof of interpreting protein binding affinity of biomolecules from the perspective of protein kinetics.

Professor Kim said, “Until now, the protein binding affinity of biomolecules was determined by a direct interaction between two molecules. Our research has identified an important fact that the structure opening rate of proteins also plays a crucial role in determining their binding affinity.”

[Picture]

A correlation graph of opening rate (kopening) and binding affinity (kd) between protein’s stable, open state and its unstable, partially closed state.

2014.05.02 View 9223 -

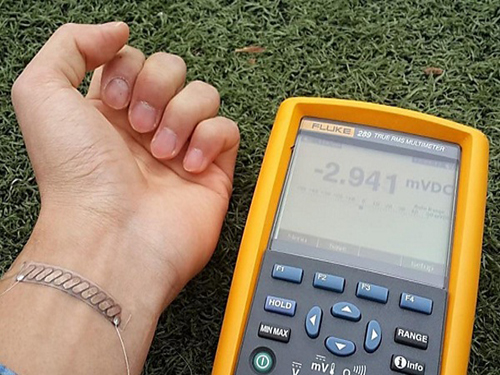

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 19715

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 19715 -

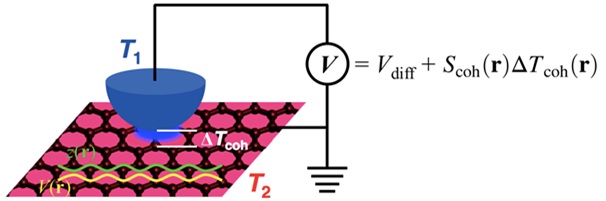

An Electron Cloud Distribution Observed by the Scanning Seebeck Microscope

All matters are made of small particles, namely atoms. An atom is composed of a heavy nucleus and cloud-like, extremely light electrons.

Korean researchers developed an electron microscopy technique that enables the accurate observation of an electron cloud distribution at room-temperature. The achievement is comparable to the invention of the quantum tunneling microscopy technique developed 33 years ago.

Professor Yong-Hyun Kim of the Graduate School of Nanoscience and Technology at KAIST and Dr. Ho-Gi Yeo of the Korea Research Institute of Standards and Science (KRISS) developed the Scanning Seebeck Microscope (SSM). The SSM renders clear images of atoms, as well as an electron cloud distribution. This was achieved by creating a voltage difference via a temperature gradient.

The development was introduced in the online edition of Physical Review Letters (April 2014), a prestigious journal published by the American Institute of Physics.

The SSM is expected to be economically competitive as it gives high resolution images at an atomic scale even for graphene and semiconductors, both at room temperature. In addition, if the SSM is applied to thermoelectric material research, it will contribute to the development of high-efficiency thermoelectric materials.

Through numerous hypotheses and experiments, scientists now believe that there exists an electron cloud surrounding a nucleus. IBM's Scanning Tunneling Microscope (STM) was the first to observe the electron cloud and has remained as the only technique to this day. The developers of IBM microscope, Dr. Gerd Binnig and Dr. Heinrich Rohrer, were awarded the 1986 Nobel Prize in Physics.

There still remains a downside to the STM technique, however: it required high precision and extreme low temperature and vibration. The application of voltage also affects the electron cloud, resulting in a distorted image.

The KAIST research team adopted a different approach by using the Seebeck effect which refers to the voltage generation due to a temperature gradient between two materials.

The team placed an observation sample (graphene) at room temperature (37~57℃) and detected its voltage generation. This technique made it possible to observe an electron cloud at room temperature.

Furthermore, the research team investigated the theoretical quantum mechanics behind the electron cloud using the observation gained through the Seebeck effect and also obtained by simulation capability to analyze the experimental results.

The research was a joint research project between KAIST Professor Yong-Hyun Kim and KRISS researcher Dr. Ho-Gi Yeo. Eui-Seop Lee, a Ph.D. candidate of KAIST, and KRISS researcher Dr. Sang-Hui Cho also participated. The Ministry of Science, ICT, and Future Planning, the Global Frontier Initiative, and the Disruptive Convergent Technology Development Initiative funded the project in Korea.

Picture 1: Schematic Diagram of the Scanning Seebeck Microscope (SSM)

Picture 2: Electron cloud distribution observed by SSM at room temperature

Picture 3: Professor Yong-Hyun Kim

2014.04.04 View 12784

An Electron Cloud Distribution Observed by the Scanning Seebeck Microscope

All matters are made of small particles, namely atoms. An atom is composed of a heavy nucleus and cloud-like, extremely light electrons.

Korean researchers developed an electron microscopy technique that enables the accurate observation of an electron cloud distribution at room-temperature. The achievement is comparable to the invention of the quantum tunneling microscopy technique developed 33 years ago.

Professor Yong-Hyun Kim of the Graduate School of Nanoscience and Technology at KAIST and Dr. Ho-Gi Yeo of the Korea Research Institute of Standards and Science (KRISS) developed the Scanning Seebeck Microscope (SSM). The SSM renders clear images of atoms, as well as an electron cloud distribution. This was achieved by creating a voltage difference via a temperature gradient.

The development was introduced in the online edition of Physical Review Letters (April 2014), a prestigious journal published by the American Institute of Physics.

The SSM is expected to be economically competitive as it gives high resolution images at an atomic scale even for graphene and semiconductors, both at room temperature. In addition, if the SSM is applied to thermoelectric material research, it will contribute to the development of high-efficiency thermoelectric materials.

Through numerous hypotheses and experiments, scientists now believe that there exists an electron cloud surrounding a nucleus. IBM's Scanning Tunneling Microscope (STM) was the first to observe the electron cloud and has remained as the only technique to this day. The developers of IBM microscope, Dr. Gerd Binnig and Dr. Heinrich Rohrer, were awarded the 1986 Nobel Prize in Physics.

There still remains a downside to the STM technique, however: it required high precision and extreme low temperature and vibration. The application of voltage also affects the electron cloud, resulting in a distorted image.

The KAIST research team adopted a different approach by using the Seebeck effect which refers to the voltage generation due to a temperature gradient between two materials.

The team placed an observation sample (graphene) at room temperature (37~57℃) and detected its voltage generation. This technique made it possible to observe an electron cloud at room temperature.

Furthermore, the research team investigated the theoretical quantum mechanics behind the electron cloud using the observation gained through the Seebeck effect and also obtained by simulation capability to analyze the experimental results.

The research was a joint research project between KAIST Professor Yong-Hyun Kim and KRISS researcher Dr. Ho-Gi Yeo. Eui-Seop Lee, a Ph.D. candidate of KAIST, and KRISS researcher Dr. Sang-Hui Cho also participated. The Ministry of Science, ICT, and Future Planning, the Global Frontier Initiative, and the Disruptive Convergent Technology Development Initiative funded the project in Korea.

Picture 1: Schematic Diagram of the Scanning Seebeck Microscope (SSM)

Picture 2: Electron cloud distribution observed by SSM at room temperature

Picture 3: Professor Yong-Hyun Kim

2014.04.04 View 12784 -

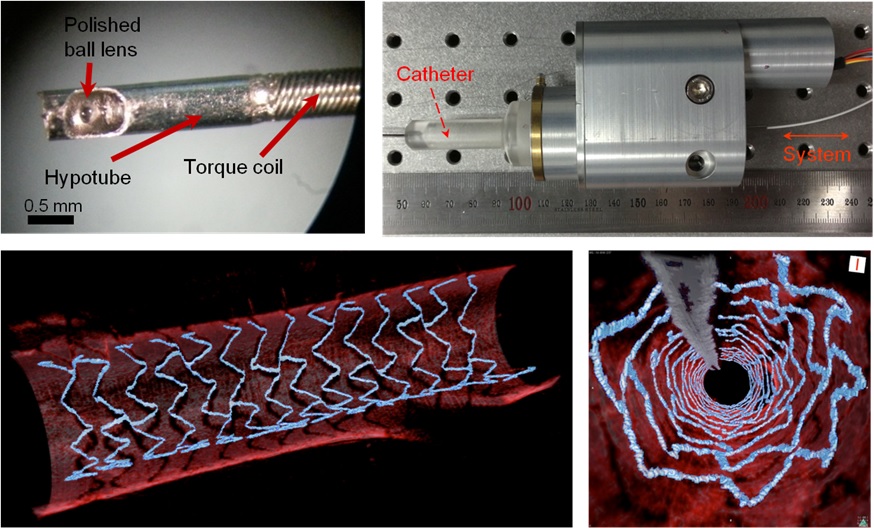

High Resolution 3D Blood Vessel Endoscope System Developed

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 10122

High Resolution 3D Blood Vessel Endoscope System Developed

Professor Wangyeol Oh of KAIST’s Mechanical Engineering Department has succeeded in developing an optical imaging endoscope system that employs an imaging velocity, which is up to 3.5 times faster than the previous systems. Furthermore, he has utilized this endoscope to acquire the world’s first high-resolution 3D images of the insides of in vivo blood vessel.

Professor Oh’s work is Korea’s first development of blood vessel endoscope system, possessing an imaging speed, resolution, imaging quality, and image-capture area. The system can also simultaneously perform a functional imaging, such as polarized imaging, which is advantageous for identifying the vulnerability of the blood vessel walls.

The Endoscopic Optical Coherence Tomography (OCT) System provides the highest resolution that is used to diagnose cardiovascular diseases, represented mainly by myocardial infarction.

However, the previous system was not fast enough to take images inside of the vessels, and therefore it was often impossible to accurately identify and analyze the vessel condition. To achieve an in vivo blood vessel optical imaging in clinical trials, the endoscope needed to be inserted, after which a clear liquid flows instantly, and pictures can be taken in only a few seconds.

The KAIST research team proposed a solution for such problem by developing a high-speed, high-resolution optical tomographic imaging system, a flexible endoscope with a diameter of 0.8 mm, as well as a device that can scan the imaging light within the blood vessels at high speed. Then, these devices were combined to visualize the internal structure of the vessel wall.

Using the developed system, the researchers were able to obtain high-resolution images of about 7 cm blood vessels of a rabbit’s aorta, which is similar size to human’s coronary arteries. The tomography scan took only 5.8 seconds, at a speed of 350 scans per second in all three directions with a resolution of 10~35㎛.

If the images are taken every 200 ㎛, like the currently available commercial vascular imaging endoscopes, a 7cm length vessel can be imaged in only one second.

Professor Wangyeol Oh said, “Our newly developed blood vessel endoscope system was tested by imaging a live animal’s blood vessels, which is similar to human blood vessels. The result was very successful.”

“Collaborating closely with hospitals, we are preparing to produce the imaging of an animal’s coronary arteries, which is similar in size to the human heart,” commented Professor Oh on the future clinical application and commercialization of the endoscope system. He added, “After such procedures, the technique can be applied in clinical patients within a few years.”

Professor Oh’s research was supported by the National Research Foundation of Korea and the Global Frontier Project by the Korean government. The research results were published in the 2014 January’s edition of Biomedical Optics Express.

Figure 1: End portion of optical endoscope (upper left)

Figure 2: High-speed optical scanning unit of the endoscope (top right)

Figure 3: High-resolution images of the inside of in vivo animal blood vessels (in the direction of vascular circumference and length)

Figure 4: High-resolution images of the inside of in vivo animal blood vessels (in the direction of the vein depth)

2014.03.25 View 10122 -

Box-shaped Pressure Vessel for LNG Developed by KAIST Research Team

Earlier today, Korean researchers successfully showcased the installation and operation of a box-shaped, high-pressure tank for the storage of liquefied natural gas in Pohang, Republic of Korea. The development was the first of its kind in the world. Pressure vessels have many applications and are widely used within the petrochemical, energy, and other industrial sectors where the transport and storage of many types of pressurized gases and fluids are essential. Pressure vessels must be designed, manufactured, installed, and operated strictly in accordance with the appropriate codes and standards since they can, in cases of leak or rupture, pose considerable health and safety hazards. Pressure vessels are normally designed in the form of a cylindrical or spherical tank. These shapes are, in principle, highly efficient in withstanding internal pressure, but rather inefficient in terms of space utilization. The tanks fit very poorly within a typically prismatic-shaped room. They cannot be packed closely together, so they do not efficiently utilize the overall space. Moreover, cylindrical or spherical tanks are not easily scalable to very large sizes because the wall thickness of the tank must increase proportionally to its overall radius. Therefore, a large pressure vessel unavoidably will have very thick walls, which are difficult and expensive to manufacture, requiring a great amount of thick-walled steel to be rolled, forged, and welded together. KAIST researchers, sponsored by POSCO, a multinational steel-making company based in Pohang, Republic of Korea, have taken a turnabout approach to construct a pressure vessel that is neither cylindrical nor spherical. Professors Pål G. Bergan and Daejun Chang and of Ocean Systems Engineering at KAIST developed a box-type, large size pressure vessel for the storage and transportation of liquids such as liquefied petroleum gas (LPG), compressed natural gas (CNG), or liquefied natural gas (LNG). The box-shaped pressure vessel has an internal, load-carrying lattice-type structure. The lattice pattern is modular in all three spatial directions, thereby effectively anchoring and balancing pressure forces on the external walls of the vessel. The modular lattice can easily be adapted to prescribed pressure levels as the overall volumetric dimensions are directly linked to the number of repetitive modules. A giant prismatic pressure vessel with a size of 20,000 m3 and a design pressure of 10 atmospheres (10 barg) can be built simply by scaling up a smaller size pressure vessel. It is interesting to note that the thickness of steel walls remains unchanged and that the weight of steel per unit storage volume goes down as the vessel size increases. Professor Chang explained the benefit of a prismatic or box-shaped pressure vessel.“If we use cylindrical pressure vessels to supply LNG fuel for a large container ship, for example, many fuel tanks will be needed. Those tanks will take up large and valuable space onboard because the cylinders have to be lined up. In our case, however, much less space is needed. The operation of a ship becomes simpler with one fuel tank rather than with many. Furthermore, our box-type pressure vessel can be designed with dimensions that precisely fit a ship. For a container ship, there may be room for a substantially higher number of containers to be loaded than when using cylindrical vessels. In a case study on a 13,000 TEU container ship, the value of the increased transport capacity tuned out USD 8.4 million for one year of operation for one ship.”The manufacturing cost of a pressure vessel has been reduced as well. Several types of special steel for cryogenic (low temperature) applications have been investigated in design and analysis studies, and this includes a new type of high-manganese steel that is being developed by POSCO. Regardless of materials, in any instance of large pressure vessels, the new lattice tank technology can offer significant savings of combined capital and operational costs. Professor Bergan was also upbeat regarding the impact of the KAIST technology innovation. “Our box-type pressure vessel represents ground-breaking research. This innovative technology will dramatically change the rules of the game for industry concerning production, transportation, and storage of fluids under high pressure and at low temperatures.”The showcased prismatic pressure vessel was a scale-down model with a volume size of 80 m3 and design pressure of 10 atmospheres. The vessel complies with the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC), the international standard for the appropriateness of design, fabrication, and inspection of boilers and pressure vessels. It passed the 15 pressure testing in January 2014 and received an accreditation from the ASME BPVC (ASME U2 Stamp). KAIST’s prismatic pressure vessel will be presented and displayed at Gastech 2014, the largest global conference and exhibition in the natural gas, LNG, and hydrocarbons industry. This event will take place on March 24-27 at KINTEX in Ilsan, Republic of Korea. Youtube: http://www.youtube.com/watch?v=woJwc5zisxk&list=TLGOLcI7L6_YYTn0lImPqNyeppQWRXqUt5Picture 1: The prototype of a prismatic pressure vesselPicture 2: A lattice pattern that is lined inside a prismatic pressure tankPicture 3: Above is a container ship having a box-shaped pressure vessel as a fuel tank, and below are traditional cylindrical fuel tanks.

2014.03.25 View 13176

Box-shaped Pressure Vessel for LNG Developed by KAIST Research Team

Earlier today, Korean researchers successfully showcased the installation and operation of a box-shaped, high-pressure tank for the storage of liquefied natural gas in Pohang, Republic of Korea. The development was the first of its kind in the world. Pressure vessels have many applications and are widely used within the petrochemical, energy, and other industrial sectors where the transport and storage of many types of pressurized gases and fluids are essential. Pressure vessels must be designed, manufactured, installed, and operated strictly in accordance with the appropriate codes and standards since they can, in cases of leak or rupture, pose considerable health and safety hazards. Pressure vessels are normally designed in the form of a cylindrical or spherical tank. These shapes are, in principle, highly efficient in withstanding internal pressure, but rather inefficient in terms of space utilization. The tanks fit very poorly within a typically prismatic-shaped room. They cannot be packed closely together, so they do not efficiently utilize the overall space. Moreover, cylindrical or spherical tanks are not easily scalable to very large sizes because the wall thickness of the tank must increase proportionally to its overall radius. Therefore, a large pressure vessel unavoidably will have very thick walls, which are difficult and expensive to manufacture, requiring a great amount of thick-walled steel to be rolled, forged, and welded together. KAIST researchers, sponsored by POSCO, a multinational steel-making company based in Pohang, Republic of Korea, have taken a turnabout approach to construct a pressure vessel that is neither cylindrical nor spherical. Professors Pål G. Bergan and Daejun Chang and of Ocean Systems Engineering at KAIST developed a box-type, large size pressure vessel for the storage and transportation of liquids such as liquefied petroleum gas (LPG), compressed natural gas (CNG), or liquefied natural gas (LNG). The box-shaped pressure vessel has an internal, load-carrying lattice-type structure. The lattice pattern is modular in all three spatial directions, thereby effectively anchoring and balancing pressure forces on the external walls of the vessel. The modular lattice can easily be adapted to prescribed pressure levels as the overall volumetric dimensions are directly linked to the number of repetitive modules. A giant prismatic pressure vessel with a size of 20,000 m3 and a design pressure of 10 atmospheres (10 barg) can be built simply by scaling up a smaller size pressure vessel. It is interesting to note that the thickness of steel walls remains unchanged and that the weight of steel per unit storage volume goes down as the vessel size increases. Professor Chang explained the benefit of a prismatic or box-shaped pressure vessel.“If we use cylindrical pressure vessels to supply LNG fuel for a large container ship, for example, many fuel tanks will be needed. Those tanks will take up large and valuable space onboard because the cylinders have to be lined up. In our case, however, much less space is needed. The operation of a ship becomes simpler with one fuel tank rather than with many. Furthermore, our box-type pressure vessel can be designed with dimensions that precisely fit a ship. For a container ship, there may be room for a substantially higher number of containers to be loaded than when using cylindrical vessels. In a case study on a 13,000 TEU container ship, the value of the increased transport capacity tuned out USD 8.4 million for one year of operation for one ship.”The manufacturing cost of a pressure vessel has been reduced as well. Several types of special steel for cryogenic (low temperature) applications have been investigated in design and analysis studies, and this includes a new type of high-manganese steel that is being developed by POSCO. Regardless of materials, in any instance of large pressure vessels, the new lattice tank technology can offer significant savings of combined capital and operational costs. Professor Bergan was also upbeat regarding the impact of the KAIST technology innovation. “Our box-type pressure vessel represents ground-breaking research. This innovative technology will dramatically change the rules of the game for industry concerning production, transportation, and storage of fluids under high pressure and at low temperatures.”The showcased prismatic pressure vessel was a scale-down model with a volume size of 80 m3 and design pressure of 10 atmospheres. The vessel complies with the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC), the international standard for the appropriateness of design, fabrication, and inspection of boilers and pressure vessels. It passed the 15 pressure testing in January 2014 and received an accreditation from the ASME BPVC (ASME U2 Stamp). KAIST’s prismatic pressure vessel will be presented and displayed at Gastech 2014, the largest global conference and exhibition in the natural gas, LNG, and hydrocarbons industry. This event will take place on March 24-27 at KINTEX in Ilsan, Republic of Korea. Youtube: http://www.youtube.com/watch?v=woJwc5zisxk&list=TLGOLcI7L6_YYTn0lImPqNyeppQWRXqUt5Picture 1: The prototype of a prismatic pressure vesselPicture 2: A lattice pattern that is lined inside a prismatic pressure tankPicture 3: Above is a container ship having a box-shaped pressure vessel as a fuel tank, and below are traditional cylindrical fuel tanks.

2014.03.25 View 13176 -

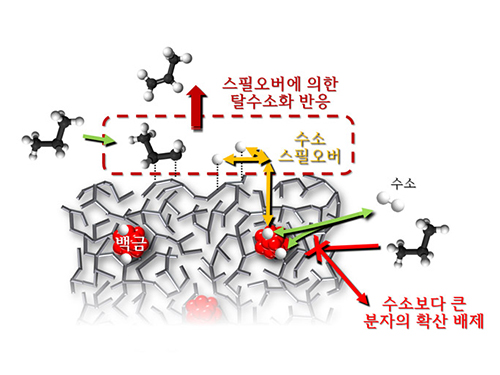

Spillover Phenomenon Identified Using Model Catalyst System

Researchers at KAIST have identified spillover phenomenon, which has remained controversial since its discovery in the early 1960s.

KAIST Department of Chemical and Biomolecular Engineering’s Professor Min-Gi Choi and his team has explained the "spillover phenomenon," using their own model catalyst system where platinum is selectively located within the amorphous aluminosilicate.

The research results were published on the 25th February online edition of Nature Communications.

Spillover refers to a phenomenon that occurs when hydrogen atoms that have been activated on the surface of metals, such as platinum, move to the surface of the catalyst. It was predicted that this phenomenon can be used to design a catalyst with high activity and stability, and thus has been actively studied over the last 50 years.

However, many cases of the known catalysts involved competing reactions on the exposed metal surface, which made it impossible to directly identify the presence and formation mechanism of spillover.

The catalysts developed by the researchers at KAIST used platinum nanoparticles covered with aluminosilicate. This only allowed the hydrogen molecules to pass through and has effectively blocked the competing reactions, enabling the research team to study the spillover phenomenon.

Through various catalyst structure and reactivity analysis, as well as computer modeling, the team has discovered that Brönsted acid sites present on the aluminosilicate plays a crucial role in spillover phenomenon.

In addition, the spillover-based hydrogenation catalyst proposed by the research team showed very high hydrogenation and dehydrogenation activity. The ability of the catalyst to significantly inhibit unwanted hydrogenolysis reaction during the petrochemical processes also suggested a large industrial potential.

Professor Min-Gi Choi said, “This particular catalyst, which can trigger the reaction only by spillover phenomenon, can be properly designed to exceed the capacity of the conventional metal catalysts. The future goal is to make a catalyst with much higher activity and selectivity.”

The research was conducted through funds subsidized by SK Innovation and Ministry of Science, ICT and Future Planning.

The senior research fellow of SK Innovation Seung-Hun Oh said, “SK Innovation will continue to develop a new commercial catalyst based on the technology from this research.”

Juh-Wan Lim and Hye-Yeong Shin led the research as joint first authors under supervision of Professor Min-Gi Choi and computer modeling works were conducted by KAIST EEWS (environment, energy, water, and sustainability) graduate school’s Professor Hyeong-Jun Kim.

2014.03.03 View 9233

Spillover Phenomenon Identified Using Model Catalyst System

Researchers at KAIST have identified spillover phenomenon, which has remained controversial since its discovery in the early 1960s.

KAIST Department of Chemical and Biomolecular Engineering’s Professor Min-Gi Choi and his team has explained the "spillover phenomenon," using their own model catalyst system where platinum is selectively located within the amorphous aluminosilicate.

The research results were published on the 25th February online edition of Nature Communications.

Spillover refers to a phenomenon that occurs when hydrogen atoms that have been activated on the surface of metals, such as platinum, move to the surface of the catalyst. It was predicted that this phenomenon can be used to design a catalyst with high activity and stability, and thus has been actively studied over the last 50 years.

However, many cases of the known catalysts involved competing reactions on the exposed metal surface, which made it impossible to directly identify the presence and formation mechanism of spillover.

The catalysts developed by the researchers at KAIST used platinum nanoparticles covered with aluminosilicate. This only allowed the hydrogen molecules to pass through and has effectively blocked the competing reactions, enabling the research team to study the spillover phenomenon.

Through various catalyst structure and reactivity analysis, as well as computer modeling, the team has discovered that Brönsted acid sites present on the aluminosilicate plays a crucial role in spillover phenomenon.

In addition, the spillover-based hydrogenation catalyst proposed by the research team showed very high hydrogenation and dehydrogenation activity. The ability of the catalyst to significantly inhibit unwanted hydrogenolysis reaction during the petrochemical processes also suggested a large industrial potential.

Professor Min-Gi Choi said, “This particular catalyst, which can trigger the reaction only by spillover phenomenon, can be properly designed to exceed the capacity of the conventional metal catalysts. The future goal is to make a catalyst with much higher activity and selectivity.”

The research was conducted through funds subsidized by SK Innovation and Ministry of Science, ICT and Future Planning.

The senior research fellow of SK Innovation Seung-Hun Oh said, “SK Innovation will continue to develop a new commercial catalyst based on the technology from this research.”

Juh-Wan Lim and Hye-Yeong Shin led the research as joint first authors under supervision of Professor Min-Gi Choi and computer modeling works were conducted by KAIST EEWS (environment, energy, water, and sustainability) graduate school’s Professor Hyeong-Jun Kim.

2014.03.03 View 9233 -

KAIST developed an extremely low-powered, high-performance head-mounted display embedding an augmented reality chip

Walking around the streets searching for a place to eat will be no hassle when a head-mounted display (HMD) becomes affordable and ubiquitous. Researchers at the Korea Advanced Institute of Science and Technology (KAIST) developed K-Glass, a wearable, hands-free HMD that enables users to find restaurants while checking out their menus. If the user of K-Glass walks up to a restaurant and looks at the name of the restaurant, today’s menu and a 3D image of food pop up. The Glass can even show the number of tables available inside the restaurant. K-Glass makes this possible because of its built-in augmented reality (AR) processor. Unlike virtual reality which replaces the real world with a computer-simulated environment, AR incorporates digital data generated by the computer into the reality of a user. With the computer-made sensory inputs such as sound, video, graphics or GPS data, the user’s real and physical world becomes live and interactive. Augmentation takes place in real-time and in semantic context with surrounding environments, such as a menu list overlain on the signboard of a restaurant when the user passes by it, not an airplane flight schedule, which is irrelevant information, displayed. Most commonly, location-based or computer-vision services are used in order to generate AR effects. Location-based services activate motion sensors to identify the user’s surroundings, whereas computer-vision uses algorithms such as facial, pattern, and optical character recognition, or object and motion tracking to distinguish images and objects. Many of the current HMDs deliver augmented reality experiences employing location-based services by scanning the markers or barcodes printed on the back of objects. The AR system tracks the codes or markers to identify objects and then align them with virtual reality. However, this AR algorithm is difficult to use for the objects or spaces which do not have barcodes, QR codes, or markers, particularly those in outdoor environments and thus cannot be recognized. To solve this problem, Hoi-Jun Yoo, Professor of Electrical Engineering at KAIST and his team developed, for the first time in the world, an AR chip that works just like human vision. This processor is based on the Visual Attention Model (VAM) that duplicates the ability of human brain to process visual data. VAM, almost unconsciously or automatically, disentangles the most salient and relevant information about the environment in which human vision operates, thereby eliminating unnecessary data unless they must be processed. In return, the processor can dramatically speed up the computation of complex AR algorithms. The AR processor has a data processing network similar to that of a human brain’s central nervous system. When the human brain perceives visual data, different sets of neurons, all connected, work concurrently on each fragment of a decision-making process; one group’s work is relayed to other group of neurons for the next round of the process, which continues until a set of decider neurons determines the character of the data. Likewise, the artificial neural network allows parallel data processing, alleviating data congestion and reducing power consumption significantly. KAIST’s AR processor, which is produced using the 65 nm (nanometers) manufacturing process with the area of 32 mm2, delivers 1.22 TOPS (tera-operations per second) peak performance when running at 250 MHz and consumes 778 miliWatts on a 1.2V power supply. The ultra-low power processor shows 1.57 TOPS/W high efficiency rate of energy consumption under the real-time operation of 30fps/720p video camera, a 76% improvement in power conservation over other devices. The HMDs, available on the market including the Project Glass whose battery lasts only for two hours, have revealed so far poor performance. Professor Yoo said, “Our processor can work for long hours without sacrificing K-Glass’s high performance, an ideal mobile gadget or wearable computer, which users can wear for almost the whole day.” He further commented:“HMDs will become the next mobile device, eventually taking over smartphones. Their markets have been growing fast, and it’s really a matter of time before mobile users will eventually embrace an optical see-through HMD as part of their daily use. Through augmented reality, we will have richer, deeper, and more powerful reality in all aspects of our life from education, business, and entertainment to art and culture.” The KAIST team presented a research paper at the International Solid-State Circuits Conference (ISSCC) held on February 9-13, 2014 in San Francisco, CA, which is entitled “1.22TOPS and 1.52mW/MHz Augmented Reality Multi-Core Processor with Neural Network NoC for HMD Applications.”Youtube Link: http://www.youtube.com/watch?v=wSqY30FOu2s&feature=c4-overview&list=UUirZA3OFhxP4YFreIJkTtXw

2014.02.20 View 15385

KAIST developed an extremely low-powered, high-performance head-mounted display embedding an augmented reality chip

Walking around the streets searching for a place to eat will be no hassle when a head-mounted display (HMD) becomes affordable and ubiquitous. Researchers at the Korea Advanced Institute of Science and Technology (KAIST) developed K-Glass, a wearable, hands-free HMD that enables users to find restaurants while checking out their menus. If the user of K-Glass walks up to a restaurant and looks at the name of the restaurant, today’s menu and a 3D image of food pop up. The Glass can even show the number of tables available inside the restaurant. K-Glass makes this possible because of its built-in augmented reality (AR) processor. Unlike virtual reality which replaces the real world with a computer-simulated environment, AR incorporates digital data generated by the computer into the reality of a user. With the computer-made sensory inputs such as sound, video, graphics or GPS data, the user’s real and physical world becomes live and interactive. Augmentation takes place in real-time and in semantic context with surrounding environments, such as a menu list overlain on the signboard of a restaurant when the user passes by it, not an airplane flight schedule, which is irrelevant information, displayed. Most commonly, location-based or computer-vision services are used in order to generate AR effects. Location-based services activate motion sensors to identify the user’s surroundings, whereas computer-vision uses algorithms such as facial, pattern, and optical character recognition, or object and motion tracking to distinguish images and objects. Many of the current HMDs deliver augmented reality experiences employing location-based services by scanning the markers or barcodes printed on the back of objects. The AR system tracks the codes or markers to identify objects and then align them with virtual reality. However, this AR algorithm is difficult to use for the objects or spaces which do not have barcodes, QR codes, or markers, particularly those in outdoor environments and thus cannot be recognized. To solve this problem, Hoi-Jun Yoo, Professor of Electrical Engineering at KAIST and his team developed, for the first time in the world, an AR chip that works just like human vision. This processor is based on the Visual Attention Model (VAM) that duplicates the ability of human brain to process visual data. VAM, almost unconsciously or automatically, disentangles the most salient and relevant information about the environment in which human vision operates, thereby eliminating unnecessary data unless they must be processed. In return, the processor can dramatically speed up the computation of complex AR algorithms. The AR processor has a data processing network similar to that of a human brain’s central nervous system. When the human brain perceives visual data, different sets of neurons, all connected, work concurrently on each fragment of a decision-making process; one group’s work is relayed to other group of neurons for the next round of the process, which continues until a set of decider neurons determines the character of the data. Likewise, the artificial neural network allows parallel data processing, alleviating data congestion and reducing power consumption significantly. KAIST’s AR processor, which is produced using the 65 nm (nanometers) manufacturing process with the area of 32 mm2, delivers 1.22 TOPS (tera-operations per second) peak performance when running at 250 MHz and consumes 778 miliWatts on a 1.2V power supply. The ultra-low power processor shows 1.57 TOPS/W high efficiency rate of energy consumption under the real-time operation of 30fps/720p video camera, a 76% improvement in power conservation over other devices. The HMDs, available on the market including the Project Glass whose battery lasts only for two hours, have revealed so far poor performance. Professor Yoo said, “Our processor can work for long hours without sacrificing K-Glass’s high performance, an ideal mobile gadget or wearable computer, which users can wear for almost the whole day.” He further commented:“HMDs will become the next mobile device, eventually taking over smartphones. Their markets have been growing fast, and it’s really a matter of time before mobile users will eventually embrace an optical see-through HMD as part of their daily use. Through augmented reality, we will have richer, deeper, and more powerful reality in all aspects of our life from education, business, and entertainment to art and culture.” The KAIST team presented a research paper at the International Solid-State Circuits Conference (ISSCC) held on February 9-13, 2014 in San Francisco, CA, which is entitled “1.22TOPS and 1.52mW/MHz Augmented Reality Multi-Core Processor with Neural Network NoC for HMD Applications.”Youtube Link: http://www.youtube.com/watch?v=wSqY30FOu2s&feature=c4-overview&list=UUirZA3OFhxP4YFreIJkTtXw

2014.02.20 View 15385 -

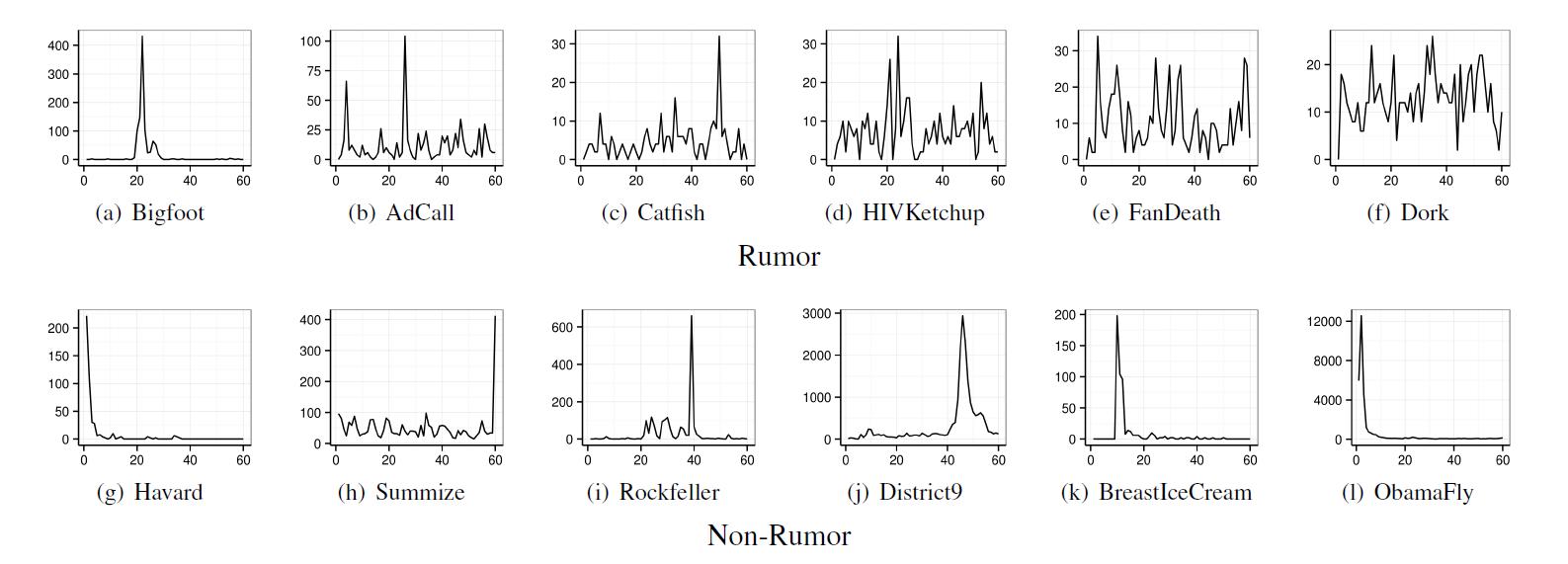

Is it possible to identify rumors on SNS?

Rumors

sporadically spread with people with fewer followers in the centerResearched

over 100 rumors in the US from 2006 to 2009 Is it

possible to filter information on SNS such as Twitter and Facebook? A research

team led by Professor Mee-Young Cha from the Department of Cultural Technology

Graduate School at KAIST, Professor Kyo-Min Jung of Seoul National University,

Doctor Wei Chen and Yajun Wang of Microsoft Asia, has developed a technology

that can accurately filter out information on Twitter to 90% accuracy. The

research not only deduced a new mathematical model, network structure, and

linguistic characteristics on rumors from SNS data, but is also expected to

enhance the effort to make secure technology to regulate Internet rumors. The team

analysed the characteristics of rumors in over 100 widespread cases in the US

from 2006 to 2009 on Twitter. The team gathered data, which included a range of

areas such as politics, IT, health and celebrity gossips, and their analysis

could identify rumors to 90% accuracy. The filtering was more accurate in

rumors that included slanders or insults. The

research team identified three characteristics of the spread of rumors. Firstly,

rumors spread continuously. Normal news spreads widely once and is mentioned

rarely again on media, but rumors tend to continue for years. Secondly,

rumors spread through sporadic participation of random users with no

connections. Rumors start from people with fewer followers and spread to the

more popular. This phenomenon is often observed in rumors concerning

celebrities or politicians. Lastly,

rumors have unique linguistic characteristics. Rumors frequently include words

(such as “it may be true,” “although not certain, I think,” “although I cannot

fully remember”) related to psychological processes that question, deny, or

infer the reliability of the information. Professor

Cha said, “This research deduced not only a statistical and mathematical model

but also is an integrated research on social psychological theory on the

characteristics of rumors that attract great attention from the society based

on ample data.” The results

were made public in IEEE International Conference on Data Mining last December

in Texas, USA.

2014.02.03 View 9357

Is it possible to identify rumors on SNS?

Rumors

sporadically spread with people with fewer followers in the centerResearched

over 100 rumors in the US from 2006 to 2009 Is it

possible to filter information on SNS such as Twitter and Facebook? A research

team led by Professor Mee-Young Cha from the Department of Cultural Technology

Graduate School at KAIST, Professor Kyo-Min Jung of Seoul National University,

Doctor Wei Chen and Yajun Wang of Microsoft Asia, has developed a technology

that can accurately filter out information on Twitter to 90% accuracy. The

research not only deduced a new mathematical model, network structure, and

linguistic characteristics on rumors from SNS data, but is also expected to

enhance the effort to make secure technology to regulate Internet rumors. The team

analysed the characteristics of rumors in over 100 widespread cases in the US

from 2006 to 2009 on Twitter. The team gathered data, which included a range of